Press release

SiC Power Devices Manufacturing Plant Setup Report 2025: Industry Overview, and Profitability

Silicon Carbide (SiC) power devices are advanced semiconductor components made from silicon carbide material, known for their high thermal conductivity, wide bandgap, and superior efficiency compared to traditional silicon-based devices. These characteristics enable SiC power devices to operate at higher voltages, temperatures, and frequencies, making them ideal for electric vehicles, renewable energy systems, industrial power supplies, and aerospace applications.Setting up a SiC power devices manufacturing plant involves establishing facilities for wafer fabrication, epitaxy, device processing, and packaging under cleanroom conditions. With growing demand for energy-efficient electronics, this venture offers strong potential for profitability and technological advancement.

IMARC Group's report, titled "SiC Power Devices Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a SiC power devices manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

SiC Power Devices Industry outlook 2025

The SiC (Silicon Carbide) power devices industry is rapidly growing, driven by electric vehicle adoption, renewable energy integration, and industrial power efficiency needs. SiC devices provide higher voltage tolerance, faster switching, and lower heat losses than traditional silicon, making them ideal for EV inverters, chargers, and grid systems. Advances in wafer technology, epitaxy, and packaging are improving performance and scalability. Challenges include high manufacturing costs, yield limitations, supply chain constraints, and the need to adapt existing silicon-based system designs. Overall, SiC is becoming essential for next-generation energy-efficient electronics.

Request for a Sample Report: https://www.imarcgroup.com/sic-power-devices-manufacturing-plant-project-report/requestsample

Key Insights for SiC Power Devices Manufacturing Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=23922&method=1911

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a SiC Power Devices Plant

• Land & Infrastructure: Costs for acquiring land, constructing cleanrooms, production halls, offices, and utilities.

• Equipment & Machinery: High-precision tools for wafer fabrication, epitaxy, device processing, etching, doping, metallization, and packaging.

• Raw Materials: SiC substrates, chemicals, gases, and other semiconductor-grade inputs.

• Labor & Expertise: Skilled engineers, technicians, and operators for production, R&D, and quality control.

• Cleanroom & Environmental Controls: HVAC, filtration, humidity control, and waste management systems.

• R&D & Testing: Device prototyping, testing equipment, and quality assurance systems.

• Utilities & Maintenance; Continuous power, water, and facility upkeep for high-tech operations.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=23922&flag=C

Economic Trends Influencing SiC Power Devices Plant Setup Costs 2025

• Material Costs: Transition to larger SiC wafers are reducing per-unit costs and improving economies of scale.

• Labor Market Dynamics: Skilled labor shortages and wage increases are raising operational expenses.

• Supply Chain Challenges: Geopolitical tensions and trade policies impact the availability and cost of critical components.

• Government Incentives: Subsidies and supportive policies for domestic semiconductor manufacturing can lower capital expenditures.

• Technological Advancements: Innovations in SiC processing equipment improve yield and reduce production costs.

• Utility & Infrastructure Costs: Rising electricity, water, and facility maintenance costs influence overall setup investment.

• R&D and Quality Control: Continuous investment in research, prototyping, and testing affects initial capital requirements.

Challenges and Considerations for Investors

• High Capital Investment: Setting up a SiC power devices plant requires significant upfront costs for land, cleanrooms, machinery, and raw materials.

• Technological Complexity: Advanced semiconductor fabrication demands specialized equipment, expertise, and strict quality control.

• Skilled Labor Shortage: Recruiting and retaining trained engineers and technicians can be difficult and costly.

• Supply Chain Risks: Dependence on limited suppliers for SiC wafers, chemicals, and equipment can disrupt production.

• Market Competition: Rapid innovation and global players increase competitive pressure and pricing challenges.

• Regulatory Compliance: Meeting environmental, safety, and industry standards adds operational and financial considerations.

