Press release

Setup Report on PCB (Printed Circuit Board) Plant: Cost and Economics

A Printed Circuit Board (PCB) is a crucial electronic component that mechanically supports and electrically connects various electronic parts using conductive tracks, pads, and layers of copper laminated on a non-conductive base. It serves as the backbone of most electronic devices, from consumer gadgets and medical equipment to automotive systems and industrial machinery. PCBs can be single-sided, double-sided, or multilayer, depending on complexity and application, and they enable compact, efficient, and reliable functioning of electronic circuits.Setting up a PCB manufacturing plant involves selecting suitable land, installing machinery for designing, etching, laminating, and testing boards, ensuring compliance with environmental and safety standards, hiring skilled technicians, and establishing raw material supply chains.

IMARC Group's report, titled "PCB (Printed Circuit Board) Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a PCB (printed circuit board) manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/pcb-manufacturing-plant-project-report/requestsample

PCB (Printed Circuit Board) Industry Outlook 2025:

The PCB (Printed Circuit Board) industry outlook for 2025 indicates steady growth driven by increasing demand for advanced electronics, 5G infrastructure, electric vehicles, and IoT applications. Technological advancements in miniaturization, flexible PCBs, and high-density interconnects are expected to enhance production efficiency and performance. Asia-Pacific remains the dominant manufacturing hub, supported by strong supply chains and government initiatives. Sustainability and eco-friendly manufacturing practices are gaining prominence, shaping future industry standards and competitiveness globally.

Key Insights for PCB (Printed Circuit Board) Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a PCB (Printed Circuit Board) Plant:

• Raw Materials: Land and Infrastructure: Cost of land acquisition, construction, and facility layout for production, storage, and administration.

• Machinery and Equipment: Investment in etching machines, drilling systems, laminators, plating units, and testing equipment.

• Raw Materials: Procurement of copper-clad laminates, solder masks, chemicals, and other consumables.

• Labor and Training: Expenses for hiring skilled operators, engineers, and staff training programs.

• Utilities and Energy: Costs associated with electricity, water, and waste treatment systems.

• Quality Control and Testing: Setup of inspection, testing, and certification units to ensure product standards.

• Licensing and Compliance: Regulatory approvals, environmental clearances, and safety certifications.

• Working Capital: Operational costs for inventory management, maintenance, and logistics.

Economic Trends Influencing PCB (Printed Circuit Board) Plant Setup Costs 2025:

• Raw Material Price Volatility: Fluctuations in copper, resin, and chemical prices continue to impact overall production costs.

• Supply Chain Disruptions: Global logistics challenges and semiconductor shortages are influencing equipment and material availability.

• Rising Energy Costs: Increasing electricity and fuel prices are driving up manufacturing and operational expenses.

• Technological Advancements: Adoption of automation and AI-based production systems is raising initial investment but improving long-term efficiency.

• Labor Market Dynamics: Higher demand for skilled technicians and engineers is contributing to wage growth.

• Environmental Regulations: Stricter sustainability and waste management standards are adding compliance-related costs.

• Government Incentives: Subsidies and tax benefits for electronics manufacturing are helping offset setup expenditures in key regions.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9086&flag=C

Challenges and Considerations for Investors in PCB (Printed Circuit Board) Plant Projects:

• High Capital Investment: Significant upfront costs for advanced machinery, infrastructure, and quality assurance systems.

• Technological Complexity: Rapid innovation in multilayer and flexible PCBs requires continuous equipment upgrades and R&D spending.

• Supply Chain Dependency: Reliance on imported raw materials and components can create cost and timeline uncertainties.

• Environmental Compliance: Strict regulations on chemical disposal and emissions demand sustainable manufacturing practices.

• Skilled Workforce Shortage: Limited availability of trained personnel affects productivity and operational efficiency.

• Market Competition: Intense competition from established Asian manufacturers pressures pricing and profit margins.

• Economic Fluctuations: Currency volatility and changes in trade policies influence cost structures and export viability.

Conclusion:

The establishment of a PCB (Printed Circuit Board) manufacturing plant in 2025 presents significant growth opportunities aligned with expanding demand across electronics, automotive, and telecommunications sectors. However, success depends on careful consideration of capital requirements, technological advancements, and regulatory compliance. Strategic investment in automation, sustainable production, and skilled workforce development can enhance operational efficiency and competitiveness. With favorable government incentives and evolving market dynamics, investors who adopt a long-term, innovation-driven approach are well positioned to capitalize on the global shift toward advanced and eco-friendly PCB production.

