Press release

Cyclopropane Production Plant Setup 2025: Process, Machinery & Investment Guide

Cyclopropane is a colorless, flammable gas with the chemical formula C3H6, primarily used as an anesthetic and in organic synthesis. It serves as a critical intermediate in the production of various pharmaceuticals and specialty chemicals. Cyclopropane's high ring strain and reactivity make it an essential compound for chemical transformations, polymer research, and material science applications. Additionally, it plays a role in producing agrochemicals and serves as a component in certain advanced fuel formulations due to its high energy content.Setting up a Cyclopropane production plant involves precise handling of hazardous raw materials such as propylene and hydrogen under controlled conditions. The process requires advanced catalytic reactors, gas purification units, and strict safety systems to prevent leaks and explosions. The setup also demands specialized infrastructure for storage, transportation, and compliance with environmental and occupational safety standards. Automation and continuous monitoring systems are vital for operational stability and quality assurance.

IMARC Group's "Cyclopropane Production Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a detailed and practical guide for entrepreneurs and businesses looking to enter the specialty gas manufacturing sector. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in establishing a successful production plant-from assessing market trends to addressing operational challenges. It provides valuable insights into essential components such as cyclopropane production plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/cyclopropane-manufacturing-plant-project-report/requestsample

Cyclopropane Industry Outlook 2025:

The cyclopropane industry outlook for 2025 shows steady growth driven by the rising demand for high-purity gases in pharmaceuticals, research laboratories, and chemical synthesis. Increasing investments in R&D, coupled with advancements in catalyst design and process safety, are enhancing production efficiency. Moreover, growing demand from the healthcare sector for inhalation anesthetics and specialty intermediates is expanding market potential. However, stringent regulatory requirements for storage and handling of flammable gases may influence production costs and entry barriers for new manufacturers.

Key Insights for Cyclopropane Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Unlock Full Access-Purchase Now!: https://www.imarcgroup.com/checkout?id=10618&method=1911

Key Cost Components of Setting Up a Cyclopropane Plant:

• Raw Materials: Procurement of propylene and hydrogen gases for the catalytic reaction.

• Machinery and Equipment: Catalytic reactors, compressors, condensers, gas purifiers, safety valves, and storage cylinders.

• Infrastructure Development: Explosion-proof buildings, gas containment systems, ventilation setups, and fire suppression units.

• Labor and Staffing: Skilled chemical engineers, safety officers, operators, and maintenance technicians.

• Safety and Environmental Compliance: Investment in advanced leak detection systems, emission control, and gas scrubbing units.

• Licensing and Regulatory Approvals: Costs associated with obtaining hazardous material handling licenses, safety audits, and pollution control approvals.

• R&D and Quality Control: Establishing laboratory facilities for purity testing, catalyst optimization, and process safety validation.

• Logistics and Supply Chain: Specialized storage and transportation systems for compressed gas cylinders ensuring safety compliance.

Economic Trends Influencing Cyclopropane Plant Setup Costs 2025:

• Raw Material Price Volatility: Changes in propylene and hydrogen prices affect overall production costs.

• Energy Costs: Rising electricity and fuel expenses impact compressor and purification unit operations.

• Environmental Regulations: Increasingly strict safety and emission norms require additional investments in compliance systems.

• Technological Advancements: Adoption of efficient catalysts and automation systems reduces energy consumption and improves yield.

• Global Supply Chain Disruptions: Delays in equipment delivery and logistics challenges may affect project timelines and costs.

• Financing Conditions: Shifts in interest rates and credit availability influence project feasibility and ROI.

• Industrial Demand Growth: Expanding pharmaceutical and specialty chemical sectors sustain long-term demand for cyclopropane.

Challenges and Considerations for Investors in Cyclopropane Plant Projects:

• Safety Risks: Managing flammable gases under high pressure requires advanced process controls and emergency protocols.

• Regulatory Compliance: Compliance with international safety and environmental standards adds to capital and operating costs.

• Energy Efficiency: High power consumption during compression and purification stages necessitates efficient system design.

• Raw Material Supply Stability: Securing consistent access to high-purity propylene and hydrogen is critical for uninterrupted operations.

• Market Volatility: Demand fluctuations from end-use industries may impact profitability.

• Capital Intensity: Substantial upfront investment in specialized equipment and infrastructure is required.

