Press release

Aircraft Polymer Seals Market is Forecasted to Reach US$2.4 Billion in 2034, Says Stratview Research

The global aircraft polymer seals market is projected to witness a growth rate of 3.4% annually from 2024 to 2034, with an anticipated size of US$2.4 billion by 2034, according to an analysis by Stratview Research.Stratview Research, a global market research firm, has launched a report on the global aircraft polymer seals market, which provides a comprehensive outlook of the global and regional industry forecast, current & emerging trends, segment analysis, competitive landscape, & more.

Click here to get a free sample of the report:

https://www.stratviewresearch.com/Request-Sample/2952/aircraft-polymer-seals-market.html#form

Market Statistics:

Market Size in 2034- US$2.4 billion

Growth (CAGR)- 3.4% during 2024-2034

Cumulative Sales Opportunity during 2025-2034- USD 21.60 billion

Forecast Period- 2024-2034

Trend Period- 2018-2022

Base Year- 2023

Number of Segments Covered- 7

Number of Tables & Graphs- 100+

Country-Level Market Assessment- 20

Segment Insights on the Aircraft Polymer Seals Market:

The global aircraft polymer seals market is segmented based on Aircraft type, Application type, Function type, Material type, Motion type, End-User type, and Region.

Based on aircraft type -

The aircraft polymer seals market is divided into light commercial aircraft, regional aircraft, helicopters, military aircraft, and general aviation Commercial aircraft are expected to maintain their dominance in the market throughout the forecast period.

The dominance of commercial aircraft in the aircraft polymer seals market can be attributed primarily to the sheer scale of global commercial aviation activity. Airlines continue to expand their fleets to meet the rising demand for air travel, especially in emerging economies in Asia-Pacific and the Middle East. As commercial aircraft are produced in significantly higher volumes than military or general aviation aircraft, the corresponding demand for components such as polymer seals is proportionately larger. Each commercial aircraft requires a vast number of seals across various applications including fuselage joints, engines, cabin interiors, landing gear systems, and hydraulic lines, making them the largest consumer segment for these products.

Furthermore, the increasing emphasis on fuel efficiency and emissions reduction in the commercial aviation sector is accelerating the adoption of lightweight, high-performance materials like advanced elastomers and thermoplastics in sealing applications. Aircraft manufacturers such as Boeing and Airbus are incorporating more polymer-based components into new-generation aircraft to reduce weight and improve performance, thereby driving higher demand for polymer seals.

Additionally, the frequent maintenance and overhaul cycles that commercial aircraft undergo compared to military or general aviation aircraft result in a steady aftermarket demand for replacement seals, further reinforcing the segment's dominance.

The long operational life and high utilization rate of commercial aircraft also contribute to consistent seal consumption, both at the OEM stage and throughout the maintenance lifecycle. Combined with strong order backlogs for new aircraft and the rise of low-cost carriers expanding regional networks, the commercial aviation segment is expected to remain the key driver of growth in the aircraft polymer seals market over the coming years.

Based on application type -

The aircraft polymer seals market is divided into airframe, nacelles & engines, aircraft interiors, landing gear wheels & brakes, flight control actuation & hydraulics, and other applications.

The airframe segment is expected to remain the dominant application type in the aircraft polymer seals market due to the extensive use of seals throughout the aircraft's primary structural components. The airframe includes the fuselage, wings, tail, and control surfaces, areas where sealing is critical for maintaining structural integrity, aerodynamic performance, and environmental protection. These components are exposed to harsh external conditions, including pressure differentials, temperature extremes, moisture, and UV radiation, necessitating the use of highly durable and specialized polymer seals to ensure safe and efficient operation.

Additionally, airframe structures feature numerous joints, panels, doors, and access points that require sealing to prevent air and fluid leaks, reduce vibration, and improve aerodynamic efficiency. As aircraft designs evolve to incorporate more composites and lightweight materials, polymer seals are increasingly preferred due to their compatibility with these advanced materials and their ability to maintain flexibility, resilience, and long-term sealing performance.

The size and surface area of the airframe compared to other aircraft systems also contribute to its dominant share in seal consumption. Simply put, more sealing material and diverse types of seals are needed in the airframe than in engines, interiors, or hydraulics. Furthermore, the maintenance, repair, and overhaul (MRO) of airframe structures often involve seal inspections and replacements, which reinforces consistent aftermarket demand.

