Press release

Global Precision Dosing Equipment for Food Processing Market 2025 to Reach USD 4623 Million by 2031 at 10.1% CAGR Led by GEA Group and Tetra Pak

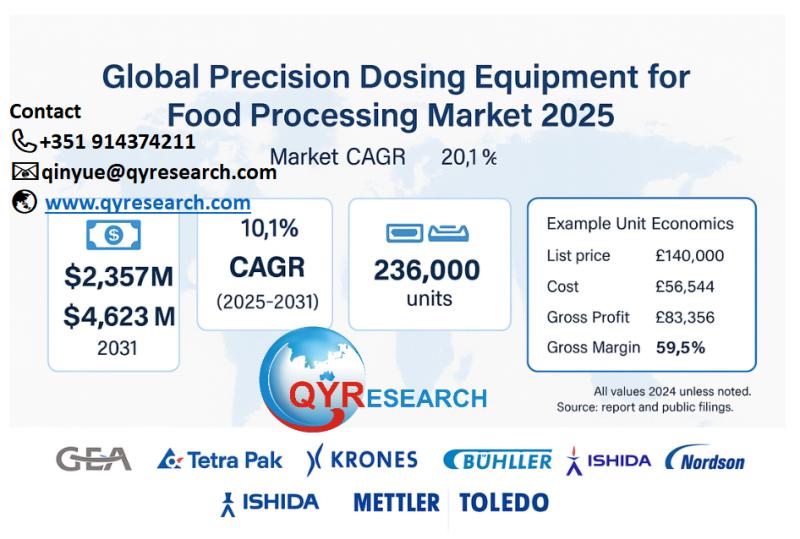

The new report Global Precision Dosing Equipment for Food Processing Market Outlook, In-Depth Analysis & Forecast to 2031 from QYResearch projects the market to expand from US$ 2,357 million in 2024 to US$ 4,623 million by 2031, a 10.1% CAGR (2025-2031). In 2024, global output reached ~236,000 units at an average price of ~US$10,000 per unit. The category covers high-accuracy liquid, powder and granule dosing systems used in dosing, filling, seasoning and ingredient-mixing stages across food plants. Evolving U.S. tariff policies are called out as adding trade-cost volatility and supply-chain uncertainty.Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) https://www.qyresearch.com/sample/4940421

Company List

GEA Group

Tetra Pak

Bosch Packaging Technology

Krones AG

Bühler Group

SPX FLOW

IMA Group

MULTIVAC

JBT Corporation

Syntegon Technology

Rovema GmbH

Handtmann

Vemag Maschinenbau

Endress+Hauser

Yamato Scale

Ishida Co., Ltd.

Hassia-Redatron

OPTIMA packaging group

Foss Analytical

Hosokawa Micron

Siemens AG

Mettler-Toledo

Fortress Technology

Nordson Corporation

Heat and Control

Provisur Technologies

Accutek Packaging Equipment

Treif Maschinenbau

Reiser

Graco Inc.

Product profiles for five leading companies:

GEA Group - Scan-Vibro Loss-in-Weight (LIW) Dosing System FES

• Dosing range: 0.5-100 kg/h (batch or continuous).

• Measurement/control: entire feeder, hopper, and material continuously weighed via high-precision load cells; HMI controller; stand-alone or Ethernet/IP integration to SCADA.

• Hygiene/compliance: USDA 3-A / EHEDG options; easy-clean design; low-maintenance.

• Use cases: precise dosing of additives/ingredients in food & dairy lines.

Tetra Pak - Ingredient Doser M3

• Ingredient throughput: 10-200 L/h; product flow: 100-2,000 L/h.

• Max inclusion size: 12 mm (continuous, accurate injection into ice cream and other liquid/viscous products).

• Designed for inline dosing with high repeatability and reduced product loss.

Krones AG - Contiflow Mixer (Dosing & Carbonation)

• Output sizes: 15 / 30 / 45 / 60 / 75 / 90 m3/h, each operable at 33-100% of rated capacity.

• Dosing capability: up to 8 liquid ingredients; mass-flow metering with register controller; "highly accurate" syrup & CO2 dosing enabling up to 0.2% syrup savings.

