Press release

Global Aluminum Extrusion Market Set for Robust Growth, Driven by Innovation and Sustainability Initiatives

The global aluminum extrusion market is entering a period of remarkable expansion, with an estimated market valuation of USD 138.6 billion in 2025 projected to reach USD 217.3 billion by 2035, reflecting a compound annual growth rate (CAGR) of 4.6% over the forecast period. This growth trajectory is propelled by the increasing demand for lightweight, durable, and corrosion-resistant materials across diverse industrial sectors, as well as advancements in precision engineering and sustainable manufacturing practices.Automotive and Aerospace Lead the Charge

Among product categories, the automotive chassis segment is poised to dominate, accounting for nearly 48.6% of total market revenue in 2025. This surge is fueled by the growing adoption of lightweight aluminum structures to meet stringent emission standards and enhance vehicle performance. Aluminum's superior strength-to-weight ratio and durability make it ideal for automotive chassis, contributing to crash performance, fuel efficiency, and electric vehicle innovations.

Full Market Report available for delivery. For purchase or customization, please request here:

https://www.futuremarketinsights.com/reports/sample/rep-gb-5463

Meanwhile, the aerospace sector emerges as the leading end-user segment, representing 42.7% of market revenue in 2025. Aluminum extrusions are extensively employed in structural components, fuselage frames, and seating systems due to their lightweight yet high-strength properties. Increasing global air travel and the expansion of commercial fleets are further boosting demand. Additionally, innovations in high-strength aluminum alloys specifically designed for aerospace applications are reinforcing the prominence of this sector.

Technological Advancements Driving Market Expansion

The market's robust outlook is underpinned by technological innovations in die design, automation, and alloy development. Manufacturers are increasingly investing in automation solutions and precision extrusion technologies, enabling the production of complex profiles suitable for automotive, aerospace, construction, and electronics applications. Industry leaders are also focusing on energy-efficient production processes and sustainability initiatives, meeting regulatory standards while enhancing operational efficiency.

High-capacity aluminum extrusion machinery is facilitating faster throughput, improved accuracy, and reduced waste, which are critical for meeting the demands of large-scale industrial applications. These advancements, coupled with increasing focus on lightweight materials to improve fuel efficiency and reduce environmental impact, are creating new growth avenues for established manufacturers and emerging players alike.

Regional Insights and Growth Hotspots

North America, Asia-Pacific, and Europe are key regions driving market expansion. In the United States, strong demand from the automotive sector and increased adoption of green building practices are contributing to growth. China, accounting for nearly 59.5% of global market share, continues to lead due to robust manufacturing capabilities and rising infrastructure investments. Europe maintains its position as a significant market, supported by stringent industrial standards, strong automotive and aerospace industries, and adoption of innovative extrusion technologies.

Asia-Pacific, excluding China, is emerging as a high-growth region. Rapid urbanization, expansion of the automotive sector in India and Thailand, and increasing adoption of aluminum in construction are creating lucrative opportunities. Favorable government policies, such as India's National Aluminium Policy, are further encouraging the use of aluminum extrusions across industries.

Sustainability and Lightweight Materials Driving Demand

The global shift toward sustainable manufacturing and lightweight materials is a major driver for aluminum extrusions. Aluminum's recyclability, corrosion resistance, and structural strength make it an ideal alternative to steel, wood, and plastics. Its ability to be recycled repeatedly without loss of integrity aligns with eco-friendly initiatives, particularly in automotive, aerospace, and construction applications. The growing demand for lightweight vehicles, energy-efficient buildings, and sustainable packaging solutions continues to propel market growth.

Challenges and Opportunities for Market Players

Despite the promising growth outlook, the aluminum extrusion market faces challenges such as high capital costs, energy-intensive production processes, fluctuating aluminum prices, and competition from alternative materials. Establishing a full-scale extrusion facility requires substantial investment, and production efficiency may be constrained by slower extrusion speeds.

