Press release

Insulin Pens Manufacturing Plant Project Latest Report 2025 - Complete Setup, Machinery, and Cost Analysis by IMARC Group

Insulin Pens are advanced medical devices designed to provide accurate, convenient, and painless insulin delivery for diabetic patients. These pens combine modern engineering with user-friendly design to ensure controlled dosage and improved adherence to treatment regimens. With diabetes cases rising globally, insulin pens have become an essential component of diabetic care, leading to strong market potential for their manufacturing.Setting up an Insulin Pens Manufacturing Plant involves precision engineering, regulatory compliance, and high-quality component integration. The production process requires sourcing durable plastics, stainless steel needles, cartridges, and electronic parts (for smart pens), along with establishing cleanroom manufacturing environments and sterilization units.

IMARC Group's "Insulin Pens Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a complete blueprint for setting up an insulin pen production facility. It covers detailed insights into the production process, capital investment, machinery cost, quality assurance, market performance, and financial analysis.

This report serves as a valuable resource for entrepreneurs, investors, and manufacturers seeking to enter or expand in the global medical device market.

Stop Guessing: Grab Your Free Data Sample: https://www.imarcgroup.com/insulin-pens-manufacturing-plant-project-report/requestsample

Insulin Pens Industry Outlook 2025:

The global insulin pens market is witnessing robust growth due to the increasing prevalence of diabetes, rising adoption of self-administered drug delivery systems, and technological innovations like Bluetooth-enabled smart pens. Manufacturers are focusing on developing eco-friendly, refillable, and digital monitoring-enabled pens that enhance patient convenience.

Government initiatives promoting diabetes management, combined with growing healthcare infrastructure in emerging economies, are further boosting market demand. However, the high cost of advanced pens and regulatory complexities in device approvals pose key challenges for new entrants.

Key Insights for Insulin Pens Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout and Infrastructure

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation and Logistics Costs

• Utility Requirements (Power, Water, HVAC Systems)

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit and Margin

• Net Profit and Margin

Secure Your Access: Buy Now and Start Instantly: https://www.imarcgroup.com/checkout?id=9600&method=1911

Key Cost Components of Setting Up an Insulin Pens Manufacturing Plant:

• Raw Materials: Medical-grade plastics, stainless steel needles, silicone rubber, ink for labeling, and packaging materials.

• Machinery and Equipment: Injection molding machines, precision assembly systems, sterilization units, inspection and testing instruments, and packaging lines.

• Infrastructure Development: Cleanroom environment, HVAC systems, sterile water units, and waste management facilities.

• Labor and Staffing: Skilled engineers, technicians, quality control specialists, and operators.

• Safety and Compliance: ISO 13485 certification, GMP standards, and FDA/CE regulatory approvals.

• Licensing and Regulatory Approvals: Medical device manufacturing licenses, safety clearances, and environmental permits.

• R&D and Quality Control: Product performance testing labs and continuous innovation in pen design and safety features.

• Logistics and Supply Chain: Efficient packaging, cold chain (for insulin cartridges), and global distribution network.

Economic Trends Influencing Insulin Pens Plant Setup Costs 2025:

• Rising Demand: Increasing global diabetes cases and government health initiatives drive market growth.

• Technological Innovation: Smart insulin pens with connectivity features increase setup complexity and costs.

• Regulatory Challenges: Stringent device approval processes add to compliance investment.

• Material Costs: Price fluctuations in medical-grade plastics and metals influence total setup cost.

• Automation Adoption: Advanced robotic assembly lines improve precision but require higher initial investment.

Challenges and Considerations for Investors:

• Compliance with medical device regulations and clinical safety standards.

• High precision manufacturing requiring specialized machinery.

• Need for advanced testing, calibration, and validation systems.

• Competitive pricing and continuous R&D investment.

• Long approval timelines and certification procedures.

Need Clarity? Schedule Your Free Analyst Consultation: https://www.imarcgroup.com/request?type=report&id=9600&flag=C

Conclusion:

Investing in an Insulin Pens Manufacturing Plant offers promising opportunities within the rapidly growing diabetes management sector. Continuous innovation, strong quality assurance, and adherence to global regulatory norms are key to building a competitive edge. With rising demand for smart and refillable insulin delivery systems, manufacturers entering this space can achieve sustainable profitability and global market expansion.

Report Also Coverge:

• Plant Location: Selection of an industrial site with strong safety and logistics infrastructure.

• Plant Capacity: Customization based on target market requirements.

• Machinery: Options available for semi-automated or fully automated systems.

• List of Machinery Providers: Identification of verified equipment suppliers.

Services:

• Market Entry and Opportunity Assessment

• Competitive Intelligence and Benchmarking

• Procurement Research

• Pricing and Cost Research

• Sourcing Partner Identification

• Distribution Partner Identification

• Contract Manufacturer Identification

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Insulin Pens Manufacturing Plant Project Latest Report 2025 - Complete Setup, Machinery, and Cost Analysis by IMARC Group here

News-ID: 4217396 • Views: …

More Releases from IMARC Group

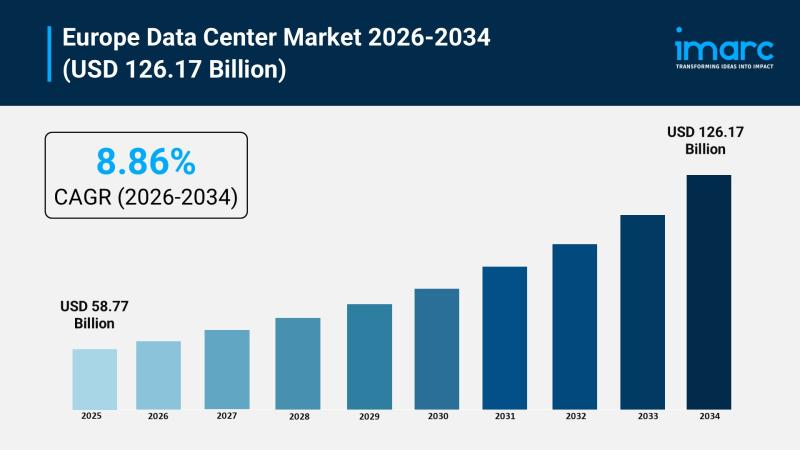

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

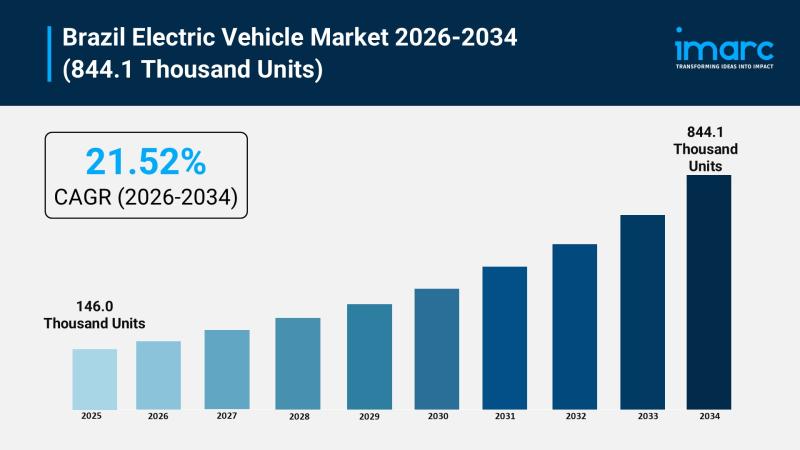

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…