• CO2 dosing accuracy: ≤ 0.08 g/L (σ1, at stable conditions).

Bühler Group - Micro-Dosing (MSDC/MZMC)

• Technologies: MSDC loss-in-weight (gravimetric) and MZMC volumetric, single-screw design.

• Throughput range: 0.75-240 dm3/h (≈ 0.75-240 L/h).

• Accuracy: 0.1% of scale capacity (micro-dosing system; high-precision weighing).

• Sanitation: stainless/electropolished contact parts; dust-controlled bin filling; fast changeover for multi-component recipes.

Ishida Co., Ltd. - CCW-RV Series Multihead Weighers

• Speed & formats: up to 240 wpm on a 16-head RV; dual-outlet models routinely 140 wpm; 28-head variants 200 wpm dual-outlet (≈400 packs/min total using twin timing hoppers).

• Applications: fast-flowing products and mix dosing; 4-mix configurations reach 60 wpm per section with booster hoppers for accuracy.

• Benefits: high speed with reduced give-away, small footprint, preset recipe storage.

Application List

Beverage Production

Dairy Processing

Bakery Processing

Meat and Ready-to-Eat Food Processing

Others

Classification List

Liquid Dosing Equipment

Powder Dosing Equipment

Granule Dosing Equipment

Multi-ingredient Dosing Systems

Others

Latest Data

Market size: US$ 2,357 million (2024) → US$ 4,623 million (2031)

• CAGR: 10.1% (2025-2031)

• Production volume (2024): ~236,000 units

• Average price (2024): ~US$10,000 per unit

• Methodology coverage: 2020-2024 history; forecast to 2031; segmentation by type & application; regional deep dives; competitive landscape; supply-chain overview; and strategic recommendations.

Cost, Gross Profit & Gross Margin - benchmarked with sourced figures:

For a new, food-grade precision weigher/doser, a published new price example is a Yamato 24-head multihead weigher at ~£140,000. Using peer OEM gross margins as a benchmark for precision dispensing/weighing businesses - Nordson FY2024 gross margin 55.2% and Mettler-Toledo 2024 gross margin ~59.5% - the implied COGS and gross profit for that unit would be:

• at 55.2% margin → COGS ≈ £62,720, Gross profit ≈ £77,280;

• at ~59.5% margin → COGS ≈ £56,644, Gross profit ≈ £83,356.

These calculations use the cited list price and publicly reported, company-level gross margins as benchmarks to illustrate typical economics for precision dosing/weighing equipment.

Downstream companies:

The Coca-Cola Company

PepsiCo

Nestlé

Danone

Arla Foods

Fonterra

Lactalis

Heineken

Anheuser-Busch InBev

Carlsberg Group

Mondelez International

Ferrero

General Mills

Kraft Heinz

Grupo Bimbo

2025 Trendlines & Company Milestones

Automation moves from "accuracy" to "autonomy."

In 2025, precision dosing is graduating from static set-points to adaptive, closed-loop autonomy. OEMs are embedding load cells, flow meters and vision systems into dosing stations and tying them to PLCs and edge analytics so the line can self-correct for ingredient variability (e.g., particle size, moisture, viscosity) without operator intervention. This shift is visible both in powder micro-ingredient skids and in high-speed liquid micro-dosing at the end of beverage lines. The outcome is consistent grams-per-dose at higher speeds and with fewer give-away losses, underpinning the market's double-digit growth outlook through 2031. Real-world implementations in 2024-2025 include multi-channel gravimetric dosing for ready meals and salads, where lines meter multiple components by weight to tight tolerances while maintaining throughput.

New food formats are refactoring plant design - and dosing follows.

Alternative proteins and fermentation-derived ingredients are pushing equipment makers to build "pilot-to-scale" testbeds where processors can iterate recipes and then scale with predictable dosing behavior. The most visible milestone is GEA's New Food Application & Technology Center (ATC) in Janesville, Wisconsin, officially opened July 17, 2025, a US$20 million pilot plant built on renewable energy. The ATC concentrates technologies for plant-based, cell-based and precision-fermentation foods - all of which depend on finely metered nutrient feeds, enzymes, stabilizers and flavors. The facility shortens time-to-scale by letting customers validate dosing regimes under production-like conditions, including hygienic design and CIP/SIP cycles.

