Press release

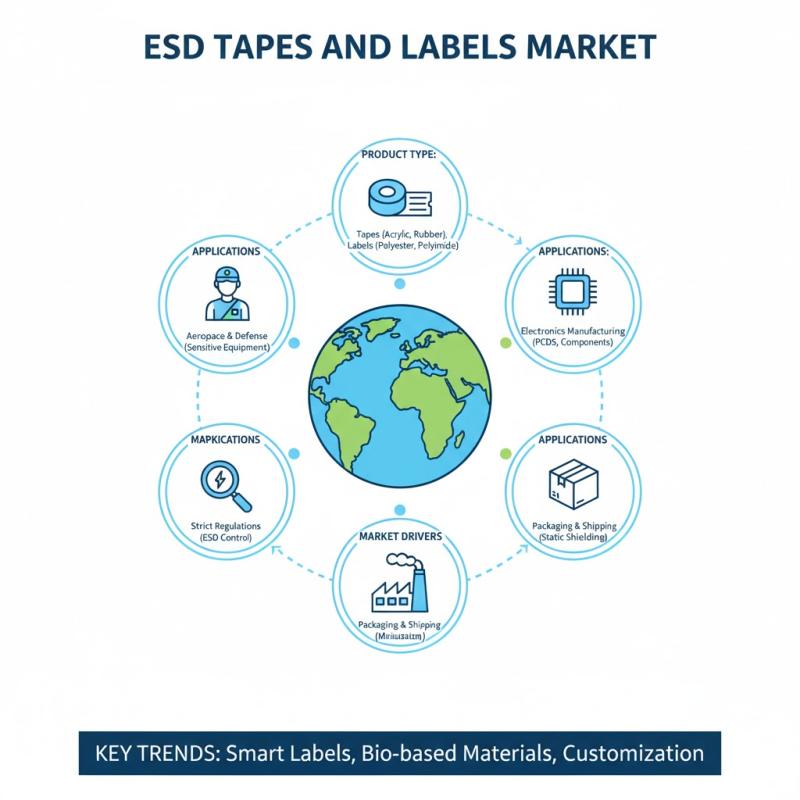

ESD Tapes and Labels market will expand USD 4,253.3 million by 2035, growing at 4.5% CAGR with strong electronics and aerospace demand.

The global market for ESD (electrostatic discharge) tapes and labels is entering a new decade of expansion driven by technological innovation, the rise of miniaturized electronics, and heightened quality standards in manufacturing. Valued at USD 2,738.8 million in 2025, the market is expected to reach USD 4,253.3 million by 2035, expanding at a steady 4.5% CAGR. This reflects a world increasingly dependent on efficient anti-static solutions that ensure the protection and reliability of sensitive electronic components.As industries evolve towards smaller yet more advanced devices-from smartphones and medical electronics to satellites and autonomous cars-the need for dependable ESD protection has never been greater. ESD tapes and labels have become essential in preventing static-related damage during assembly, packaging, and transportation, securing both performance and safety for high-value components.

ESD's Role in a Digitally Connected Era

Electronic and electrical manufacturing represents the most dominant segment of the market, contributing over 45% of total industry value by 2025. The sector's demand is centered on safeguarding semiconductors, printed circuit boards (PCBs), microchips, and sensors-components that power modern-day devices used globally. For manufacturers such as Intel, TSMC, and Samsung, ESD protection materials are now woven into every stage of their logistics and production processes to prevent static shock or contamination.

ESD tapes, expected to generate USD 1,604.9 million by 2025, remain vital in cushioning circuits from electrostatic exposure. These tapes are pivotal during intricate product assembly and reliable label application, enabling traceability, safety compliance, and consistent quality assurance for electronics manufacturers worldwide. As product miniaturization continues, companies are placing renewed emphasis on ensuring zero-compromise protection during increasingly complex production cycles.

Growing Integration in Aerospace and Defense

Beyond consumer electronics, demand for advanced anti-static protection is accelerating across aerospace and defense. Precision-made electronic systems used in avionics, radar, and missile guidance systems operate under extreme temperatures, vibrations, and altitudes-conditions that amplify ESD risks.

For critical applications where even minor static exposure can result in catastrophic malfunction, ESD tapes and labels offer innovation-driven reliability. Global defense contractors such as Boeing and Lockheed Martin continuously employ cutting-edge ESD materials to maintain safety and durability throughout assembly lines and secure transport. As aerospace projects integrate higher volumes of electronic circuitry and automation systems, dependence on advanced ESD materials will grow substantially over the decade.

