Press release

Aluminum Honeycomb Core Market to Reach USD 3,446.92 million by 2032, Growing at a CAGR of 6.80% says Credence Research

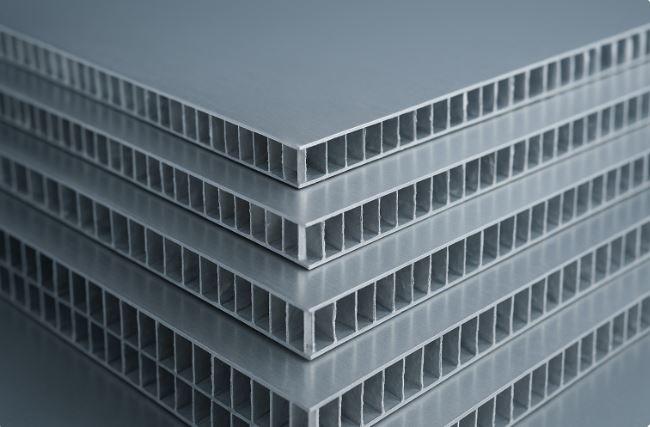

Market OverviewThe Global Aluminum Honeycomb Core Market size was valued at USD 1,282.78 million in 2018, expanding to USD 1,960.93 million in 2024, and is projected to reach USD 3,446.92 million by 2032, registering a CAGR of 6.80% during the forecast period. This consistent growth reflects the increasing demand for lightweight, high-strength materials across various industries, including aerospace, automotive, and construction. The aluminum honeycomb core's unique hexagonal structure offers superior strength-to-weight ratios, making it an essential component in modern engineering applications.

The growing emphasis on sustainable materials and energy-efficient designs has significantly influenced the adoption of aluminum honeycomb cores. These cores help reduce material usage while maintaining mechanical integrity, enabling manufacturers to meet stringent fuel efficiency and performance standards. Furthermore, rising infrastructure development and the modernization of transport systems in emerging economies have accelerated product adoption. The market's relevance extends beyond traditional aerospace use, finding new ground in electric vehicles, building panels, and wind turbine blades.

Technological innovations such as precision extrusion and advanced bonding techniques have enhanced product quality and cost efficiency. As a result, aluminum honeycomb cores have become a preferred choice for next-generation engineering solutions. The market is expected to continue its robust growth, supported by the global trend toward lightweighting and the rising demand for sustainable, corrosion-resistant materials.

Preview the report with a detailed sample and understand how it can benefit your business strategy. Request a free sample https://www.credenceresearch.com/report/aluminum-honeycomb-core-market

Market Drivers

Rising Demand for Lightweight Materials

The growing need for lightweight materials across automotive, aerospace, and transportation sectors remains a primary growth driver. Aluminum honeycomb cores provide excellent stiffness-to-weight ratios, leading to reduced fuel consumption and improved performance. In aerospace, they play a critical role in aircraft flooring, panels, and control surfaces, reducing overall weight by up to 40% compared to traditional materials. Additionally, lightweight components contribute to lower greenhouse gas emissions, helping companies meet stringent environmental regulations. The increasing trend toward electric and hybrid vehicles further accentuates the demand for weight-optimized materials. Manufacturers are investing in research and development to improve core efficiency, making aluminum honeycomb solutions more accessible and versatile for various industrial applications.

Expansion in the Construction Industry

The global construction industry's focus on green and sustainable materials has enhanced aluminum honeycomb adoption. Architects and engineers increasingly use honeycomb panels in facades, ceilings, and claddings due to their strength, durability, and fire resistance. This trend is particularly visible in high-rise commercial projects in Asia-Pacific and the Middle East, where lightweight yet strong materials are preferred for safety and energy efficiency. Furthermore, the material's corrosion resistance ensures long-term structural integrity in harsh environmental conditions. Governments' push for sustainable building certifications, such as LEED, has also reinforced the use of aluminum honeycomb panels. Combined with design flexibility, this has created a growing market for innovative architectural solutions.

Technological Advancements in Manufacturing

Innovations in bonding, lamination, and extrusion techniques have reduced production costs and improved the precision of honeycomb cores. Companies now offer customizable core geometries for specific mechanical and thermal properties. These advancements have expanded market accessibility, making aluminum honeycomb cores suitable for both high-end aerospace applications and mid-tier industrial uses. In addition, automation in manufacturing processes ensures higher throughput and quality consistency, reducing wastage and operational costs. Industry players are also experimenting with hybrid materials and coatings to enhance fire resistance, durability, and surface aesthetics, driving broader adoption across emerging sectors such as railways and marine engineering.

