Press release

Lower Explosive Limit not equal to Alarm Value: 3 Major Pitfalls in Combustible Gas Detection

Gas Detection Safety Essentials: From Concentration Units to 4-in-1 DetectionDuring confined space operations, a worker entered without testing the oxygen concentration and fainted due to hypoxia. In a chemical plant, a combustible gas alarm falsely triggered because the unit was mistakenly set to mg/m instead of ppm... These real cases highlight a core issue: a lack of knowledge in gas detection can directly lead to safety accidents.

As a safety manager or frontline professional, do you understand the difference between %LEL and %VOL? Why must a 4-in-1 Gas Detector [https://www.safety-shield.com/gas-detector/] measure these four specific gases? How is the explosion risk assessed for different combustible gases?

Image: https://ecdn6.globalso.com/upload/p/3640/image_other/2025-09/3-major-pitfalls-in-combustible-gas-detection.png

I. Gas Concentration Units: Don't "Mismatch Them" - These 4 Units Must Be Distinguished**

The first step in gas detection is understanding "concentration units." Different units correspond to different scenarios. Confusing them leads to errors in setting alarm values and assessing risks. The four common units each have a specific role:

1. %LEL: The "Explosion Early Warning" for Combustible Gases

* Full Name: Percentage of Lower Explosive Limit

* Function: Specifically used to warn of the explosion risk of combustible gases.

* For example, the Lower Explosive Limit (LEL value) of methane is 5%VOL. Therefore, 100%LEL equals 5%VOL (at this concentration, an explosion will occur upon contact with an ignition source).

* Practical Application: During on-site detection, the first-level alarm is typically set at less than or equal to 25%LEL (a cautionary warning), and the second-level alarm at less than or equal to 50%LEL (requires immediate gas shutoff and activation of ventilation fans).

2. %VOL: The "Intuitive Proportion" of Gas Volume**

* Full Name: Volume Percentage

* Function: Directly reflects the volume percentage of a gas in the air, suitable for detecting high-concentration gases.

* For example, the normal oxygen content in air is 21%VOL. A level below 19.5%VOL indicates oxygen deficiency, while a level above 23.5%VOL may support combustion.

* Typical Gases: Oxygen (O), Carbon Dioxide (CO), Nitrogen (N), etc.

3. PPM: The "Magnifying Glass" for Trace Toxic Gases

* Full Name: Parts Per Million

* Function: Used to detect very low concentrations of toxic/harmful gases; it's equivalent to "finding 1 gram of salt in 1 ton of water."

* Gases like Hydrogen Sulfide (HS) and Carbon Monoxide (CO) can be fatal even at concentrations as low as a few dozen PPM.

* Conversion Relationship: 1%VOL = 10,000 PPM. (Remember this formula: To convert %VOL to PPM, move the decimal point four places to the right; to convert PPM to %VOL, move it four places to the left. E.g., 2%VOL = 20,000 PPM; 500 PPM = 0.05%VOL).

4. mg/m: The "Mass Unit" for Environmental Monitoring

* Full Name: Milligrams per Cubic Meter

* Function: Commonly used by environmental protection agencies to measure the mass concentration of pollutants, such as PM. or formaldehyde in industrial exhaust.

* Important Note on Conversion: The conversion between mg/m and PPM is affected by temperature and pressure. Under standard conditions (25 degrees C, 1 atm), it can be simplified as: mg/m almost equal to (Molecular Weight of Gas times PPM) / 24.45.

* For example, the molecular weight of CO is 28. Therefore, 50 PPM of CO almost equal to (28 times 50) / 24.45 almost equal to 57.2 mg/m.

Key Point: Unit confusion is the biggest hidden danger! For instance, the occupational exposure limit for CO is 20 mg/m, which is approximately 17 PPM. If a detector's unit is PPM but the alarm is set at 20 mg/m, it's equivalent to the "alarm being disabled," with potentially unimaginable consequences.

II. Four-Gas Detection: The Essential First Line of Defense

Confined spaces (such as sewage wells, storage tanks, and fermentation pits) are high-risk areas for gas poisoning and explosions. The four-gas detector serves as the indispensable "first line of defense," simultaneously monitoring four critical gases:

1. Targets: Why These Four Gases?

* Oxygen (O): Essential for life! The safe range is 19.5%VOL to 23.5%VOL. Levels below 19.5%VOL can cause suffocation (dizziness, coma), while levels above 23.5%VOL easily trigger fires (in an oxygen-rich environment, even static electricity can ignite clothing).

* Combustible Gases (LEL): Detects the explosion risk from gases like methane and propane, using the %LEL unit. The first-level alarm is set at less than or equal to 25%LEL, and the second-level alarm at less than or equal to 50%LEL (reaching 100%LEL means the concentration has hit the lower explosive limit, where ignition will cause an explosion).

