Press release

Fluoropolymers (PTFE) Production Cost Report 2025: Feasibility and Profitability Roadmap for Investors

Setting up a fluoropolymers (PTFE) production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Fluoropolymers (PTFE) Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a fluoropolymers (PTFE) production plant, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/fluoropolymers-manufacturing-plant-project-report/requestsample

What are Fluoropolymers (PTFE)?

Fluoropolymers (PTFE) production involves the manufacturing of polytetrafluoroethylene, a high-performance polymer known for its exceptional chemical resistance, low friction, and non-stick properties. The process typically includes the polymerization of tetrafluoroethylene monomers under controlled conditions to create a durable, heat-resistant material. PTFE is then processed into sheets, rods, films, coatings, and molded components for various applications. It is widely used in industries such as automotive, aerospace, electronics, chemical processing, and cookware due to its ability to withstand extreme temperatures and harsh chemicals while maintaining excellent mechanical and electrical properties, making it ideal for critical industrial and consumer products.

What is Driving the Fluoropolymers (PTFE) Market?

The fluoropolymers (PTFE) market is driven by growing demand for high-performance materials in industrial, automotive, and electronics applications. PTFE's superior resistance to chemicals, heat, and corrosion makes it essential in critical environments such as chemical processing plants, semiconductor manufacturing, and electrical insulation. Increasing use in non-stick cookware, medical devices, and aerospace components further supports market growth. Technological advancements in processing techniques and the development of eco-friendly production methods are expanding PTFE's applications. Additionally, the rise of renewable energy projects, electric vehicles, and advanced communication technologies is creating new opportunities for PTFE in sealing, gaskets, wiring, and protective coatings.

Buy Now: https://www.imarcgroup.com/checkout?id=9216&method=1911

Key Steps Required to Set Up a Fluoropolymers (PTFE) Production Plant

1. Market Analysis

The report provides insights into the landscape of the fluoropolymers (PTFE) industry at the global level. The report also provides a segment-wise and region-wise breakup of the global fluoropolymers (PTFE) industry. Additionally, it also provides the price analysis of feedstocks used in the production of fluoropolymers (PTFE), along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the fluoropolymers (PTFE) production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for the fluoropolymers (ptfe) production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for fluoropolymers (ptfe) production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a fluoropolymers (PTFE) production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9216&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales{@}imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fluoropolymers (PTFE) Production Cost Report 2025: Feasibility and Profitability Roadmap for Investors here

News-ID: 4202395 • Views: …

More Releases from IMARC Group

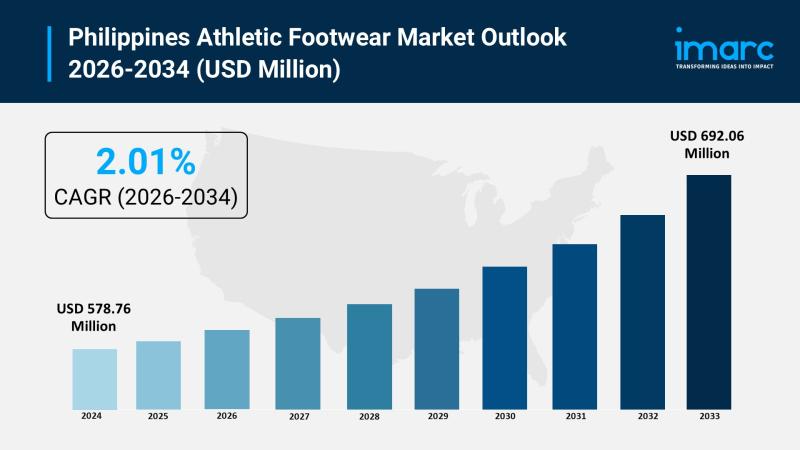

Philippines Athletic Footwear Market 2026 to Reach USD 692.06 Million by 2034 Am …

Market Overview

The Philippines athletic footwear market size was valued at USD 578.76 Million in 2025 and is projected to reach USD 692.06 Million by 2034, growing at a compound annual growth rate of 2.01% from 2026-2034. The market is expanding rapidly, driven by increasing health consciousness, fitness trends, and demand for stylish yet functional shoes. With a growing middle class and a focus on performance and comfort, the Philippines athletic…

