Press release

Chopped Strand Mat Stitch Bonding Machine Market Set for 6.2% Growth Through 2035

The global chopped strand mat stitch bonding machine market enters a transformative decade as composite material innovation and manufacturing automation converge to reshape production capabilities across automotive, aerospace, and construction industries. With market valuations projected to surge from USD 325.0 million in 2025 to USD 593.2 million by 2035, representing an absolute increase of USD 268.2 million and a robust compound annual growth rate of 6.2%, equipment manufacturers, technology providers, and composite producers are strategically positioning themselves to capture emerging opportunities in precision bonding systems and intelligent manufacturing solutions.Dual-Phase Growth Strategy Defines Market Evolution

The chopped strand mat stitch bonding machine landscape demonstrates distinctive expansion characteristics across two critical development phases. During the initial period spanning 2025 through 2030, market valuations will advance from USD 325.0 million to USD 439.1 million, generating USD 114.1 million in incremental value representing 42.5% of total decade growth. This foundational phase emphasizes rising penetration of automated nonwoven manufacturing equipment in composite production facilities, increasing demand for high-performance fiber reinforcement solutions, and growing adoption of advanced stitching bonding technologies that address complex composite manufacturing requirements.

The subsequent acceleration phase from 2030 to 2035 promises intensified momentum as market values climb from USD 439.1 million to USD 593.2 million, contributing an additional USD 154.1 million constituting 57.5% of overall expansion. This maturation period will witness the proliferation of intelligent manufacturing systems, development of enhanced production efficiency features, and advancement of automated quality control systems. The growing adoption of lightweight composite materials in aerospace and automotive industries will drive demand for increasingly sophisticated stitch bonding solutions with specialized technical capabilities that meet stringent performance specifications.

Established Leaders and Innovation-Driven Competitors Shape Market Dynamics

The competitive landscape features specialized equipment manufacturers, automation technology companies, and nonwoven processing solution providers investing substantially in advanced manufacturing systems development and equipment performance optimization. Market leaders including Dilo Group maintain competitive advantages through comprehensive nonwoven manufacturing solutions with established engineering expertise and industrial-grade equipment capabilities developed over decades of precision manufacturing innovation.

Andritz Laroche differentiates through specialized material processing equipment emphasizing performance, reliability, and operational efficiency that appeal to composite manufacturers requiring consistent production quality. Autefa Solutions competes through innovative manufacturing systems focusing on automation and intelligent operation features that address next-generation composite production requirements.

Technology innovators such as A.Celli Nonwovens specialize in advanced production equipment with integrated technology solutions, while Techno Plants offers professional-grade manufacturing equipment with comprehensive technical support capabilities. Progressive Technologies delivers established industrial solutions with advanced automation technologies targeting high-performance applications in aerospace and automotive sectors.

Regional specialists including Jiangsu Yingyang Nonwoven Machinery, Zhentai Nonwoven Machinery, Qingdao Textile Machinery, and Changzhou Runyuan Warp Knitting Machinery provide competitive manufacturing capabilities and regional market expertise, particularly in rapidly expanding Asian markets where cost-performance ratios significantly influence procurement decisions and equipment deployment strategies.

Geographic Markets Reveal Differentiated Expansion Trajectories

China establishes global leadership with the highest projected growth rate of 8.4% compound annual growth rate through 2035, driven by rapid expansion of composite manufacturing infrastructure and increasing demand for automated production equipment. The country's growing automotive and aerospace sectors, combined with expanding construction material manufacturing, create significant demand for efficient nonwoven processing solutions. Government manufacturing upgrade initiatives support establishment of modern production facilities and automated manufacturing complexes, driving demand for advanced stitch bonding equipment throughout major industrial zones.

India demonstrates exceptional market potential with a 7.8% growth rate, supported by increasing industrial sector development and growing awareness of automated manufacturing equipment benefits. The country's expanding composite materials industry and rising manufacturing standards drive demand for advanced nonwoven processing solutions as manufacturing facilities gradually implement automated production equipment to maintain quality standards and operational efficiency.

Germany maintains technology leadership with a 7.1% growth rate through focus on manufacturing quality standards and advanced production technology adoption. German composite manufacturers implement sophisticated stitch bonding systems meeting stringent performance requirements and operational specifications, characterized by emphasis on equipment precision, operational efficiency, and compliance with comprehensive manufacturing standards.

Brazil records substantial growth at 6.5%, emphasizing manufacturing modernization and equipment upgrade initiatives as the country's expanding automotive and construction sectors gradually integrate automated production equipment to enhance manufacturing efficiency and product quality. The United States demonstrates solid expansion at 5.9%, focusing on technology advancement and production efficiency as established composite manufacturing industries implement comprehensive automation capabilities.

Technology Segments and Application Markets Drive Strategic Opportunities

Upper short-cut stitching machines command dominant market positioning with 52% market share through superior bonding quality and operational efficiency catering to diverse composite manufacturing applications. These systems deliver consistent material integrity and high-speed processing capabilities ensuring production flexibility across diverse material specifications, making them the preferred choice for composite manufacturers, automotive suppliers, aerospace contractors, and construction material producers.