Sustainability and Recyclability Factors

The market benefits from growing environmental awareness and regulatory mandates promoting recyclable materials. Aluminum is 100% recyclable without loss of strength, aligning perfectly with circular economy goals. Manufacturers are integrating recycled aluminum in production, thereby minimizing carbon emissions and appealing to eco-conscious customers. Beyond environmental benefits, sustainable practices also offer economic advantages, as the use of recycled materials reduces dependence on primary aluminum sources and stabilizes raw material costs. Rising consumer preference for eco-friendly products further encourages companies to adopt sustainable manufacturing processes, strengthening market demand.

Market Challenges

High Production Costs

Despite its benefits, the aluminum honeycomb core's manufacturing process remains capital-intensive. Advanced machinery and bonding technologies significantly raise production costs, making it difficult for small-scale manufacturers to compete. The need for precise quality control and specialized labor adds to the financial burden. Additionally, energy-intensive production processes contribute to higher operating expenses, impacting pricing strategies in competitive markets. For new entrants, these cost barriers can slow down market penetration despite high demand for lightweight materials.

Complex Fabrication and Handling

The intricate hexagonal structure requires precision during fabrication and assembly. Improper handling can lead to core deformation or delamination, affecting product integrity and increasing wastage rates during manufacturing. Transportation and installation also require careful handling to prevent damage, adding logistical complexity. The requirement for trained personnel and specialized equipment further limits adoption in smaller industrial setups. These factors collectively pose operational challenges that need mitigation through process standardization and employee training.

Competition from Alternative Materials

Composite materials such as Nomex, carbon fiber, and thermoplastic cores offer competitive strength-to-weight ratios. Their increasing use in automotive and aerospace applications poses a challenge to aluminum honeycomb cores, especially in high-performance sectors. Certain composites also provide superior thermal resistance and electromagnetic shielding, which aluminum cores cannot fully match. As a result, manufacturers must innovate and differentiate their products through performance optimization, cost efficiency, and sustainability to maintain market share.

Market Volatility in Raw Material Prices

Fluctuating aluminum prices impact production costs and profit margins. Market instability, driven by geopolitical tensions or supply chain disruptions, can hinder manufacturers' ability to maintain consistent pricing and profitability. Exchange rate fluctuations in global trade further exacerbate cost unpredictability. Additionally, scarcity of high-grade aluminum or reliance on imports in certain regions can disrupt supply chains, affecting production schedules and long-term contracts.

Market Opportunity

Growing Adoption in Electric Vehicles (EVs)

With the automotive industry's shift toward electrification, aluminum honeycomb cores are gaining traction in EV body structures and battery enclosures. Their lightweight nature enhances energy efficiency and range, creating a promising opportunity for market expansion. Manufacturers are exploring hybrid core solutions that integrate aluminum with composites for optimized weight reduction. Furthermore, government incentives for EV production and stringent emission regulations globally are accelerating the integration of lightweight materials in vehicle designs. This trend is expected to continue, opening new revenue streams for aluminum honeycomb core suppliers.

Increased Demand in Aerospace Modernization

Airlines are investing in next-generation aircraft with enhanced fuel efficiency. Lightweight interior panels and structural components made from aluminum honeycomb cores support these advancements, offering long-term contracts for suppliers. Airlines also require durable and fire-resistant materials to meet safety certifications. Rising air travel in emerging markets has expanded the global fleet, creating additional demand for advanced materials. Collaborations between aerospace manufacturers and honeycomb core suppliers are fostering innovation and boosting product adoption.

Emerging Applications in Renewable Energy

The renewable energy sector presents significant potential, especially in wind turbine manufacturing and solar panel reinforcement. The use of honeycomb cores helps improve structural rigidity while minimizing weight. Lightweight turbine blades enable higher rotational speeds, improving energy efficiency and output. Solar panel manufacturers are also leveraging honeycomb structures for enhanced durability and easier installation. As countries invest heavily in renewable infrastructure, these applications represent a sustainable growth avenue for the market.

