Press release

Copper Sheet Manufacturing Plant Setup Cost 2025: Detailed Project Report and Business Plan

Setting up a copper sheet manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Copper Sheet Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a copper sheet manufacturing plant cost, covering everything from product overview and manufacturing processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/copper-sheet-manufacturing-plant-project-report/requestsample

What is Copper Sheet?

A copper sheet is known as flat thin copper metal produced through rolling copper toward uniform thicknesses used for art, business, and diverse factory tasks. Copper sheets have superb electrical conductivity with corrosion resistance also with malleability. Copper sheets are in wide use for roofing, cladding, electrical components, heat exchangers, also decorative items due to these properties. Varying grades, thicknesses, and finishes are present for needs. Since copper sheets can withstand extreme weather as well as are durable, architectural projects prefer them, and healthcare and food-related applications find them useful because of their antimicrobial properties.

What is Driving the Copper Sheet Market?

The copper sheet industry sees some strong growth given demand rises in renewable energy, electronics, electrical, also construction sectors. Copper sheets are increasingly adopted within energy-efficient systems, green buildings, also solar panels. This increasing adoption does create important opportunities. Consumption increases due to urbanization plus infrastructure projects especially in Asia-Pacific as the global shift to sustainable recyclable materials helps market expansion. Production of electric vehicles is surging, and this strengthens all the demand. Electronics have a need for efficient heat dissipation and for this also strengthens demand. Key difficulties do remain, however, regarding copper price fluctuations as well as to the high processing cost. For industry players to invest in advanced manufacturing technologies also to explore eco-friendly production methods such that they can improve quality also can reduce costs while they align with global sustainability goals.

Buy now: https://www.imarcgroup.com/checkout?id=15850&method=1911

Key Steps Required to Set Up a Copper Sheet Plant

1. Market Analysis

The report provides insights into the landscape of the copper sheet industry at the global level. The report also provides a segment-wise and region-wise breakup of the global copper sheet industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of copper sheet, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the copper sheet manufacturing plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for copper sheet manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for copper sheet manufacturing

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=15850&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a copper sheet manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on manufacturing capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Copper Sheet Manufacturing Plant Setup Cost 2025: Detailed Project Report and Business Plan here

News-ID: 4204235 • Views: …

More Releases from IMARC

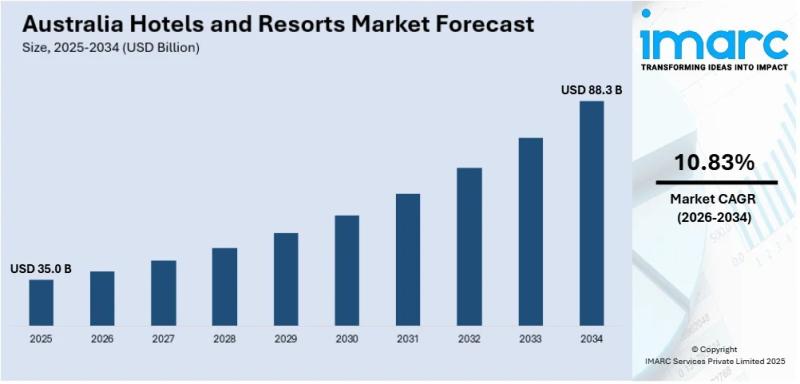

Australia Hotels and Resorts Market Projected to Reach USD 82.80 Billion by 2033

Market Overview

The Australia hotels and resorts market size reached USD 31.40 Billion in 2024 and is projected to expand at a CAGR of 11.40 % during 2025-2033, reaching approximately USD 82.80 Billion by 2033. Market growth is driven by rising domestic and international tourism, increasing disposable incomes, and greater investment in luxury, experiential, and eco-friendly accommodations. The surge in travel demand has led to heightened occupancy rates and average daily…

India Perfume Market Strategic Outlook Report: Growth Drivers, Value Pools & Com …