Hygienic, dust-free micro-ingredient dosing is now a competitive wedge.

For bakeries and RTE foods, the battleground has shifted to micro-dosing of high-value, potent ingredients (enzymes, improvers, flavors, spices) with minimal cross-contamination and dust exposure. Solutions marketed for dust-free, direct-to-mixer dosing and rapid changeover have proliferated, targeting both artisan and industrial plants. Suppliers emphasize closed transfer, recipe management, and small-batch agility to support SKU proliferation without sacrificing OEE. Offerings like Powdermatic lines (now branded under Powdea) illustrate the push toward sealed, recipe-driven small-ingredient dosing cells that preserve hygiene and reduce waste.

Liquid micro-dosing hits line-speed - including in moving containers.

Dosing is also racing forward in liquids. High-speed precision dosing platforms that meter micro-doses into moving containers are migrating from R&D to production, especially in beverages. These systems can inject flavors or concentrates in milliseconds with food-grade editions tailored for drink lines, cutting valve counts and simplifying carousels while keeping tight volume control. The value proposition is higher flexibility (shorter flavor runs, late-stage customization) with less cleaning downtime. The technology's trajectory - from aerospace-grade magnetic valves to modern beverage dosing - underlines how cross-industry innovation is reshaping food lines in 2025.

Retail and foodservice automation blends slicing, robotics - and dosing.

Beyond factories, dosing precision is being embedded into modular fresh-food stations for retail and foodservice. In June 2025, Bizerba and partners demonstrated a robot-assisted sandwich station that unites slicing, vacuum gripping, robotic handling and high-precision dosing into an on-demand, contactless workflow - built for supermarkets, petrol stations and hospital canteens. That's a signal that "precision" isn't restricted to upstream processing: it's moving to the counter, where exact portioning and cleanability matter for both cost control and food safety.

Throughput without compromising grams-level accuracy.

A 2025 refrain is "no trade-offs." Multi-lane, multi-channel gravimetric systems keep appearing because they reconcile throughput with target-weight accuracy across complex recipes - think multi-component salads, ready meals, or bakery toppings. These systems measure and place equal doses across many tracks, ensuring even cooking and distribution while reducing waste. They also integrate upstream calibration and downstream positioning to keep weight dispersion tight. For processors, the practical win is fewer reworks and higher first-pass yield.

Economics: why precision dosing pays in 2025.

The economics are strengthened by OEM profitability that funds R&D and service programs. Precision dispensing specialists reported robust gross margins in 2024-2025 - for example, Nordson's FY2024 gross margin ~55% and Mettler-Toledo's gross margin ~59-61% - supporting sustained investments in sensors, controls and software. At the plant level, precise dosing trims ingredient give-away, raises yield and reduces allergen cross-contact risks, directly improving COGS while de-risking compliance. Coupled with the market's forecast 10.1% CAGR, equipment ROI is increasingly justified by measurable waste reduction and labor offsets from smarter, self-correcting systems.

Sustainability and safety by design.

2025 buyers insist on CIP/SIP-friendly, hygienic designs with fewer crevices, enclosed transfer and automated cleaning validation. Dust-free powder handling and accurate liquid metering also curb fugitive emissions and product loss, contributing to both safety and sustainability goals. Emerging AI layers are being piloted to predict drifts in flowability or viscosity from sensor proxies (temperature, humidity, torque), then pre-emptively tune augers, vibratory feeders or valves - keeping lines within spec without frequent stops.

Request for Pre-Order Enquiry On This Report https://www.qyresearch.com/customize/4940421

Regional pulse: flexibility beats footprint.

