Press release

Inspection Machines Market Set for 5.1% Growth: Powering the Future of Automated Quality Control from 2025 to 2035

The global inspection machines market is poised for steady expansion, expected to grow from USD 785.6 million in 2025 to USD 1,291.9 million by 2035, registering a CAGR of 5.1%. This growth marks a new era in manufacturing efficiency and product safety, with inspection machines becoming essential tools across industries such as pharmaceuticals, food and beverages, automotive, and electronics.Buy Now & Save: Premium Market Report at $5,000 | Discount Details Inside:- https://www.futuremarketinsights.com/reports/sample/rep-gb-2132

As manufacturers around the world strive to achieve higher accuracy, lower defects, and full compliance with stringent safety regulations, inspection systems have emerged as the backbone of automated quality control. These advanced technologies ensure that every product leaving the production line meets global quality benchmarks, reducing recalls, optimizing processes, and enhancing brand reputation.

Meeting the Rising Demand for Safety and Traceability

A growing global focus on quality assurance and consumer safety is fueling widespread adoption of inspection technologies. Industries such as pharmaceuticals and food processing are under increasing regulatory pressure to guarantee that every product is safe, accurately labeled, and free from contamination. Automated inspection machines detect cracks, scratches, missing parts, and incorrect labeling in real time, safeguarding both end users and manufacturers from potential risks.

In addition, traceability is becoming a cornerstone of modern manufacturing. Inspection machines integrated with advanced data collection systems are enabling full product tracking from production to distribution. This capability is particularly crucial in sectors with strict compliance mandates, where traceability ensures accountability and transparency across the supply chain.

Automation Accelerating Efficiency and Precision

As factories transition toward automation and Industry 4.0 standards, the integration of inspection machines within production lines has become a critical growth factor. Automated inspection systems not only match the speed of high-volume manufacturing but also minimize human error and production downtime.

From pharmaceuticals to automotive components, the ability to perform precise inspections at rapid speeds is helping manufacturers maintain competitiveness in global markets. These technologies also reduce operational costs by identifying defects early in the production cycle-saving time, materials, and resources.

Overcoming Barriers to Adoption

Despite the promising outlook, manufacturers face challenges such as high initial investment costs and integration complexities. Advanced inspection systems, particularly those leveraging artificial intelligence and multi-technology solutions, require substantial upfront expenditure. Smaller enterprises often struggle with the cost of installation, maintenance, and staff training.

Integration with legacy systems also presents hurdles. Older equipment may not readily support AI-driven inspection tools, necessitating infrastructure upgrades. Regular calibration and maintenance are essential to ensure consistent accuracy, as poor upkeep can lead to false readings and production inefficiencies.

However, the long-term benefits-enhanced quality, reduced waste, and improved compliance-far outweigh these initial challenges. Forward-thinking manufacturers are increasingly viewing inspection systems as strategic investments that deliver measurable returns through efficiency and reliability.

Pricing and Technology Shaping Market Dynamics

The inspection machines market offers diverse pricing models depending on complexity and functionality. Basic inspection tools such as metal detectors and checkweighers range from USD 5,000 to USD 75,000, catering to food, beverage, and consumer goods industries with moderate regulation.

At the higher end, sophisticated systems such as AI-powered vision inspection, automated optical inspection (AOI), and X-ray or CT scanners can exceed USD 300,000. These machines serve heavily regulated industries like pharmaceuticals, medical devices, and automotive manufacturing, where microscopic precision and non-destructive testing are critical.

Understanding these pricing tiers helps manufacturers align their quality strategies with operational goals. Businesses can choose scalable solutions based on their production complexity, ensuring compliance while optimizing capital investment.

Technology Transforming the Inspection Landscape

Technological evolution continues to redefine inspection capabilities. Artificial Intelligence (AI) and Machine Learning (ML) are making inspection machines smarter and more adaptable. These systems can learn from past inspections, adjust automatically to new product variations, and even predict potential failures before they occur.

Meanwhile, advancements in imaging technologies-such as 3D vision, infrared, and multi-spectral imaging-are enabling manufacturers to detect even the smallest defects. In automotive and electronics production, X-ray and CT systems now provide non-destructive internal analysis, ensuring product integrity without slowing down output.

This technological shift is enabling manufacturers to achieve zero-defect production, a long-standing industry goal that is now within reach thanks to digital inspection innovations.

Global Market Insights: Regional Growth Hotspots

Across global markets, the demand for inspection systems reflects varying degrees of industrial maturity. Germany leads with an anticipated CAGR of 8.9%, driven by precision manufacturing in automotive, aerospace, and medical devices. The UK follows with strong growth of 7.1%, anchored by its pharmaceutical and food industries.

India, at 6.1% CAGR, is rapidly adopting automation in sectors such as automotive and electronics, while China's large-scale industrial base continues to expand its investment in automated inspection to meet tightening safety standards. In the United States, innovation in medical devices and strict regulatory frameworks sustain high demand for advanced inspection technologies.