Conclusion

Setting up a SiC power devices plant offers significant opportunities in the rapidly growing energy-efficient electronics market. Despite high capital investment and technological complexities, advancements in SiC technology, strong industry demand, and supportive policies make this venture profitable and strategically valuable for investors seeking long-term growth in next-generation semiconductor solutions.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SiC Power Devices Manufacturing Plant Setup Report 2025: Industry Overview, and Profitability here

News-ID: 4222372 • Views: …

More Releases from IMARC Group

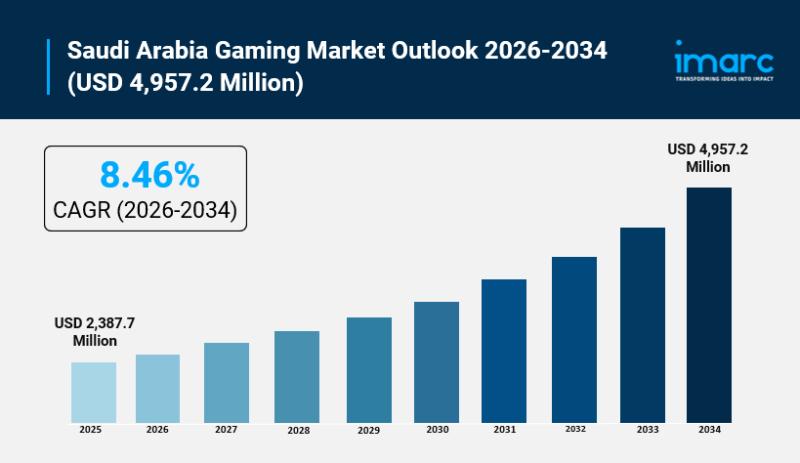

Saudi Arabia Gaming Market is Set For Strong Growth, Projected to Reach USD 4,95 …

Saudi Arabia Gaming Market Overview

Market Size in 2025: USD 2,387.7 Million

Market Forecast in 2034: USD 4,957.2 Million

Market Growth Rate 2026-2034: 8.46%

According to IMARC Group's latest research publication, "Saudi Arabia Gaming Market Report by Device Type (Consoles, Mobiles and Tablets, Computers), Platform (Online, Offline), Revenue (In-Game Purchase, Game Purchase, Advertising), Type (Adventure/Role Playing Games, Puzzles, Social Games, Strategy, Simulation, and Others), Age Group (Adult, Children), and Region 2026-2034", the Saudi Arabia…

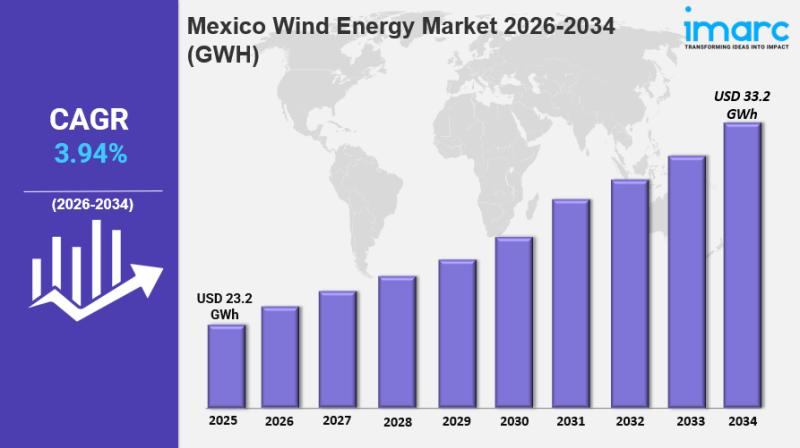

Mexico Wind Energy Market Size, Share, Industry Overview, Trends and Forecast 20 …

IMARC Group has recently released a new research study titled "Mexico Wind Energy Market Report by Component (Turbine, Support Structure, Electrical Infrastructure, and Others), Rating (≤ 2 MW, >2 ≤ 5 MW, >5 ≤ 8 MW, >8 ≤ 10 MW, >10 ≤ 12 MW, >12 MW), Installation (Offshore, Onshore), Turbine Type (Horizontal Axis, Vertical Axis), Application (Utility, Industrial, Commercial, Residential), and Region 2026-2034", offers a detailed analysis of the market…

