Press release

Polybutadiene Rubber (PBR) Manufacturing Plant Report 2025: Project Details, Machinery Requirements, and Cost Involved

Setting up a polybutadiene rubber (PBR) manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Polybutadiene Rubber (PBR) Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a polybutadiene rubber manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request for a Sample Report: https://www.imarcgroup.com/polybutadiene-rubber-pbr-manufacturing-plant-project-report/requestsample

Polybutadiene Rubber (PBR) Manufacturing Plant

The Polybutadiene Rubber (PBR) manufacturing plant cost primarily depends on various factors such as plant capacity, location, raw material availability, production technology, and infrastructure setup. The plant setup involves key cost components including land acquisition, construction, machinery installation, utilities, manpower, and working capital. Major raw materials required are butadiene monomer, catalysts, and stabilizers, which significantly influence the overall production cost due to market price volatility. The process technology-such as solution or emulsion polymerization-also impacts both capital and operational expenditures. Additionally, energy consumption, waste management, and environmental compliance requirements contribute to recurring expenses. A medium-scale plant with modern automation can achieve economies of scale, reducing per-unit production costs and improving ROI. Overall, the total investment typically includes fixed capital costs, operating costs, and contingency reserves to ensure uninterrupted operations and sustainable profitability. A detailed feasibility study is essential to evaluate cost optimization strategies, resource efficiency, and financial projections before setup.

Market Drivers and Business Strategy

The Polybutadiene Rubber (PBR) market is primarily driven by the growing demand from the automotive sector, especially for manufacturing tires, owing to its excellent abrasion resistance, high elasticity, and durability. Rising vehicle production, infrastructure development, and replacement tire demand are fueling PBR consumption globally. Additionally, the expanding use of PBR in industrial belts, footwear, golf balls, and various molded products is further driving market growth. From a business strategy perspective, manufacturers are focusing on cost optimization through vertical integration, strategic sourcing of butadiene, and adoption of energy-efficient technologies. Expanding production capacity near petrochemical hubs helps reduce raw material transportation costs. Companies are also investing in R&D to develop high-performance grades of PBR with enhanced mechanical properties and low rolling resistance to meet sustainability goals. Strategic alliances and long-term contracts with tire manufacturers help ensure steady demand and price stability. Moreover, adopting digital manufacturing and automation improves process efficiency and reduces downtime, enhancing competitiveness in the global market.

Buy Now: https://www.imarcgroup.com/checkout?id=23083&method=1911

Key Steps Required to Set Up a Polybutadiene Rubber (PBR) Plant

1. Market Analysis

The report provides insights into the landscape of the polybutadiene rubber industry at the global level. The report also provides a segment-wise and region-wise breakup of the global polybutadiene rubber industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of polybutadiene rubber, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the polybutadiene rubber manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for polybutadiene rubber manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for polybutadiene rubber production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a polybutadiene rubber manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=23083&flag=C

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polybutadiene Rubber (PBR) Manufacturing Plant Report 2025: Project Details, Machinery Requirements, and Cost Involved here

News-ID: 4222624 • Views: …

More Releases from IMARC Group

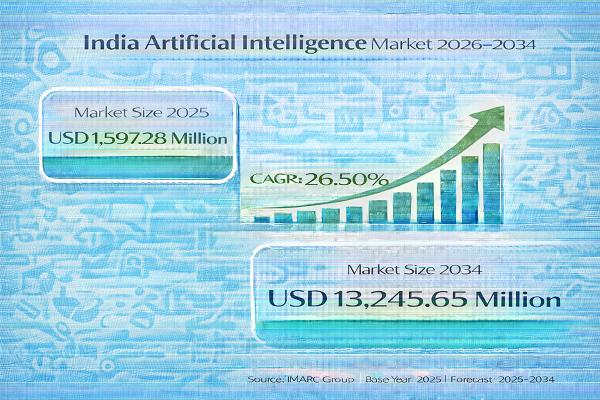

India Artificial Intelligence Market Projected to Reach 13,245.65 Million by 203 …

India Artificial Intelligence Market : Report Introduction

According to IMARC Group's report titled "India Artificial Intelligence Market Size, Share, Trends and Forecast by Type, Offering, Technology, System, End-Use Industry, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-artificial-intelligence-market/requestsample

