Press release

Fastening Power Tools Market Driving Precision, Efficiency, and Technological Advancements in Modern Industrial Operations

The global fastening power tools market size is likely to be valued at US$4.0 Billion in 2025 and is estimated to reach US$6.4 Billion by 2032, growing at a CAGR of 7.1% during the forecast period 2025-2032, driven by robust expansion in construction and automotive manufacturing sectors, with global infrastructure investments and vehicle production modernization creating sustained demand for efficient assembly solutions.Technological advances in lithium-ion batteries and AI-powered smart tools are transforming the industry by boosting productivity, extending runtime, and enabling predictive maintenance. The move toward cordless and electric systems is replacing pneumatic tools, while Industry 4.0 and smart factories drive demand for IoT-enabled fastening tools with torque control and automated assembly.

Get a Sample PDF Brochure of the Report: https://www.persistencemarketresearch.com/samples/23530

Technological Advancements Transforming Fastening Power Tools

The fastening power tools industry has experienced a significant technological evolution over the past decade. Traditional manual fastening methods, while reliable, were often time-consuming and lacked consistency, especially in large-scale industrial applications. Modern fastening power tools, ranging from cordless drills to automated screwdrivers and torque-controlled wrenches, have revolutionized how industries approach assembly and construction tasks. Advanced tools now incorporate brushless motors, offering higher efficiency, longer lifespans, and reduced maintenance needs. Additionally, intelligent torque control systems and digital interfaces allow operators to achieve precise fastening without damaging components, ensuring both speed and quality. Integration with IoT devices and smart factory systems further enhances operational efficiency, as real-time monitoring of tool performance and maintenance needs becomes possible, minimizing downtime and optimizing resource allocation.

Enhancing Precision and Operational Efficiency

Precision has become a defining factor in modern industrial operations, and fastening power tools are central to achieving this goal. Industrial applications, particularly in automotive, aerospace, and electronics manufacturing, demand consistent torque and exact alignment to maintain product integrity. High-performance power tools ensure uniform fastening, reducing assembly errors and improving overall product quality. Automation in fastening operations further enhances efficiency by speeding up repetitive tasks and allowing operators to focus on complex processes. By minimizing human error and reducing manual labor, industries not only achieve higher productivity but also lower operational costs, reflecting the critical role of advanced fastening power tools in optimizing industrial workflows.

Read More In Detail: https://www.persistencemarketresearch.com/market-research/fastening-power-tools-market.asp

Safety and Ergonomics in Modern Fastening Tools

As industrial work environments evolve, safety and ergonomics have become key considerations in tool design. Modern fastening power tools are engineered to reduce operator fatigue and prevent workplace injuries. Lightweight materials, balanced designs, and vibration-dampening technologies make these tools easier to handle during extended operations. Safety features such as automatic shut-off, torque-limiting mechanisms, and insulated grips protect operators from accidents and electrical hazards. By integrating these features, manufacturers not only comply with regulatory standards but also enhance worker productivity and morale. Ergonomically designed tools ensure that operators can maintain high performance over longer periods without compromising safety, reinforcing the importance of user-centered innovation in the fastening power tools industry.

Sustainability and Energy Efficiency

Sustainability is becoming an integral focus for manufacturers of fastening power tools. Energy-efficient cordless tools, powered by advanced lithium-ion batteries, are replacing older, less efficient models, reducing energy consumption and lowering carbon footprints. Battery management systems extend the lifespan of power sources and allow for faster charging, ensuring uninterrupted operations. Additionally, manufacturers are increasingly adopting recyclable materials and eco-friendly production processes to minimize environmental impact. By prioritizing sustainability, the fastening power tools market aligns with broader industrial initiatives aimed at reducing resource consumption and promoting environmentally responsible practices, which are becoming increasingly important to customers and regulatory bodies alike.

