Press release

How much does it cost to set up a carboxymethyl cellulose (CMC) production plant?

Carboxymethyl Cellulose (CMC) is a water-soluble polymer derived from cellulose, widely recognized for its thickening, stabilizing, and film-forming properties. It is extensively used across diverse industries, including food and beverages, pharmaceuticals, cosmetics, textiles, paper processing, and oil drilling. The rising demand for biodegradable and sustainable additives continues to strengthen the market potential for CMC, making investment in a CMC Production Plant a highly attractive opportunity.Establishing a CMC production facility involves several key stages, including cellulose activation, etherification using monochloroacetic acid, purification, drying, and packaging. The setup requires specialized reactors, mixers, filtration systems, and quality control laboratories to ensure product uniformity and compliance with international standards. Efficient raw material sourcing, process optimization, and environmental management play pivotal roles in ensuring long-term profitability.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/carboxymethyl-cellulose-manufacturing-plant-project-report/requestsample

IMARC Group's "Carboxymethyl Cellulose (CMC) Production Plant Setup Cost Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive blueprint for entrepreneurs, investors, and business planners looking to enter this rapidly growing market. The report covers essential project parameters, including capital investments, operating expenditures, plant layout design, and financial projections.

Carboxymethyl Cellulose Industry Outlook 2025:

The global CMC industry is witnessing robust growth driven by increasing utilization in processed foods, personal care formulations, and industrial applications. In the food sector, CMC functions as a stabilizer and emulsifier in ice creams, sauces, and bakery items. In pharmaceuticals, it is used as a binder and viscosity modifier. Furthermore, the rising emphasis on eco-friendly and non-toxic polymers is promoting the use of cellulose derivatives over synthetic alternatives. However, fluctuating raw material costs and stringent environmental regulations may impact overall plant setup economics.

Leading Carboxymethyl Cellulose (CMC) Manufacturers:

• Ashland Inc.

• Dow Chemical Company

• CP Kelco

• Sevasa Industries Pvt Ltd

• Nouryon

• Lotte Fine Chemical Co.

Latest Industry Developments:

2025: Nippon Paper Industries significantly boosted its support for Europe's electric vehicle (EV) battery sector in 2025 by opening a new, 24,000-tonne-per-year production facility in Hungary. The plant is dedicated to manufacturing lithium-ion battery-grade Carboxymethyl Cellulose (CMC), a crucial component for meeting the soaring demand from European EV manufacturers.

Key Insights for Carboxymethyl Cellulose Production Plant Setup:

Detailed Process Flow:

• Product Overview

• Manufacturing Process Steps

• Mass Balance and Raw Material Requirements

• Quality Assurance and Technical Tests

• Process Safety and Environmental Compliance

Project Details, Requirements, and Costs Involved:

• Land and Site Development

• Plant Layout and Design

• Machinery and Equipment Requirements

• Raw Material Procurement and Costs

• Utility and Packaging Requirements

• Transportation and Supply Chain Planning

• Workforce and Staffing Needs

Need Clarity? Schedule Your Free Analyst Consultation: https://www.imarcgroup.com/request?type=report&id=18496&flag=C

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Setting up a Carboxymethyl Cellulose (CMC) Production Plant demands significant capital investment in plant construction, specialized machinery, and environmental control systems. Operational expenditures mainly include raw materials (cellulose, sodium hydroxide, and monochloroacetic acid), utilities such as water and electricity, labor, and maintenance. Advanced process automation can help improve efficiency and reduce long-term operating costs.

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure and Revenue Projections

• Profitability Analysis

• Taxation and Depreciation

• Financial Feasibility Indicators

Key Cost Components of Setting Up a Carboxymethyl Cellulose (CMC) Production Plant:

• Raw Materials: High-purity cellulose, sodium hydroxide, monochloroacetic acid, and solvents.

• Machinery and Equipment: Reactors, filtration units, dryers, mixers, and packaging systems.

• Infrastructure Development: Land acquisition, plant construction, utility setup, and waste management systems.

• Labor and Staffing: Process engineers, chemical operators, safety supervisors, and administrative teams.

• Safety and Environmental Compliance: Effluent treatment, ventilation systems, and emissions control mechanisms.

• Licensing and Regulatory Approvals: Environmental and industrial permits, safety certifications, and quality standards.

• R&D and Quality Control: Laboratory infrastructure for testing viscosity, purity, and degree of substitution.

• Logistics and Supply Chain: Storage, distribution, and transportation of raw materials and finished products.

Economic Trends Influencing Carboxymethyl Cellulose Plant Setup Costs 2025:

• Raw Material Price Fluctuations: Variability in cellulose and chemical reagent costs directly affects input expenses.

• Technological Advancements: Continuous improvements in process automation and solvent recovery systems reduce operational costs.