Shifting Preferences in Semiconductor Protection

While ESD tapes and labels remain mainstream solutions, parts of the semiconductor sector are adopting alternative methods for ultra-sensitive components, using anti-static trays, conductive foams, and sealed ESD-safe packaging. These alternatives provide total encapsulation for precision products like wafers and integrated circuits, minimizing charge transfer during production.

However, ESD tapes and labels continue to dominate mass storage, handling, and packaging operations due to their adaptability and lower cost. Their recurring use across cleanrooms, testing setups, and shipping facilities secures their indispensable position, especially for large-scale electronics producers seeking robust and cost-efficient ESD management systems.

Key Factors Driving Innovation

The ESD tapes and labels market's evolution ties deeply to the broader advancement of materials science and sustainability practices. The growing use of PET (polyethylene terephthalate) as a face material captures nearly half the global market share for its durability, tensile strength, and unmatched resistance to static discharge. PET-based ESD materials also offer transparency, making them suitable for barcode labeling and traceability-particularly within mission-critical environments like automotive electronics and aerospace systems.

As manufacturers commit to carbon-neutral operations, PET has emerged as the preferred substrate due to its recyclability and low environmental footprint. In addition, advancements in conductive adhesives and print-compatible coatings enable tapes and labels to meet more stringent performance and environmental standards simultaneously.

Semi-Annual Performance Snapshot

Industry data reveals a moderately steady semi-annual trajectory, with the first half of the next decade (2025-2035) expected to show a CAGR of 3.9%, ramping up to 5.1% in the latter half as industrial and electronics manufacturing gain further momentum. These values reflect consistent growth across regions, supported by continued technology adoption across consumer and industrial device ecosystems.

Regional Dynamics and Manufacturing Insights

The United States leads North America's ESD tapes and labels demand with a projected CAGR of 3.2% through 2035, primarily driven by Silicon Valley's robust semiconductor production ecosystem. Companies such as Intel and AMD require extensive static protection to safeguard fragile wafers and chipsets used in AI processors, 5G technology, and electric vehicle electronics. ESD materials are integrated rigorously into manufacturing facilities and storage environments to maintain reliability under delicate operating conditions.

In Europe, Germany remains at the forefront of market growth due to rapid automotive electrification. Manufacturers like BMW, Volkswagen, and Audi use ESD-protected packaging materials on production lines for driver-assistance and battery-management systems. These anti-static solutions protect embedded sensors and control units from electrostatic failure, a critical element in autonomous and EV technologies.

Meanwhile, Asia-Pacific's expansion-driven by China and India-reflects the center of global electronic manufacturing relocation. China's semiconductor, data center, and telecommunications infrastructure are increasingly reliant on anti-static technologies, while India's growing electronics manufacturing base is propelling its demand at a CAGR of 5.7%.

Market Organization and Competitive Expansion

The global ESD tapes and labels market maintains a structured yet competitive hierarchy represented by three distinct tiers. Tier 1 leaders like 3M Company, Brady Corporation, Desco Industries, and Polyonics, Inc. dominate through advanced material technologies, extensive product portfolios, and international supply networks. Their expertise spans across reconditioning, high-performance labeling, and precision ESD tape engineering, ensuring compliance with stringent manufacturing standards.

Tier 2 participants such as Ultratape Industries, Electrotek Static Controls, Lotus Tapes, and Advance Tapes International exhibit strong regional market knowledge and R&D agility, balancing quality with cost-effectiveness to serve regional OEMs. Tier 3 comprises localized enterprises focusing on niche industries or markets, often supplying tailor-made materials for specialized device manufacturing within regional sectors.

Increasing collaboration among Tier 1 and Tier 2 firms, alongside mergers and acquisitions, is reshaping the market environment. Notably, Flexcon Global's participation in major international trade shows demonstrates growing industry cooperation and open innovation. Manufacturers are keen to explore biodegradable anti-static materials and conductive polymer options to align with sustainability mandates.

A Future Defined by Electronics, Efficiency, and Sustainability

With global electronics manufacturing poised for rapid upgrades-from smart home devices to upcoming 6G infrastructure-the demand for static protection materials will grow consistently. ESD tapes and labels are not only preventing damage to high-precision parts but also helping companies meet global compliance standards for product quality, safety, and environmental performance.

Both established stakeholders like 3M and Brady Corporation and emerging manufacturers across Asia are investing in advanced coating technologies and conductive adhesive chemistry to enhance ESD protection efficiency. These innovations also aim to extend product durability, flexibility, and resistance to varying industrial conditions.

