Press release

Polymer Matrix Composites (PMC) Manufacturing Plant Project Report 2025

Polymer Matrix Composites (PMC) are advanced materials composed of a polymer resin matrix reinforced with fibers such as carbon, glass, or aramid. These composites combine light weight, high strength, corrosion resistance, and thermal stability, making them ideal for aerospace, automotive, marine, and construction applications. PMCs enhance structural performance while reducing overall weight, offering superior durability and design flexibility compared to conventional materials.Setting up a PMC plant involves sourcing high-quality polymer resins and reinforcing fibers, followed by processes like molding, curing, and finishing. Key requirements include specialized fabrication machinery, skilled technicians, quality control labs, controlled production environments, and safety and environmental compliance to ensure consistent, high-performance composite products.

IMARC Group's report, titled "Polymer Matrix Composites (PMC) Manufacturing Plant Setup Cost 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a polymer matrix composites (pmc) manufacturing plant. It covers a comprehensive market overview to micro-level information, such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Polymer Matrix Composites (PMC) Industry Outlook 2025:

The PMC industry in 2025 is expected to grow significantly, driven by rising demand for lightweight, high-strength materials in aerospace, automotive, and renewable energy sectors. Advancements in fiber technologies, government incentives for sustainable materials, and increased adoption in industrial and construction applications are fueling global market expansion.

Request for Sample Report: https://www.imarcgroup.com/polymer-matrix-composites-manufacturing-plant-project-report/requestsample

Key Insights for Polymer Matrix Composites (PMC) Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=15785&method=1911

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Polymer Matrix Composites (PMC) Plant:

• Land, building, and infrastructure

• Polymer resins and reinforcing fiber procurement

• Molding, curing, and fabrication machinery

• Skilled labor and technical training

• Utilities and energy supply

• Quality control and testing equipment

• Packaging, storage, and logistics

• Licensing, safety, and environmental compliance

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=15785&flag=C

Economic Trends Influencing Polymer Matrix Composites (PMC) Plant Setup Costs 2025:

• Growing demand for lightweight and high-performance materials

• Fluctuating raw material (resin and fiber) prices

• Technological advancements in composite fabrication

• Expansion of aerospace, automotive, and renewable energy sectors

• Government policies supporting sustainable and advanced materials

• Energy and operational cost variations

Challenges and Considerations for Investors in Polymer Matrix Composites (PMC) Plant Projects:

• High initial investment and specialized machinery costs

• Ensuring consistent quality of raw materials

• Skilled workforce availability

• Compliance with environmental and safety standards

• Competition from established composite manufacturers

• Market demand fluctuations and long-term adoption trends

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polymer Matrix Composites (PMC) Manufacturing Plant Project Report 2025 here

News-ID: 4222752 • Views: …

More Releases from IMARC Group

Fantasy Sports Market in India 2026: Size, Share, Growth Rate & Industry Forecas …

India Fantasy Sports Market Overview

According to IMARC Group's report titled "India Fantasy Sports Market Size, Share, Trends and Forecast by Sports Type, Platform, Demographics, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

The India fantasy sports market size was valued at USD 27.0 Billion in 2025. IMARC Group estimates that the market will expand to reach USD 519.8 Billion…

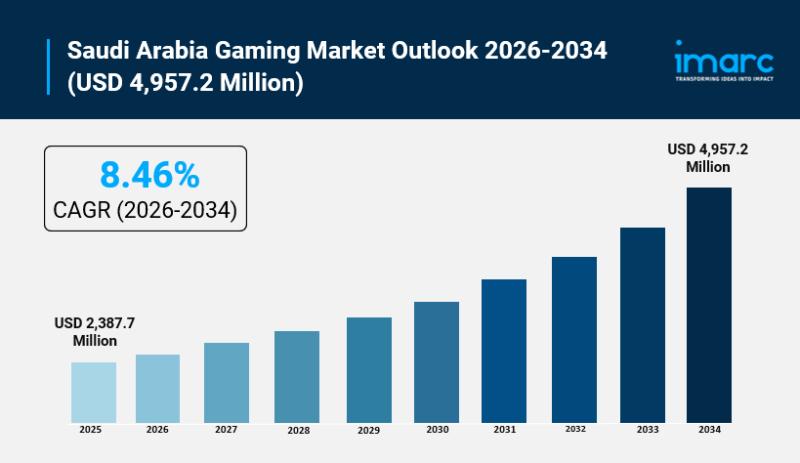

Saudi Arabia Gaming Market is Set For Strong Growth, Projected to Reach USD 4,95 …

