Press release

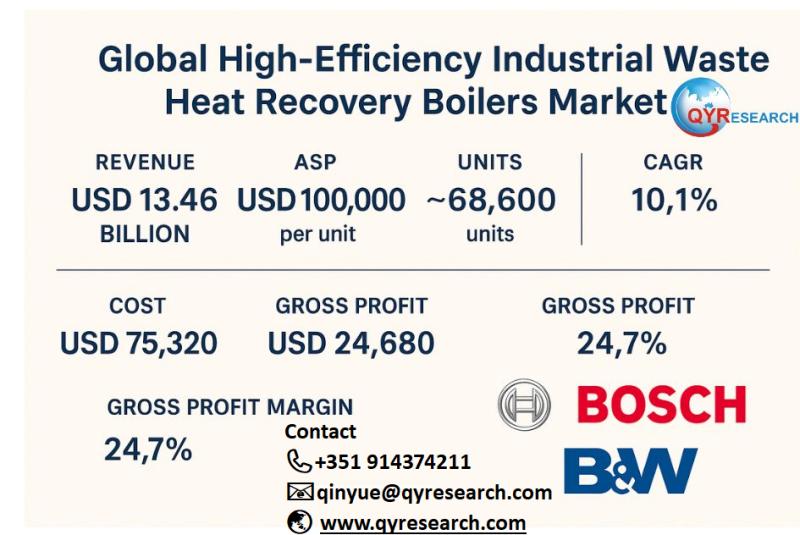

Global High Efficiency Industrial Waste Heat Recovery Boilers Market to Reach USD 13.46 Billion by 2031 Led by Bosch and B&W

The global market for High-Efficiency Industrial Waste Heat Recovery Boilers is accelerating as manufacturers and end-users push toward deeper decarbonization and lower energy bills. According to the 2025 edition of Global High-Efficiency Industrial Waste Heat Recovery Boilers Market Outlook, In-Depth Analysis & Forecast to 2031 from QYResearch, the market is projected to grow from US$ 6,863 million in 2024 to US$ 13,459 million by 2031, a 10.1% CAGR (2025-2031).Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) https://www.qyresearch.com/sample/4936811

Company List

Bosch Thermotechnology

General Electric

Siemens Energy

Mitsubishi Power

ABB

Babcock & Wilcox Enterprises

Cleaver-Brooks

John Wood Group PLC

Valmet

Thermax Limited

Viessmann

Hoval

ZVU Engineering

AC Boilers

Bono Energia

Rentech Boiler Systems

Forbes Marshall

Aalborg CSP

Cannon Bono Energia

Doosan Heavy Industries & Construction

Foster Wheeler

Hamon D'Hondt

Enertime

Kawasaki Heavy Industries

Hitachi Zosen Inova

Amec Foster Wheeler

Sugimat

PETROJET

Climeon

Clayton Industries

Product profiles for five leading companies:

Bosch Thermotechnology - Universal Heat Recovery Steam Boiler (HRSB)

• Type: Heat-recovery shell boiler for process steam from waste flue gas

• Steam output: 400-4,100 kg/h

• Safety pressure: 10 or 16 bar (saturated steam)

• Flue-gas side: Accepts waste-gas temps up to 550 °C; handles ~500-23,500 kg/h flue-gas volume

• Integration: Suitable for ~0.5-4 MWel CHP units; optional economizer and flue-gas bypass for efficiency/continuity

Babcock & Wilcox - Refinery FCCU Waste Heat Boiler (case spec)

• Service: Replacement FCCU CO-boiler with waste-heat recovery unit at a large U.S. refinery

• Steam generation: 111,900 lb/h (≈14.1 kg/s)

• Steam conditions: 415 psig (≈28.6 bar), 574 °F (≈301 °C)

• Features: Integrated sootblowers; designed for FCC flue-gas duty to improve reliability and extend run length

Thermax Limited - Waste Heat Recovery Boiler (Cement PH/AQC System)

• Reference duty (kiln ~4,800 TPD): Three-boiler configuration (Preheater, Calciner, Clinker Cooler)

• Steam generation (approx.): PH: 9 TPH; Calciner: 21 TPH; Cooler: 20 TPH

• Steam conditions: 17 kg/cm2(g) (≈1.67 MPa(g)), 325 °C

• Flue-gas inputs (approx.): PH 111,000 Nm3/h @ 365 °C; Calciner 250,000 Nm3/h @ 365 °C; Cooler 210,000 Nm3/h @ 375 °C; dust up to ~100 g/Nm3 (design basis)