Click Here to Purchase the Report:- https://www.futuremarketinsights.com/checkout/2132

Key Industry Players and Competitive Outlook

The inspection machines market remains highly competitive, featuring a blend of established global players and agile innovators. Industry leaders such as Mettler-Toledo International Inc., ANTARES VISION S.r.l., Tofflon Science & Technology Co. Ltd., Proditec Automatic Inspection Machines, Brevetti C.E.A. Spa, and Cognex Corporation are setting benchmarks in automation, vision technology, and integration efficiency.

These companies are focusing on tailored solutions-ranging from metal detection and X-ray inspection to AI-powered systems-enabling manufacturers to meet specific regulatory and production needs. As the industry evolves, partnerships and innovation will remain central to achieving greater efficiency, safety, and compliance in global manufacturing.

Empowering the Future of Manufacturing

From ensuring product integrity to optimizing production throughput, inspection machines are transforming how manufacturers define quality. With a projected market value of USD 1.29 billion by 2035, these systems represent not just a technological upgrade but a strategic imperative for industries aiming to thrive in an increasingly automated world.

In a decade defined by smart manufacturing, inspection machines are more than tools-they are catalysts of growth, precision, and trust.

Latest Responsible Resource Management & Safety Reports:-

Industrial Water Analysis Market

https://www.futuremarketinsights.com/reports/industrial-water-analysis-market

Ammunition Market

https://www.futuremarketinsights.com/reports/ammunition-market

Industrial Protective Clothing Market

https://www.futuremarketinsights.com/reports/industrial-protective-clothing-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analystsworldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Inspection Machines Market Set for 5.1% Growth: Powering the Future of Automated Quality Control from 2025 to 2035 here

News-ID: 4213664 • Views: …

More Releases from Future Market Insights

Hybrid Paper-Polymer Material System for Lightweight Structural Components Marke …

Market Overview: Structural Lightweighting Gains Commercial Momentum

The Hybrid Paper-Polymer Material Systems for Lightweight Structural Components Market is witnessing sustained growth as manufacturers prioritize lightweighting, material efficiency, and predictable mechanical performance. Valued at USD 740.0 million in 2026, the market is forecast to reach USD 1,788 million by 2036, expanding at a CAGR of 9.1%. Growth is driven by redesign strategies that integrate stiffness control, impact tolerance, and reduced material intensity…

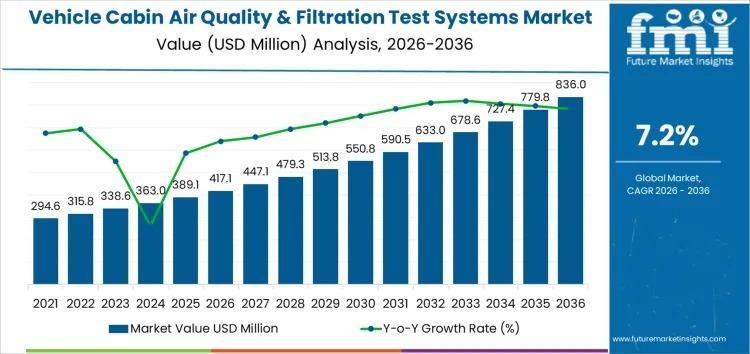

Global Vehicle Cabin Air Quality & Filtration Test Systems Market Growth Outlook …

Global Vehicle Cabin Air Quality & Filtration Test Systems Market Forecast and Outlook 2026-2036

The Vehicle Cabin Air Quality & Filtration Test Systems Market is projected to expand from USD 417.1 million in 2026 to USD 836 million by 2036, reflecting a steady CAGR of 7.20%. This surge is driven by growing consumer awareness about in-vehicle air quality, increasing adoption of electric vehicles (EVs), and stringent regulations governing cabin air pollution.…

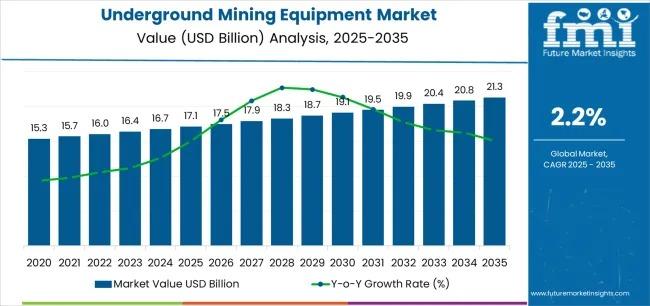

Global Underground Mining Equipment Market 2025-2035: Growth Driven by Automatio …

Global Underground Mining Equipment Market Forecast 2025-2035: Electrification and Automation Drive Expansion

The Underground Mining Equipment Market is entering a transformative decade, projected to grow from USD 17.1 billion in 2025 to USD 21.3 billion by 2035. This growth trajectory underscores mining operators' increasing focus on battery-electric systems, automation, and eco-friendly mining solutions, which are redefining operational efficiency, safety, and productivity in underground extraction environments.