• Technological Upgradation: Continuous innovation is essential to improve process safety and operational efficiency.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=10618&flag=C

Conclusion:

In conclusion, investing in a Cyclopropane production plant offers promising prospects, especially with the growing industrial and pharmaceutical applications of specialty gases. The rising emphasis on safe and sustainable chemical processes enhances the long-term potential of this sector. However, successful project execution demands meticulous planning, compliance with safety norms, and efficient cost control strategies. With proper technological integration and adherence to regulatory standards, investors can establish a competitive and profitable cyclopropane manufacturing business.

Customization Options Available:

• Plant Location: Selection of optimal location for the plant.

• Plant Capacity: Customization based on desired production capacity.

• Machinery: Choice between automatic, semi-automatic, or manual machinery.

• List of Machinery Providers: Identification of suitable machinery suppliers.

Services:

• Market Entry and Opportunity Assessment

• Competitive Intelligence and Benchmarking

• Procurement Research

• Pricing and Cost Research

• Sourcing Partner Identification

• Distribution Partner Identification

• Contract Manufacturer Identification

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cyclopropane Production Plant Setup 2025: Process, Machinery & Investment Guide here

News-ID: 4213955 • Views: …

More Releases from IMARC Group

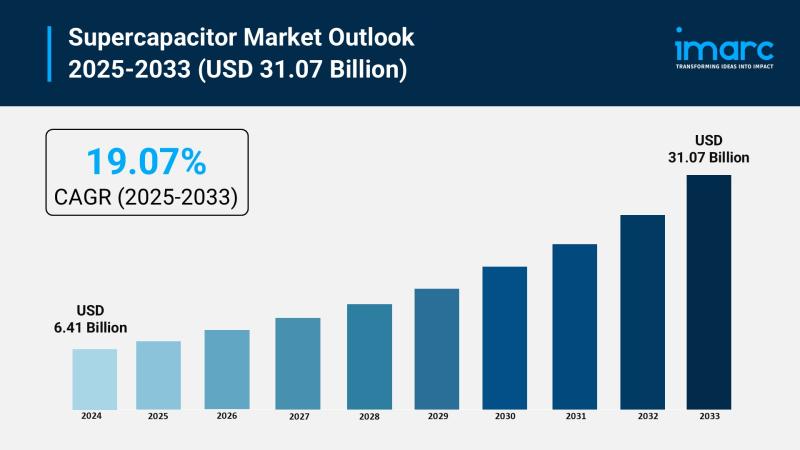

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

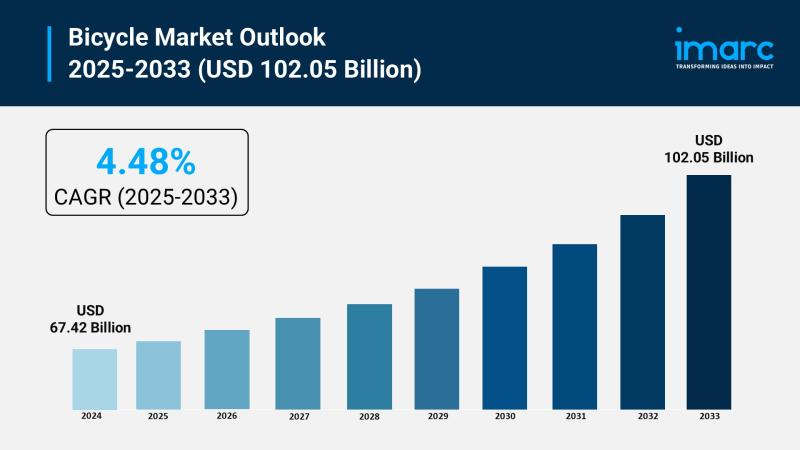

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

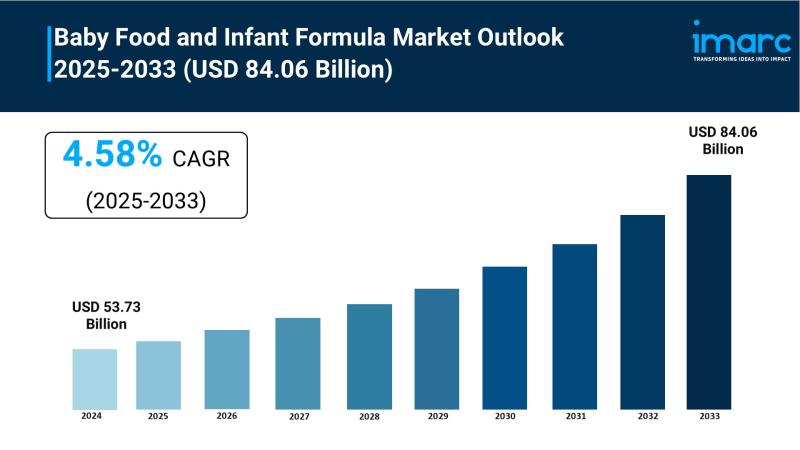

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

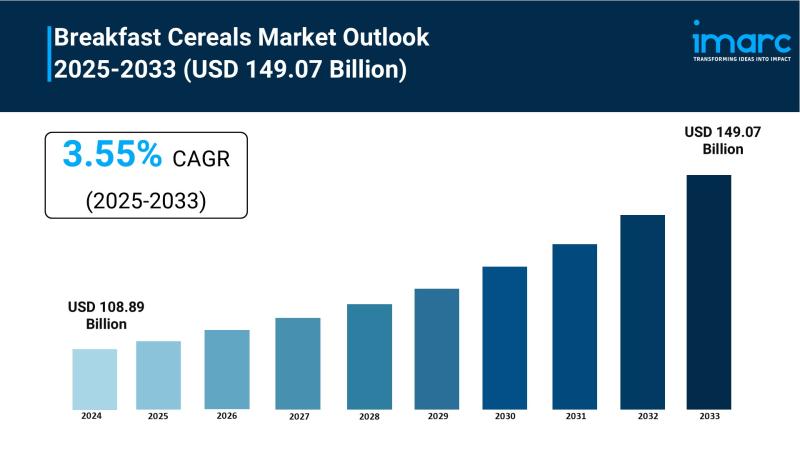

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for Cyclopropane

Lubricating Oil Manufacturing Plant Cost | Detailed Project Report 2024

IMARC Group's report titled "Lubricating Oil Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for setting up a lubricating oil manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In…

1-Fluorocyclopropane-1-Sulfonamide Market Growth Status and Outlook 2023-2029 |G …