While detailed regional dollar splits vary, the growth logic is consistent: North America and Europe lean toward retrofits that add precision to aging lines (automation overlays, vision weighing, recipe management), while APAC adds new capacity and seeks modular, multi-ingredient dosing to accommodate fast-changing SKU portfolios. Across regions, tariff uncertainty and component supply swings encourage platform architectures - swappable dosing modules, common control stacks and faster changeovers - to keep TCO predictable even when upstream parts prices fluctuate.

Chapter Outline:

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Information:

Tel: +1 626 2952 442 ; +351 914374211(Tel & Whatsapp); +86-1082945717

Email: qinyue@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About us:

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

Related Report:

Global Precision Dosing Equipment for Food Processing Market Outlook, In‐Depth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/4940421/precision-dosing-equipment-for-food-processing

Precision Dosing Equipment for Food Processing - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/4940420/precision-dosing-equipment-for-food-processing

2025-2031全球与中国食品加工用精密定量设备市场现状及未来发展趋势

https://www.qyresearch.com.cn/reports/5750381/precision-dosing-equipment-for-food-processing

2025年全球食品加工用精密定量设备行业总体规模、主要企业国内外市场占有率及排名

https://www.qyresearch.com.cn/reports/5750380/precision-dosing-equipment-for-food-processing

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Precision Dosing Equipment for Food Processing Market 2025 to Reach USD 4623 Million by 2031 at 10.1% CAGR Led by GEA Group and Tetra Pak here

News-ID: 4206562 • Views: …

More Releases from QYResearch Europe

Global Aerospace Grade Smart Assembly Lines Market 2024 USD 4251 Million to 2031 …

According to recent report from QYResearch, the global market for aerospace-grade smart assembly lines stood at US$4,251 million in 2024 and is projected to reach US$8,712 million by 2031 at a 10.2% CAGR (2025-2031). In 2024, approximately 670 lines were produced globally at an average selling price (ASP) of about US$6.343 million per line. These highly automated systems integrate AI, industrial robotics, advanced sensing, and digital control to deliver repeatable,…

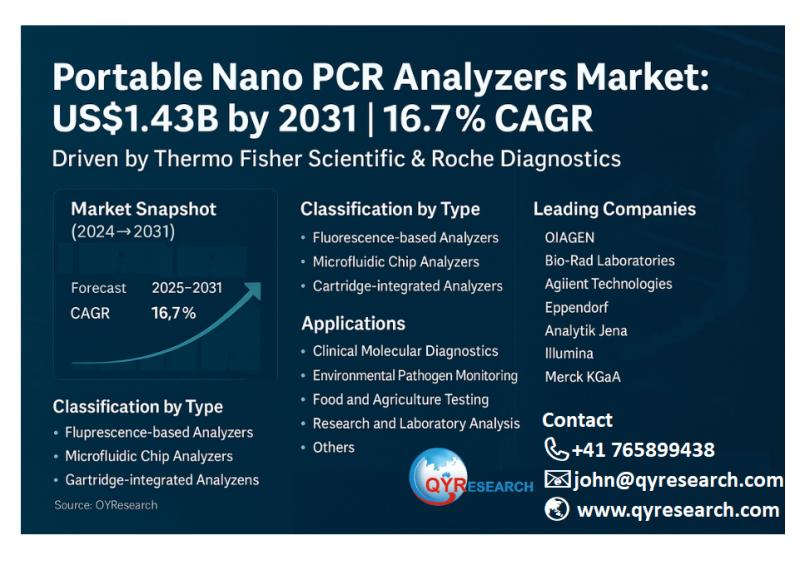

Portable Nano PCR Analyzers Market Growth to US$1.43 Billion by 2031 with 16.7% …

According to the latest QYResearch Report, the global market for Portable Nano PCR Analyzers was valued at US$484 million in 2024 and is expected to reach US$1,427 million by 2031, growing at a CAGR of 16.7% during the forecast period of 2025-2031. Global production in 2024 reached around 96,800 units, with an average price of about US$5,000 per unit. These portable devices utilize nanotechnology-enhanced PCR processes for rapid on-site genetic…

Global Multiphase Flow Conveying Equipment Market to Reach USD 10.88 Billion by …

