Press release

Laptop Charger Manufacturing Plant Setup Report 2025 | Project Economics, Cost Structure, and ROI Analysis

A laptop charger is an external power adapter that converts alternating current from wall outlets into direct current suitable for charging a laptop's battery and powering the device. It typically consists of a power brick containing transformer and rectifier circuits, along with cables connecting to both the electrical outlet and the laptop. The charger regulates voltage and current to match the laptop's specifications, preventing damage from power fluctuations while ensuring efficient energy transfer.Establishing a laptop charger manufacturing facility requires securing industrial space with adequate power supply and ventilation. Essential equipment includes injection molding machines for plastic casings, automated circuit board assembly lines, coil winding machines for transformers, and testing stations for quality control. The facility needs separate zones for component storage, assembly, testing, and packaging. Hiring skilled technicians and engineers is crucial, alongside implementing safety protocols for handling electrical components and establishing supply chains for sourcing raw materials like copper wire, circuit boards, and plastic resins.

IMARC Group's "Laptop Charger Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a detailed and practical guide for entrepreneurs and businesses looking to enter the manufacturing industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful manufacturing plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as laptop charger manufacturing plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/laptop-charger-manufacturing-plant-project-report/requestsample

Laptop Charger Industry Outlook 2025:

The laptop charger industry in 2025 is experiencing significant transformation driven by universal charging standards, particularly USB-C Power Delivery adoption across manufacturers. Growing demand for compact, high-wattage GaN (gallium nitride) chargers is reshaping product development, offering improved efficiency and portability. The market faces pressure from sustainability initiatives pushing modular designs and repair-friendly products, while wireless charging technology continues gradual integration. Supply chain diversification remains critical following recent global disruptions, with manufacturers expanding production across multiple regions. The shift toward remote work sustains steady demand, though market maturity in developed regions drives competition increasingly toward emerging markets and premium fast-charging segments.

Key Insights for Laptop Charger Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Laptop Charger Plant:

• Land and Infrastructure - Industrial plot acquisition or lease, factory building construction or renovation, warehouse space, office facilities, and utility connections including three-phase power supply

• Machinery and Equipment - Injection molding machines, SMT assembly lines, coil winding machines, soldering equipment, cable cutting and stripping machines, ultrasonic welding units, and automated testing systems

• Raw Materials and Components - Printed circuit boards, transformers, capacitors, resistors, diodes, copper wire, plastic granules for casings, cables, connectors, and packaging materials

• Quality Control and Testing - High-voltage testing equipment, load testers, temperature chambers, safety certification testing apparatus, and calibration instruments

• Labor Costs - Salaries for production workers, quality control technicians, engineers, supervisors, maintenance staff, and administrative personnel

• Compliance and Certifications - Safety certifications (UL, CE, FCC), environmental compliance permits, factory inspections, product testing fees, and ongoing regulatory compliance costs

• Working Capital - Initial inventory procurement, operational expenses for first few months, supplier advance payments, and emergency contingency funds

Economic Trends Influencing Laptop Charger Plant Setup Costs 2025:

• Rising Material Costs - Copper, semiconductor chips, and plastic resin prices remain elevated due to supply chain constraints and increased global demand for electronics components

• Labor Market Tightness - Skilled technician shortages and competitive wages in manufacturing sectors are driving up personnel costs across production facilities

• Energy Price Volatility - Fluctuating electricity and fuel costs impact operational expenses, particularly for energy-intensive processes like injection molding and assembly operations

• Interest Rate Environment - Higher borrowing costs affect financing for capital equipment purchases and construction, increasing overall project investment requirements

• Currency Fluctuations - Exchange rate volatility impacts imported machinery costs and component sourcing from international suppliers, particularly affecting emerging market manufacturers

• Automation Investment Pressure - Growing need for automated production lines to maintain competitiveness increases upfront capital expenditure despite long-term labor savings

• Regulatory Compliance Costs - Stricter environmental standards, energy efficiency requirements, and safety certifications are adding to initial setup and ongoing operational expenses

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=22755&flag=C

Challenges and Considerations for Investors in Laptop Charger Plant Projects:

• Rapid Technology Obsolescence - Fast-evolving charging standards like USB-C and GaN technology require continuous equipment upgrades and R&D investment to remain competitive

• Intense Market Competition - Saturated market with established manufacturers and low-cost producers creates pressure on profit margins and market entry barriers

• Certification Complexity - Navigating multiple international safety standards and certifications across different markets adds time and cost before revenue generation begins

• Supply Chain Dependencies - Reliance on specialized component suppliers creates vulnerability to shortages, price fluctuations, and geopolitical disruptions affecting production continuity

