Press release

Acetic Anhydride Production Cost Report 2025: Detailed Guide on Plant Setup, CapEx/OpEx and Profitability

Acetic anhydride is a colorless, highly reactive organic compound with the chemical formula (CH3CO)2O. It is primarily used as an acetylating agent in the production of cellulose acetate, pharmaceuticals, perfumes, and dyes. The compound exhibits a strong, pungent odor and reacts vigorously with water to form acetic acid. Due to its reactivity, it is widely employed in industrial chemical synthesis and requires careful handling and storage under controlled conditions.Establishing an acetic anhydride manufacturing plant involves selecting an appropriate production process, typically via acetic acid dehydration or ketene-based synthesis. Essential considerations include securing raw material supply, installing corrosion-resistant equipment, ensuring stringent safety measures, and obtaining environmental clearances. Efficient process design and automation can enhance yield and operational safety while minimizing production costs and emissions.

IMARC Group's report, titled "Acetic Anhydride Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an acetic anhydride production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/acetic-anhydride-manufacturing-plant-project-report/requestsample

Acetic Anhydride Industry outlook 2025

The acetic anhydride industry outlook for 2025 indicates steady growth driven by rising demand in pharmaceuticals, cellulose acetate, and chemical intermediates. Expanding applications in textile and packaging sectors, along with increased use in drug formulation, are supporting market expansion. Asia-Pacific continues to dominate production and consumption due to strong industrial infrastructure and raw material availability. However, regulatory restrictions on controlled substances and environmental concerns may influence trade dynamics. Ongoing advancements in catalytic and sustainable production technologies are expected to improve efficiency and reduce environmental impact across the industry.

Key Insights for Acetic Anhydride Production Plant Setup

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up an Acetic Anhydride Plant

• Raw Materials: Procurement of acetic acid, ketene, catalysts, and other chemical inputs.

• Plant and Machinery: Investment in reactors, distillation columns, heat exchangers, condensers, and storage tanks.

• Utilities: Costs related to power, water, steam generation, and cooling systems.

• Infrastructure Development: Land acquisition, site preparation, and construction of production and storage facilities.

• Labor and Staffing: Skilled and unskilled workforce for operations, maintenance, and quality control.

• Environmental and Safety Compliance: Equipment for emissions control, waste management, and safety systems.

• Transportation and Logistics: Supply chain setup for raw material sourcing and product distribution.

• Working Capital: Operational funds for raw materials, utilities, and day-to-day expenses.

• Research and Quality Control: Laboratory setup for product testing, process monitoring, and quality assurance.

• Licensing and Regulatory Approvals: Fees and documentation for environmental, safety, and industrial certifications.

Economic Trends Influencing Acetic Anhydride Plant Setup Costs 2025:

• Fluctuating Raw Material Prices: Volatility in acetic acid and methanol prices continues to impact overall production and setup costs.

• Energy Price Inflation: Rising global energy costs increase expenses for heating, cooling, and process operations.

• Supply Chain Disruptions: Geopolitical tensions and trade restrictions affect the availability and pricing of critical inputs and equipment.

• Regulatory Compliance Costs: Stricter environmental and safety regulations elevate investment in pollution control and sustainable technologies.

• Technological Advancements: Adoption of energy-efficient and catalytic production methods reduces long-term costs but raises initial capital investment.

• Labor Market Conditions: Increasing demand for skilled chemical engineers and technicians contributes to higher labor costs.

• Currency Exchange Volatility: Exchange rate fluctuations influence the cost of imported machinery and raw materials.

• Government Incentives and Policies: Subsidies, tax benefits, or restrictions on chemical manufacturing significantly shape capital allocation and project feasibility.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=20785&flag=C

Challenges and Considerations for Investors in Acetic Anhydride Plant Projects:

• Regulatory Restrictions: Stringent government controls due to acetic anhydride's potential misuse in illicit drug production require strict licensing and compliance.

• Environmental Management: High environmental standards demand advanced waste treatment, emission control, and safety systems, increasing operational complexity.

