Press release

Mercuric Oxide Production Plant 2025: IMARC Group Report Details Raw Materials, Financial Feasibility, and Market Prospects

Mercuric Oxide is a bright red or orange crystalline solid with the chemical formula HgO, widely used in specialty batteries, chemical reagents, and laboratory applications. When heated or exposed to reducing agents, it decomposes to release oxygen and elemental mercury, making it useful in controlled chemical processes. Its high toxicity and environmental impact, however, require stringent handling protocols and regulatory compliance.Setting up a Mercuric Oxide production plant requires secure sourcing of elemental mercury, controlled oxidation systems or precipitation setups, advanced vapor containment equipment, and full-scale environmental safety measures. Specialized machinery, airtight processing environments, and legal clearances are critical for establishing a safe and compliant manufacturing unit.

IMARC Group's "Mercuric Oxide Production Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a detailed and practical guide for entrepreneurs and businesses looking to enter this niche segment of the specialty chemical industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful manufacturing plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as mercuric oxide production plant setup cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/mercuric-oxide-manufacturing-plant-project-report/requestsample

Mercuric Oxide Industry Outlook 2025:

The Mercuric Oxide industry outlook for 2025 indicates stable demand in specialized sectors such as defense-grade battery manufacturing, precision laboratory reagents, and controlled oxidation catalysts. However, global mercury usage restrictions and rising regulatory scrutiny are influencing production dynamics. Growth opportunities remain for high-purity, small-scale manufacturing in regulated environments. Technological improvements in mercury recovery, waste treatment, and vapor containment will be critical to sustaining compliance and profitability in this segment.

Key Insights for Mercuric Oxide Production Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Unlock Full Access-Purchase Now!: https://www.imarcgroup.com/checkout?id=11259&method=1911

Key Cost Components of Setting Up a Mercuric Oxide Plant:

• Raw Materials: Secure procurement of elemental mercury, sulfuric acid or oxidizing agents, and neutralizing chemicals for waste treatment.

• Machinery and Equipment: Mercury oxidation chambers, precipitation tanks, drying units, vapor scrubbers, fume hoods, PPE stations, and mercury vapor detectors.

• Infrastructure Development: Acid-resistant flooring, ventilation systems, airtight lab construction, mercury spill containment trenches, and utility support.

• Labor and Staffing: Skilled chemical engineers, lab technicians, hazardous material handlers, safety officers, and plant supervisors.

• Safety and Environmental Compliance: Wastewater treatment systems, gas scrubbing units, air filtration units, gas detectors, hazardous material disposal equipment.

• Licensing and Regulatory Approvals: High compliance costs related to mercury use, environmental licensing, safety certifications, and periodic audits.

• R&D and Quality Control: In-house labs for purity testing, decomposition point verification, and mercury recovery process optimization.

• Logistics and Supply Chain: Secure, licensed transportation for mercury raw materials and finished goods, compliant packaging for toxic substances.

Economic Trends Influencing Mercuric Oxide Plant Setup Costs 2025:

• Mercury Price Volatility: Global supply restrictions and limited mining sources are causing frequent fluctuations in mercury prices.

• Environmental Regulation Pressure: Increasing global alignment with the Minamata Convention is tightening production and disposal requirements.

• Energy Cost Trends: Rising industrial electricity prices are impacting heating, oxidation, and drying operations.

• Labor Market Inflation: Demand for highly trained hazardous materials handlers is raising staffing costs.

• Technological Shifts: Advanced mercury recovery and vapor containment systems are increasing upfront equipment investments but lowering long-term emissions liabilities.

• Limited Plant Location Options: Zoning restrictions and public resistance to mercury-based facilities are limiting site availability and increasing location costs.

• Global Demand Consolidation: Declining mass-market demand is concentrating market share in specialized, regulated applications.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=11259&flag=C

Challenges and Considerations for Investors in Mercuric Oxide Plant Projects:

• Toxicity Management: Continuous monitoring, specialized equipment, and personnel training are necessary to manage mercury hazards.