Expanding Use in Architectural Innovations

Modern architectural projects increasingly demand materials that combine aesthetic appeal with structural efficiency. Aluminum honeycomb cores are now being used in large-scale stadiums, airports, and smart buildings, offering design flexibility and energy-efficient solutions. Their lightweight nature allows architects to create expansive, open spaces without compromising safety or durability. Additionally, coatings and finishes can be customized for aesthetic requirements, further expanding their appeal in contemporary construction projects. Regulatory encouragement for energy-efficient and fire-resistant materials also boosts market opportunities in urban development initiatives.

Market Segmentation

By Grade Type:

• 3003 Aluminum Honeycomb Core

• 5052 Aluminum Honeycomb Core

• 5056 Aluminum Honeycomb Core

• Commercial-Grade Aluminum Honeycomb Core

By Application:

• Aerospace

• Automotive

• Construction

• Others

By Region:

North America

• U.S.

• Canada

• Mexico

Europe

• UK

• France

• Germany

• Italy

• Spain

• Russia

• Belgium

• Netherlands

• Austria

• Sweden

• Poland

• Denmark

• Switzerland

• Rest of Europe

Asia Pacific

• China

• Japan

• South Korea

• India

• Thailand

• Indonesia

• Vietnam

• Malaysia

• Philippines

• Taiwan

• Rest of Asia Pacific

Latin America

• Brazil

• Argentina

• Peru

• Chile

• Colombia

• Rest of Latin America

Middle East & Africa

• GCC Countries

• South Africa

• Rest of the Middle East and Africa

Regional Analysis

North America

North America dominates the aluminum honeycomb core market, driven by its strong aerospace and defense manufacturing base. The U.S. leads in adoption due to Boeing's extensive use of lightweight composites, while Canada and Mexico contribute through automotive and construction applications. Additionally, technological innovation hubs in the U.S. are developing advanced manufacturing processes to enhance product performance. Government contracts in defense and aviation sectors also provide stable demand for high-quality aluminum honeycomb cores. This combination of industrial strength and innovation continues to make North America a significant regional market.

Europe

Europe maintains a substantial market share supported by technological advancements and sustainability mandates. Germany, France, and the UK are key markets with leading aerospace firms and automotive manufacturers integrating honeycomb structures for lightweight efficiency. European manufacturers emphasize high-performance materials for both commercial aviation and luxury automotive sectors. Government policies promoting environmental sustainability further encourage the use of recyclable aluminum materials. Research collaborations among European universities and industrial players also accelerate innovation, contributing to the region's competitiveness in this market.

Asia-Pacific

Asia-Pacific is the fastest-growing regional market, propelled by large-scale industrialization in China, India, and South Korea. The region's expanding EV production and infrastructure development are significant growth contributors. China remains the largest producer and consumer, supported by favorable government incentives. Rapid urbanization and infrastructure expansion in India and Southeast Asia are also driving the adoption of lightweight construction materials. Investments in domestic aerospace and defense industries further strengthen the region's position in the aluminum honeycomb core market.

Latin America

The Latin American market shows moderate growth, with Brazil and Mexico focusing on adopting lightweight materials in automotive and construction sectors. Economic recovery and urban development projects are stimulating market demand. Additionally, local manufacturers are exploring collaborations with global suppliers to access advanced materials and technologies. Government policies promoting sustainable infrastructure development create opportunities for honeycomb core adoption. Expansion in the renewable energy sector, including wind and solar projects, also contributes to market potential in the region.

Middle East & Africa

The Middle East & Africa region is emerging steadily due to the rise in commercial infrastructure projects and the need for sustainable building materials. GCC countries are particularly investing in advanced architectural panels and aerospace components incorporating aluminum honeycomb cores. Industrialization in South Africa and other parts of the Middle East is increasing the demand for lightweight and durable materials. Strategic collaborations with international suppliers are also fostering technology transfer and boosting regional market capabilities. The growing emphasis on energy-efficient construction and transportation solutions further strengthens market prospects.

Top Companies

• Hexcel Corporation

• Alcoa Corporation

• Arconic Corporation

• Kaiser Aluminum Corporation

• Dongguan Jinyu Aluminum Co., Ltd.

• Shanghai Metal Corporation

• Nippon Light Metal Co., Ltd.

