Press release

Poly Methyl Methacrylate (PMMA) Production Cost Analysis 2025: CapEx, OpEx, and ROI Analysis

Setting up a poly methyl methacrylate (PMMA) production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Poly Methyl Methacrylate (PMMA) Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a PMMA production plant setup cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/poly-methyl-methacrylate-manufacturing-plant-project-report/requestsample

What is Poly Methyl Methacrylate (PMMA)?

The cost of setting up a PMMA production plant depends on several critical factors, including plant capacity, production technology, raw material availability, location, utility requirements, and compliance with environmental standards. Establishing a medium- to large-scale PMMA plant generally requires significant capital investment, often ranging in the tens of millions of dollars, due to the need for specialized polymerization reactors, continuous casting equipment, and extrusion systems. Major cost components include land acquisition, site development, polymerization units, monomer handling facilities, sheet casting or extrusion lines, storage infrastructure, utilities, wastewater treatment, and safety systems. Additionally, the procurement of feedstock such as methyl methacrylate (MMA) monomer, initiators, and additives, along with advanced polymer processing equipment for bulk, suspension, or emulsion polymerization, adds substantially to initial expenses. Operating costs further involve labor, energy, maintenance, and logistics. The setup cost also varies depending on whether the plant uses bulk polymerization, suspension polymerization, or continuous casting methodologies. Compliance with strict international and regional regulatory frameworks, particularly regarding industrial-grade and optical-grade production standards, environmental emissions control, and workplace safety regulations, can significantly increase both capital and operational costs. However, while initial investment is substantial, PMMA production plants offer attractive long-term returns due to the product's wide applications in automotive, construction, electronics, signage, medical devices, and optical components, making them a strategic venture for specialized polymer and materials manufacturing investors.

What is Driving the PMMA Market?

The PMMA production plant cost market is primarily driven by rising demand for lightweight and durable materials across automotive, construction, electronics, and signage industries worldwide. With growing consumption of PMMA as a glass substitute in automotive glazing, architectural applications, LED lighting diffusers, and display screens, the need for high-quality transparent thermoplastics has surged, influencing plant expansion and setup costs. Rapid advancement in polymer technology and manufacturing capabilities in regions such as North America, Europe, and Asia-Pacific has also increased investment in specialized acrylic production infrastructure, creating strong incentives for new plant developments. Additionally, volatility in raw material prices for methyl methacrylate monomer and crude oil derivatives directly impacts feedstock availability and cost structure, thereby shaping overall project economics. Regulatory compliance and the integration of advanced, environmentally-friendly polymerization processes further contribute to escalating capital investment requirements. Automotive manufacturers, construction companies, and electronics producers are also demanding production facilities with enhanced optical clarity, improved weather resistance, and higher output efficiency, driving up initial setup expenditures. Furthermore, supply chain optimization, temperature-controlled storage infrastructure, and specialized transportation logistics for polymer materials add to the financial outlay. Despite the high cost, favorable return on investment, coupled with growing demand for sustainable alternatives to glass and traditional plastics, continues to stimulate market interest in PMMA production projects, making it a strategic sector for materials innovation and industrial supply chain competitiveness.

Buy Now: https://www.imarcgroup.com/checkout?id=9466&method=1911

Key Steps Required to Set Up a PMMA Plant

1. Market Analysis

The report provides insights into the landscape of the PMMA industry at the global level. The report also provides a segment-wise and region-wise breakup of the global PMMA industry. Additionally, it also provides the price analysis of feedstocks used in the production of PMMA, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the PMMA production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for PMMA production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for PMMA production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=9466&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a PMMA production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Poly Methyl Methacrylate (PMMA) Production Cost Analysis 2025: CapEx, OpEx, and ROI Analysis here

