Press release

Rupture Disc Market Enhancing Industrial Safety and Process Reliability with Advanced Pressure Relief Solutions

Global Rupture Disc market to reach US$ 914.2 million by 2033. Due to increasing awareness towards industrial safety, there has been a significant demand for industrial safety gears, accessories and process measures. Recently, there has been an increase in demand for high-performance rupture discs. Key manufacturers are adhering to variety of operating safety regulations in order to meet dynamic industrial demand and enhance product sales globally. Regulatory authorities have developed several regulations to improve operational safety. The global market for rupture disc is expected to create an incremental opportunity of about US$ 284.6 Mn during 2023-2033, growing at a CAGR of 3.8% between 2023 and 2033.Get a Sample PDF Brochure of the Report: https://www.persistencemarketresearch.com/samples/30133

Ensuring Safety in Industrial Operations

Rupture discs are critical safety devices designed to protect pressure vessels, pipelines, and industrial equipment from overpressure situations. By providing a controlled release point for excess pressure, rupture discs prevent catastrophic failures, equipment damage, and potential hazards to personnel. Unlike traditional pressure relief systems, rupture discs offer a fast-acting, reliable solution that responds immediately when pressure exceeds predetermined limits. Industries such as chemical processing, oil and gas, pharmaceuticals, and power generation rely on these devices to maintain safe operational conditions, prevent accidents, and ensure compliance with stringent safety regulations.

Fast and Reliable Pressure Relief

The primary advantage of rupture discs is their ability to provide instantaneous pressure relief. These devices are engineered to burst at precise pressure thresholds, offering a predictable and reliable response to overpressure scenarios. The rapid action of rupture discs is particularly important in systems handling hazardous chemicals or high-pressure gases, where even minor delays in pressure release could result in dangerous situations. By eliminating lag times, rupture discs protect sensitive equipment, minimize the risk of explosions or leaks, and maintain uninterrupted industrial operations. Their reliability and simplicity make them an indispensable component in safety-critical applications.

Read More In Detail: https://www.persistencemarketresearch.com/market-research/rupture-disc-market.asp

Enhancing Process Reliability

Beyond safety, rupture discs contribute to overall process reliability. In many industrial systems, maintaining stable pressure is essential for operational efficiency and product quality. Rupture discs act as a safeguard, preventing unexpected pressure spikes that could disrupt processes or damage equipment. By ensuring that systems operate within safe pressure ranges, these devices help maintain consistent flow rates, optimal production conditions, and minimal downtime. Industries that prioritize process reliability-such as pharmaceuticals, food and beverage, and petrochemicals-benefit from the peace of mind and operational continuity provided by advanced rupture disc technology.

Versatility Across Industries

Rupture discs are highly versatile and find application across a wide range of industries. In oil and gas, they protect pipelines, storage tanks, and processing equipment from sudden pressure surges. In chemical and pharmaceutical plants, rupture discs safeguard reactors, autoclaves, and pressure vessels, ensuring that delicate production processes remain undisturbed. Food and beverage industries utilize rupture discs in high-pressure processing and carbonation systems to maintain safety and product consistency. Power generation facilities depend on these devices to protect boilers, turbines, and condensers from overpressure conditions. This adaptability highlights the importance of rupture discs as universal safety components across industrial sectors.

Technological Advancements Driving Adoption

Recent technological advancements have enhanced the performance, reliability, and applicability of rupture discs. Modern discs are available in a variety of materials, including stainless steel, nickel alloys, and burst-rated polymers, enabling their use in diverse chemical and temperature environments. Advanced designs, such as reverse buckling and scored domes, provide precise burst characteristics and long-term stability under fluctuating pressures. Some rupture discs now feature integrated sensors and monitoring systems, allowing real-time tracking of pressure conditions and early detection of potential system issues. These innovations ensure that rupture discs continue to meet the evolving demands of modern industrial operations.

Integration with Safety Systems

Rupture discs are increasingly integrated with comprehensive safety systems, including relief valves, pressure sensors, and automated shutdown mechanisms. This integration allows industries to implement multi-layered protection strategies that optimize both safety and operational efficiency. In complex processing plants, rupture discs act as a first line of defense, while complementary devices handle controlled depressurization or shutdown protocols. The synergy between rupture discs and other safety systems enhances overall plant safety, reduces the risk of equipment damage, and ensures compliance with regulatory standards. Such integration underscores the importance of rupture discs as a key component of holistic industrial safety strategies.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/30133

Reducing Maintenance and Operational Costs

One of the notable advantages of rupture discs is their ability to reduce maintenance and operational costs. Unlike traditional mechanical relief devices, rupture discs have no moving parts, minimizing wear and tear and extending service life. Their simple design also reduces the frequency of inspections, replacements, and downtime, which can be costly in industrial settings. By preventing overpressure damage to expensive equipment, rupture discs indirectly save on repair and replacement costs. Industries benefit not only from enhanced safety and reliability but also from the economic efficiency provided by these durable and low-maintenance devices.