However, these challenges also present opportunities for manufacturers to innovate. The rising demand for customized and complex extruded profiles allows both established companies and startups to explore niche applications and differentiate themselves. Automation, Industry 4.0 integration, and energy-efficient processes are key strategies enabling market players to overcome cost pressures while expanding their offerings.

Get the Report Brochure Now:

https://www.futuremarketinsights.com/reports/brochure/rep-gb-5463

Key Players Expanding Their Footprint

The market features a mix of established industry leaders and emerging manufacturers. Tier-1 players such as Hindalco Industries, Jindal Aluminium Limited, China Zhongwang Holdings, Constellium N.V., Hydro Extrusions, Arconic Inc., and Kaiser Aluminum Corp. dominate with extensive production capacities and global reach. Tier-2 companies, including Zahit Aluminum, Bonnell Aluminum, SKM Co., Keymark Corporation, and Hulamin Ltd., focus on regional markets while leveraging innovative technologies to expand their footprint.

Several companies are actively investing in new facilities and technological upgrades. For instance, Hindalco Industries recently announced the opening of a new extrusion plant in Silvassa, aimed at producing a diverse range of aluminum products for downstream applications. These investments demonstrate the commitment of both established and new manufacturers to scale operations and address evolving market demands.

Future Outlook

Looking ahead, the aluminum extrusion market is expected to maintain a steady growth trajectory through 2035, driven by rising adoption in automotive, aerospace, and construction sectors, ongoing technological advancements, and sustainability initiatives. The market's expansion is also supported by increasing urbanization, infrastructure development, and the growing emphasis on lightweight, energy-efficient solutions.

With aluminum's unmatched combination of recyclability, strength, and versatility, the extrusion market is well-positioned to cater to the demands of modern industries. Manufacturers embracing innovation, customization, and sustainable practices are likely to thrive, creating a dynamic and competitive landscape.

Conclusion

The aluminum extrusion market presents significant opportunities for growth, fueled by the demand for lightweight, durable, and corrosion-resistant materials across a range of industries. Technological innovation, sustainability efforts, and regional expansion are shaping the future of this market, providing a fertile ground for both established players and new entrants. As global industries continue to prioritize efficiency, environmental responsibility, and advanced engineering solutions, aluminum extrusion stands at the forefront of modern manufacturing, driving performance, and innovation worldwide.

Key Companies in Aluminum Extrusion Market:

Hindalco Industries | Jindal Aluminium Limited | China Zhongwang Holdings Limited | Constellium N.V. | Hydro Extrusions | Arconic Inc. | Zahit Aluminum | Bonnell Aluminum | SKM Co., Ltd. | Keymark Corporation | Kaiser Aluminum Corp. | Hulamin Ltd. | WISPECO Aluminium

Explore Similar Insights

Aluminum Extrusion Lubricants Market

https://www.futuremarketinsights.com/reports/aluminum-extrusion-lubricants-market

Aluminum Composite Materials Market

https://www.futuremarketinsights.com/reports/aluminum-composite-materials-market

Aluminum Coated Thermal Protective Clothing Market

https://www.futuremarketinsights.com/reports/aluminum-coated-thermal-protective-clothing-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Aluminum Extrusion Market Set for Robust Growth, Driven by Innovation and Sustainability Initiatives here