Saudi Arabia Gaming Market Overview

Market Size in 2025: USD 2,387.7 Million

Market Forecast in 2034: USD 4,957.2 Million

Market Growth Rate 2026-2034: 8.46%

According to IMARC Group's latest research publication, "Saudi Arabia Gaming Market Report by Device Type (Consoles, Mobiles and Tablets, Computers), Platform (Online, Offline), Revenue (In-Game Purchase, Game Purchase, Advertising), Type (Adventure/Role Playing Games, Puzzles, Social Games, Strategy, Simulation, and Others), Age Group (Adult, Children), and Region 2026-2034", the Saudi Arabia…

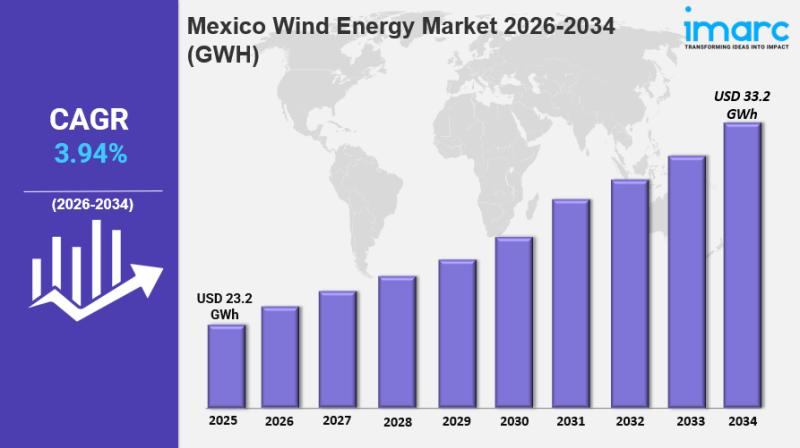

Mexico Wind Energy Market Size, Share, Industry Overview, Trends and Forecast 20 …

IMARC Group has recently released a new research study titled "Mexico Wind Energy Market Report by Component (Turbine, Support Structure, Electrical Infrastructure, and Others), Rating (≤ 2 MW, >2 ≤ 5 MW, >5 ≤ 8 MW, >8 ≤ 10 MW, >10 ≤ 12 MW, >12 MW), Installation (Offshore, Onshore), Turbine Type (Horizontal Axis, Vertical Axis), Application (Utility, Industrial, Commercial, Residential), and Region 2026-2034", offers a detailed analysis of the market…

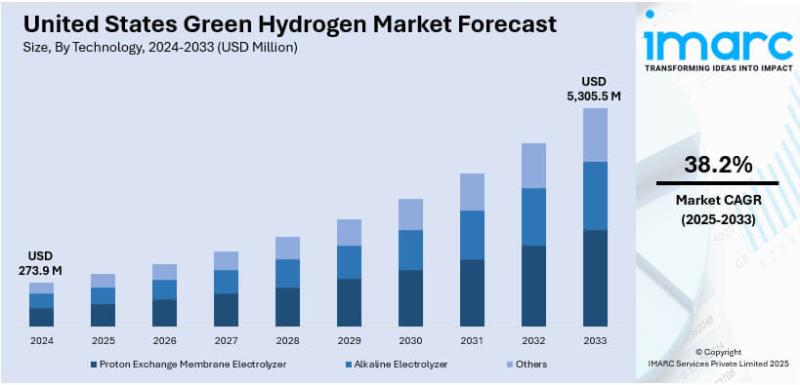

U.S. Green Hydrogen Market to Reach USD 5,305.5 Million by 2033 | CAGR 38.2%

Market Overview

The United States green hydrogen market size was valued at USD 273.9 Million in 2024 and is expected to reach USD 5,305.5 Million by 2033, exhibiting a CAGR of 38.2% during the forecast period 2025-2033. Growth is primarily driven by supportive government policies including the Bipartisan Infrastructure Law and Inflation Reduction Act, rapid technological advancements in electrolyzer efficiency, expanding applications in transportation and heavy industry, growing private-sector investments, and…