Supporting Regulatory Compliance

Rupture discs play a critical role in helping industries comply with stringent safety and environmental regulations. Regulatory bodies, including OSHA, ASME, and API, require proper overpressure protection for industrial equipment handling hazardous materials. Rupture discs ensure that pressure relief mechanisms meet specified burst ratings and performance standards, providing documented proof of compliance. The adoption of high-quality rupture discs demonstrates a commitment to workplace safety and regulatory adherence, reducing the risk of legal and financial penalties. Compliance, combined with enhanced safety, makes rupture discs essential components in industrial risk management strategies.

Enhancing Environmental Safety

Environmental protection is a growing concern in industrial operations, particularly in industries handling volatile or hazardous substances. Rupture discs minimize the risk of accidental releases, spills, or explosions, protecting both workers and the surrounding environment. Certain designs are engineered for leak-tight performance, preventing emissions until the device actuates. By controlling pressure safely and efficiently, rupture discs help industries meet environmental standards, reduce pollution risks, and promote sustainable operational practices. Their contribution to environmental safety reinforces their value beyond mere operational protection.

Innovation and Future Prospects

The future of rupture discs is shaped by ongoing innovation in materials, design, and digital integration. Advances in high-strength alloys, corrosion-resistant coatings, and temperature-tolerant polymers are expanding the applicability of rupture discs to more challenging environments. Integration with smart sensors and IoT-enabled monitoring systems allows predictive maintenance and real-time pressure tracking, enhancing safety and operational oversight. As industries embrace digital transformation and prioritize safety, reliability, and environmental responsibility, rupture discs are expected to become even more intelligent, adaptable, and indispensable in modern industrial infrastructure.

Workforce Training and Operational Expertise

While rupture discs are inherently simple and reliable, proper installation, monitoring, and maintenance are essential for optimal performance. Operators and engineers must be trained to select appropriate burst ratings, handle materials safely, and ensure proper integration with other safety devices. Training programs enhance workforce competency, enabling personnel to utilize rupture discs effectively while minimizing risk. Skilled operation ensures that these devices provide consistent protection, maintain process reliability, and support broader safety and compliance objectives. Workforce expertise complements technological innovation, maximizing the benefits of rupture disc implementation.

Global Relevance and Market Leadership

The adoption of rupture discs is global, with industries in North America, Europe, and Asia leading in safety-conscious manufacturing practices. The U.S., in particular, is a significant market due to its advanced industrial infrastructure, regulatory frameworks, and emphasis on worker and environmental safety. U.S. manufacturers contribute to global standards by producing high-performance, reliable, and innovative rupture discs suitable for diverse industrial applications. The international influence of American technology and best practices underscores the strategic importance of rupture discs in promoting industrial safety, reliability, and operational excellence worldwide.

Related Reports:

https://www.persistencemarketresearch.com/market-research/agricultural-sprayers-market.asp

https://www.persistencemarketresearch.com/market-research/hydraulic-hoses-market.asp

https://www.persistencemarketresearch.com/market-research/industrial-automation-market.asp

https://www.persistencemarketresearch.com/market-research/collaborative-robot-market.asp

https://www.persistencemarketresearch.com/market-research/construction-lasers-market.asp

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Rupture Disc Market Enhancing Industrial Safety and Process Reliability with Advanced Pressure Relief Solutions here

News-ID: 4206888 • Views: …

More Releases from Persistence Market Research

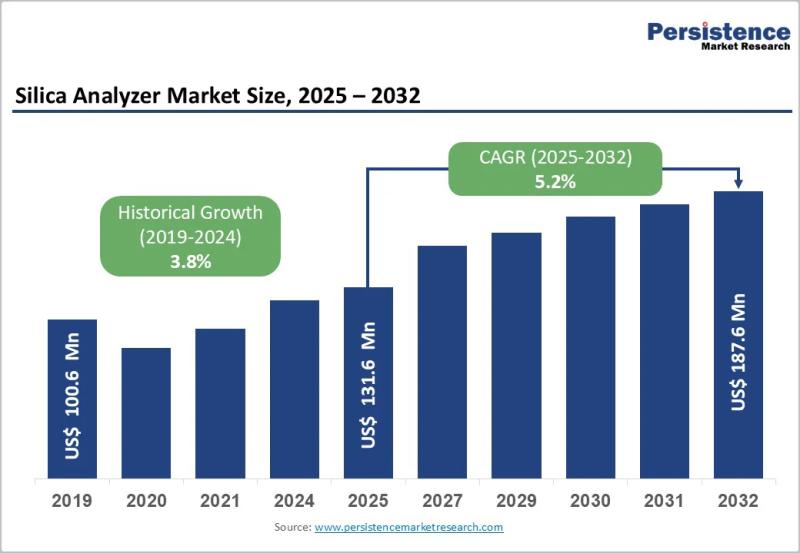

Silica Analyzer Market Size to Reach US$187.6 Million by 2032 - Persistence Mark …