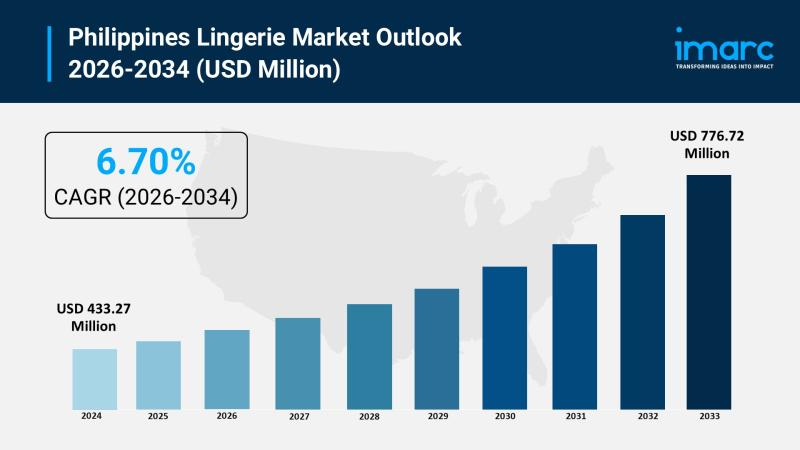

IMARC Group: Philippines Lingerie Market 2026 | Poised for Rapid Growth at 6.70% …

Market Overview

The Philippines lingerie market size was valued at USD 433.27 Million in 2025 and is projected to reach USD 776.72 Million by 2034, growing at a compound annual growth rate (CAGR) of 6.70% during 2026-2034. The market is experiencing robust expansion driven by evolving consumer preferences, rising disposable incomes, and increasing emphasis on comfort and personal expression in intimate apparel. Urbanization and expanding retail infrastructure are reshaping purchasing patterns…

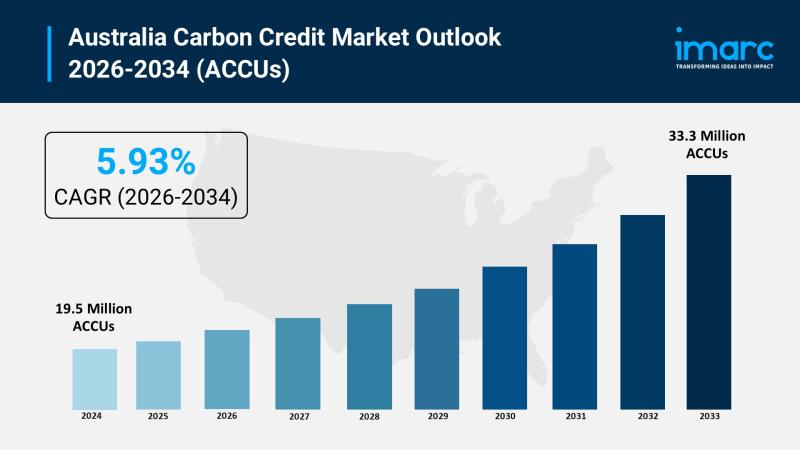

Australia Carbon Credit Market 2026 | Worth 33.3 Million ACCUs by 2034

Market Overview

The Australia carbon credit market size reached 19.5 Million ACCUs in 2025 and is projected to reach 33.3 Million ACCUs by 2034, exhibiting a CAGR of 5.93% during the forecast period 2026-2034. The industry is expanding significantly due to favorable government policies and regulations, increased dedication to corporate social responsibility, expanded international trade prospects, and significant expansion in renewable energy projects.

Request a Sample Report: https://www.imarcgroup.com/australia-carbon-credit-market/requestsample

