Press release

Lithium Sulfate Production Plant Setup Cost Report: A Strategic Guide to Establishing Your Manufacturing Unit

Lithium Sulfate (Li2SO4) is an inorganic compound widely used in the production of lithium-ion batteries, ceramics, glass, pharmaceuticals, and as a catalyst in chemical synthesis. With the global surge in demand for electric vehicles (EVs), renewable energy storage systems, and advanced electronic devices, the need for Lithium Sulfate Production Plants has significantly increased.The IMARC Group explores the key aspects of setting up a Lithium Sulfate manufacturing facility, covering raw materials, machinery, safety protocols, cost analysis, and market outlook-providing a clear roadmap for entrepreneurs, manufacturers, and investors.

What is Lithium Sulfate?

Lithium Sulfate is a white, crystalline solid with high solubility in water. It is commonly available in anhydrous and monohydrate forms and exhibits properties valuable in both industrial and pharmaceutical applications.

Major Uses of Lithium Sulfate:

• Battery Manufacturing: Used in lithium-ion battery electrolytes and precursors.

• Glass and Ceramics: Enhances strength and thermal resistance in specialty glasses and glazes.

• Pharmaceuticals: Used in psychiatric medications and electrolyte balance therapies.

• Catalysts: Acts as a catalyst or reagent in fine chemical synthesis and polymerization processes.

The increasing adoption of clean energy solutions and electrification of transportation is directly contributing to the rising demand for lithium compounds, including Lithium Sulfate.

Request Your Sample to Get Started!: https://www.imarcgroup.com/lithium-sulfate-manufacturing-plant-project-report/requestsample

Setting Up a Lithium Sulfate Production Plant:

Establishing a Lithium Sulfate production facility involves multiple technical, operational, and regulatory steps. A robust setup ensures product quality, process efficiency, and environmental compliance.

Key Raw Materials and Chemical Process:

Raw Materials Required:

• Lithium Carbonate (Li2CO3) or Lithium Hydroxide (LiOH) - primary lithium sources.

• Sulfuric Acid (H2SO4) - reacts with lithium compounds to produce Lithium Sulfate.

Production Process Overview:

1. Reaction Phase:

o Lithium carbonate or lithium hydroxide is reacted with sulfuric acid in a controlled reactor.

o The exothermic reaction produces Lithium Sulfate and water (plus carbon dioxide if Li2CO3 is used).

2. Filtration and Purification:

o The solution is filtered to remove any impurities or unreacted solids.

o Impurities such as iron, magnesium, or calcium may be removed via precipitation or ion exchange.

3. Crystallization:

o The purified solution undergoes evaporation and controlled cooling to crystallize Lithium Sulfate.

4. Drying and Packaging:

o The crystals are dried to obtain the final monohydrate or anhydrous product and packed in moisture-resistant containers.

Get Instant Access-Buy Now!: https://www.imarcgroup.com/checkout?id=11035&method=1911

Plant Setup Requirements and Infrastructure:

1. Site Selection and Layout:

• Must ensure proximity to raw material suppliers and transport infrastructure.

• Adequate space for production zones, quality control labs, storage, and utilities.

2. Essential Equipment and Machinery:

• Reactors with acid-resistant linings

• Filtration units (pressure filters or centrifuges)

• Crystallizers and evaporators

• Drying systems (tray or rotary dryers)

• Storage tanks (for acid and lithium compounds)

• Packaging and handling units

• Waste treatment and emission control systems

3. Utilities Required:

• Electricity and water supply

• Steam generation systems

• Air compressors

• Exhaust and ventilation systems

• Effluent treatment facilities

Cost and Financial Analysis for Lithium Sulfate Plant:

Capital Expenditure (CapEx):

• Land & Infrastructure Development: Site preparation, plant construction, utilities.

• Machinery & Equipment: Reactors, filtration systems, crystallizers, dryers, etc.

• Safety & Environmental Systems: Emission control, ETPs, gas scrubbers.

Operating Expenditure (OpEx):

• Raw Materials: Lithium carbonate or hydroxide and sulfuric acid procurement.

• Labor Costs: Skilled and unskilled workers, chemical engineers, technicians.

• Utility Costs: Power, water, steam, and fuel consumption.

• Maintenance & Logistics: Regular upkeep of equipment, transportation costs.

• Regulatory Compliance: Licenses, inspections, and audits.

Revenue and Profitability:

• Revenue is primarily derived from the sale of battery-grade or industrial-grade Lithium Sulfate.

• Premium pricing is possible for high-purity products used in energy storage.

• Profit margins are influenced by lithium market dynamics, operational efficiency, and product purity.

Key Cost Components for Lithium Sulfate Manufacturing:

• Raw Materials: Lithium carbonate/hydroxide and sulfuric acid costs dominate input expenses.

• Processing Equipment: Cost of corrosion-resistant reactors and filtration systems.

• Energy Consumption: Significant electricity and steam usage for crystallization and drying.

