Press release

Copper Anodes Manufacturing Plant Project Report 2025

The copper anodes industry has become one of the fastest-growing segments in the metal processing sector, supported by increasing demand across global markets. Setting up a copper anodes manufacturing plant requires more than just infrastructure; it involves strategic planning, investment, efficient equipment, and strong market awareness. This article presents an overview of copper anodes manufacturing plants, covering setup, processing stages, market trends, investment considerations, and operational requirements.What About Copper Anodes?

Copper anodes are the most widely traded product in the world copper industry. They are cast copper plates of 99%+ copper. These anodes are used for electrorefining and electroplating. The anodes are used as the positive electrodes in the electrolytic cells that make high-purity cathode copper (99.99% copper). Copper anodes produce refined copper for electrical wiring, electronics, construction, telecommunications, and renewable energy. Copper is a good conductor of electricity and heat and is recyclable. The wider use of copper anodes for both copper refining and copper electroplating has resulted in a demand for anodes of higher quality, with more stringent dimensional tolerances and chemical and physical compositions. For that reason, quality specifications, minimization of impurities and optimal casting parameters are getting even more important, as copper refineries and industry require ever-more efficient, energy-saving and sustainable metallurgical copper production.

Request a Sample Report: https://www.imarcgroup.com/copper-anodes-manufacturing-plant-project-report/requestsample

What is Driving the Copper Anodes Market?

The copper anodes global market is directly affected from the demand for refined copper worldwide. The demand is increasing due to growth in the electrical and electronics industry worldwide, growth in electrification including production of electric vehicles, infrastructure for renewable energy such as solar panels and wind turbine generators, and upgradation of the power grid. The construction industry in emerging economies requires refined copper for electrical wires, piping, and other components of built infrastructure.

The telecommunications network is a further driver of demand for refined metallic copper, demonstrated by persistent demand for 5G networks and data centers. Ever since, the clean energy technology revolution and the electrification of the automobile revolution have put copper at the center of all energy transition plans with the demand according to the International Energy Agency projecting to 2040. Electroplating, particularly for the manufacture of electronic, automotive, and decorative finishes, requires a continuous supply of copper plating anodes. The global move towards a circular economy and copper recycling has increased demand for anodes manufactured from secondary copper. Additionally, expansions of copper mining and refining capacity in Latin America, Africa, and the Asia-Pacific region have expanded the potential market for anode production, and environmental legislation promoting energy efficient refining technology and sustainable metallurgical practices are also impacting the market. Buyers increasingly select suppliers which are responsible producers and have a transparent supply chain.

Understanding Copper Anodes Manufacturing

• Copper anodes manufacturing refers to converting raw copper materials (blister copper,or copper concentrates) into cast anode plates suitable for electrorefining processes.

• Manufacturing activities include copper melting in furnaces, refining to remove impurities, alloying adjustments, casting into anode molds with specific dimensions and weights, cooling and solidification, trimming and finishing, quality inspection, and packaging for shipment.

• Copper anode quality depends on achieving target specifications for copper content, controlled impurity levels (iron, sulfur, oxygen), dimensional accuracy, flat surfaces, and proper ear/lug configuration for hanging in electrolytic cells.

• Efficiency in the process ensures consistent anode quality, compliance with refinery specifications and metallurgical standards, optimal current efficiency in electrorefining, and the ability to meet diverse customer requirements from large-scale refineries to specialized electroplating operations.

Key Components of a Business Plan

• Executive Summary: Outlines vision, mission, and business objectives.

• Market Research: Identifies demand patterns, consumer behavior, and competitive players.

• Operational Strategy: Includes plant design, capacity, workflow, and quality assurance measures.

• Marketing and Sales Plan: Defines distribution channels, branding, and positioning in domestic and export markets.

• Financial Planning: Covers projected investments, cost structures, and revenue expectations.

• Risk Assessment: Evaluates potential challenges such as raw material supply, regulatory compliance, and market fluctuations.

Capital Investment Overview

CapEx (Capital Expenditure):

• Land acquisition, plant construction, utilities setup, and equipment purchase.

• One-time costs associated with establishing infrastructure and ensuring processing efficiency.

• Defines long-term productivity and competitiveness.

OpEx (Operating Expenditure):

• Recurring costs including labor, utilities, packaging, storage, and transportation.

• Raw material procurement and regular equipment maintenance.

• Compliance with safety certifications, hygiene practices, and quality control standards.

Machinery and Equipment Requirements

Primary Equipment:

• Rotary or reverberatory furnaces for copper melting and refining.

• Holding furnaces for maintaining molten copper temperature.

• Anode casting machines or casting wheels for continuous production.

• Anode molds with precise dimensional specifications.

• Overhead cranes and material handling systems for hot metal operations.

• Cooling beds or water quenching systems for solidification.

• Trimming and finishing equipment for anode edges and lugs.

• Sample drilling equipment for quality analysis.

• Spectroscopy or chemical analysis instruments for composition testing.

Buy Report Now: https://www.imarcgroup.com/checkout?id=24049&method=1911

Supporting Equipment:

• Flux and alloying material feeders.

• Fume extraction and air pollution control systems.

• Refractory materials for furnace lining.

• Temperature monitoring and control systems.

• Water treatment systems for cooling operations.

• Storage racks and handling equipment for finished anodes.

• Safety equipment including protective gear and fire suppression systems.

Operating Costs

• Labor salaries, training, and workforce management including skilled furnace operators.

• Utilities such as electricity or natural gas for melting operations, water for cooling, and compressed air.

• Maintenance and servicing of machinery and equipment including refractory replacement.