• Regulatory Hurdles: Permitting, licensing, and environmental impact assessments can cause significant delays and add to CapEx.

• Declining Consumer Battery Demand: Mercury-free alternatives in consumer electronics are reducing overall demand.

• High Capital Intensity: Advanced containment infrastructure and safety systems significantly increase setup costs.

• Raw Material Sourcing Constraints: Mercury availability is globally limited, often regulated, and requires long-term contracts with certified suppliers.

• Public Perception and Social Licensing: Projects involving mercury face scrutiny from environmental groups and local communities.

• Waste Disposal Compliance: Stringent restrictions on mercury waste handling and export can affect operational planning and costs.

Conclusion:

In conclusion, investing in a Mercuric Oxide Production Plant presents niche opportunities within a highly specialized market but is fraught with significant technical, regulatory, and environmental challenges. The global shift away from mercury-based products has reduced mass-market applications, but precision industries still require controlled and compliant production. Investors must carefully assess legal feasibility, establish robust safety frameworks, and explore market demand in defense, research, and catalyst applications to ensure project success.

Customization Options Available:

• Plant Location: Selection of optimal location for the plant.

• Plant Capacity: Customization based on desired production capacity.

• Machinery: Choice between automatic, semi-automatic, or manual machinery.

• List of Machinery Providers: Identification of suitable machinery suppliers.

Services:

• Market Entry and Opportunity Assessment

• Competitive Intelligence and Benchmarking

• Procurement Research

• Pricing and Cost Research

• Sourcing Partner Identification

• Distribution Partner Identification

• Contract Manufacturer Identification

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Mercuric Oxide Production Plant 2025: IMARC Group Report Details Raw Materials, Financial Feasibility, and Market Prospects here

News-ID: 4210797 • Views: …

More Releases from IMARC Group

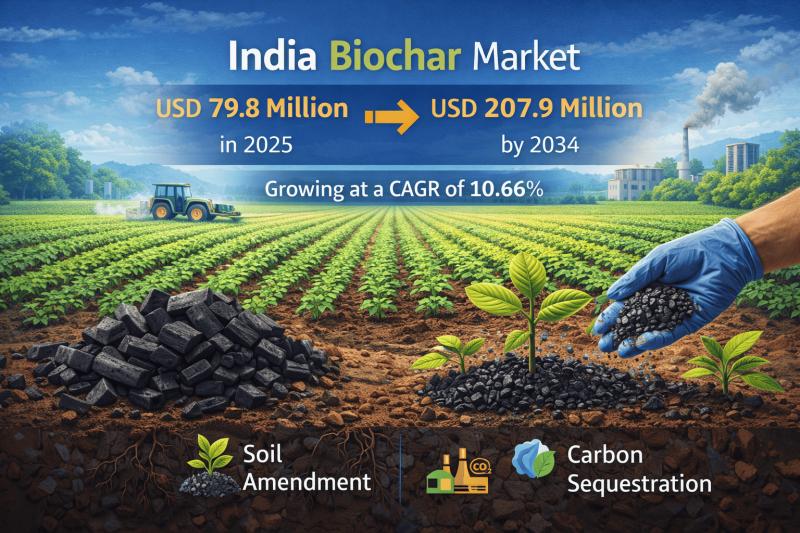

India Biochar Market Expected to Reach USD 207.9 Million by 2034, Industry Growi …

IMARC Group's latest research publication "India Biochar Market Size, Share, Trends and Forecast by Feedstock Type, Technology Type, Product Form, Application, and Region, 2026-2034" the India biochar market size reached USD 79.8 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 207.9 Million by 2034, exhibiting a growth rate (CAGR) of 10.66% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-biochar-market/requestsample

What is Biochar?