The composite materials industry segment represents 68% of market demand, highlighting its position as the most significant application sector. This dominance stems from unique production requirements where consistent material bonding and structural integrity prove critical to final product performance. Stitch bonding machines suit these environments through superior material reinforcement capabilities delivered quickly and effectively during high-volume production runs.

Strategic Imperatives for Market Stakeholders and Report Beneficiaries

For established manufacturers seeking market expansion, opportunities exist through precision manufacturing leadership in upper short-cut systems, high-growth industrial applications targeting composite and automotive sectors, and manufacturing automation integration with Industry 4.0 capabilities. New entrants can capture market share through emerging market expansion strategies, energy efficiency innovations, and premium technology features including advanced automation and multi-layer processing capabilities.

Prospective report purchasers including composite material producers, automotive manufacturers, aerospace contractors, and equipment procurement professionals will find comprehensive insights regarding technology selection criteria, competitive positioning strategies, and geographic market opportunities. Manufacturing executives evaluating automation investments can leverage detailed market intelligence to optimize equipment procurement decisions and technology deployment strategies aligned with production efficiency objectives, quality enhancement requirements, and long-term competitive positioning across diverse composite manufacturing and nonwoven processing applications.

Get Instant Access for Only $5,000 | Don't Miss This Exclusive Offer!

https://www.futuremarketinsights.com/reports/sample/rep-gb-26790

Checkout Now to Access Industry Insights:

https://www.futuremarketinsights.com/checkout/26790

Explore Similar Insights

Strand Displacement Amplification (SDA) Market

https://www.futuremarketinsights.com/reports/strand-displacement-amplification-sda-market

Prestressed Concrete Wire and Strand Market

https://www.futuremarketinsights.com/reports/prestressed-concrete-wire-and-strand-market

Machine Tool Oils Market

https://www.futuremarketinsights.com/reports/machine-tool-oils-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Chopped Strand Mat Stitch Bonding Machine Market Set for 6.2% Growth Through 2035 here

News-ID: 4209550 • Views: …

More Releases from Future Market Insights

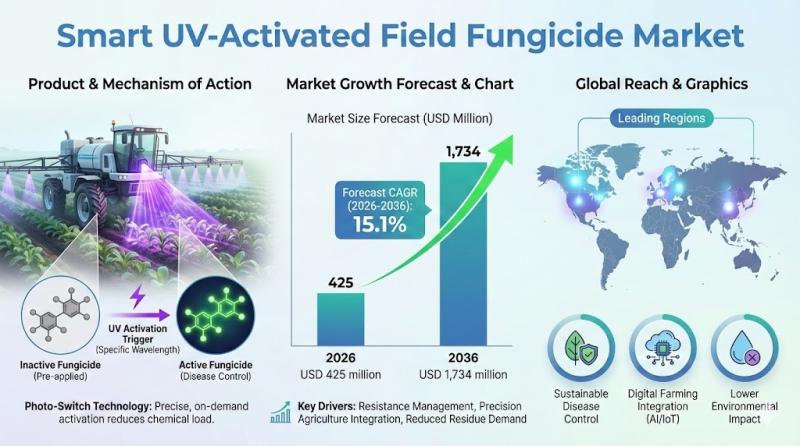

Smart UV-Activated Field Fungicide Market to Grow at 15.1% CAGR, Surpassing USD …

Market Overview: Precision Fungicides Drive Sustainable Growth

The global Smart UV-Activated Field Fungicide Market is witnessing rapid expansion as agriculture transitions toward precision-led, environmentally responsible crop protection. Valued at USD 425 million in 2026, the market is forecast to reach USD 1,734 million by 2036, registering a strong CAGR of 15.1%. UV-activated fungicides remain inactive until exposed to specific ultraviolet light conditions, ensuring targeted disease control while significantly reducing chemical overuse…

Global PET Depolymerization Technology Market Outlook 2026-2036: Growth Driven b …

Global PET Depolymerization Technology Market Forecast and Strategic Insights

The PET Depolymerization Technology Market is witnessing rapid adoption across packaging, textiles, and industrial polymer sectors. Valued at USD 1.5 billion in 2026, the market is expected to reach USD 4.3 billion by 2036, reflecting a robust CAGR of 11.1%. Growth is primarily shaped by increasing regulatory oversight, feedstock traceability requirements, and approvals for food and industrial applications. Early alignment with these…