* Hydrogen Sulfide (HS): A highly toxic gas with a rotten egg smell, commonly found in sewage pools and septic tanks. Even concentrations around 100 PPM can be instantly fatal ("lightning strike" poisoning).

* Carbon Monoxide (CO): A colorless, odorless "invisible killer" produced by incomplete combustion (e.g., gas leaks, internal combustion engine exhaust). Exposure to levels above 200 PPM can lead to unconsciousness and death.

2. Detection Procedure: The Three Crucial Steps - "Ventilate right Test right Work"

* Ventilate First: Before entering a confined space, forced ventilation is mandatory (using explosion-proof fans; pure oxygen ventilation is strictly prohibited! Pure oxygen can turn the environment into a "powder keg").

* Then Detect: Detection should follow the sequence of "Oxygen right Combustible Gas right HS right CO," with results available within 30 seconds. Monitoring points should be close to gas release sources (Open areas: combustible gases less than or equal to 10 meters from the source, toxic gases less than or equal to 4 meters; Enclosed spaces: combustible gases less than or equal to 5 meters, toxic gases less than or equal to 2 meters).

* Then Work: Entry is permitted only after passing the detection. Continuous real-time monitoring is required during work (the detector should be worn on the chest, near the mouth and nose). Evacuate immediately upon any alarm.

3. Alarms & Interlocks: "Automatic Lifesaving" in Critical Moments

* Combustible Gas Alarm:

* First-level alarm ( less than or equal to 25%LEL): Personnel on-site must immediately investigate.

* Second-level alarm ( less than or equal to 50%LEL): Must automatically activate exhaust fans and shut off the gas supply valve (e.g., the quick-closing gas valve in a boiler room).

* Oxygen Alarm: If levels fall below 19.5%VOL or exceed 23.5%VOL, stop work immediately and initiate forced ventilation.

* Toxic Gas Alarm [https://www.safety-shield.com/toxic-gas-alarm/]s (HS, CO): Set based on the "Occupational Exposure Limit" (OEL).

* First-level alarm: less than or equal to 100% OEL

* Second-level alarm: less than or equal to 200% OEL

* Example: The OEL for CO is 20 mg/m (approximately 17 PPM). Thus, the first-level alarm is 17 PPM, and the second-level is 34 PPM.

According to the Chinese National Standard GB/T 50493-2019 (Design Standard for Combustible and Toxic Gas Detection and Alarm in Petroleum and Chemical Industries) , the first-level alarm setpoint for toxic gases should meet the following requirements:

1. Standard First-Level Alarm Setpoint

* Value: less than or equal to 100% OEL (Occupational Exposure Limit)

* Purpose: Triggers when the toxic gas concentration reaches the OEL, prompting personnel to take emergency measures like ventilation and personal protection to avoid cumulative health damage from prolonged exposure.

2. Alternative Standard under Special Circumstances

* If the detector's range cannot accommodate the conventional 0~300% OEL measurement range, the first-level alarm can be adjusted to less than or equal to 5% IDLH (Immediately Dangerous to Life and Health Concentration).

* Example: The IDLH for Hydrogen Sulfide is 300ppm, so the first-level alarm would need to be less than or equal to 15ppm.

Media Contact

Company Name: Sichuan Shield Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=lower-explosive-limit-alarm-value-3-major-pitfalls-in-combustible-gas-detection]

Country: China

Website: https://www.safety-shield.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lower Explosive Limit not equal to Alarm Value: 3 Major Pitfalls in Combustible Gas Detection here

News-ID: 4223538 • Views: …

More Releases from ABNewswire

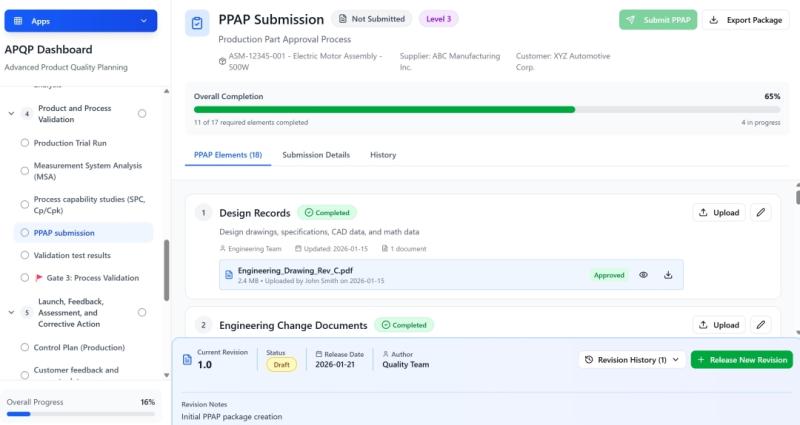

Excedify Launches AI-Powered APQP Management Software for End-to-End Product & P …

Excedify has launched a new AI-powered APQP management software designed to eliminate fragmented quality tools and manual coordination. The platform connects Voice of Customer, requirements, BOMs, FMEAs, phases, gates, timelines, teams, and release management in one synchronized system, helping engineering and quality teams execute APQP faster, with full traceability and audit readiness.