Global Info Research announces the release of the report "Global 1-Fluorocyclopropane-1-Sulfonamide Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors,…

Cycloalkanes Market Growth Value To Cross $9.1 Billion By 2031 | Growth With Rec …

Allied Market Research published a report, titled, "Cycloalkanes Market by Type (Small Rings, Common Rings, Medium Rings, and Others), by Application (Pharmaceutical, Personal Care, Oil and Gas, and Others), and Region (North America, Europe, Asia-Pacific, and LAMEA): Global Opportunity Analysis and Industry Forecast, 2022-2031" According to the report, the global cycloalkanes industry generated $5.3 billion in 2021 and is estimated to reach $9.1 billion by 2031, witnessing a CAGR of…

Cycloalkanes Market Overview With Detailed Analysis, Competitive Landscape, Fore …

Cycloalkanes are hydrocarbons with a molecule having a ring of carbon atoms connected by single bonds that are utilized as an intermediary in the chemical manufacture of synthetic rubbers that are used in a variety of manufacturing and medical applications. Many synthetic products, including plastics, textiles, adhesives, and solvents, are made from cyclohexane. New o-substituted 2-phenyl imino-1-aza-cycloalkanes and their production which have new, useful and surprising properties as compared to…

Cycloalkanes Market Leading Global Companies and Regional Average Pricing Analys …

Allied Market Research published a report, titled, "Cycloalkanes Market by Type (Small Rings, Common Rings, Medium Rings, and Others), by Application (Pharmaceutical, Personal Care, Oil and Gas, and Others), and Region (North America, Europe, Asia-Pacific, and LAMEA): Global Opportunity Analysis and Industry Forecast, 2022-2031" According to the report, the global cycloalkanes industry generated $5.3 billion in 2021 and is estimated to reach $9.1 billion by 2031, witnessing a CAGR of…

Short Range Surveillance Radar Market Share and Growth Factors Covid-19 Impact A …

It shines a spotlight on competitors who are increasing market share around the world. Knowing all of the specifics about competitors, such as their weaknesses and strengths, allows you to seize the proper opportunity. Another crucial aspect of Market Research is the identification of commercial activities. It shows the negative impact of the COVID-19 epidemic on several businesses. Another wonderful feature of Market Report is that it calculates market size.…