Press release

Global Intelligent CNC Woodworking Machines Market to Reach USD 15.35 Billion by 2031 at 10.1% CAGR, Driven by HOMAG and Biesse

According to the recent report from QYResearch, intelligent CNC woodworking machinery is entering a new adoption phase defined by AI-assisted programming, automation-ready software, and compact, high-throughput cells that compress footprint while expanding capability. Building on 2024's strong production base and accelerating through 2025, vendors are shipping more software-defined machines and connected cells that close the loop from CAM to quality, while end-users in furniture, cabinetry and architectural millwork are re-tooling for mass customization and shorter lead times.Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) https://www.qyresearch.com/sample/4940637

Latest Data (from the report, reconciled with current news)

• Global market size is projected to rise from US$ 7,826 million in 2024 to US$ 15,348 million by 2031, a 10.1% CAGR (2025-2031).

• Global output in 2024 reached ~391,000 units, with an average selling price (ASP) ≈ US$ 20,000 per unit.

• Intelligent CNC systems are characterized by smart programming, automatic tool changing, and precision multi-operation machining; adoption is deepest in furniture manufacturing, cabinets, architectural woodworking, and interior fit-out.

Cost, Gross Profit & Margin Overview

Based on audited manufacturer data and the 2024 ASP benchmark of US$20,000 per unit:

• KDT Machinery reported a gross margin of approximately 32.1%, implying a gross profit of around US$6,416 per unit and a cost of goods sold (COGS) of US$13,584 per unit.

• Nanxing Machinery reported a gross margin between 16.6% and 17.4%, yielding gross profit per unit between US$3,312 and US$3,480, and COGS between US$16,520 and US$16,688 per unit.

Industrywide, the 2024 gross-profit pool is estimated between US$1.3 and 2.5 billion, with aggregate COGS of US$5.3-6.5 billion. Western suppliers such as HOMAG (Dürr Group) reported gross margins near 22.7%, aligning with this global benchmark range.

2025 Headlines & Company Updates

• Hexagon's ALPHACAM introduced automation features such as multi-head nesting and optimized routing, cutting total production time by up to 50%.

• Makera launched the Z1 desktop intelligent CNC at IFA 2025, winning an Innovation Award for bringing industrial precision to compact creators' machines.

• HOMAG Group reported improved 2025 profitability through service expansion and digitalization initiatives, demonstrating resilience in soft furniture demand conditions.

• Laguna Tools expanded production for its entry-level KX:24 smart CNC router, emphasizing intuitive touch-based operation for small workshops.

Leading Companies

Homag Group

Biesse Group

SCM Group

IMA Schelling Group

Weinig Group

Michael Weinig AG

Felder Group

Greda srl

Anderson Group

Masterwood

Nanxing Machinery

HOLZ-HER

KDT Machinery

HOMAG China

CEHISA

MAKA Systems GmbH

Altendorf Group

Reichenbacher Hamuel GmbH

Weeke Bohrsysteme GmbH

Format-4

Komo Machine Inc.

Thermwood Corporation

AXYZ Automation Group

Bacci

Griggio Srl

Cosmec Technology

CMS Industries

Barbaric GmbH

Laguna Tools

Casadei Industria

Application List

Furniture Manufacturing

Cabinet Making

Architectural Woodworking

Interior Decoration

Others

Classification List

CNC Engraving Machines

CNC Tenoning Machines

CNC Drilling Machines

CNC Cutting Machines

Others

5 Product Spotlights

1) Biesse - ROVER A Plus

A twin-head machining center with tool capacity up to 83 positions, designed for nesting, boring, and routing of panels and solid wood. It bridges mid- to high-range production, enabling flexible automation without large factory infrastructure.

2) SCM - Morbidelli M100 / M200

A versatile all-in-one CNC platform with working fields up to 5510×1620 mm and vector speeds of 56-78 m/min. It uses a 15 kW spindle at 24,000 rpm with 44-60-position tool changers and optional 5-axis capability. Drilling operations are up to 60% faster than previous generations.

3) Felder (FORMAT-4) - Creator 950

A compact vertical CNC machine with a footprint of only about 5 m2, capable of complete four-sided formatting. Its zero-setup workflow and intuitive interface make it ideal for small workshops and custom furniture producers.

4) Thermwood - Cut Ready / CabinetShop 45

An AI-assisted "no-programming" CNC router for cabinet manufacturing. It uses a 13 HP spindle running up to 24,000 rpm and integrates laser volumetric compensation for precision. Operators can produce cabinets directly from predefined recipes, bypassing G-code programming.