• Labor and Safety Training: Skilled labor is required for handling chemicals safely.

• Waste Disposal: Chemical waste management and neutralization systems are critical.

Challenges and Considerations for Investors:

• Lithium Market Volatility: Prices for lithium compounds can fluctuate due to global demand-supply imbalances.

• Environmental Regulations: Strict rules for acid handling, effluent treatment, and air emissions must be met.

• High CapEx Requirements: Entry barriers due to expensive raw materials and plant infrastructure.

• Purity Standards: Meeting battery-grade lithium specifications requires advanced purification systems.

• Technology Upgrades: Continuous R&D investment is needed to improve yield, purity, and efficiency.

Global Market Outlook for Lithium Sulfate - 2025 and Beyond:

The global lithium market is expected to expand significantly, primarily driven by the clean energy transition. Lithium Sulfate, as a precursor in battery chemistry and industrial formulations, is poised to benefit from:

• Accelerated EV Production: Governments and OEMs globally are pushing for EV adoption.

• Energy Storage Systems: Grid-scale storage and portable electronics demand more lithium-based batteries.

• Strategic Mining Investments: Expansion of lithium mining and refining projects will support feedstock availability.

• Technological Advancements: Improved recycling methods and greener extraction technologies will support market growth.

Speak to an Analyst or Request a Custom Project Report: https://www.imarcgroup.com/request?type=report&id=11035&flag=C

Project Economics Snapshot:

Capital Investment Breakdown:

• Land and Site Development

• Plant Construction

• Equipment Installation

• Compliance and Licensing

Operating Cost Breakdown:

• Raw Material Costs

• Utility and Energy Costs

• Labor and Maintenance

• Quality Control and Packaging

Profitability Metrics:

• Total Revenue Forecast

• Net and Gross Margins

• Return on Investment (ROI)

• Payback Period Estimation

Conclusion:

Setting up a Lithium Sulfate Production Plant presents a strategic opportunity in the rapidly growing energy materials market. With robust demand from the battery and electronics sectors, the long-term outlook for Lithium Sulfate remains strong. However, careful attention must be paid to regulatory compliance, raw material sourcing, and process efficiency. By leveraging modern technology and adhering to best practices in safety and quality control, manufacturers can position themselves competitively in the global lithium value chain.

Customization Options Available:

• Plant Location: Selection of optimal location for the plant.

• Plant Capacity: Customization based on desired production capacity.

• Machinery: Choice between automatic, semi-automatic, or manual machinery.

• List of Machinery Providers: Identification of suitable machinery suppliers.

Services:

• Market Entry and Opportunity Assessment

• Competitive Intelligence and Benchmarking

• Procurement Research

• Pricing and Cost Research

• Sourcing Partner Identification

• Distribution Partner Identification

• Contract Manufacturer Identification

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lithium Sulfate Production Plant Setup Cost Report: A Strategic Guide to Establishing Your Manufacturing Unit here

News-ID: 4210728 • Views: …

More Releases from IMARC Group

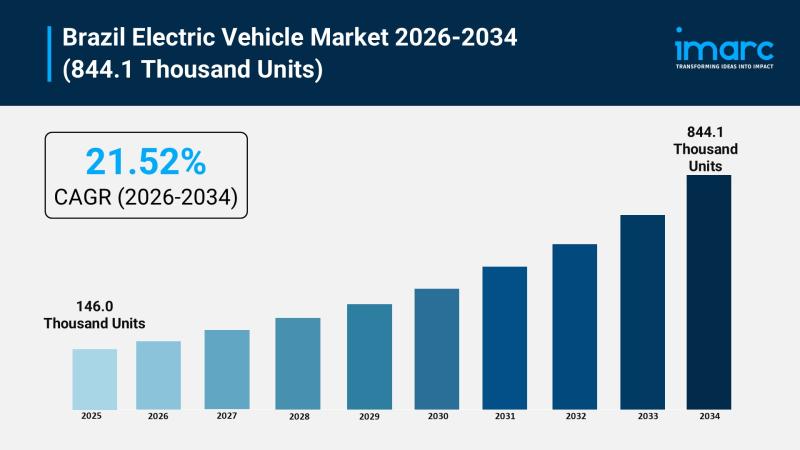

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

Titanium Sponge Manufacturing Plant DPR - 2026, Demand Analysis, Machinery, CapE …

Setting up a titanium sponge manufacturing plant positions investors in one of the most strategically vital segments of the global advanced materials supply chain. The titanium sponge industry is experiencing sustained growth propelled by increasing demand for high-performance materials in aerospace, automotive, and medical sectors. As global industries accelerate their adoption of lightweight, high-strength, and corrosion-resistant materials, and government policies continue to support domestic manufacturing of critical materials and clean-energy…