Buy Now: https://www.imarcgroup.com/checkout?id=9086&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Setup Report on PCB (Printed Circuit Board) Plant: Cost and Economics here

News-ID: 4208696 • Views: …

More Releases from IMARC Group

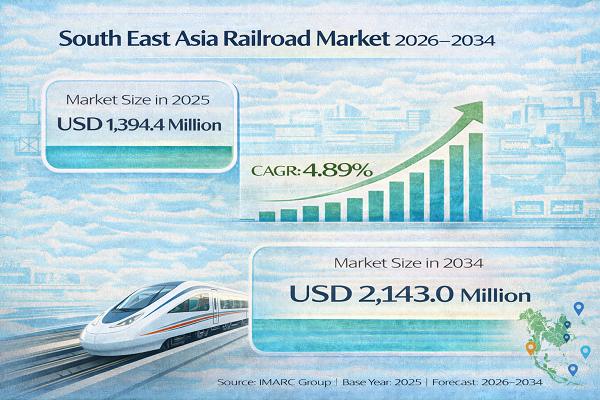

South East Asia Railroad Market Set to Reach USD 2,143.0 Million by 2034, Expand …

South East Asia Railroad Market : Report Introduction

According to IMARC Group's report titled "South East Asia Railroad Market Size, Share | Forecast 2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Get Instant Access to the Free Sample (Corporate Email Required): https://www.imarcgroup.com/south-east-asia-railroad-market/requestsample

South East Asia Railroad Market Overview (2026-2034)

The South East Asia railroad market size reached USD 1,394.4 Million in 2025. The market…

Amino Acid Production Plant Cost 2026: CapEx, OpEx & ROI Analysis

Setting up an Amino Acid Production Plant positions investors in a rapidly growing industrial segment, driven by increasing global demand for amino acids across multiple end-use sectors. Amino acids are organic compounds that form the building blocks of proteins and play critical roles in metabolism, enzyme function, and nutritional supplementation. The integrated manufacturing process involves raw material handling (such as glucose, molasses, or corn syrup), fermentation or chemical synthesis, purification,…

Flow Battery Manufacturing Plant Cost 2026: Feasibility Study and Profitability …

Setting up a Flow Battery Manufacturing Plant positions investors in a rapidly expanding segment of the energy storage industry. Flow batteries are electrochemical storage systems where energy is stored in liquid electrolytes that flow through electrochemical cells. They offer unique advantages including long cycle life, modular scalability, high safety, and the ability to discharge fully without damage. These attributes make them ideal for grid-scale energy storage, renewable energy integration, EV…

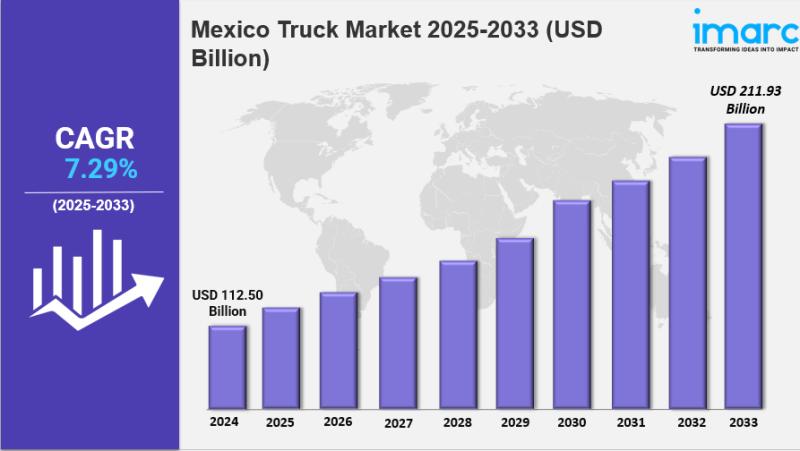

Mexico Truck Market Size, Share, Industry Overview, Trends and Forecast 2033

IMARC Group has recently released a new research study titled "Mexico Truck Market Size, Share, Trends and Forecast by Vehicle Type, Tonnage Capacity, Fuel Type, Application, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Truck Market Overview

The Mexico truck market size reached USD 112.50 Billion in 2024. Looking forward, IMARC Group expects…

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…