India Perfume Market 2025-2033

According to IMARC Group's report titled "India Perfume Market Report by Perfume Type (Premium, Mass), End User (Female, Male, Unisex), and Region 2025-2033", this report provides a structured assessment of the factors shaping the India perfume market through 2033. It outlines the sector's core growth drivers, emerging value pools, and the evolving competitive landscape. The analysis supports decision-makers in evaluating demand patterns, margin opportunities, and competitive positioning…

How to Start a Wine Tasting Events Business: Market Trends, Investment Requireme …

Overview

IMARC Group's "Wine Tasting Events Business Plan and Project Report 2025" provides a comprehensive framework for establishing and operating a successful wine tasting events business. This in-depth report analyzes key market trends, investment opportunities, operational models, revenue streams, and financial projections, offering actionable insights for entrepreneurs, hospitality brands, event organizers, wineries, and investors.

Whether launching a new experiential events venture or expanding an existing hospitality or lifestyle business, this report delivers…

India Luxury Fashion Industry Size, Share, Growth Trends, Top Brands & Market Ou …

According to the latest report by IMARC Group, titled "India Luxury Fashion Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, End User, and Region, 2025-2033," the report presents a thorough review featuring the India luxury fashion market share, size, growth, trends, and research of the industry.

India Luxury Fashion Market Overview

The India luxury fashion market size reached USD 9.37 Billion in 2024. It is expected to grow…

More Releases for Copper

Copper Mining Market is Booming Worldwide | Major Giants Turquoise Hill, Copper …

HTF MI recently introduced Global Copper Mining Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2025-2033). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence.

Major companies in Copper Mining Market are:

Codelco, BHP, Freeport-McMoRan, Glencore, Rio Tinto, KGHM, First Quantum Minerals, Southern Copper, Antofagasta, Lundin Mining,…

Copper And Copper Alloy Welding Wire Market Size Analysis by Application, Type, …

According to Market Research Intellect, the global Copper And Copper Alloy Welding Wire market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

With a robust Compound Annual Growth Rate (CAGR) of roughly 4.5%, the global market…

Copper Alloy And Copper Powder Market Size Analysis by Application, Type, and Re …

USA, New Jersey- According to Market Research Intellect, the global Copper Alloy And Copper Powder market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The market for copper alloys and copper powder is steadily rising due to rising demand from a variety of industrial sectors, such…

Copper and Copper Alloy Foil Market Size, Scope 2031 by Key Companies- Amari Cop …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲: According to Verified Market Reports analysis, the global Copper and Copper Alloy Foil Market size was valued at USD 13.60 Billion in 2023 and is projected to reach USD 24.34 Billion by 2031, growing at a CAGR of 8.67% during the forecasted period 2024 to 2031.

The Copper and Copper Alloy Foil Market is poised for growth due to the increasing demand for high-performance materials across various industries,…

Global Copper and Copper-alloy Foils

LP INFORMATION recently released a research report on the Copper and Copper-alloy Foils

Contact US

LP INFORMATION

E-mail: info@lpinformationdata.com

Tel: 001-626-346-3938 (US) 00852-58080956 (HK) 0086 15521064060 (CN)

Add: 17890 Castleton St. Suite 162 City of Industry, CA 91748 US

Website: https://www.lpinformationdata.com

About Us:

LP INFORMATION (LPI) is a professional market report publisher based in America, providing high quality market research reports with competitive prices to help decision makers make informed decisions and take strategic actions…

Global Copper and Copper-alloy Foils (

LP INFORMATION offers a latest published report on Copper and Copper-alloy Foils (

Contact US

LP INFORMATION

E-mail: info@marketresearchreportstore.com

Tel: CN:0086-13660489451 HK: 00852-58081523 USA:001-626-3463946

Add: 17890 Castleton Street Suite 218 City of Industry CA 91748 United States

Website: https://www.marketresearchreportstore.com

About Us

LP INFORMATION (LPI) is a professional organization related to market research reports in all directions .To provide customers with a variety of market research reports,…