5) AXYZ - INFINITE Modular Router

A large-format modular CNC router with extendable lengths from 16 ft to 32 ft. It offers 10 HP direct-drive spindles, servo drives, and a seven-position automatic tool changer, supporting high-mix, large-panel production such as cabinetry and doors.

Downstream Customer List

IKEA Industry

nobilia

Häcker Küchen

Schüller Küchen

Howdens Joinery

Wren Kitchens

MasterBrand Cabinets

American Woodmark

Cabinetworks Group

JELD-WEN

Masonite

Ashley Furniture Industries

Nobia AB

Ballingslöv

Starmark Cabinetry

Market Trend (2025)

1. Software-Driven Throughput

The 2025 market centers on software acceleration. Automation-ready CAM systems such as ALPHACAM and Biesse's bSuite have demonstrated that improved nesting algorithms and multi-head optimization can cut setup and runtime by up to half, raising effective machine utilization without additional capital expenditure.

2. No-Code and Low-Skill CNC Operation

A defining shift is the movement toward simplified CNC interfaces. Thermwood's Cut Ready platform exemplifies the "no-code" concept-operators generate toolpaths automatically through templates rather than manual programming. This reduces training time and opens CNC adoption to smaller firms facing skilled labor shortages.

3. Compact High-Output Work Cells

Manufacturers are compressing functionality into smaller footprints. Felder's vertical Creator 950 enables full processing in 5 m2 of space, while AXYZ's modular designs let users double throughput by adding table sections. Such compact intelligent systems align with the rising cost of factory space and growing customization demands.

4. Connectivity and Energy Efficiency

The integration of IoT sensors and adaptive control algorithms is making predictive maintenance and energy optimization standard features. Across router and drilling categories, connected systems report uptime gains of 10-15% and energy savings of 8-10% through load-balancing drives and smart standby modes.

5. Expansion of the Tooling Ecosystem

The CNC woodworking tools market is forecast to grow from US$ 8.2 billion in 2025 to US$ 13.3 billion by 2035 (CAGR ≈ 5%). This expansion is driven by higher spindle utilization, multi-operation heads, and the need for precision aggregates in high-speed cutting.

6. Service-Oriented Profit Models

Major OEMs such as HOMAG are increasing service and software income as hardware margins tighten. Remote diagnostics, subscription-based CAM suites, and predictive maintenance contracts now account for over 25% of recurring revenue in top-tier European brands.

7. Regional Policy and Supply Chain Impacts

Evolving trade and tariff policies in the U.S., EU, and Asia-Pacific regions are reshaping sourcing strategies. Localized assembly of high-end CNC controllers in China and Germany has intensified price competition, while U.S. importers face tariff volatility that adds up to 6-8% cost variability across quarters.

Latest Achievements

Hexagon achieved measurable cycle-time reductions with ALPHACAM automation updates, proving software-driven efficiency can rival mechanical upgrades.

• HOMAG improved profitability in H1 2025 by expanding service packages and optimizing production costs.

• Makera gained global recognition for democratizing precision CNC with the award-winning Z1 desktop system.

• SCM enhanced single-cell versatility through faster drilling cycles and modular five-axis configurations.

• AXYZ increased throughput flexibility with scalable table lengths in its INFINITE series, catering to panel furniture and door manufacturers.

Request for Pre-Order Enquiry On This Report https://www.qyresearch.com/customize/4940637

Conclusion

The intelligent CNC woodworking machines market is moving decisively toward software-defined productivity, automation without complexity, and data-driven reliability. In 2025, winning suppliers are those that deliver measurable reductions in setup and downtime, not merely higher spindle power. As mass customization overtakes mass production, furniture and cabinet manufacturers are adopting compact, connected, and adaptive CNC solutions that blend digital intelligence with physical craftsmanship-marking a pivotal step in the digital transformation of woodworking.

Contact Information:

Tel: +1 626 2952 442 ; +351 914374211(Tel & Whatsapp); +86-1082945717

Email: qinyue@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About us:

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

Related Report:

Global Intelligent CNC Woodworking Machines Market Outlook, In Depth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/4940637/intelligent-cnc-woodworking-machines

Intelligent CNC Woodworking Machines - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/4940636/intelligent-cnc-woodworking-machines

2025-2031全球与中国智能数控木工机械市场现状及未来发展趋势

https://www.qyresearch.com.cn/reports/5750563/intelligent-cnc-woodworking-machines

2025-2031中国智能数控木工机械市场现状研究分析与发展前景预测报告

https://www.qyresearch.com.cn/reports/5750562/intelligent-cnc-woodworking-machines

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Intelligent CNC Woodworking Machines Market to Reach USD 15.35 Billion by 2031 at 10.1% CAGR, Driven by HOMAG and Biesse here