Kawasaki Heavy Industries - Cement Plant Waste Heat Power Generation (PH + AQC Boilers)

• System scope: Preheater (PH) and Air-Quenching Cooler (AQC) waste-heat boilers driving a steam turbine-generator

• Plant impact: Typically supplies ~20-30% of a cement plant's electricity demand; ~30% coverage cited on modern PH lines

• Output benchmarks: 25-45 kWh per ton of clinker; for a 5,000 TPD line, indicative ~6-9 MW net depending on losses and cyclone stages

• Footprint: Extensive installed base and long track record on cement WHR systems

RENTECH Boiler Systems - Custom Waste Heat / HRSG Solutions

• Capacity envelope: Custom waste-heat boilers and HRSGs up to ~400,000 lb/h steam (≈50 kg/s)

• Typical design pressures: ~150-1,000 psig

• Thermal limits: HRSG designs handling gas paths to ~1,600 °F (≈871 °C); fresh-air firing options for turbine-offline operation

• Process conditions: Configurable for high flue-gas pressure, solids loading, and corrosive constituents; engineered to industry standards

Application List

Steel Industry

Cement Industry

Glass Manufacturing

Chemical and Petrochemical Industry

Others

Classification List

Flue Gas Waste Heat Recovery Boiler

Hot Water Waste Heat Recovery Boiler

Steam Waste Heat Recovery Boiler

Latest Data

• Forecasted Market Size in 2031: US$ 13,459 million

• CAGR (2025-2031): 10.1%

• Market Size available for years: 2025-2031

• 2024 global production: ~68,600 units

• Average selling price (ASP) 2024: ~US$100,000 per unit

• Regional Outlook (high level): Growth across North America, Europe, and Asia-Pacific, with APAC leading expansion and Europe/North America supported by policy-driven industrial decarbonization programs.

Cost / Gross Profit / Gross Profit Margin

Using the report's ASP ≈ US$100,000 and company-reported gross margins from leading OEMs active in boilers and waste-heat solutions, the indicative economics per unit are as follows:

• Babcock & Wilcox (gross margin ≈ 24.68% in 2024):

Approx. gross profit US$24,680; cost of goods sold ≈ US$75,320.

• Bosch Group (gross margin ≈ 30.7% in 2024):

Approx. gross profit US$30,700; cost ≈ US$69,300.

• Thermax (FY25 gross profit margin ≈ 8.7%):

Approx. gross profit US$8,700; cost ≈ US$91,300.

Interpretation: These are company-reported gross margins at enterprise/segment level applied to the product ASP as a reasonable proxy to illustrate per-unit economics in this category; actual project margins vary by specification, scope, and contract structure.

2025 Trend Briefing & Notable Company Results

Electrification, low-grade heat capture, and digital optimization are redefining waste-heat recovery in 2025. Industrial buyers in steel, cement, glass, and chemicals are accelerating projects that turn exhaust and process heat into useful steam and hot water, shrinking fuel bills and Scope-1 emissions while de-risking exposure to volatile gas prices and evolving carbon costs. The market's 10.1% CAGR through 2031 (from US$ 6.9B in 2024 to US$ 13.5B) reflects not only higher adoption rates but also rising average system sophistication: higher-temperature materials, corrosion-and-fouling-resistant heat exchangers, smarter soot-blowing, and deeper integration with plant controls.

Flagship achievement-industrial steam, without the flame. In 2025, AtmosZero installed the first commercial Boiler 2.0-an electric, heat-pump-based, drop-in industrial steam system-at New Belgium Brewing (Fort Collins, U.S.). The milestone demonstrates that medium-pressure process steam can be delivered without on-site combustion, using high-efficiency vapor-compression cycles that convert electricity into steam at markedly better system COP than traditional resistance boilers. The installation was completed with no production downtime, signaling maturing retrofit pathways for brownfield facilities. AtmosZero also announced its manufacturing ramp at a 100,000-sq-ft factory in Colorado-evidence that the supply side is mobilizing to meet industrial electrification demand. For energy managers, the upshot is clear: when grid CO2 intensity is falling (or when paired with renewables/PPAs), electric steam begins to out-compete gas not only on carbon but increasingly on total cost of ownership.

