Press release

Cheese Balls Manufacturing Plant Setup Report Latest - Full Project Report with Cost, Business Plan, Machinery & Profit Detail

Cheese Balls are crunchy, bite-sized snacks made primarily from cornmeal, cheese powder, and seasoning blends. Known for their savory flavor and airy texture, cheese balls have gained immense popularity among all age groups as a convenient and delicious snack option. With growing demand for ready-to-eat snacks, the global cheese ball manufacturing industry presents lucrative opportunities for entrepreneurs and investors.Setting up a Cheese Balls Manufacturing Plant requires sourcing high-quality raw materials such as corn grits, cheese powder, edible oil, and flavoring agents, along with the establishment of extrusion, frying, and packaging systems. A robust setup ensures consistent product quality, hygienic production, and efficient large-scale manufacturing.

IMARC Group's "Cheese Balls Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive roadmap for establishing a cheese ball production unit. The report covers all major aspects, including process design, raw material requirements, plant layout, machinery cost, project economics, and revenue projections.

This report serves as a complete guide for investors, entrepreneurs, and stakeholders aiming to enter the fast-growing snack food market with a competitive and profitable business model.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/cheese-balls-manufacturing-plant-project-report/requestsample

Cheese Balls Industry Outlook 2025:

The cheese balls industry outlook for 2025 reflects consistent growth, driven by increasing consumer preference for convenience foods, innovative flavor development, and expanding retail distribution networks. Rising disposable incomes, urbanization, and changing snacking habits are supporting the global demand. Additionally, technological advancements in extrusion and frying systems are helping manufacturers improve product quality and reduce oil absorption, enhancing health appeal.

However, fluctuating raw material prices and growing health concerns related to fried snacks pose certain challenges. Many manufacturers are thus focusing on baked variants and low-fat formulations to cater to evolving consumer preferences.

Key Insights for Cheese Balls Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout and Design

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Material and Equipment

• Transportation and Logistics Costs

• Utility Requirements (Power, Water, Gas)

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit and Margin

• Net Profit and Margin

Secure Your Access: Buy Now and Start Instantly: https://www.imarcgroup.com/checkout?id=19336&method=1911

Key Cost Components of Setting Up a Cheese Balls Manufacturing Plant:

• Raw Materials: Cornmeal, cheese powder, vegetable oil, flavoring agents, and seasoning.

• Machinery and Equipment: Extruder, fryer, oil filter, flavoring drum, dryer, cooling conveyor, and packaging machines.

• Infrastructure Development: Land acquisition, building construction, ventilation, and drainage systems.

• Labor and Staffing: Operators, food technologists, machine supervisors, quality assurance staff, and packaging personnel.

• Safety and Compliance: Food-grade machinery, HACCP certification, fire safety, and hygiene protocols.

• Licensing and Regulatory Approvals: FSSAI certification, environmental clearance, and local authority permits.

• R&D and Quality Control: Laboratory setup for product testing, flavor optimization, and shelf-life analysis.

• Logistics and Supply Chain: Distribution network establishment for raw materials and finished goods.

Economic Trends Influencing Cheese Balls Plant Setup Costs 2025:

• Raw Material Price Volatility: Fluctuations in dairy products, oil, and cornmeal prices.

• Energy Costs: Rising electricity and gas costs affecting frying and extrusion operations.

• Technology Integration: Automation in packaging and quality control improving efficiency.

• Consumer Demand Trends: Shift towards baked or low-oil variants for health-conscious consumers.

• Inflationary Pressures: Higher construction and labor costs impacting total setup investment.

Challenges and Considerations for Investors:

• Ensuring product consistency and taste standardization.

• Managing competition from established snack brands.

• Meeting strict food safety and hygiene regulations.

• High energy consumption during frying and extrusion.

• Developing effective branding and distribution strategies.

Resolve Your Doubts: Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=19336&flag=C

Conclusion:

Investing in a Cheese Balls Manufacturing Plant offers strong growth potential owing to increasing global snack consumption and innovations in food processing technology. Entrepreneurs focusing on product diversification, health-oriented formulations, and efficient manufacturing systems can achieve long-term profitability and brand success in this dynamic market segment.

Report Also Coverge:

• Plant Location: Selection of an industrial site with strong safety and logistics infrastructure.

• Plant Capacity: Customization based on target market requirements.

• Machinery: Options available for semi-automated or fully automated systems.

• List of Machinery Providers: Identification of verified equipment suppliers.

Services:

• Market Entry and Opportunity Assessment

• Competitive Intelligence and Benchmarking

• Procurement Research

• Pricing and Cost Research

• Sourcing Partner Identification

• Distribution Partner Identification

• Contract Manufacturer Identification

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cheese Balls Manufacturing Plant Setup Report Latest - Full Project Report with Cost, Business Plan, Machinery & Profit Detail here

News-ID: 4217329 • Views: …

More Releases from IMARC Group

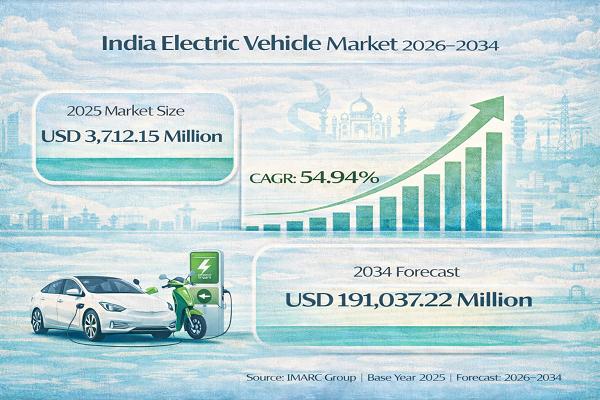

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…