News-ID: 4214792 • Views: …

More Releases from QYResearch Europe

Global Aerospace Grade Smart Assembly Lines Market 2024 USD 4251 Million to 2031 …

According to recent report from QYResearch, the global market for aerospace-grade smart assembly lines stood at US$4,251 million in 2024 and is projected to reach US$8,712 million by 2031 at a 10.2% CAGR (2025-2031). In 2024, approximately 670 lines were produced globally at an average selling price (ASP) of about US$6.343 million per line. These highly automated systems integrate AI, industrial robotics, advanced sensing, and digital control to deliver repeatable,…

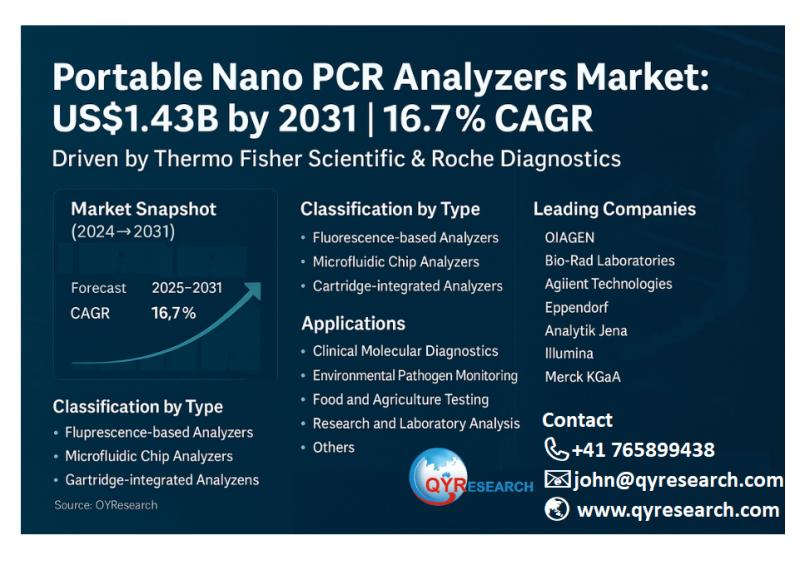

Portable Nano PCR Analyzers Market Growth to US$1.43 Billion by 2031 with 16.7% …

According to the latest QYResearch Report, the global market for Portable Nano PCR Analyzers was valued at US$484 million in 2024 and is expected to reach US$1,427 million by 2031, growing at a CAGR of 16.7% during the forecast period of 2025-2031. Global production in 2024 reached around 96,800 units, with an average price of about US$5,000 per unit. These portable devices utilize nanotechnology-enhanced PCR processes for rapid on-site genetic…

Global Multiphase Flow Conveying Equipment Market to Reach USD 10.88 Billion by …

The global market for Multiphase Flow Conveying Equipment is transitioning from a specialized engineering niche to a core enabler of industrial efficiency across upstream energy, chemicals, mining, and wastewater sectors. According to QYResearch 2025 edition of Multiphase Flow Conveying Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031, the market was valued at US$7,380 million in 2024 and is projected to reach US$10,879 million by 2031,…

Global Smart Eye-Tracking Medical Devices Market Size Reaches US$3.0 Billion by …

The global Smart Eye-Tracking Medical Devices market has entered a stage of accelerated clinical adoption and product diversification. According to QYResearch 2025 Global Smart Eye-Tracking Medical Devices Market Research Report, the market was valued at US$973 million in 2024 and is projected to reach US$3,009 million by 2031, growing at a CAGR of 17.5% from 2025 to 2031. Global output in 2024 reached approximately 64,900 units, with an average price…

More Releases for CNC

XTJ CNC Elevates Custom CNC Machining for Highly Precise Industrial Applications

Carmel, IN 46032, United States, 28th Jan 2026 - XTJ CNC, a prominent provider of custom CNC machining servicesa prominent provider of custom CNC machining services, has announced significant advancements in its capabilities to better serve industries requiring high-precision components. With a focus on custom CNC machining, the company is reinforcing its reputation as a trusted partner in the aerospace, automotive, and electronics sectors. These advancements reflect XTJ CNC's commitment…

Benefits of CNC Machining for Custom Robotic Projects - Tuofa CNC Machining

Robotics is evolving quickly, and higher-performance robots demand stronger mechanical consistency. As DOF increases, joint stacks and mounting interfaces must align accurately to preserve smooth, repeatable motion. CNC machining delivers custom parts with controlled dimensions and reliable quality, reducing fit issues during assembly. It also shortens prototype cycles and supports small-batch production, helping robotics teams convert designs into dependable hardware.

Robotics is getting smarter and smarter. Better perception, smarter control loops,…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…