Industry-Specific Applications and Trends

The demand for fastening power tools is influenced by industry-specific requirements and emerging trends. In the automotive sector, the emphasis on precision and speed has led to widespread adoption of torque-controlled cordless screwdrivers and automated fastening systems. Aerospace manufacturing, with its stringent quality standards, requires tools capable of delivering consistent performance for critical assemblies. In construction, the need for robust and versatile tools drives innovation in high-capacity cordless drills and impact drivers. Furthermore, trends such as Industry 4.0, smart factories, and automated assembly lines are creating opportunities for interconnected, sensor-enabled fastening tools that communicate with central systems, providing data-driven insights for maintenance, performance, and workflow optimization.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/23530

Regional Dynamics and Market Drivers

Regional differences play a significant role in shaping the fastening power tools market. North America benefits from advanced manufacturing infrastructure, a focus on automation, and high adoption rates of cordless tools, particularly in the automotive and construction sectors. Europe, driven by stringent safety regulations and sustainability initiatives, emphasizes precision, ergonomics, and eco-friendly designs. The Asia-Pacific region, with rapidly expanding industrial bases in countries such as China, India, and Japan, exhibits strong demand for cost-effective yet technologically advanced tools to support large-scale manufacturing and construction projects. These regional trends highlight the interplay of technological adoption, regulatory frameworks, and industrial growth in driving demand for advanced fastening power tools.

Challenges in the Fastening Power Tools Industry

Despite strong growth prospects, the industry faces several challenges. High initial costs for advanced, automated, or smart fastening tools can be prohibitive for small-scale manufacturers and construction firms. Maintenance and repair of sophisticated machinery require specialized expertise, which can limit accessibility in certain regions. Additionally, fluctuating raw material prices, especially for high-grade metals and battery components, can impact production costs and profitability. Rapid technological evolution also presents a challenge, as tools may become obsolete quickly, requiring frequent upgrades and ongoing investment. Addressing these challenges requires a combination of strategic planning, training, and support from manufacturers to ensure tools remain accessible, reliable, and cost-effective across diverse applications.

Innovation as a Key Growth Driver

Innovation continues to propel the fastening power tools market forward. Manufacturers are increasingly focusing on modular, adaptable designs that cater to diverse industrial applications. Integration of digital monitoring, IoT connectivity, and AI-driven analytics provides operators with insights into tool performance, maintenance needs, and assembly efficiency. New developments in cordless technologies, battery life, and lightweight materials enhance usability and energy efficiency. Additionally, smart fastening solutions capable of adjusting torque and speed automatically based on component requirements are revolutionizing assembly processes, reducing errors, and improving production speed. Companies that invest in research and development, training programs, and collaborative initiatives with industrial clients are well-positioned to lead the market and shape the future of fastening power tools.

Future Outlook and Opportunities

The future of the fastening power tools market is poised for sustained growth, driven by ongoing industrial automation, technological advancements, and increasing demand for precision manufacturing. Emerging opportunities lie in smart factory integrations, battery innovation, and the expansion of sustainable tool solutions. There is significant potential for retrofitting existing industrial operations with advanced fastening tools to enhance efficiency, reduce labor dependency, and improve product quality. Furthermore, expanding industrial activities in emerging economies, coupled with government initiatives to modernize manufacturing and construction infrastructure, will continue to fuel demand. The convergence of automation, connectivity, and sustainability is expected to redefine operational workflows, positioning fastening power tools as indispensable instruments in modern industrial operations.