• Raw Material Dependence: Price fluctuations and supply uncertainties of acetic acid and catalysts affect production economics.

• Capital Intensity: High initial investment in process equipment, technology, and infrastructure can impact project feasibility.

• Market Volatility: Demand variations in downstream industries such as pharmaceuticals and textiles influence long-term profitability.

• Technological Selection: Choosing efficient and sustainable production methods is crucial for cost control and regulatory compliance.

• Logistics and Distribution: Safe handling, storage, and transportation of a reactive chemical add to operational challenges.

• Skilled Workforce Availability: Recruiting experienced technical and safety personnel remains essential for smooth plant operation.

Conclusion:

The establishment of an acetic anhydride manufacturing plant presents significant opportunities within the global chemical and pharmaceutical industries, driven by consistent demand and technological advancements. However, the venture requires careful consideration of regulatory compliance, environmental sustainability, and market volatility. Strategic investment in efficient production technologies, skilled workforce development, and reliable supply chain networks is essential for long-term success. With prudent planning and adherence to global safety and environmental standards, investors can achieve competitive advantages and sustainable profitability in the evolving acetic anhydride market.

Buy Now: https://www.imarcgroup.com/checkout?id=20785&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Acetic Anhydride Production Cost Report 2025: Detailed Guide on Plant Setup, CapEx/OpEx and Profitability here

News-ID: 4220203 • Views: …

More Releases from IMARC Group

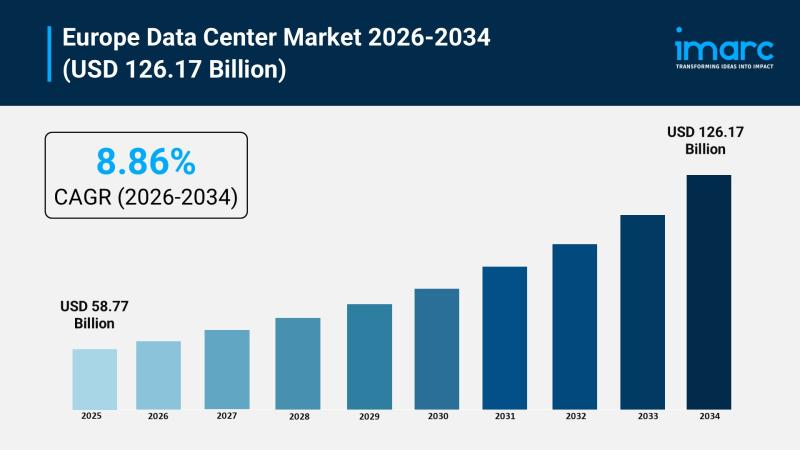

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

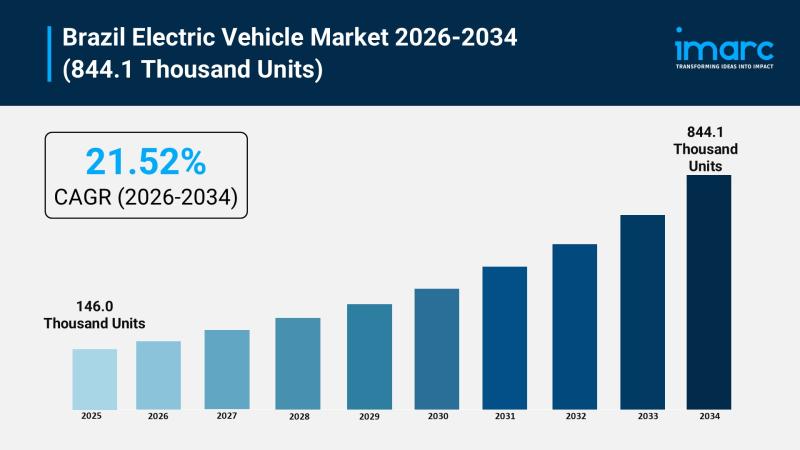

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…