India Artificial Intelligence Market Overview

The India artificial intelligence market size was valued at…

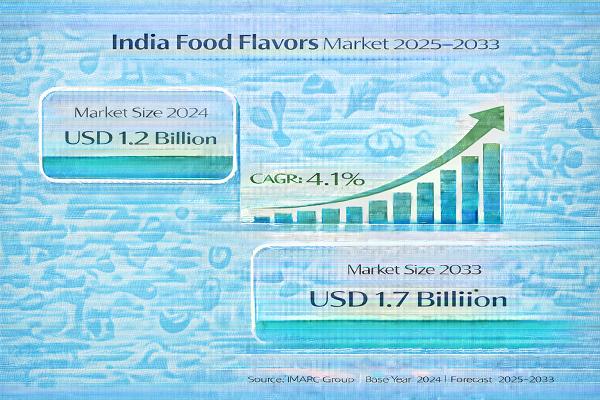

India Food Flavors Market Expected to Reach USD 1.7 Billion by 2033, Driven by 4 …

India Food Flavors Market Report Introduction

According to IMARC Group's report titled "India Food Flavors Market Size, Share, Trends and Forecast by Type, Form, End User, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Note : We are in the process of updating our reports to cover the 2026-2034 forecast period. For the most recent data, insights, and industry updates,…

India Peptide Synthesis Market Expected to Reach USD 52.48 Million by 2034, Indu …

IMARC Group's latest research publication "India Peptide Synthesis Market Size, Share, Trends and Forecast by Product, Technology, Application, End Use, and Region, 2026-2034" the India peptide synthesis market size reached USD 30.86 Million in 2025. The market is expected to reach USD 52.48 Million by 2034, exhibiting a growth rate (CAGR) of 6.08% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-peptide-synthesis-market/requestsample

What is Peptide Synthesis?

Peptide synthesis is the chemical or biological process of…

India Smart Advertising Market Expected to Reach USD 275.30 Million by 2034, Ind …

IMARC Group's latest research publication "India Smart Advertising Market Size, Share, Trends and Forecast by Component, Product, End Use, and Region, 2026-2034" the India smart advertising market size was valued at USD 68.71 Million in 2025. The market is expected to reach USD 275.30 Million by 2034, exhibiting a growth rate (CAGR) of 16.68% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-smart-advertising-market/requestsample

What is Smart Advertising?

Smart advertising refers to digital, data-driven advertising solutions…

More Releases for PBR

Track Polybutadiene Rubber (PBR) Price Trend Historical and Forecast

Executive Summary

Polybutadiene Rubber (PBR) - a key synthetic elastomer used predominantly in tire, automotive, and industrial applications - exhibited nuanced price behavior across global markets from Q4 2024 through the quarter ending September 2025. While price indices experienced modest rises in North America and Europe in Q3 2025, APAC markets recorded notable softening amid oversupply and subdued downstream demand. Across regions, price movements were shaped by changing automotive sector dynamics,…

From post-processing to native generation: Hitem3D's new approach pairs geometry …

For years, 3D pipelines have lived with an awkward compromise: geometry defines the shape, and textures are something you slap on afterward. It's efficient, and it works - until it doesn't.

The cracks show up the moment a model needs to be more than a pretty render. When you move into 3D printing, manufacturing, or any high-fidelity output, that classic "build the mesh first, then project details onto it" workflow can…

Polybutadiene Rubber (PBR) Market Strengthens as Automotive and Tire Industries …

Pune, India - December 2025 - The Polybutadiene Rubber (PBR) Market is experiencing significant growth as manufacturers of tires, automotive components, and industrial products increasingly adopt PBR for its high resilience, wear resistance, and low-temperature performance. Polybutadiene rubber is widely used in tire treads, belts, gaskets, and other high-performance applications.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/69345

The market is driven by growing automotive production, expanding tire demand, and…

Polybutadiene (BR) Market Trends That Will Shape the Next Decade: Insights from …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

How Large Will the Polybutadiene (BR) Market Size By 2025?

The market for polybutadiene (BR) has witnessed swift expansion lately. It's projected to enlarge from a valuation of $24.12 billion in 2024 to $26.67 billion in 2025, posting a compound annual growth rate (CAGR) of 10.6%. This notable growth…

Global Brake Line Market 2017 - Centric, Dorman, Beck Arnley, AC Delco, PBR, Ben …

The report focuses on global major leading industry players with information such as company profiles, product picture and specifications, sales, market share and contact information. What’s more, the Brake Line industry development trends and marketing channels are analyzed.

The Global Brake Line Industry report gives a comprehensive account of the Global Brake Line market. Details such as the size, key players, segmentation, SWOT analysis, most influential trends and business environment of…

Export 3D Scene to GLTF 2.0 Format & Customize Non-PBR to PBR Materials using .N …

What’s new in this release?

Aspose team is pleased to announce the release of Aspose.3D for .NET 17.06.0. The new version 17.6 of the API adds support of exporting 3D scenes to GLTF 2.0 (ASCII or Binary) format. GLTF 2.0 only supports PBR materials and Aspose.3D for .NET API internally converts Non-PBR materials to PBR materials as well as allows developers to customize the convert procedure. The recent version 17.6 also…