By 2035, ESD tapes and labels are expected to become foundational components across every touchpoint in the electronics supply chain-from material transport to device integration. With its role bridging safety, sustainability, and manufacturing reliability, the global industry now stands as a cornerstone of the future digital economy, powered by precision, performance, and protection.

Get Instant Access for Only $5,000 | Don't Miss This Exclusive Offer!

https://www.futuremarketinsights.com/reports/sample/rep-gb-5505

Checkout Now to Access Industry Insights:

https://www.futuremarketinsights.com/checkout/5505

Explore Similar Insights

ESD Safe Matting Market

https://www.futuremarketinsights.com/reports/esd-safe-matting-market

ESD Divider Market

https://www.futuremarketinsights.com/reports/eds-dividers-market

ESD Stackable Box Market

https://www.futuremarketinsights.com/reports/esd-stackable-boxes-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release ESD Tapes and Labels market will expand USD 4,253.3 million by 2035, growing at 4.5% CAGR with strong electronics and aerospace demand. here

News-ID: 4213792 • Views: …

More Releases from Future Market Insights

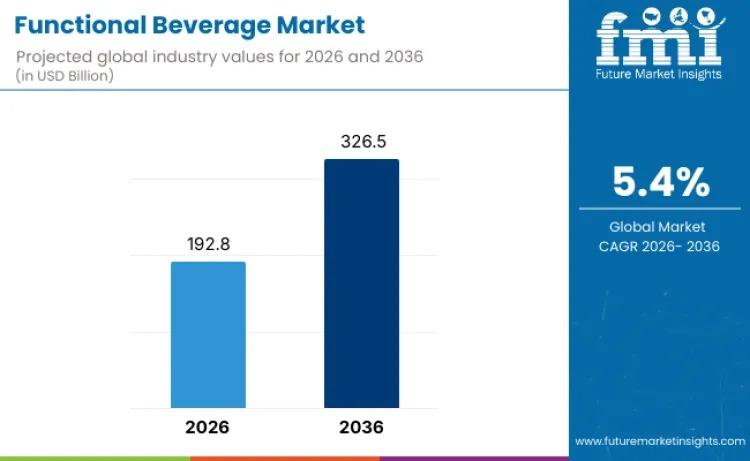

Functional Beverage Market Forecast 2026-2036: Global Industry to Reach USD 326. …

The global functional beverage industry is projected to reach USD 192.8 billion in 2026, reflecting sustained momentum driven by preventive healthcare awareness and consumer demand for health-enhancing drink formulations. According to Future Market Insights (FMI), total revenue is forecast to expand at a CAGR of 5.4% from 2026 to 2036, elevating the market value to USD 326.5 billion by 2036.

Growth is underpinned by rising wellness-oriented consumption patterns, the rapid expansion…

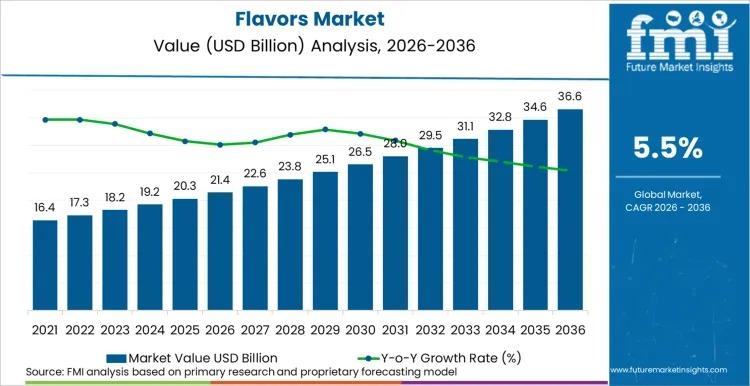

Flavors Market Forecast 2026-2036: Global Industry to Reach USD 36.6 Billion by …

The global flavors industry is poised for sustained expansion, with valuation projected to reach USD 21.4 billion in 2026. According to the latest assessment, revenues are expected to grow at a steady 5.5% CAGR through 2036, pushing the total market value beyond USD 36.6 billion by the end of the forecast period. Rising consumption of processed food and beverages, combined with increasing consumer demand for authentic taste experiences, continues to…

Hybrid Paper-Polymer Material System for Lightweight Structural Components Marke …