Related Reports:

https://www.persistencemarketresearch.com/market-research/laser-cutting-machine-market.asp

https://www.persistencemarketresearch.com/market-research/glass-processing-equipment-market.asp

https://www.persistencemarketresearch.com/market-research/pcb-laser-machine-market.asp

https://www.persistencemarketresearch.com/market-research/automatic-fire-sprinkler-systems-market.asp

https://www.persistencemarketresearch.com/market-research/mining-drones-market.asp

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fastening Power Tools Market Driving Precision, Efficiency, and Technological Advancements in Modern Industrial Operations here

News-ID: 4215205 • Views: …

More Releases from Persistence Market Research

Cryogenic Storage Tanks Market Predicted to Hit US$ 12.8 Billion by 2033 Driven …

According to the latest study by Persistence Market Research, the global cryogenic storage tanks market is likely to be valued at US$ 8.6 billion in 2026 and is projected to reach US$ 12.8 billion by 2033, expanding at a CAGR of 5.8% during the forecast period 2026-2033. Rising demand for liquefied gases across energy, healthcare, food processing, and industrial manufacturing sectors is emerging as a key driver shaping the market's…

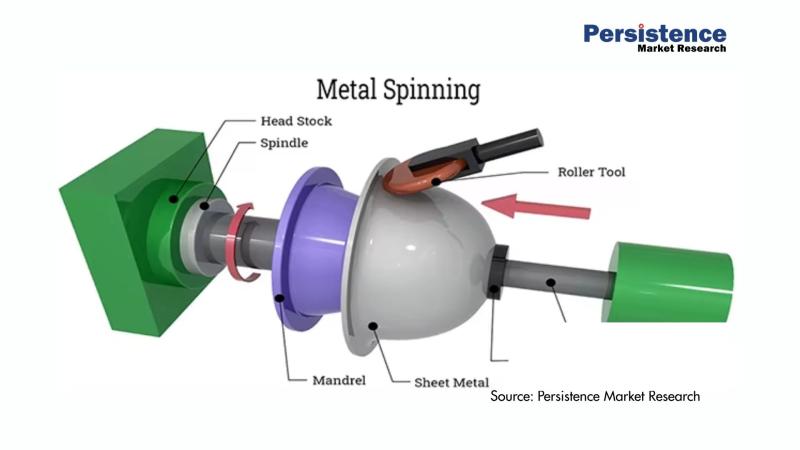

Metal Spinning Products Market Projected to Grow to US$ 4.0 billion by 2033 - Pe …

The global metal spinning products market is poised for substantial growth in the coming years. According to a recent study by Persistence Market Research, the market size is anticipated to reach US$ 4.0 billion by 2033, growing at a robust compound annual growth rate (CAGR) of 4.2% from its current valuation of US$ 3.0 billion in 2026. Metal spinning, a process of shaping metal into precise and symmetrical shapes, is…

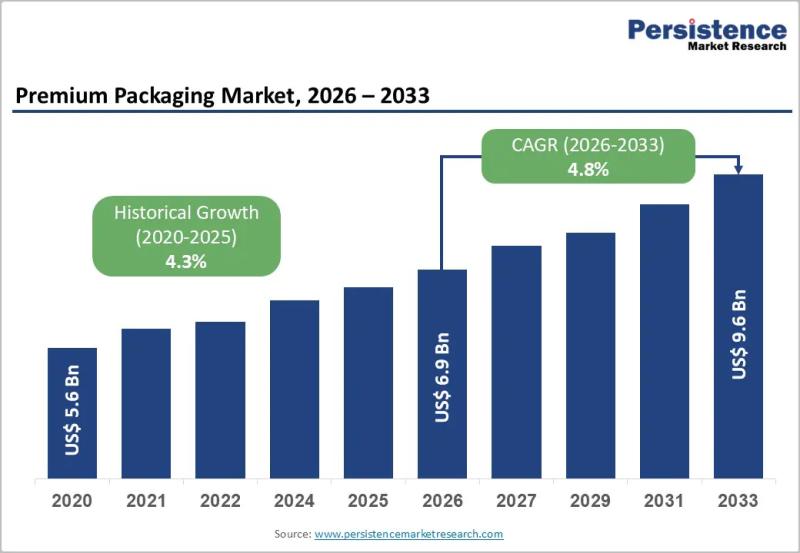

Premium Packaging Market Size Worth US$9.6 Billion by 2033 - Persistence Market …