Heat-pump + WHR hybrids move center stage. Beyond boilers, high-lift industrial heat pumps are being blended with waste-heat recovery to harvest low-grade heat once considered too cool to monetize. In 2025, GEA announced deployments that repurpose waste heat from food production and district-energy assets, in some cases relegating the boiler to backup duty. The Tallinn project with Utilitas and multiple food-processing references show that when cooling and heating are co-optimized, a single integrated system can cool the process stream and simultaneously raise waste heat to useful hot-water/steam temperatures, trimming both electrical and fuel loads. This pattern is spreading to beverages, meat processing, and specialty chemicals, where continuous duty, tight temperature control, and clean-in-place cycles reward closed-loop heat reuse.

Policy & procurement unlock pipeline scale. In June 2025, ENGIE announced a sweeping partnership with Airbus to decarbonize 22 European industrial sites by 2030, targeting 20% energy-purchase reductions and 85% GHG cuts. Programs like this aggregate multiple heat-recovery and electrified-steam opportunities under a single commercial umbrella, easing vendor qualification and speeding deployment. Meanwhile, the Renewable Thermal Collaborative updated its Industrial Heat Pump Decision Support Tools in 2025, improving technology screening and ROI modeling for large thermal energy users. These initiatives tend to shorten sales cycles for WHR boilers integrated with electrified preheating and steam boosting.

R&D focuses on low-temperature economics and control. The California Energy Commission in 2025 reported on a low-temperature WHR system designed for economic viability, underscoring where many plants still sit: plenty of low-grade heat, historically overlooked due to poor payback or process constraints. In parallel, 2025 white papers from automation vendors emphasize advanced process control (APC) and energy-aware optimization-ensuring the recovered heat is actually used at the right time/temperature and that emissions costs are reflected in control objectives. Combining smart controls, self-cleaning exchangers, and predictive maintenance materially improves realized efficiency, narrowing the gap between design intent and field performance.

What's new on the boiler itself? For high-efficiency WHR boilers, 2025 innovations concentrate on:

• Materials & geometry to increase heat-transfer coefficients while resisting acid dewpoint corrosion and particulate fouling common in steel/cement flue gas;

• Modular economizers and condensing sections, with smart condensate handling;

• Digital twins & soft sensors that track effective UA, flag fouling onset, and optimize soot-blowing intervals to protect both efficiency and tube life;

• Hydrogen-ready and multi-fuel integration, ensuring the boiler island remains compatible with future fuels and hybridized with electric steam boosters;

• Procurement models (ESCO-style, heat-as-a-service) that de-risk capex, increasingly important given tariff-driven cost volatility on metals and components.

Margins and pricing remain disciplined. Public filings in 2024-2025 show gross margin dispersion across global boiler OEMs-from single-digit GP% in some project-heavy mixes to ~25-31% at diversified engineering groups. For buyers, the practical read-through is that spec-tight projects command higher ASPs but can pay back through energy savings and carbon-cost avoidance. For sellers, the mix shift toward higher-value WHR + electrification packages (boiler + heat pump + controls + service) aims to stabilize gross profit while delivering better lifecycle outcomes.

Sector snapshots.

• Steel & Cement: High-temperature exhaust streams continue to anchor demand, especially where kiln and reheat furnaces run 24/7-ideal for base-load WHR steam that displaces fossil-fired boilers.

• Glass Manufacturing: Continuous furnaces with consistent flue profiles are seeing larger WHR + ORC or WHR to power/steam hybrids in Asia and the Middle East.

• Chemicals & Petrochemicals: Growing emphasis on product purity and uptime favors modular WHR retrofits that avoid process side risks, with digital monitoring to maintain heat-balance targets.

• Food & Beverage: 2025 case studies show waste vapor streams and hot-water loops being harvested and re-lifted via heat pumps, drastically cutting fuel; boilers either trim or sit on standby-a sharp break from legacy designs.

Supply chain watch-outs. The report highlights that evolving U.S. tariff policies continue to inject trade-cost volatility, affecting alloy steels, tube bundles, and control hardware. OEMs are responding with dual-sourcing, localized fabrication, and modular skids to contain lead times and protect pricing. Simultaneously, the AI-driven expansion of data centers is raising electricity demand-indirectly nudging industrials toward on-site heat efficiency so that grid power can be reserved for core loads. Large electrical OEMs' 2025 outlooks echo this tension: strong demand, disciplined margins, and continued focus on grid and gas-service businesses that complement electrified process heat.