Based on function type -

The aircraft polymer seals market is divided into aerodynamic surface sealing, fire seals, conductive and insulative seals, air & fluid management seals, and other functions.

Fire seals are projected to be the fastest-growing functional type of the aircraft polymer seals market throughout the forecast period, largely because of the increasing focus on passenger safety and increased regulations. Fire seals are specifically designed to endure the extreme temperatures and also the spread of fire and smoke in some of the most critical areas, such as engine nacelles, cargo compartments, and firewall structures.

Additional demand for fire seals will continue to grow as aircraft design evolves, and new types of high-performance, multi-use, and fire-resistant materials are brought in line with FAA and EASA safety regulations. This will continue to drive the demand for advanced polymer fire seals. The development of next-generation aircraft, featuring higher engine temperatures and composite materials, creates new issues that will require aircraft OEMs and Tier 1 suppliers to not only have reliable fire and thermal management solutions but also ones that can physically withstand the heat. Aircraft OEMs and Tier 1 suppliers are continuously revolutionizing and reinventing sealing technologies to enhance fire-resistant capabilities, in addition to improving (reducing) weight and overall life expectancy.

Rising pressures from the increasing number of aircraft deliveries, combined with the increasing focus on in-service maintenance and upgrades, are another factor in driving demand for fire seals in both the new-build and retrofit markets. The opportunities being presented to the aircraft fire seals and thermal management industry, combined with the regulatory, technical, and operational needs, will continue to position fire seals as the fastest growing functional type of the aircraft polymer seals market.

Based on material type -

The aircraft polymer seals market is divided into elastomeric seals and thermoplastic seals.

Elastomeric seals are expected to retain their dominance in the aircraft polymer seals market due to their exceptional flexibility, resilience, and sealing performance across a wide range of operating conditions. These seals are primarily made from synthetic rubber compounds such as fluorosilicone, EPDM, and fluorocarbon (FKM), which offer excellent resistance to extreme temperatures, chemical exposure, and environmental degradation, conditions commonly encountered in aviation. Their ability to conform to complex geometries and maintain tight seals even under pressure differentials and dynamic motion makes them highly suitable for critical aircraft systems such as airframes, engines, hydraulics, and landing gear.

One of the key reasons for the dominance of elastomeric seals is their versatility. They can be engineered to meet specific performance criteria including fire resistance, conductivity, fluid compatibility, and low-temperature flexibility. This adaptability makes elastomeric seals suitable for a broad range of functions, from fire and fluid management seals to aerodynamic and insulation seals. Their use across both static and dynamic sealing applications further expands their relevance throughout the aircraft.

Based on end-user type -

The aircraft polymer seals market is divided into OE and aftermarket.

The aftermarket segment is projected to grow at a faster rate in the aircraft polymer seals market, primarily due to the aging global aircraft fleet and the rising demand for maintenance, repair, and overhaul (MRO) services. As aircraft remain in service for decades, they undergo periodic maintenance cycles that require inspection and replacement of critical components, including polymer seals, which are subject to wear, thermal degradation, and chemical exposure over time. This routine need for seal replacement, especially in high-stress applications such as engines, landing gear, and hydraulic systems, fuels consistent aftermarket demand.

Furthermore, the growth of commercial aviation in emerging economies has led to a sharp increase in the number of in-service aircraft, many of which are older models requiring more frequent maintenance. Airlines are also under pressure to maintain high levels of operational efficiency and safety, making timely seal replacement a key part of preventative maintenance strategies. Additionally, aviation regulatory bodies enforce strict compliance with airworthiness standards, often mandating the use of certified and approved sealing materials during aircraft servicing, another factor boosting aftermarket sales.

Which Region Shows the Most Promising Growth Forecast and Opportunity?

The analysis suggests that North America is expected to be the dominant market by region for the aircraft polymer seals during the forecast period. This growth outlook is majorly attributed to the following-

• North America is projected to remain the dominant regional market for aircraft polymer seals throughout the forecast period, driven by its well-established aerospace industry, high defense spending, and large commercial aircraft fleet.

• The region is home to major aircraft manufacturers such as Boeing, Lockheed Martin, and Gulfstream, as well as leading tier-one suppliers and seal manufacturers.

• This strong industrial base supports continuous demand for high-performance sealing solutions across both original equipment manufacturing (OEM) and aftermarket services.