The global market for Multiphase Flow Conveying Equipment is transitioning from a specialized engineering niche to a core enabler of industrial efficiency across upstream energy, chemicals, mining, and wastewater sectors. According to QYResearch 2025 edition of Multiphase Flow Conveying Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031, the market was valued at US$7,380 million in 2024 and is projected to reach US$10,879 million by 2031,…

Global Smart Eye-Tracking Medical Devices Market Size Reaches US$3.0 Billion by …

The global Smart Eye-Tracking Medical Devices market has entered a stage of accelerated clinical adoption and product diversification. According to QYResearch 2025 Global Smart Eye-Tracking Medical Devices Market Research Report, the market was valued at US$973 million in 2024 and is projected to reach US$3,009 million by 2031, growing at a CAGR of 17.5% from 2025 to 2031. Global output in 2024 reached approximately 64,900 units, with an average price…

More Releases for Dosing

Peristaltic Dosing Pumps Market Size Driven by Precision Dosing and Industrial A …

The peristaltic dosing pumps market size is poised for significant growth, supported by trends in industrial automation, technological advancements, and the increasing demand for precision in dosing applications. As the market continues to evolve, stakeholders can capitalize on emerging opportunities by focusing on innovation, quality, and customer satisfaction.

The major players in the Peristaltic Dosing Pumps market include Interscience, Etatron, Verder, Cole Parmer, Watson Marlow, PSG Technologies, ProMinent, Baoding Longer, Chongqing…

Volumetric Dosing Dispenser Market Size 2024 to 2031.

Market Overview and Report Coverage

A Volumetric Dosing Dispenser is a type of equipment used in various industries for accurate and precise dispensing of liquids or granular materials. The market for Volumetric Dosing Dispensers is expected to experience significant growth in the coming years. With a projected CAGR of 7.80% during the forecasted period, the market is anticipated to witness a rise in demand due to the increasing automation in…

Flocculant Dosing System Market Research Report 2023

Flocculant Dosing System Market

The global Flocculant Dosing System market was valued at US$ million in 2022 and is anticipated to reach US$ million by 2029, witnessing a CAGR of % during the forecast period 2023-2029. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

North American market for Flocculant Dosing System is estimated to increase from $ million in 2023 to reach $ million by 2029,…

Patient Enablement and Immunotherapeutic Drug Self-Dosing

(Amherst, NH) – The administration of therapeutic immune modulators is becoming an increasingly important healthcare treatment option for a growing number diseases and indications having broad implications for patient health and well-being. But to fully exploit the value of this class of therapeutics in both human and commercial terms, developers must successfully navigate the inherent limitations of drug storage and administration, moving away from infusion and toward injection as a…

Dosing Systems Market Size, Share, Price | Industry Report

Dosing Systems Market Size, Share, Price | Industry Report 2019 Market Research Report to It’s a Database.

Download sample copy of This Report @ https://goo.gl/dR5mtr

This report estimates the dosing systems market size in terms of $million. This has been broken down into component regions and further split into countries.

Dosing systems are required to inject chemicals or liquids in production/processing of different products. Production activities across the globe coupled…

United States Dosing Systems Market Report 2021

Notes:

Sales, means the sales volume of Dosing Systems

Revenue, means the sales value of Dosing Systems

This report studies sales (consumption) of Dosing Systems in USA market, focuses on the top players, with sales, price, revenue and market share for each player, covering

Advanced Holdings Ltd(Singapore)

AllTech Dosieranlagen GmbH(Germany)

Buhler AG(Switzerland)

Brightwell Dispensers Ltd(U.K.)

Dioxide Pacific Pty Ltd(Australia)

Doyen Machinery Co. Ltd(China)

Request Sample Report:

http://www.reportbazzar.com/request-sample/?pid=649748&ptitle=United+States+Dosing+Systems+Market+Report+2021&req=Sample

ELMET Elastomere Produktions- und Dienstleistungs GmbH(Austria)

Frames(The Netherlands)

Grundfos Water Treatment Gmbh(Germany)

IDEX Corporation(U.S.)

LEWA Gmbh(Germany)

Metito Holdings Limited(U.A.E)

NETZSCH Pumpen…