News-ID: 4195973 • Views: …

More Releases from Future Market Insights

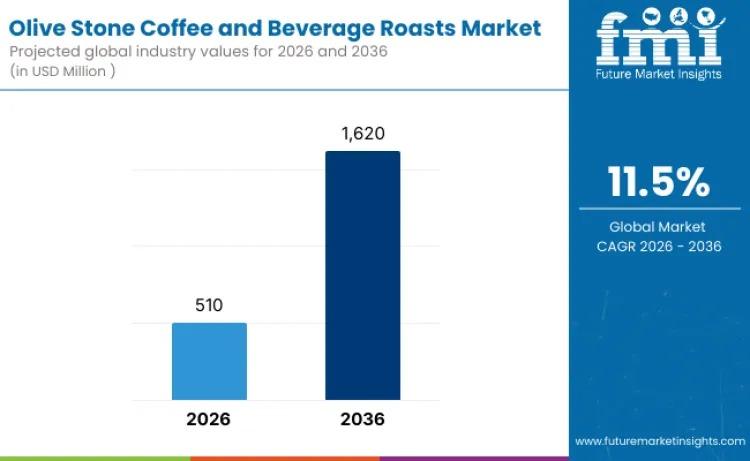

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

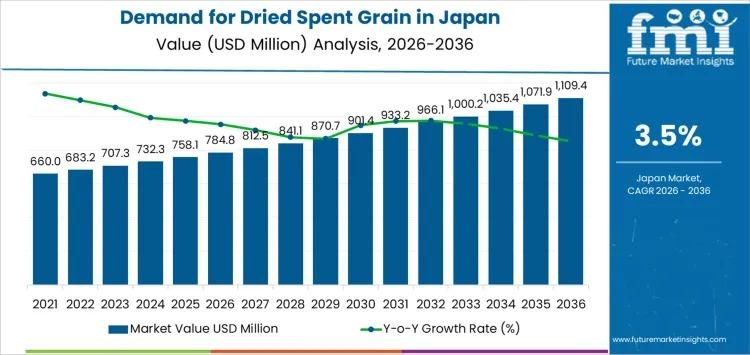

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

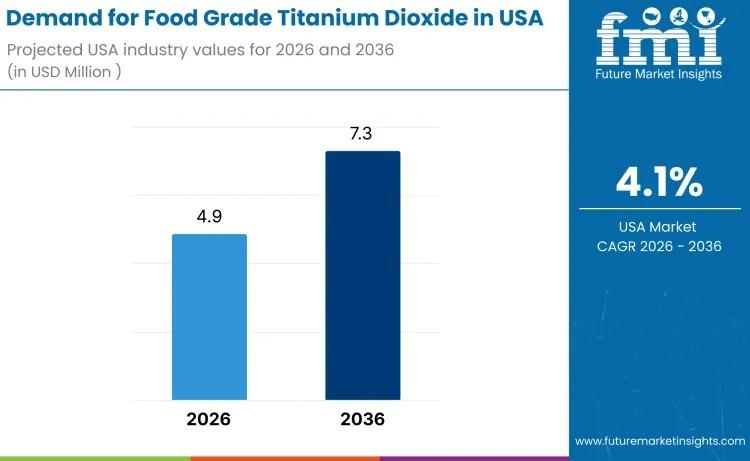

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

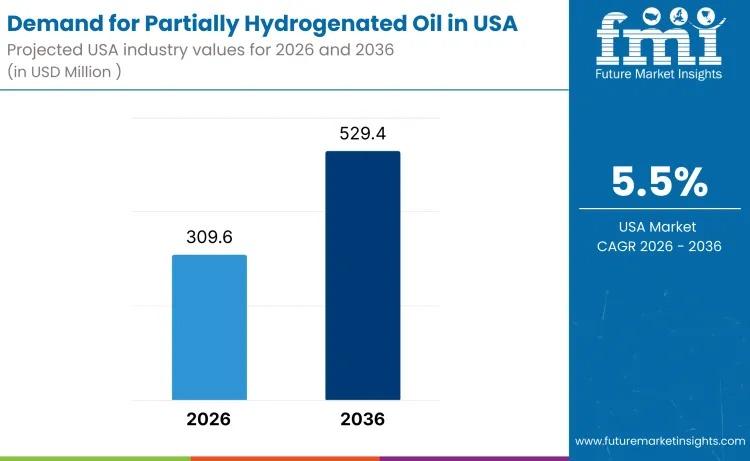

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…