• Additionally, the presence of a vast number of in-service aircraft, particularly in the United States, ensures steady demand for maintenance, repair, and overhaul (MRO), further fueling the consumption of polymer seals.

• Another key factor behind North America's dominance is its high investment in military aviation. The U.S. Department of Defense operates one of the largest fleets of military aircraft globally, with ongoing modernization programs and new aircraft procurements driving the need for specialized polymer seals that can withstand harsh operational environments.

• At the same time, the commercial aviation sector in the region is thriving, with major airlines expanding their fleets and upgrading older aircraft to improve fuel efficiency and meet sustainability goals, initiatives that often involve replacing or upgrading sealing components.

Aircraft Polymer Seals Market Drivers:

Some of the key drivers listed in the report are given below.

• The growing demand for lightweight and fuel-efficient aircraft, as polymer seals contribute to overall weight reduction without compromising performance,

• Increasing aircraft production, particularly in commercial aviation, and rising air travel globally are boosting the need for reliable sealing solutions.

• The push for improved safety, durability, and resistance to extreme temperatures and chemicals further supports the adoption of advanced polymer materials.

• The expanding defence industry and the need for regular maintenance and retrofitting of aging aircraft fleets also contribute to market growth.

Top Companies in the Aircraft Polymer Seals Market:

Major OEMs in the market are striving to achieve type certification for their aircraft polymer seals aircraft. After completing certification, they collaborate with established aircraft and automotive giants to accelerate commercial manufacturing. Stratview Research has identified the following companies as the top market players:

• Eaton Corporation Plc

• EnPro Industries

• Freudenberg Group

• Green Tweed & Co.

• Hutchinson SA

• Parker Hannifin Corporation

• Saint Gobain S.A.

• SKF Group

• TransDigm Group Inc.

• Trelleborg AB

For Customization or Any Other Queries, Get in Touch with Our Industry Experts at - sales@stratviewresearch.com

The reports might be useful:

- Aircraft Pressure Sensors Market: https://ivebo.co.uk/read-blog/158489

- Aircraft MRO Market: https://irnews.exblog.jp/34604506/

- Data Center Busway Market: https://www.stratviewresearch.com/press_details/data-center-busway-market-forecast-to-reach-9-4-billion-by-2031

400 Renaissance Center, Suite 2600,

Detroit, Michigan, MI 48243

United States of America

Website: www.stratviewresearch.com

Mail Us: sales@stratviewresearch.com

Press: media@stratviewresearch.com

Stratview Research is a global market research firm that highly specializes in aerospace & defense, chemicals, and a few other industries.

It launches a limited number of reports annually on the above-mentioned specializations. Thorough analysis and accurate forecasts in this report enable the readers to take convincing business decisions.

Stratview Research has been helping companies meet their global and regional growth objectives by offering customized research services. These include market assessment, due diligence, opportunity screening, voice of customer analysis, market entry strategies, and more.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aircraft Polymer Seals Market is Forecasted to Reach US$2.4 Billion in 2034, Says Stratview Research here

News-ID: 4217526 • Views: …

More Releases from Stratview Research

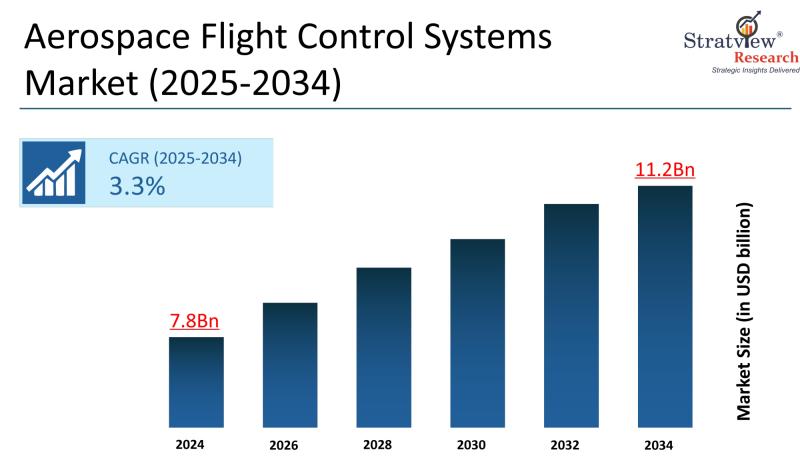

Aerospace Flight Control Systems Market to Reach US$ 11.2 Billion by 2034, Says …