Biochar is a carbon-rich material produced through…

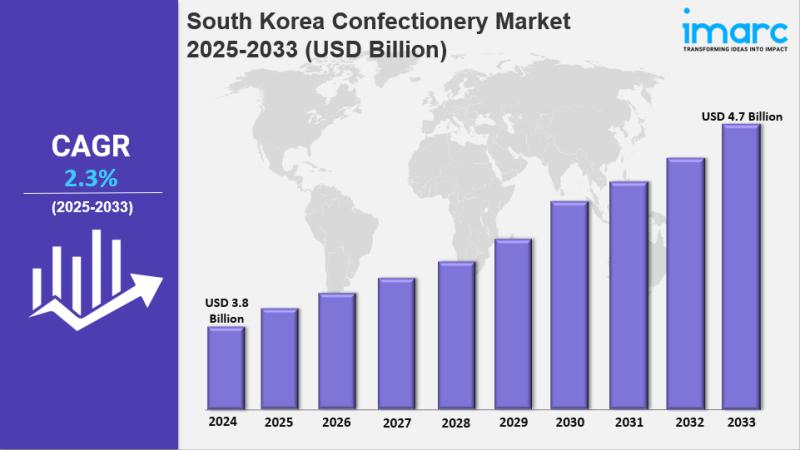

South Korea Confectionery Market Size, Growth, Latest Trends and Forecast To 203 …

IMARC Group has recently released a new research study titled "South Korea Confectionery Market Report by Product Type (Hard-Boiled Sweets, Mints, Gums and Jellies, Chocolate, Caramels and Toffees, Medicated Confectionery, Fine Bakery Wares, and Others), Age Group (Children, Adult, Geriatric), Price Point (Economy, Mid-Range, Luxury), Distribution Channel (Supermarkets and Hypermarkets, Convenience Stores, Pharmaceutical and Drug Stores, Online Stores, and Others), and Region 2025-2033", offers a detailed analysis of the market…

India Facility Management Market Expected to Reach USD 7.13 Billion by 2034, Ind …

IMARC Group's latest research publication "India Facility Management Market Size, Share, Trends and Forecast by Solution, Service, Deployment Type, Organization Size, Vertical, and Region, 2026-2034" The India facility management market size was valued at USD 2.86 Billion in 2025 and is projected to reach USD 7.13 Billion by 2034, growing at a compound annual growth rate of 10.66% from 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-facility-management-market/requestsample

What is Facility Management?

Facility management refers to…

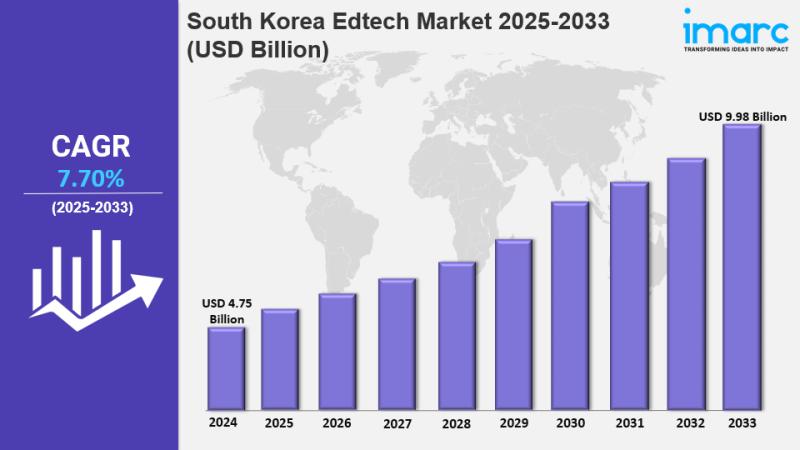

South Korea Edtech Market Share, Size, In-Depth Insights, Trends and Forecast To …

IMARC Group has recently released a new research study titled "South Korea Edtech Market Report by Sector (Preschool, K-12, Higher Education, and Others), Type (Hardware, Software, Content), Deployment Mode (Cloud-based, On-premises), End User (Individual Learners, Institutes, Enterprises), and Region 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview:

South Korea edtech market size reached USD…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…