• Quality Control Demands - Strict safety requirements and liability risks necessitate robust testing protocols and quality assurance systems, increasing operational complexity

• Shifting Consumer Preferences - Trend toward universal chargers and device manufacturers bundling fewer accessories may reduce standalone charger demand over time

• Environmental Regulations - Growing e-waste legislation, right-to-repair mandates, and sustainability requirements demand investment in eco-friendly materials and recyclable designs

Conclusion:

Establishing a laptop charger manufacturing plant in 2025 presents both promising opportunities and notable challenges for investors. While steady demand from the growing laptop market and the shift toward advanced charging technologies like GaN and USB-C Power Delivery create viable business prospects, success requires careful navigation of rising setup costs, intense competition, and evolving regulations. Strategic planning around technology adoption, supply chain resilience, quality assurance, and compliance with international standards is essential. Investors must balance substantial capital requirements against market uncertainties while remaining adaptable to rapid technological changes and sustainability mandates that are reshaping the industry landscape.

Buy Now: https://www.imarcgroup.com/checkout?id=22755&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Laptop Charger Manufacturing Plant Setup Report 2025 | Project Economics, Cost Structure, and ROI Analysis here

News-ID: 4211425 • Views: …

More Releases from IMARC Group

Bioethanol Production Plant Cost 2026: Raw Materials & Pricing Trends

Setting up a Bioethanol Production Plant positions investors in one of the most stable and essential segments of the renewable energy and biofuel value chain, backed by sustained global growth driven by rising demand for clean-burning renewable fuels, increasing adoption of sustainable energy alternatives across automotive, pharmaceutical, and chemical industries, accelerating decarbonization requirements across global energy systems, and the dual-benefit advantages of reducing carbon emissions while simultaneously supporting rural agricultural…

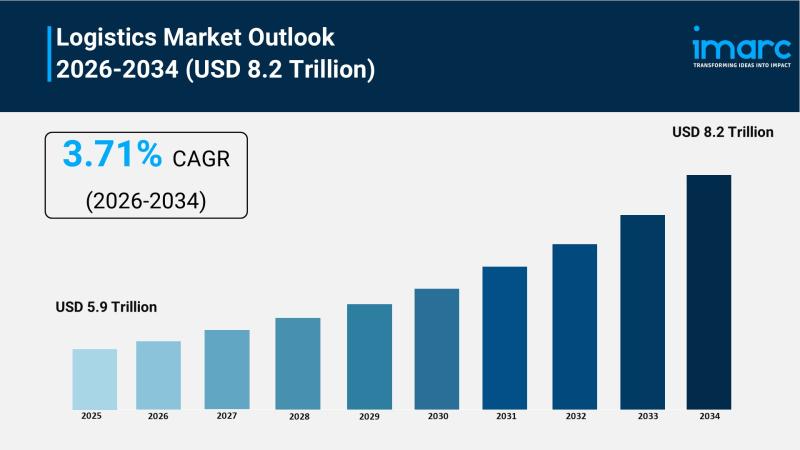

Logistics Market to Reach USD 8.2 Trillion by 2034, Growing at a CAGR of 3.71%

Market Overview:

The Logistics Market is experiencing steady expansion, driven by E-commerce Growth, Technological Advancements, and Globalization of Trade. According to IMARC Group's latest research publication, "Logistics Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The global logistics market size was valued at USD 5.9 Trillion in 2025. Looking forward, the industry is projected to reach USD 8.2 Trillion by 2034, exhibiting a CAGR of 3.71% during 2026-2034.

This…

Alumina Refinery Manufacturing Plant DPR 2026: CapEx/OpEx Analysis with Profitab …

Setting up an alumina refinery manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of the Bayer process technology. This essential aluminum oxide serves as the primary feedstock for aluminum smelting, ceramics, and abrasives industries. Success requires careful site selection near bauxite deposits, efficient chemical processing systems, energy-intensive digestion and calcination units, reliable bauxite sourcing, and compliance with environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report,…

Motorcycle Tyre Manufacturing Plant Cost 2026: Detailed Project Report and Inves …

Setting up a Motorcycle Tyre Manufacturing Plant positions investors in one of the most stable and essential segments of the automotive components and two-wheeler value chain, backed by sustained global growth driven by rising global motorcycle ownership, increasing urban mobility needs, growing demand for affordable personal transportation, and the dual-benefit advantages of serving both OEM two-wheeler manufacturers and a high-frequency aftermarket replacement cycle. As rapid urbanization accelerates across emerging economies…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…