• Energy and Utility Costs: Rising electricity and fuel prices increase production expenditures.

• Environmental Regulations: Stricter norms for waste disposal and chemical handling elevate setup requirements.

• Market Demand: Expanding applications in pharmaceuticals, cosmetics, and food industries support steady growth.

• Financing and Investment Climate: Availability of industrial loans and government incentives influences capital planning.

Challenges and Considerations for Investors:

• High initial capital investment and infrastructure setup requirements.

• Dependence on consistent cellulose supply sources.

• Regulatory compliance related to chemical safety and wastewater management.

• Competition from synthetic and alternative thickening agents.

• Need for continuous process optimization and quality consistency.

Secure Your Access: Buy Now and Start Instantly: https://www.imarcgroup.com/checkout?id=18496&method=1911

Conclusion:

Investing in a CMC Production Plant presents strong potential for long-term returns given its growing demand across industrial and consumer sectors. Success in this segment depends on efficient production technology, strategic location selection, sustainable operations, and regulatory compliance. With proper planning and resource allocation, the CMC industry offers significant opportunities for both established manufacturers and new market entrants.

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How much does it cost to set up a carboxymethyl cellulose (CMC) production plant? here

News-ID: 4226458 • Views: …

More Releases from IMARC Group

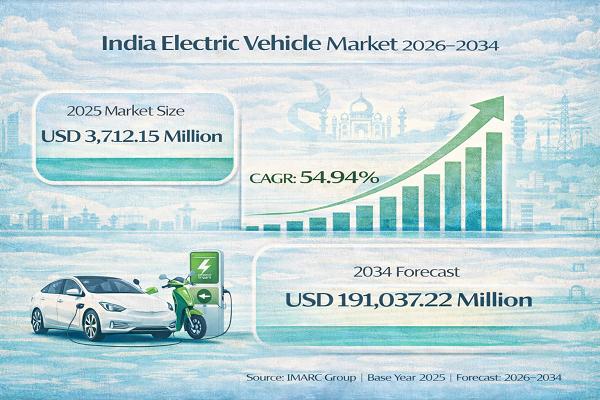

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Carboxymethyl

Carboxymethyl Cellulose Market Size Report 2025

On Mar 2, 2025, Global Info Research released a research report titled "Global Carboxymethyl Cellulose Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report provides detailed data analysis of the Carboxymethyl Cellulose market from 2020 to 2031. Including the market size and development trends of Carboxymethyl Cellulose Market, it analyzes market size indicators such as sales, sales volume, average price and CAGR, it also provides a…

Carboxymethyl Cellulose Market Size and Forecast | 2031

The Insight Partners recently announced the release of the market research titled Carboxymethyl Cellulose Market Outlook to 2031 | Share, Size, and Growth. The report is a stop solution for companies operating in the Carboxymethyl Cellulose market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities…

Carboxymethyl Cellulose Market: An In-Depth Analysis

Carboxymethyl cellulose (CMC) is a versatile and widely used cellulose derivative known for its thickening, stabilizing, and emulsifying properties. It is a white, odorless powder that is soluble in water, making it a popular ingredient in various industries, including food, pharmaceuticals, cosmetics, and paper. With an increasing demand for natural and functional additives, the CMC market has experienced significant growth over the years.

Market Size

The carboxymethyl cellulose market is expected to…

Carboxymethyl Cellulose Market

Introduction

Carboxymethyl cellulose (CMC), also known as cellulose gum, is a cellulose derivative that has gained prominence in various industries due to its multifunctional properties. It is widely used as a thickening agent, stabilizer, and emulsifier in industries like food and beverage, pharmaceuticals, cosmetics, oil and gas, and more. Carboxymethyl cellulose is derived from cellulose, which is extracted from plant cell walls. The cellulose undergoes a chemical process to introduce carboxymethyl…

Carboxymethyl Cellulose Market Size, CAGR | Trend 2030

Exclusive Report by Ameco Research: Carboxymethyl Cellulose Market Size Projected to Reach USD 3 Billion by 2030, Growing at 6% CAGR

Ameco Research is proud to announce the launch of its latest market research report, Carboxymethyl Cellulose Market. This comprehensive report provides in-depth analysis and insights into the current market trends and future projections in the Industry/Market Segment. Ameco Research has been at the forefront of providing quality market research…

Global Carboxymethyl Cellulose Market – Forecasts to 2026

As per GME’s expert research analysis, the Carboxymethyl Cellulose Market will have a moderate growth rate of around 4.7% from 2020 to 2026. The major factors driving the adoption of this chemical in the market are rapidly increasing the oil & gas industry and sudden growth in the pharmaceutical industry in terms of both volume and value of specialty drugs, the rising consumption of processed and packaged food in the…