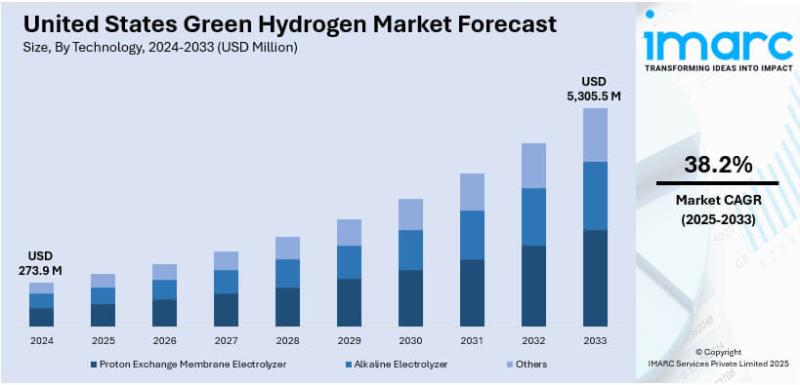

U.S. Green Hydrogen Market to Reach USD 5,305.5 Million by 2033 | CAGR 38.2%

Market Overview

The United States green hydrogen market size was valued at USD 273.9 Million in 2024 and is expected to reach USD 5,305.5 Million by 2033, exhibiting a CAGR of 38.2% during the forecast period 2025-2033. Growth is primarily driven by supportive government policies including the Bipartisan Infrastructure Law and Inflation Reduction Act, rapid technological advancements in electrolyzer efficiency, expanding applications in transportation and heavy industry, growing private-sector investments, and…

United States Electric Vehicle Charging Station Market Size, Trends, Growth and …

Market Overview

The United States electric vehicle charging station market size reached USD 3.2 Billion in 2025 and is expected to grow to USD 34.2 Billion by 2034, exhibiting a CAGR of 28.60% during the forecast period 2026-2034. Growth is primarily driven by increasing adoption of electric vehicles, government incentives and supportive policies promoting clean transportation, continuous improvements in charging technologies such as faster charging speeds and smart charging systems, and…

More Releases for SiC

SiC Schottky Barrier Diodes (SiC SBD) Market Research Report

Global Info Research announces the release of the report "Global SiC Schottky Barrier Diodes (SiC SBD) Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands…

Global SiC MOSFETs Market

SiC MOSFETs Market Overview

Silicon carbide MOSFETs have the characteristics of low on-resistance and small switching losses, which can reduce device losses and improve system efficiency, and are more suitable for high-frequency circuits. It is widely used in the fields of new energy vehicle motor controller, vehicle power supply, solar inverter, charging pile, UPS, PFC power supply and other fields. This report provides a deep insight into the global SiC MOSFETs…

SIC Discrete Device Market

The "SIC Discrete Device Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global SIC Discrete Device Market, 2024-2031

Verified Market Research's most recent report, "SIC Discrete Device Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides…

SiC MOSFET and SiC SBD Market Analysis,Demand,Trends and Forecast 2029

Global Info Research announces the release of the report "Global SiC MOSFET and SiC SBD Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across…

Global High Purity SiC Powder for SiC Single Crystal Market Insights, Forecast …

Global Info Research announces the release of the report "Global High Purity SiC Powder for SiC Single Crystal Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company…

Latest Ceramic Matrix Composites Market by Matrix Type (C/C, C/Sic, Oxide/Oxide, …

The Ceramic Matrix Composites research report is valuable for every market enthusiast, stakeholder, policymaker, and market player. It offers vital information about the industry, including crucial facts, figures, expert opinions, and the latest developments across the globe. In addition, the Ceramic Matrix Composites research report provides data on the patterns and outcomes, target business sectors and materials, limits, and advancements.

Download FREE Sample Report @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=319907

The ceramic matrix composites market…