Germany - Excedify, a leading provider of engineering and quality training, today announced the launch of its new APQP…

Why SaaS Waste Is the Silent Drain on Growing Businesses

As businesses embrace digital tools, software-as-a-service, or SaaS, has become essential to day-to-day operations. From project management and communication platforms to specialised software, companies increasingly rely on multiple subscriptions to keep teams productive and competitive.

Yet managing these subscriptions can quickly become a challenge. Employees often sign up for new tools, abandon others, or even leave the company without cancelling accounts, leaving businesses paying for services they no longer use. Over…

Phoenix Auto Repair Shop Recognized for Nearly Three Decades of Honest Vehicle S …

J-N-J Auto Service, a family-owned Phoenix shop since 1997, delivers ASE-certified repairs for all makes and models with honest pricing and a 12-month/12K-mile warranty.

Phoenix, AZ - A family-owned auto repair shop [https://maps.app.goo.gl/rBv51GPGpgN4M6fWA] on West Cactus Road has quietly built a reputation that speaks louder than any billboard. Since 1997, J-N-J Auto Service has been the go-to destination for Phoenix drivers who want straight answers and dependable results. The shop, staffed…

Escaping the "Quote Black Hole": How Rapidaccu Is Rethinking the China-to-West S …

For years, the narrative around Chinese manufacturing has been dominated by two extremes: the massive contract manufacturers (like Foxconn) that only talk to Apple, and the chaotic open market of Alibaba where quality can be a gamble.

For the average hardware engineer or procurement manager in the US or Europe, this leaves a frustrating "middle ground." They need professional traceability and engineering feedback, but they don't have the volume to command…

More Releases for PPM

Oberheiden P.C.'s PPM Attorneys Serving Clients Nationwide

February 10, 2025 - Houston, TX - Oberheiden P.C. is pleased to announce that the firm's PPM lawyers are now serving clients nationwide. The firm's lawyers have extensive experience drafting private placement memorandums (PPMs) and the other legal documents required for conducting private placement offerings, and they are now available to work with clients seeking to raise capital across the country.

According to the firm's founding attorney, Nick Oberheiden, PhD, "Under…

Project Portfolio Management (PPM) Market Analysis Report 2022 - 2030

Acumen Research and Consulting has announced the addition of the "Project Portfolio Management (PPM) Market" report to their offering.

The Project Portfolio Management (PPM) Market Report 2030 is an in depth study analyzing the current state of the Project Portfolio Management (PPM) Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on Project Portfolio Management (PPM) Market provides analysis…

2022-2028 Processor Power Module (PPM) Market | Detailed Report

The Processor Power Module (PPM) research report provides a detailed picture of the market by way of study, synthesis, and summation of data from multiple sources. The data thus presented is reliable, comprehensive and the result of extensive research both primary and secondary. The analysts have presented the various facets of the market with a particular focus on identifying the key industry influencers. Moreover, the data underlines the primary and…

T-PPM Project Management new project dashboards

T-PPM - Project Portfolio Management (https://www.t-ppm.it) is a web solution that allows you to organize, manage and plan projects and the team. T-PPM is simple and intuitive to configure and use. In the new video we have created and published we show all the features and potential of dashboards. The features are available at different levels depending on the profiling role: Project Managers or actor who make up the project…

New Linkedin TeraNet PPM Showcase

We have published a new showcase in linkedin (https://www.linkedin.com/showcase/teranet-ppm-gestione-progetti-e-attivita/) related to all the features offered by the TeraNet PPM Project Management Sytem software (https://www.t-ppm.it/features-ppm-software-gestione-progetti)

WBS, teams and contacts, milestones, kanban & chat, team activity planner, calendar and activities, personal productivity, meeting management, activity monitoring and approval WF, dashboard projects, documents, help desk, active and passive invoices, APIs, single sign-on ... some of the features that are described in the new showcase

TeraNet…

TeraNet PPM Project Management Software - New Web Site

New Web Site for TeraNet PPM: https://www.t-ppm.it. TeraNet PPM is a software environment to organize, manage, plan projects and team with simplicity and effectiveness.

TeraNet PPM integrates features of Project Management, Project Planning and Time Tracking, to increase efficiency in team work, as well as individual productivity in planning, managing and reporting activities

TeraNet PPM offers many features designed to meet both the needs of the Project Manager and the team members:…