The silica analyzer market plays a critical role in industrial water quality monitoring, particularly in sectors where high purity water is essential for operational efficiency and equipment longevity. Silica analyzers are specialized instruments used to detect and measure silica concentrations in water and steam cycles, preventing scale formation and corrosion in boilers, turbines, and cooling systems. Industries such as power generation, oil and gas, pharmaceuticals, semiconductors, and chemical processing rely…

Soybean Derivatives Market to Hit $390.8B by 2033, Growing at 4.5% CAGR

The global soybean derivatives market is poised for sustained expansion, driven by growing demand across food, feed, and industrial applications. The market is projected to be valued at US$ 288.1 billion in 2026 and is expected to reach US$ 390.8 billion by 2033, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2026 to 2033. This growth underscores the continued significance of soybean derivatives as…

Europe Electric Vehicle Market to Reach US$ 571.9 Bn by 2033 as Tesla, Volkswage …

The Europe electric vehicle market is witnessing unprecedented growth, driven by increasing consumer awareness, government policies promoting sustainability, and rapid advancements in electric mobility technologies. As countries across Europe adopt stricter emission regulations and incentivize the adoption of electric vehicles (EVs), manufacturers are accelerating their transition from conventional vehicles to electric alternatives. This shift is not only redefining the automotive industry but is also shaping the region's energy, transportation, and…

Nutmeg Butter Market to Reach $57.6M by 2033, Driven by Rising Demand in Food

The global nutmeg butter market is witnessing significant growth, driven by rising demand from the cosmetic, pharmaceutical, and food industries. The market is estimated to be valued at US$ 39.1 million in 2026 and is projected to reach US$ 57.6 million by 2033, reflecting a compound annual growth rate (CAGR) of 5.7% over the forecast period from 2026 to 2033.

The growth of the nutmeg butter market is largely attributed to…

More Releases for Rupture

DJ RITUALA - ACT I: RUPTURE / EXIT

DJ Rituala's work begins with a refusal.

Not of success, visibility, or recognition -

but of an image system that continues to function after the body disconnects.

ACT I: RUPTURE / EXIT documents the moment when representation stopped aligning with lived experience. The image remained intact. The schedule held. The outputs continued. What failed was sensation, presence, and physical truth.

Rituala names this condition daylight.

Daylight is not aesthetic. It is operational.

A system that prioritizes…

Rupture Disc Market Size 2024 to 2031.

Market Overview and Report Coverage

A rupture disc is a safety device designed to relieve excess pressure build-up in a pressurized system by rupturing and releasing the pressure. It is commonly used in various industries such as oil & gas, chemical, pharmaceutical, and food processing.

The current outlook for the rupture disc market is positive, with increasing demand for safety devices across industries to prevent accidents and ensure smooth operations.…

Artificial Membrane Rupture Device Market 2023

Artificial Membrane Rupture Device Market

Artificial membrane rupture devices are commonly used to rupture the amniotic sac during gynecological surgery. The instrument is made of stainless steel material to keep it rust-proof and light. The unique single-finger handle provides the surgeon with a secure grip on the instrument.

Download Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-39G14422/Global_Artificial_Membrane_Rupture_Device_Market_Research_Report_2023

The global Artificial Membrane Rupture Device market was valued at US$ million in 2022 and is anticipated to reach US$ million…

Graphite Rupture Disc Market 2020 Precise Outlook- REMBE GmbH, Fike, Mersen, ZOO …

The Graphite Rupture Disc Market 2020 report is a comprehensive, professional and in-depth research of market that delivers significant data for those who are seeking information for the Graphite Rupture Disc industry. The market report delivers the specification, key strategies, future prospect and cost structure of the industry. The report also highlighted the future trends in the Graphite Rupture Disc market that will impact the demand during the forecast period.

Available…

Graphite Rupture Disc Market Overview by 2020-2025

Scope of the Report:

The worldwide market for Graphite Rupture Disc�is expected to grow at a CAGR of roughly x% over the next five years, will reach x million US$ in 2024, from x million US$ in 2019, according to a new Global Info Research�study.

The report presents the market outlook for the Indian Phospho Gypsum product from the year 2019 to the year 2025. The report provides a definition of the…

Rupture Disc Holder Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Rupture Disc Holder Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Rupture Disc Holder players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Rupture Disc Holder with respect…