Downstream companies:

ArcelorMittal

Tata Steel

POSCO

Nippon Steel Corporation

JSW Steel

LafargeHolcim (Holcim Group)

Heidelberg Materials

CEMEX

China National Building Material (CNBM)

Saint-Gobain

Asahi Glass Co. (AGC Inc.)

BASF SE

Dow Inc.

ExxonMobil

SABIC

Request for Pre-Order Enquiry On This Report https://www.qyresearch.com/customize/4936811

Bottom line for 2025: Waste-heat recovery boilers are no longer "just" energy-saving add-ons. They are becoming anchor assets in hybrid thermal systems-paired with industrial heat pumps, smart controls, and hydrogen-ready burners-to deliver reliable, lower-carbon steam and hot water. The Boiler 2.0 milestone proves that flameless steam is commercially real; the GEA-style heat-recovery integrations prove that closed-loop thermal management can push boilers to backup rather than baseload in certain duty cycles. Against this backdrop, the market's projected 10.1% CAGR to 2031 is grounded not only in policy, but also in a robust and diversifying technical playbook that converts previously stranded heat into profitable thermal work.

Chapter Outline:

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Information:

Tel: +1 626 2952 442 ; +351 914374211(Tel & Whatsapp); +86-1082945717

Email: qinyue@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About us:

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

Related Report:

Global High-Efficiency Industrial Waste Heat Recovery Boilers Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/4936812/high-efficiency-industrial-waste-heat-recovery-boilers

Global High-Efficiency Industrial Waste Heat Recovery Boilers Market Outlook, In‐Depth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/4936811/high-efficiency-industrial-waste-heat-recovery-boilers

2025年全球工业废热高效回收锅炉行业总体规模、主要企业国内外市场占有率及排名

https://www.qyresearch.com.cn/reports/5747155/high-efficiency-industrial-waste-heat-recovery-boilers

2025-2031全球及中国工业废热高效回收锅炉行业研究及十五五规划分析报告

https://www.qyresearch.com.cn/reports/5747154/high-efficiency-industrial-waste-heat-recovery-boilers

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global High Efficiency Industrial Waste Heat Recovery Boilers Market to Reach USD 13.46 Billion by 2031 Led by Bosch and B&W here

News-ID: 4198557 • Views: …

More Releases from QYResearch Europe

Global Aerospace Grade Smart Assembly Lines Market 2024 USD 4251 Million to 2031 …

According to recent report from QYResearch, the global market for aerospace-grade smart assembly lines stood at US$4,251 million in 2024 and is projected to reach US$8,712 million by 2031 at a 10.2% CAGR (2025-2031). In 2024, approximately 670 lines were produced globally at an average selling price (ASP) of about US$6.343 million per line. These highly automated systems integrate AI, industrial robotics, advanced sensing, and digital control to deliver repeatable,…

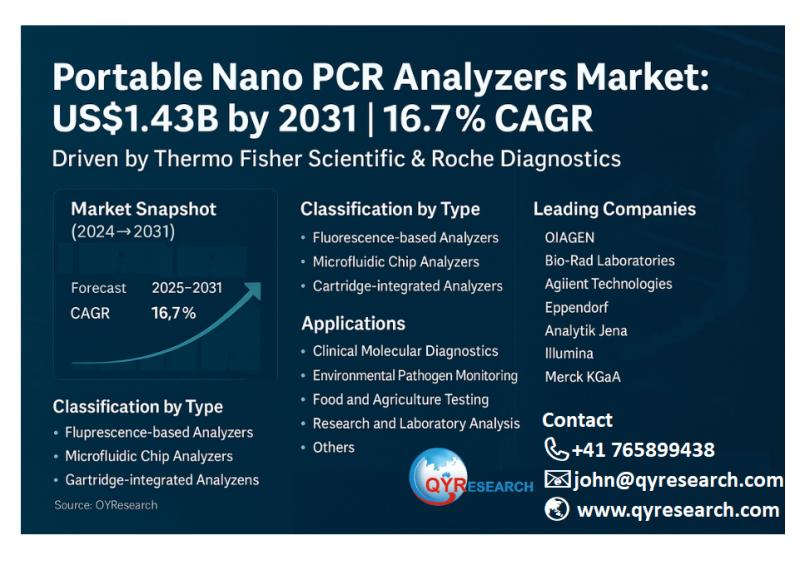

Portable Nano PCR Analyzers Market Growth to US$1.43 Billion by 2031 with 16.7% …