The premium packaging market has evolved into a critical strategic element for brand differentiation across multiple high value consumer industries. Premium packaging goes beyond basic containment and protection to deliver enhanced aesthetics tactile appeal storytelling and emotional connection. Brands increasingly view packaging as an extension of their identity and a powerful marketing tool that influences purchasing decisions at the point of sale and during the unboxing experience. This shift is…

Power MOSFET Market Growth Driven by EVs Renewable Energy and Smart Automation

The global Power MOSFET market is entering a phase of sustained expansion, driven by the accelerating need for energy-efficient and high-performance power management components across industries. In 2026, the market is expected to be valued at US$ 9.45 billion and is forecast to reach US$ 14.9 billion by 2033, registering a healthy CAGR of 6.7% during the forecast period. Power MOSFETs are essential semiconductor devices that enable efficient switching and…

More Releases for Fastening

Pure Epoxy Injection Adhesive Market Forecasting the Future: Production, Consump …

"The thorough study and analysis report is a fantastic and essential tool for worldwide market players to obtain a competitive advantage over their rivals. It contains accurate and validated projections for the global Pure Epoxy Injection Adhesive industry's size, CAGR, production, consumption, and sales. Additionally, it offers projections for industry revenue and volume until 2026. The report's readers may quickly learn about the major prospects, difficulties, and development drivers of…

Two-component Pure Epoxy Adhesive Market 2024's Trailblazing Trends: Guiding the …

"The thorough study and analysis report is a fantastic and essential tool for worldwide market players to obtain a competitive advantage over their rivals. It contains accurate and validated projections for the global Two-component Pure Epoxy Adhesive industry's size, CAGR, production, consumption, and sales. Additionally, it offers projections for industry revenue and volume until 2026. The report's readers may quickly learn about the major prospects, difficulties, and development drivers of…

Concrete Fastening Systems Market : Latest Market Research Report for Business E …

In the past few years, the Concrete Fastening Systems market experienced a huge change under the influence of COVID-19 and Russia-Ukraine War, the global market size of Concrete Fastening Systems reached the predicted milestone in 2022 with the rising CAGR from 2017-2022. Facing the complicated international situation, the future of the Concrete Fastening Systems market is full of uncertain. Report predicts that the global Concrete Fastening Systems market size will…

Aerospace Fasteners Market Forecast and Growth Analysis by 3V Fasteners, Alcoa, …

Global Aerospace Fasteners Market Information by Application (Commercial Aerospace and Military), Aircraft Class (Commercial Aircraft & Military Aircraft), and Region (Americas (North and Latin), Europe, Asia Pacific, Middle East & Africa)- Forecast To 2023

Key Players

The leading market players in the global Aerospace Fasteners Market primarily include 3V Fasteners, Alcoa, B&B Specialties, KLX, LISI Aerospace, STANLEY Engineered Fastening, NAFCO, Stanley Aerospace Fastening, and Acument Global Technologies.

Get Sample Report @ https://www.marketresearchfuture.com/sample_request/1138

Market Overview…

Global Aerospace Fastener Market - B/E Aerospace, STANLEY Engineered Fastening, …

Aerospace fasteners are a software device mechanically joins or affixes two or more objects together. Series C300 corrosion resistant (CRES) stainless steel is regarded as aerospace fasteners. Moreover, Aluminum is a lightweight metal also has application in Aerospace industry.

According to KD market insights, research provides a forecast for global aerospace fastener market for a span of 6 years i.e. between 2018 and 2023. It is expected that market will…

Global Chemical Anchors Market 2018 Overview - MKT FASTENING LLC, Powers Fastene …

Globalinforesearch.biz has recently announced the addition of new research report to its repository named, Global Chemical Anchors Market Research Report 2018. It provides a clear understanding of the market dynamics by studying the historical data and analyzing the current market situation. It aims to chalk the route of the market for the coming few years. It gives a comprehensive synopsis of the market picture including market overview, introduction, classification, market…