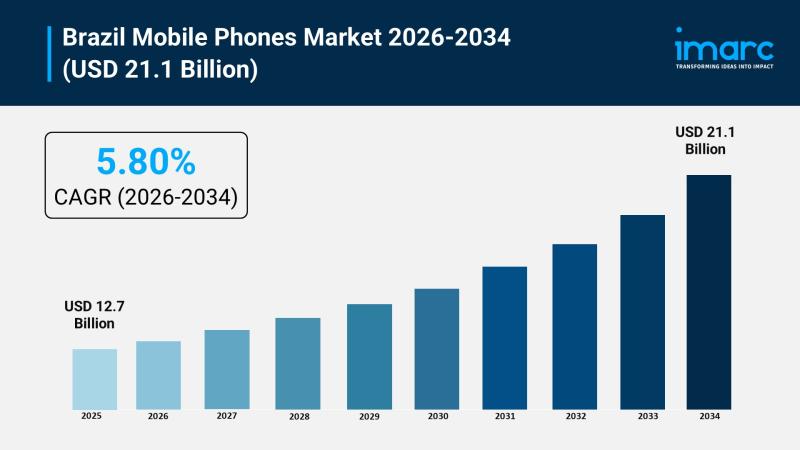

New IMARC Study: Digital Inclusion Initiatives and Online Retail Surge Propel Br …

The Brazil mobile phones market is currently witnessing steady growth, having reached a valuation of USD 12.7 Billion in 2025. Driven by rapid digital transformation and the increasing necessity for seamless connectivity in urban centers, the market is projected to reach USD 21.1 Billion by 2034. This trajectory represents a Compound Annual Growth Rate (CAGR) of 5.80% during the forecast period of 2026-2034.

Key Market Trends & Dynamics (2026-2034)

• Key Players:…

Ice Cream Manufacturing Plant DPR & Unit Setup - 2026: CapEx, OpEx & ROI Analysi …

Setting up an Ice Cream Manufacturing Plant positions investors in one of the most stable and essential segments of the food and beverage value chain, backed by sustained global growth driven by rising demand for premium frozen desserts, increasing consumption of desserts eaten at home, the expansion of food service establishments, and the dual-benefit advantages of serving both mass-market and premium consumption requirements across retail, foodservice, and household channels. As…

More Releases for Lithium

Lithium Compounds Market To Witness Massive Growth | Competitive Outlook Albemar …

Lithium compounds market is expected to gain market growth in the forecast period of 2020 to 2027. Data Bridge Market Research analyses the market to account 20.04 billion by 2027 growing with the CAGR of 20.90% in the above-mentioned forecast period. Huge investments in infrastructure developments is a vital factor driving the growth of lithium compounds market swiftly.

The Lithium Compounds Market research report assesses the ongoing as well as future…

Lithium Compounds Market 2020-2025 Global Analysis & Opportunity Assessment | Li …

The global Lithium Compound market size is projected to reach over USD 9 billion by 2025. Lithium is an alkali metal that is generally present among the soil, human body, animals, and plants. It is a light weight metal with less density when compared to other elements. The lithium compounds, primarily find its application in rechargeable and non-rechargeable batteries. The lithium is primarily used across glass & ceramics, Li-ion batteries,…

Lithium Compounds Market Analysis & Industry Outlook 2019-2025| Livent Corporati …

The global Lithium Compound market size is projected to reach over USD 9 billion by 2025. Lithium is an alkali metal that is generally present among the soil, human body, animals, and plants. It is a light weight metal with less density when compared to other elements. The lithium compounds, primarily find its application in rechargeable and non-rechargeable batteries. The lithium is primarily used across glass & ceramics, Li-ion batteries,…

Lithium Compounds Market Scenario & Industry Outlook 2019-2025| Livent Corporati …

The global lithium compound market size is projected to reach over USD 9 billion by 2025.The report on lithium compound market is aimed to equip report readers with versatile understanding on diverse marketing opportunities that are rampantly available across regional hubs. A thorough assessment and evaluation of these factors are likely to influence incremental growth prospects in the lithium compound market.

Request sample copy of this report at: https://www.adroitmarketresearch.com/contacts/request-sample/1445

Additionally, in this…

Lithium Fluoride Market players Jiangxu Ganfeng Lithium, Harshil Fluoride Brivo …

The developing in the glass, optics and electronic and electrical industries has initiated a high demand for Lithium and related compounds. Lithium and lithium based compounds are one the key substances that have dynamic usage, either as a feedstock or as product. One of the most commercially important compound is Lithium fluoride. Lithium fluoride is an odorless, crystalline lithium salt manufactured by the reaction of lithium hydroxide with hydrogen fluoride.…

Lithium Hydroxide Market | Key Players are FMC Corporation, Sociedad Quimica Min …

Lithium Hydroxide (LiOH) is an inorganic compound that is insoluble in water and partially soluble in ethanol. It is commercially available as a monohydrate (LiOH.H2O) and in anhydrous form, both of which are strong bases. On the basis of purity level, it is also available in battery grade and technical grade. Lithium hydroxide is manufactured by means of a metathesis reaction between calcium hydroxide and lithium carbonate and it finds…