Market Overview: Structural Lightweighting Gains Commercial Momentum

The Hybrid Paper-Polymer Material Systems for Lightweight Structural Components Market is witnessing sustained growth as manufacturers prioritize lightweighting, material efficiency, and predictable mechanical performance. Valued at USD 740.0 million in 2026, the market is forecast to reach USD 1,788 million by 2036, expanding at a CAGR of 9.1%. Growth is driven by redesign strategies that integrate stiffness control, impact tolerance, and reduced material intensity…

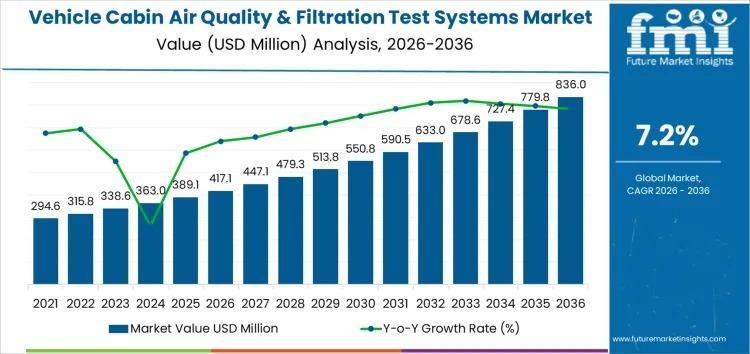

Global Vehicle Cabin Air Quality & Filtration Test Systems Market Growth Outlook …

Global Vehicle Cabin Air Quality & Filtration Test Systems Market Forecast and Outlook 2026-2036

The Vehicle Cabin Air Quality & Filtration Test Systems Market is projected to expand from USD 417.1 million in 2026 to USD 836 million by 2036, reflecting a steady CAGR of 7.20%. This surge is driven by growing consumer awareness about in-vehicle air quality, increasing adoption of electric vehicles (EVs), and stringent regulations governing cabin air pollution.…

More Releases for ESD

ESD Workstation And ESD Table Market Size and Outlook by Application, Type, and …

USA, New Jersey- According to Market Research Intellect, the global ESD Workstation And ESD Table market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The ESD workstation and ESD table market is experiencing steady growth, driven by the rising need for electrostatic discharge protection in sensitive…

ESD Epoxy Flooring Market Size and Forecast

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- The global ESD Epoxy Flooring Market is expected to record a CAGR of XX.X% from 2024 to 2031 In 2024, the market size is projected to reach a valuation of USD XX.X Billion. By 2031 the valuation is anticipated to reach USD XX.X Billion.

ESD Epoxy Flooring Market Size and Scope

The ESD epoxy flooring market is witnessing steady growth, driven by the increasing demand for high-performance, durable flooring…

ESD Safe Matting Market 2024 Product Types (Vinyl ESD Safe Matting, Rubber ESD S …

The "ESD Safe Matting Market" report provides key insights into market size, share, growth dynamics, and emerging trends, enabling businesses to make data-driven decisions and enhance their strategies for expansion. It also highlights technological advancements, diverse sales channels, market penetration, production methods, and company revenues, offering a holistic perspective of the market landscape.

Browse Full Report at: https://www.themarketintelligence.com/market-reports/esd-safe-matting-market-1121

About ESD Safe Matting Market:

The global ESD Safe Matting Market size was USD 115.53…

ESD Protection Devices Market 2022-

LOS ANGELES, United States: The research study presented in this report offers a complete and intelligent analysis of the competition, segmentation, dynamics, and geographical advancement of the global ESD Protection Devices market. It takes into account the CAGR, value, volume, revenue, production, consumption, sales, manufacturing cost, prices, and other key factors related to the global ESD Protection Devices market. The authors of the report have segmented the global ESD Protection…

Electrostatic Discharge Esd Packaging

ESD (Electrostatic Discharge Packaging) is important to safely transport and store most electronic products. It is specially designed to prevent static electricity, ensuring the integrity of the products included in the pack.

Electrostatic discharge (ESD) packaging includes a variety of functional packaging products designed to protect electronic products, especially electrostatic products, by ensuring the integrity of the products contained in the pack. The global electrostatic discharge packaging market uses materials to…

ESD Protection Diode Market 2017

Global ESD Protection Diode Industry 2022 Market Research Report analyzed the current state in the definitions, classifications, applications and industry chain structure. The report also focuses on the development trends as well as history, competitive landscape analysis, and key regions etc in the international markets.

Global ESD Protection Diode Industry 2022 Market Research Report is a professionally prepared report comprising of in-depth information as well as knowledge which is helpful to…