The aerospace flight control systems market - encompassing the complex integrated components and technologies that enable pilots and onboard systems to manage aircraft direction, stability, and movement - is forecast to grow to US$ 11.2 billion by 2034, expanding at a CAGR of 3.3 % between 2025 and 2034. This growth is primarily driven by increasing aircraft production rates and the adoption of advanced flight technologies such as fly by…

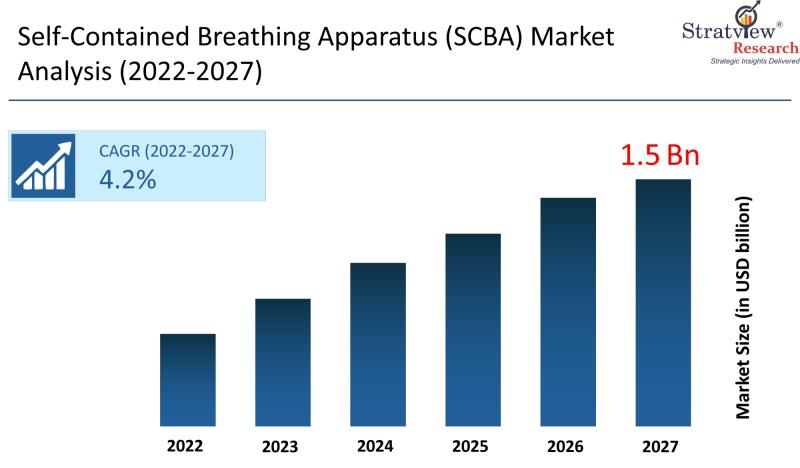

Self-Contained Breathing Apparatus (SCBA) Market to Reach US$ 1.5 Billion by 202 …

The Self-Contained Breathing Apparatus (SCBA) Market is projected to reach US$ 1.5 billion by 2027, growing at a CAGR of 4.2% over 2022-2027. SCBA systems supply breathable air in hazardous or oxygen-deficient environments, primarily for firefighting and industrial safety applications. Rising demand from firefighting and mining industries is the single most important growth driver, structurally increasing demand as organizations adopt advanced respiratory protection to meet stringent safety regulations and reduce…

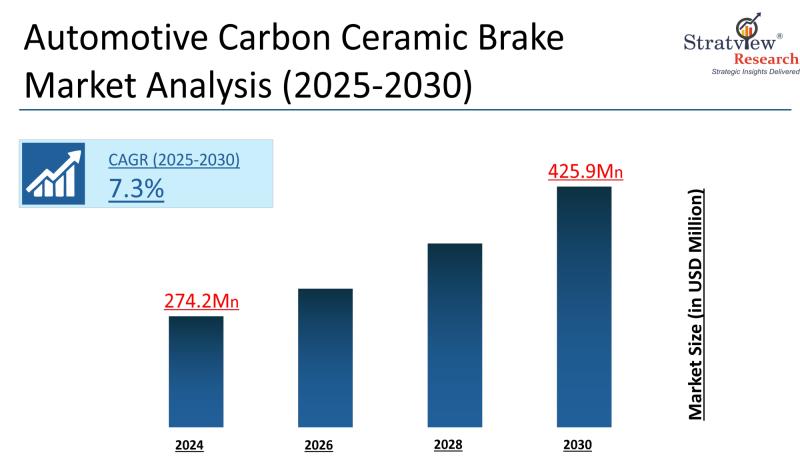

Automotive Carbon Ceramic Brake Market to Reach EU 425.9 Million by 2030, Says S …

The global automotive carbon ceramic brake market - which encompasses high performance braking systems using carbon and ceramic composite discs designed to deliver superior heat resistance, durability, and braking efficiency in luxury and performance vehicles - is projected to grow to EU 425.9 million by 2030, expanding at a CAGR of approximately 7.3% over 2025-2030. This growth is principally driven by increasing adoption of lightweight, high performance braking solutions in…