• Packaging materials including protective wrapping, banding, and pallets.

• Transportation and distribution logistics.

• Certification, compliance, and quality assurance activities.

• Environmental monitoring, emissions control, and waste management.

Raw Materials

• Additional Inputs: Alloying elements or deoxidizers if required for specific anode specifications, flux materials for refining.

• Packaging Materials: Protective wrapping materials, steel banding, wooden or steel pallets, shipping containers.

• Auxiliary Materials: Refractory materials for furnace maintenance, furnace fuels (natural gas, electricity), cooling water, mold release agents.

• Supply Considerations: Consistency of copper quality and purity, reliable sourcing partnerships with smelters suppliers, price volatility management through forward contracts, and adherence to responsible sourcing standards including conflict-free minerals certification and environmental compliance.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=24049&flag=C

Frequently Asked Questions (FAQs)

1. What is the first step in setting up a copper anodes manufacturing plant?

The process begins with developing a business plan, securing land near copper supply sources or refineries, obtaining environmental permits and manufacturing licenses, establishing relationships with copper suppliers, and arranging financing for high-capital furnace and casting equipment.

2. Why is quality control considered critical?

Quality control ensures that copper anodes meet stringent refinery specifications for copper content, impurity levels, and physical dimensions, which directly impacts electrorefining efficiency, cathode quality, energy consumption, and customer satisfaction.

3. Can copper anodes manufacturing plants focus only on domestic markets?

Yes, though many plants also target exports, as international markets, particularly in major copper-refining countries like Chile, China, Japan, and the United States, show strong demand for quality copper anodes for their electrorefining operations.

4. How does automation benefit copper anodes manufacturing?

Automation improves casting consistency, reduces labor exposure to hazardous high-temperature operations, ensures dimensional accuracy, enhances production throughput, and enables real-time quality monitoring for better process control.

5. Is backward integration into copper smelting necessary?

Not mandatory; many anode manufacturers purchase blister copper from independent smelters or metal traders, though some large operations integrate smelting and anode production for supply security and margin optimization.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Copper Anodes Manufacturing Plant Project Report 2025 here

News-ID: 4223009 • Views: …

More Releases from IMARC Group

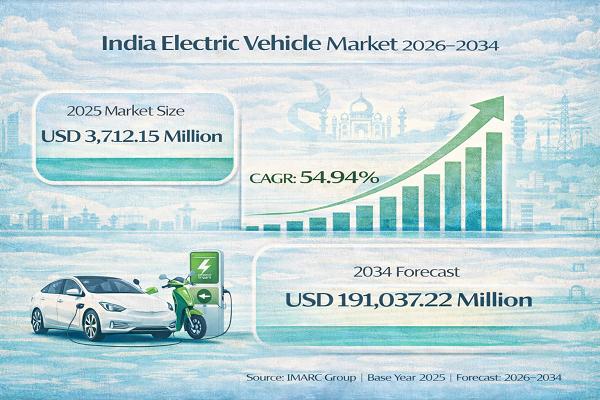

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Copper

Copper Mining Market is Booming Worldwide | Major Giants Turquoise Hill, Copper …

HTF MI recently introduced Global Copper Mining Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2025-2033). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence.

Major companies in Copper Mining Market are:

Codelco, BHP, Freeport-McMoRan, Glencore, Rio Tinto, KGHM, First Quantum Minerals, Southern Copper, Antofagasta, Lundin Mining,…

Copper And Copper Alloy Welding Wire Market Size Analysis by Application, Type, …

According to Market Research Intellect, the global Copper And Copper Alloy Welding Wire market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

With a robust Compound Annual Growth Rate (CAGR) of roughly 4.5%, the global market…

Copper Alloy And Copper Powder Market Size Analysis by Application, Type, and Re …

USA, New Jersey- According to Market Research Intellect, the global Copper Alloy And Copper Powder market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The market for copper alloys and copper powder is steadily rising due to rising demand from a variety of industrial sectors, such…

Copper and Copper Alloy Foil Market Size, Scope 2031 by Key Companies- Amari Cop …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲: According to Verified Market Reports analysis, the global Copper and Copper Alloy Foil Market size was valued at USD 13.60 Billion in 2023 and is projected to reach USD 24.34 Billion by 2031, growing at a CAGR of 8.67% during the forecasted period 2024 to 2031.

The Copper and Copper Alloy Foil Market is poised for growth due to the increasing demand for high-performance materials across various industries,…

Global Copper and Copper-alloy Foils

LP INFORMATION recently released a research report on the Copper and Copper-alloy Foils

Contact US

LP INFORMATION

E-mail: info@lpinformationdata.com

Tel: 001-626-346-3938 (US) 00852-58080956 (HK) 0086 15521064060 (CN)

Add: 17890 Castleton St. Suite 162 City of Industry, CA 91748 US

Website: https://www.lpinformationdata.com

About Us:

LP INFORMATION (LPI) is a professional market report publisher based in America, providing high quality market research reports with competitive prices to help decision makers make informed decisions and take strategic actions…

Global Copper and Copper-alloy Foils (

LP INFORMATION offers a latest published report on Copper and Copper-alloy Foils (

Contact US

LP INFORMATION

E-mail: info@marketresearchreportstore.com

Tel: CN:0086-13660489451 HK: 00852-58081523 USA:001-626-3463946

Add: 17890 Castleton Street Suite 218 City of Industry CA 91748 United States

Website: https://www.marketresearchreportstore.com

About Us

LP INFORMATION (LPI) is a professional organization related to market research reports in all directions .To provide customers with a variety of market research reports,…