According to the latest QYResearch Report, the global market for Portable Nano PCR Analyzers was valued at US$484 million in 2024 and is expected to reach US$1,427 million by 2031, growing at a CAGR of 16.7% during the forecast period of 2025-2031. Global production in 2024 reached around 96,800 units, with an average price of about US$5,000 per unit. These portable devices utilize nanotechnology-enhanced PCR processes for rapid on-site genetic…

Global Multiphase Flow Conveying Equipment Market to Reach USD 10.88 Billion by …

The global market for Multiphase Flow Conveying Equipment is transitioning from a specialized engineering niche to a core enabler of industrial efficiency across upstream energy, chemicals, mining, and wastewater sectors. According to QYResearch 2025 edition of Multiphase Flow Conveying Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031, the market was valued at US$7,380 million in 2024 and is projected to reach US$10,879 million by 2031,…

Global Smart Eye-Tracking Medical Devices Market Size Reaches US$3.0 Billion by …

The global Smart Eye-Tracking Medical Devices market has entered a stage of accelerated clinical adoption and product diversification. According to QYResearch 2025 Global Smart Eye-Tracking Medical Devices Market Research Report, the market was valued at US$973 million in 2024 and is projected to reach US$3,009 million by 2031, growing at a CAGR of 17.5% from 2025 to 2031. Global output in 2024 reached approximately 64,900 units, with an average price…

More Releases for Boiler

Methanol Boiler Market Growth in Future Scope 2025-2032 | Henan Province Sitong …

Methanol Boiler Market Analysis - 2025-2032:

Coherent Market Insights has released a new report titled "Methanol Boiler Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2032 (Version 2025)." This report provides an in-depth analysis of the Methanol Boiler industry, featuring insights on market trends and performance. It also includes a thorough examination of competitors, regional dynamics, and the latest advancements within the market.

Coverage of the Methanol Boiler Market:

The report provides…

Global Boiler Market Size (2022-2028) Top Manufacturers Analysis | Dongfang Boil …

IBI has published a report entitled Global Boiler Market Research Report which provides comprehensive data on emerging trends, market drivers, growth opportunities, and barriers that could change the dynamics of the industry market. It provides an in-depth analysis of market segments which includes the product, application, and competitor analysis.

Click Here To Order A Sample Copy Of Boiler Global Market Report : https://www.infinitybusinessinsights.com/request_sample.php?id=643779

The Boiler Global Market Research Report provides close monitoring…

Boiler Market Next Big Thing | Major Manufacturers Are Dongfang Boiler Group, Ha …

Boilers play an important role in China’s economy and the Chinese people’s lives. The boiler is one of the major equipment of thermal power generation. By the end of 2020, the installed thermal power capacity in China was 1.24517 billion kilowatts, an increase of 4.7% YOY, accounting for 56.58% of the total installed capacity of electricity in China.

Buy This Report Here @ https://www.intelligencemarketreport.com/checkout/192533

According to IMR's analysis, by the end of…

Coal Fired Boilers Market is Booming Worldwide | Tianlu Boiler Industry, Hebei X …

Coal Fired Boilers Market describes an in-depth evaluation and Covid19 Outbreak study on the present and future state of the Coal Fired Boilers market across the globe, including valuable facts and figures. Coal Fired Boilers Market provides information regarding the emerging opportunities in the market & the market drivers, trends & upcoming technologies that will boost these growth trends. The report provides a comprehensive overview including Definitions, Scope, Application, Production…

Steam Boiler Systems Global Market 2018: Key Players – Hurst Boiler, Rentech B …

Steam Boiler Systems Industry

Description

Wiseguyreports.Com Adds “Steam Boiler Systems -Market Demand, Growth, Opportunities and Analysis Of Top Key Player Forecast To 2023” To Its Research Database

This report studies the global Steam Boiler Systems market status and forecast, categorizes the global Steam Boiler Systems market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, and other regions (India,…

Global Steam Boiler Systems Sales Market 2017 - Hurst Boiler, Rentech Boiler Sys …

Steam Boiler Systems Industry Report introduced a Market Segment, Product Types, with Sales, Revenue, Price, Market Share and Growth, focuses on top players in these regions/countries, Size, Share, Demand, Analysis, Manufacturers, Type and Application, Forecast 2017 to 2022

The report begins with a broad introduction of the Steam Boiler Systems market and then drills deeper into specific segments such as application, regional markets, end-users, policy analysis, value chain structure, and emerging…