More Releases for PMC

Paper Machine Clothing (PMC) Market Size, Trends & Forecasts | Valuates Reports

Paper Machine Clothing (PMC) Market Size

The global market for Paper Machine Clothing (PMC) was valued at US$ 2640 million in the year 2024 and is projected to reach a revised size of US$ 3505 million by 2031, growing at a CAGR of 4.2% during the forecast period.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-20A9978/Global_Paper_Machine_Clothing_PMC_Market_Insights_Forecast_to_2028?utm_source=openpr&utm_medium=referral&utm_campaign=paper_machine_clothing_pmc_report

Global key players of Paper Machine Clothing (PMC) include Albany International, ANDRITZ AG, AstenJohnson, Heimbach, Nippon Filcon, etc. The top five…

Paper Machine Clothing (PMC) Market 2024 | Valuates Reports

Paper Machine Clothing (PMC) - Market Size

The global market for Paper Machine Clothing (PMC) was estimated to be worth US$ 2422.8 million in 2023 and is forecast to a readjusted size of US$ 3204.3 million by 2030 with a CAGR of 4.2% during the forecast period 2024-2030

View Sample Reports

https://reports.valuates.com/request/sample/QYRE-Auto-20A9978/Global_Paper_Machine_Clothing_PMC_Market_Insights_Forecast_to_2028

Report Scope

This report aims to provide a comprehensive presentation of the global market for Paper Machine Clothing (PMC), focusing on the total…

Understanding Process Piping with PMC Inc: A Comprehensive Guide

Process piping [https://buildwithpmc.com/process-piping/] systems are the lifelines of many industrial sectors, including chemical, pharmaceutical, petrochemical, and oil & gas industries. These systems are crucial for transporting raw materials, intermediates, and final products from one point to another within manufacturing facilities. PMC Inc [https://buildwithpmc.com/], a leader in the field of industrial piping solutions, has been at the forefront of designing, fabricating, and maintaining process piping systems that meet the highest standards…

Paper Machine Clothing (PMC) Market Gaining Momentum with Positive External Fact …

The Paper Machine Clothing (PMC) Market study with 156+ market data Tables, Pie charts & Figures is now released by HTF MI. The research assessment of the Market is designed to analyze futuristic trends, growth factors, industry opinions, and industry-validated market facts to forecast till 2029. The market Study is segmented by key a region that is accelerating the marketization. This section also provides the scope of different segments and…

Introducing Delta PMC 24V 150W Wide Range Power Supply

Delta Electronics has added another 24V Panel Mount Power Supply series to the popular PMC series. Power Factor Correction (PFC) is designed into this model which operates at 24V output with 150W power rating at wide range input of 85Vac to 264Vac. Its active PFC of >0.99 @ 115Vac significantly improves the harmonic current levels to meet EN61000-3-2 standard and also reduces energy consumption. The lightweight and tough aluminum body…

PMC PowerPC Board with Gigabit Ethernet, USB and CAN

The PMC-CPU/440 is a PCI Mezzanine Card that automatically switches to monarch (PrPMC) or non-monarch mode ac-cording to the system’s requirements. The PowerPCTM AMCC PPC440EPx with 533 MHz or 667 MHz enables a performance of 1334 DMIPS peak, is equipped with at least 256 Mbyte DDR2 RAM and 256 Mbyte NAND Flash, and offers system time sup¬port by RTC (with double layer capacitor) or IRIG-B. For CAN bus synchronization tasks,…