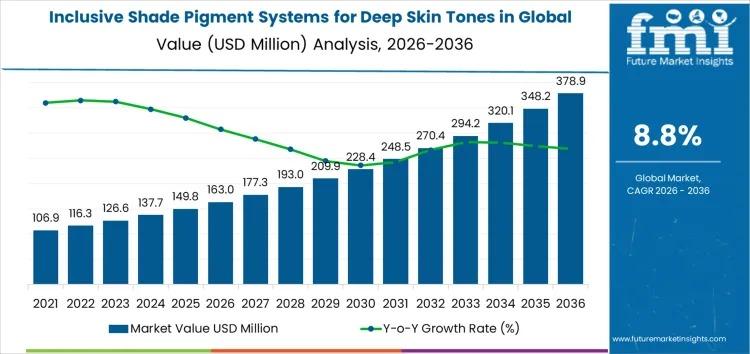

Global Inclusive Shade Pigment Systems for Deep Skin Tones Market Forecast 2026- …

The Inclusive Shade Pigment Systems for Deep Skin Tones in Global Brands Market is on a strong growth trajectory, valued at USD 163 million in 2026 and projected to reach USD 378.9 million by 2036, reflecting a CAGR of 8.8%. Growth is increasingly driven by formulation performance requirements rather than shade range expansion alone. Brand preference now emphasizes pigment dispersion stability, undertone accuracy, and batch-to-batch consistency across darker shades. Suppliers…

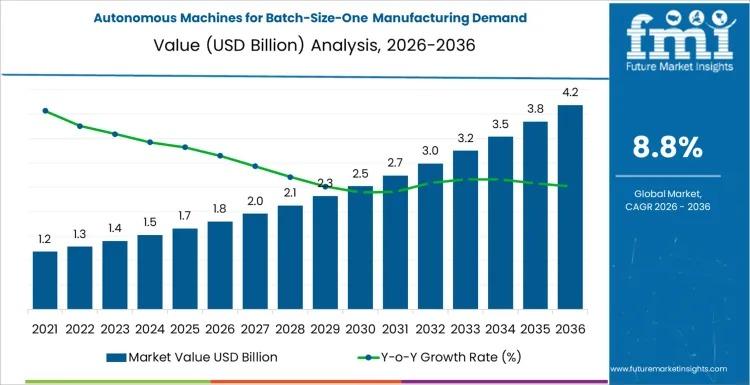

Global Autonomous Machines for Batch-Size-One Manufacturing Market 2026-2036: Gr …

The Autonomous Machines for Batch-Size-One Manufacturing Market is entering a high-growth phase as manufacturers seek to produce highly customized products efficiently while reducing setup costs and improving responsiveness. The market is projected to expand from USD 1.8 billion in 2026 to USD 4.2 billion by 2036, reflecting a strong CAGR of 8.8%. Growth is increasingly shaped by value creation across flexible automation, adaptive software, and modular hardware systems rather than…

More Releases for Machine

Concrete Block Machine market: Lucrative Segments and their Underlying Factors | …

"

The Concrete Block Machine global market is thoroughly researched in this report, noting important aspects like market competition, global and regional growth, market segmentation and market structure. The report author analysts have estimated the size of the global market in terms of value and volume using the latest research tools and techniques. The report also includes estimates for market share, revenue, production, consumption, gross profit margin, CAGR, and other key…

Agriculture Machine to Machine (M2M) Agriculture Machine to Machine (M2M)

Global Agriculture Machine to Machine (M2M) market study offers an all-inclusive analysis of the major strategies, corporate models, and market shares of the most noticeable players in this market. Significant market players of market their aggressive scene, improvement plans and arrangements are clarified in the research report. Further, the market status and SWOT analysis are conducted on a regional and country level to prepare development plans and analyse the market…

Machine To Machine (M2M) Connections Market

Machine to Machine (M2M) Connections Market Research study which offers insights of in-depth research on historic and current market size along with the expected future prospects of the market and emerging trends in the market. The Machine to Machine (M2M) Connections Market report provides crucial information about the market, including Opinions from Industry experts, and the recent progressions and developments of the Machine to Machine (M2M) Connections Market.

Mobile, other connected…

Drilling Machine Market by Type (Sensitive Drilling Machine, Upright Drilling Ma …

Asia-Pacific serves as the most productive region as compared to others with diverse industry verticals significantly investing in drilling machine. Moreover, various domestic players are investing in the automotive and military & defense sectors, which is anticipated to boost the demand for drilling machines and its components to complete the respective operations with reduced labor cost and high precision of work within optimized time. Furthermore, the drilling machine market is…

Drilling Machine Market Report 2018: Segmentation by Type (Portable Drilling Mac …

Global Drilling Machine market research report provides company profile for Halliburton, Atlas Copco, Torquado Drilling Accessories, DATRON, DMTG, DMG MORI, SMTCL, NewTech Drilling Products, Baker Huges, Cheston, National Oilwell Varco and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the…

Washing Machine Market Report 2018: Segmentation by Washing Machine Type (Drum-t …

Global Washing Machine market research report provides company profile for Frigidaire (US), Arbreau (US), Kenmore (US), ECOAP (China), Turbo Series (Korea), Avanti (Denmark), Fisher & Paykel (New Zealand), Globe House Products (US), GE (US), LG (Korea), Electrolux (Sweden), Samsung (Korea), Speed Queen(US), Bosch (Germany) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018…