News-ID: 4217904 • Views: …

More Releases from IMARC Group

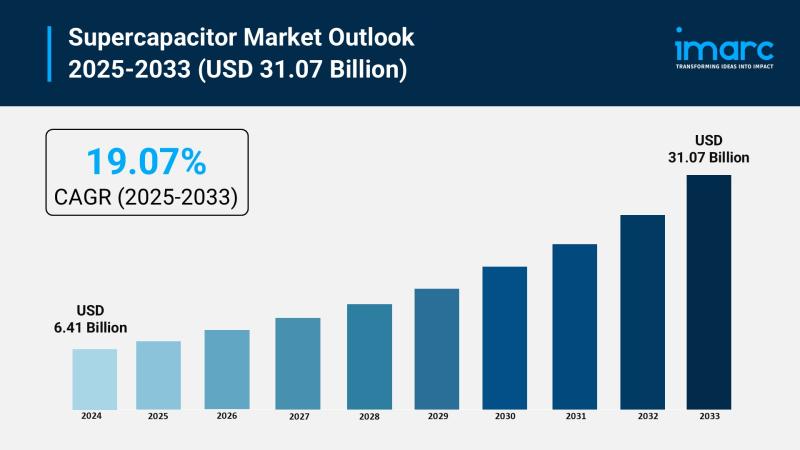

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

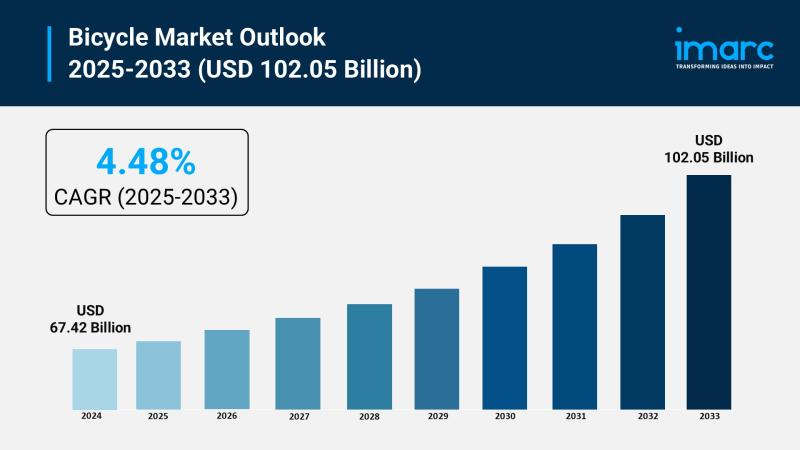

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

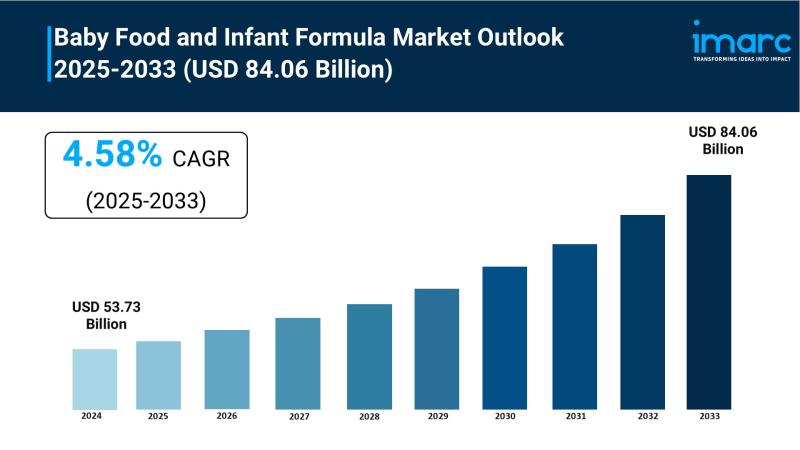

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

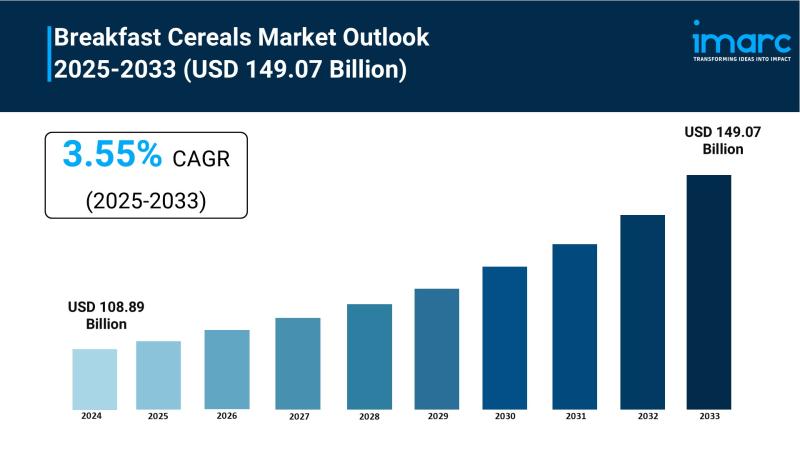

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for MMA

Online Mma Training Programs Market to Witness a Pronounce Growth during 2024-20 …

WMR's latest released Online Mma Training Programs Market Report 2024-2031 provides an in-depth exploration of the trends, challenges, and opportunities within this dynamic market landscape. From enabling technological advancements to driving innovation and sustainability initiatives, the Online Mma Training Programs Market plays a pivotal role in shaping the modern world economy. The report throws light on the competitive landscape, segmentation, geographical expansion, and revenue, production, and consumption growth of the…

Online MMA Training Programs Market Size, Share, Trends, Competitive Landscape, …

The latest intelligence report published by WMR, titled "Online MMA Training Programs Market - Growth Insights, Forecast to 2031" provides current updates and strategic steps taken by competition along with growth estimates of market size. This market study presents basic data and true figures about the market giving a deep analysis of this market based on market trends, market drivers, constraints, and prospects. The report supplies the worldwide monetary challenge…

Online Mma Training Programs Market Recent Trends, In-depth Analysis, Size and F …

The Online Mma Training Programs Market research report represents major insights on the current growth dynamics as well as the primary revenue generation elements that are available in the Online Mma Training Programs industry along with various other factors over the predicted period 2023-2030. The report on the Online Mma Training Programs market is focusing on a series of parameters including top manufacturing strategies, industry share, prime opportunities, industrial channels,…

Online Mma Training Programs Market Set to Witness Extraordinary Growth by 2030 …

The Online Mma Training Programs Market Trends Overview 2023-2030:

A new Report by Worldwide Market Reports, titled "Online Mma Training Programs Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Online Mma Training Programs market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures,…

Monobutylamine (MMA) Market 2022 | Detailed Report

The Monobutylamine (MMA) report understands the current and future competitive scenario across types, countries, and applications.It provides accurate, up-to-date analysis of markets and companies.The report use reliable information and analysis to gain a deeper understanding of the current factors impacting the industry.

The Monobutylamine (MMA) report provides exact and accurate data that helps companies of all sizes to make timely decisions. Furthermore, the report provides robust solutions to customers, assisting them…

2020 Methyl Methacrylate (MMA) Industry Report- Growth by Key Countries and Glob …

ReportsnReports added a new report on The Methyl Methacrylate (MMA) Industry report delivers the clean elaborated structure of the Report comprising each and every business-related information of the market at a global level. The complete range of information related to the Methyl Methacrylate Industry is obtained through various sources and this obtained bulk of the information is arranged, processed, and represented by a group of specialists through the application of…