Mining operators are balancing production targets with…

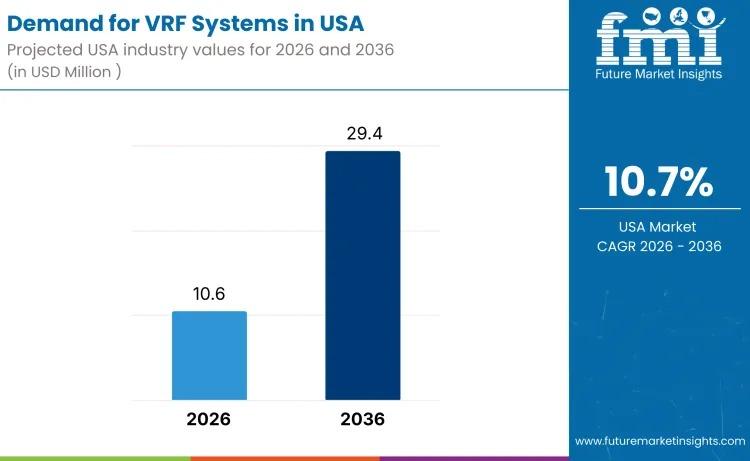

Demand for USA VRF Systems Market Accelerates as Electrification and Energy Code …

The Demand for VRF systems in the USA is entering a sustained expansion phase, supported by energy efficiency mandates and modernization of building stock. The U.S. VRF systems market is valued at USD 10.6 million in 2026 and is projected to reach USD 29.4 million by 2036, registering a compound annual growth rate (CAGR) of 10.7%.

This growth reflects increasing adoption across commercial buildings, healthcare facilities, and multi-family residential developments, where…

More Releases for Inspection

Inspection Drones Market 2032: Advancements, Trends, and AI-Enabled Industrial I …

The Inspection Drones Market size was valued at USD 8.90 Billion in 2024 and the total Inspection Drones revenue is expected to grow at a CAGR of 12.9% from 2025 to 2032, reaching nearly USD 23.50 Billion.

Inspection Drones Market Overview:

The Inspection Drones Market has garnered strong attention from industries that require rapid and accurate evaluation of assets such as power lines, wind turbines, pipelines, bridges, and industrial installations. These drones…

Railway Inspection Services Market Outlook : Solutions, Inspection Vehicles & Sy …

Railway inspection is the practice of examining rail tracks for flaws that lead to catastrophic failures causing accidents. According to the U.S. Federal Railroad Administration Office of Safety Analysis, track defects are the second cause of railway accidents in U.S. Some of the reasons causing track defects are shear stresses, wheel/rail contact stresses, thermal stresses, residual stresses, and dynamic effects. Moreover, due to contact stresses defects such as tongue lipping,…

Surface Inspection Market: Surface Inspection Market to Grow to USD 10.29B by 20 …

Surface Inspection Market Scope:

Key Insights : Surface Inspection Market size was valued at USD 5.02 billion in 2022 and is poised to grow from USD 5.44 billion in 2023 to USD 10.29 billion by 2031, growing at a CAGR of 8.3% in the forecast period (2024-2031).

Discover Your Competitive Edge with a Free Sample Report :https://www.skyquestt.com/sample-request/surface-inspection-market

Access the full 2024 Market report for a comprehensive understanding @https://www.skyquestt.com/report/surface-inspection-market

In-Depth Exploration of the global…

Thermal Drone Inspection Market Soars as Industries Embrace Efficient and Safe I …

The global thermal drone inspection market is estimated to exceed US$ 282.4 million by the end of 2023, by growing at an impressive CAGR of 13.4% over the assessment period of 2023-2033.

The deployment of thermal cameras with infrared sensors and high quality image processors has significantly expanded the applications of the thermal drones. They can be utilized in various industries, for instance, firefighting, search & rescue, ariel utility and advanced…

beXel launched different inspection modules to improve inspection quality

beXel launched a Variety of modules to facilitate the inspection process and provide smart solutions for the customers such as

(Drops Inspection, Job order management, Lifting Inspection, NDT inspection, Tubular Inspection, Desktop Offline App).

A quality inspection involves measuring, examining, testing, or gauging various characteristics of a product and comparing those results with specified requirements to determine whether there is conformity.

Quality Control (QC) is critical to build and deliver products that meet…

Carlsbad, CA Mold Inspection and Asbestos Testing Services Offered by Murrieta M …

Carlsbad, CA, December 16, 2019 – EZ Mold Inspections continues expanding its service area in San Diego County and now provides asbestos testing and mold inspections in Carlsbad, California. The inspection company is based in the Murrieta-Temecula area. The company now serves nine areas in Riverside County and two cities in San Diego County including Oceanside, CA and Carlsbad, CA.

With more than two decades of experience in real estate and…