Recent Developments

• In June 2025, Hexcel Corporation entered a long-term partnership with Kongsberg Defence & Aerospace (KONGSBERG) during the Paris Air Show. This collaboration strengthens Hexcel's role as a premier supplier of advanced composite materials for KONGSBERG's defense and aerospace programs, focusing on lightweight solutions.

• In August 2023, Arconic Corporation was acquired by Apollo Global Management in a $5.2 billion all-cash transaction, with additional investment from Irenic Capital Management. The acquisition provides Arconic with enhanced resources and strategic backing to support long-term expansion in aluminum products and architectural solutions.

Reasons to Purchase this Report:

• Gain in-depth insights into the market through both qualitative and quantitative analyses, incorporating economic and non-economic factors, with detailed segmentation and sub-segmentation by market value (USD Billion).

• Identify the fastest-growing regions and leading segments through analysis of geographic consumption trends and the key drivers or restraints affecting each market.

• Track the competitive landscape with updated rankings, recent product launches, strategic partnerships, business expansions, and acquisitions over the past five years.

• Access comprehensive profiles of key players, featuring company overviews, strategic insights, product benchmarking, and SWOT analyses to assess market positioning and competitive advantages.

• Explore current and projected market trends, including growth opportunities, key drivers, challenges, and limitations across developed and emerging economies.

• Leverage Porter's Five Forces analysis and Value Chain insights to evaluate competitive dynamics and market structure.

• Understand how the market is evolving and uncover future growth opportunities and emerging trends shaping the industry.

Related Reports -

Shape Memory Alloys Market: https://www.credenceresearch.com/report/shape-memory-alloys-market

Galvanized and Coated Iron and Steel Sheets Market - https://www.credenceresearch.com/report/galvanized-and-coated-iron-and-steel-sheets-market

Follow Us:

https://www.linkedin.com/company/credenceresearch/

https://www.facebook.com/CredenceResearch

Credence Research Europe LTD - 128 City Road, London, EC1V 2NX, UNITED KINGDOM

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 2000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Honeycomb Core Market to Reach USD 3,446.92 million by 2032, Growing at a CAGR of 6.80% says Credence Research here

News-ID: 4208229 • Views: …

More Releases from Credence Research Inc.

Renal Cell Carcinoma (RCC) Drugs Market Projected to Hit USD 5,776.4 Million by …

Market Outlook

The Renal Cell Carcinoma (RCC) Drugs Market is poised for steady expansion as global healthcare systems continue to prioritize advanced oncology therapeutics. Valued at USD 3,873.8 million in 2024, the market is projected to reach USD 5,776.4 million by 2032, reflecting a 6.13% CAGR during 2024-2032. This growth trajectory is strongly supported by rising RCC incidence worldwide, particularly in aging populations, and increasing preference for early diagnostic interventions. Pharmaceutical…

Smart Home Hub Market Projected to Hit USD 31629.5 Million by 2032, Expanding at …

Market Outlook

The Smart Home Hub Market was valued at USD 12,522 million in 2024 and is projected to surge to USD 31,629.5 million by 2032, reflecting a robust CAGR of 12.28% during the forecast period. According to Credence Research, market growth is strongly driven by rising consumer adoption of connected devices, expanding home automation ecosystems, and increasing demand for centralized control platforms that streamline interoperability among multiple smart appliances. Enhanced…

Stem Cells Market Projected to Hit USD 5,380.3 Million by 2032, Expanding at 11. …

Market Outlook

The Stem Cells Market is poised for significant expansion, with its valuation rising from USD 2,235.6 million in 2024 to USD 5,380.3 million by 2032, reflecting a robust CAGR of 11.66%. Growth is strongly influenced by accelerating investments in regenerative medicine, increasing clinical applications across orthopedics, neurology, cardiology, and oncology, and expanding approvals for stem-cell-based therapies. Advancements in induced pluripotent stem cells (iPSCs), adult stem cell technologies, and stem…

Solvent Cement Market Projected to Hit USD 5,188 Million by 2032, Expanding at 5 …

Market Outlook

The Solvent Cement Market is poised for steady expansion, with its valuation rising from USD 3,355 million in 2024 to an expected USD 5,188 million by 2032, reflecting a healthy CAGR of 5.6%. According to Credence Research, market growth is strongly influenced by expanding construction activity, rapid urban infrastructure upgrades, and the rising adoption of PVC, CPVC, and ABS piping systems in residential, commercial, and industrial applications. Solvent cement's…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…