How AI is Reshaping the…

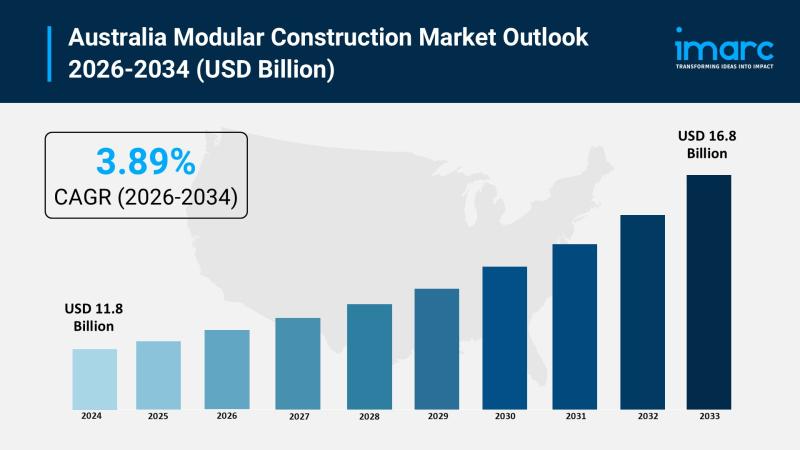

Australia Modular Construction Market 2026 | USD 16.8 Billion by 2034

Market Overview

The Australia modular construction market size reached USD 11.8 Billion in 2025 and is projected to reach USD 16.8 Billion by 2034, exhibiting a CAGR of 3.89% during the forecast period 2026-2034. The market is primarily driven by government infrastructure support, increasing housing demand, environmental considerations, and technological advances addressing the rising demand for efficient, adaptable housing solutions in urban and remote areas across the country.

Request a Sample Report:…

More Releases for PTFE

PTFE Molded Tubes Market Bright Horizons: Positive Market Indicators Revealed | …

"This comprehensive PTFE Molded Tubes report offers a deep dive into the global market, encompassing a wide spectrum of analyses to equip you with a profound understanding of its dynamics. Beyond the standard SWOT analysis, our study incorporates a diverse range of analytical approaches, including the insightful PESTLE analysis, qualitative and quantitative assessments, absolute dollar opportunity analysis, and the robust Porter's Five Forces analysis. We leave no stone unturned when…

PTFE Moulded Rods Market Regional Riches: Promising Territories for 2024 Enterpr …

"This comprehensive PTFE Moulded Rods report offers a deep dive into the global market, encompassing a wide spectrum of analyses to equip you with a profound understanding of its dynamics. Beyond the standard SWOT analysis, our study incorporates a diverse range of analytical approaches, including the insightful PESTLE analysis, qualitative and quantitative assessments, absolute dollar opportunity analysis, and the robust Porter's Five Forces analysis. We leave no stone unturned when…

PTFE Molded Tubes Market Bright Horizons: Positive Market Indicators Revealed | …

"This comprehensive PTFE Molded Tubes report offers a deep dive into the global market, encompassing a wide spectrum of analyses to equip you with a profound understanding of its dynamics. Beyond the standard SWOT analysis, our study incorporates a diverse range of analytical approaches, including the insightful PESTLE analysis, qualitative and quantitative assessments, absolute dollar opportunity analysis, and the robust Porter's Five Forces analysis. We leave no stone unturned when…

PTFE Moulded Rods Market Regional Riches: Promising Territories for 2024 Enterpr …

"This comprehensive PTFE Moulded Rods report offers a deep dive into the global market, encompassing a wide spectrum of analyses to equip you with a profound understanding of its dynamics. Beyond the standard SWOT analysis, our study incorporates a diverse range of analytical approaches, including the insightful PESTLE analysis, qualitative and quantitative assessments, absolute dollar opportunity analysis, and the robust Porter's Five Forces analysis. We leave no stone unturned when…

PTFE Fabric Market Report 2018: Segmentation by Type (PTFE Coated Fabric, Nonwov …

Global PTFE Fabric market research report provides company profile for Taconic (US), FIBERFLON (Turkey), Saint-Gobain Performance Plastics (France), W. L. Gore & Associates, Inc. (US), Chukoh Chemical Industries (Japan), Daikin Industries (Japan), Sefar AG (Switzerland) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth…

PTFE Membrane Market Analysis Report By Key Companies- Saint-Gobain, Gore, Donal …

The Report published on UpMarketResearch.com about “PTFE Membrane Market” is spread across 126 pages and provides newest industry data, market future trends, allowing you to identify the products and end users driving Revenue growth and profitability. The industry report lists and studies the leading competitors, also provides the insights with strategic industry Analysis of the key factors influencing the market

PTFE Membrane Market Research Report is a professional and in-depth study…