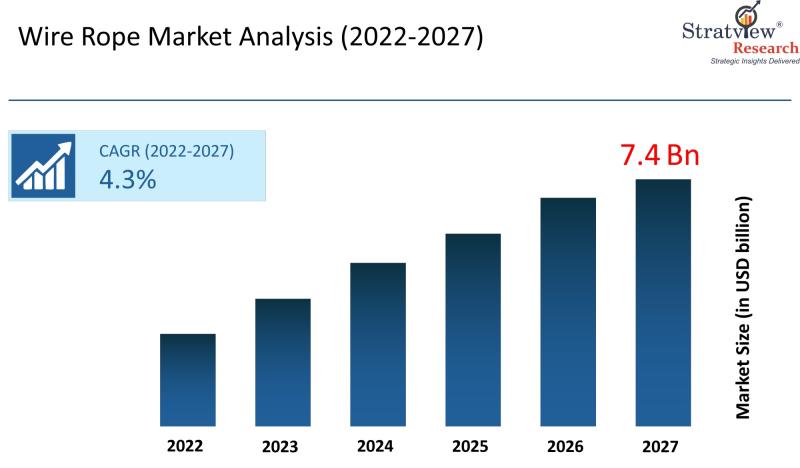

Wire Rope Market to Reach US$ 7.4 Billion by 2027, Says Stratview Research

The Wire Rope Market is projected to reach US$ 7.4 billion by 2027, expanding at a CAGR of 4.3% over the forecast period 2022-2027. Growth is primarily driven by ongoing investment in infrastructure development globally, which structurally increases demand for high-strength lifting, hoisting, and rigging solutions in construction, industrial, and maritime sectors. "Wire rope market expansion is anchored in the recovery of industrial activity and infrastructure spending after the pandemic,"…

More Releases for Aircraft

Private Plane Market Analysis By Top Keyplayers - American Champion Aircraft, Bu …

The "Private Plane Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Private Plane Market, 2024-2031

Verified Market Research's most recent report, "Private Plane Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth…

Aircraft Lighting Systems Market : Commercial Aircraft, General Aviation and Pri …

According to a new report published by Allied Market Research, titled, "Aircraft Lighting Systems Market," The aircraft lighting systems market was valued at $1.5 billion in 2020, and is estimated to reach $2.3 billion by 2030, growing at a CAGR of 4.9% from 2021 to 2030.

𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 : https://www.alliedmarketresearch.com/request-sample/2405

The aircraft lighting system industry holds a great potential in the future, owing to the rise in the global aviation…

Aircraft Refurbishing Market : Very light aircraft, Wide body aircraft, Narrow b …

The global aircraft refurbishing market was valued at $456.7 million in 2021, and is projected to reach $932.5 million by 2031, growing at a CAGR of 7.2% from 2022 to 2031.

Sample Report with Latest Industry Trends - https://www.alliedmarketresearch.com/request-toc-and-sample/9465

COVID-19 scenario analysis:

Aircraft refurbishing market might be among those exceptions of industries which are surviving despite COVID-19 pandemic, even more demand is expected to soar post pandemic.

Aircraft refurbishing market as a whole was…

Aircraft Refurbishing Market : Very light aircraft, Wide body aircraft, Narrow b …

The global aircraft refurbishing market was valued at $456.7 million in 2021, and is projected to reach $932.5 million by 2031, growing at a CAGR of 7.2% from 2022 to 2031 by Refurbishing Service (Interior, Exterior), by Aircraft Type (Very light aircraft, Wide body aircraft, Narrow body aircraft, Large body aircraft, VIP aircraft), by Type (Passenger to freighter, Commercial Aircraft Cabin, VIP Cabin Refurbishing), by End Use (Government, Commercial): Global…

Global Aircraft Line Maintenance Market By Aircraft Type: Narrow Body Aircraft ( …

According to the latest research by SkyQuest Technology, the Global Aircraft Line Maintenance Market was valued at USD 18.38 billion in 2021, and it is expected to reach USD 28.53 billion by 2028, with a CAGR of 5.80% during the forecast period of 2022 - 2028. The research provides up-to-date Aircraft Line Maintenance market analysis of the current market landscape, latest trends, drivers, and overall market environment.

Get full report…

Aircraft Cables Market End User (Commercial Aircraft, Private Aircraft, Defense …

Aircraft cable is a type of cable, which mainly finds application in the aircraft industry. The high strength and versatile aircraft cable can also be used for various pushing and pulling applications that includes sheaves, pulleys, and winches among others. The size of the aircraft cable is between 0.047 inches to 0.375 inches, and constructed in various strand namely 1X7 strand, 1X19 strand, 7X7 strand, and 7X19 strand.

Get Sample…