Press release

USA PFAS-Free Barrier Coatings for Food Paper Market Set for Explosive Growth, Reaching at 15.2% by 2035

The global PFAS-free barrier coatings for food paper market is poised for transformative growth, projected to surge from USD 1.8 billion in 2025 to USD 6.4 billion by 2035. This unprecedented expansion represents a 256% increase over the decade, reflecting a robust compound annual growth rate (CAGR) of 13.6%. As regulatory pressures mount, consumer awareness rises, and technological innovation accelerates, both established and emerging players in the market are positioning themselves to capitalize on this momentum.Driving Forces Behind Market Expansion

The shift toward PFAS-free coatings is primarily fueled by a confluence of regulatory, environmental, and consumer-driven factors. Governments worldwide are tightening restrictions on per- and polyfluoroalkyl substances (PFAS) due to their persistence in the environment and potential health impacts. These regulatory frameworks are prompting food packaging manufacturers and quick-service restaurants (QSRs) to adopt safer, more sustainable alternatives, creating significant growth opportunities for innovative coating technologies.

Full Market Report available for delivery. For purchase or customization, please request here:

https://www.futuremarketinsights.com/reports/sample/rep-gb-24982

Simultaneously, consumer health consciousness and demand for sustainable packaging solutions are influencing corporate strategies. Foodservice operators are increasingly prioritizing PFAS-free coatings to meet corporate ESG goals, reinforce brand trust, and align with evolving consumer expectations. These market dynamics have catalyzed investment in water- and bio-based coating technologies that improve barrier performance, recyclability, and cost efficiency, facilitating adoption across developed and emerging markets.

Segment Insights: Biopolymer Coatings and QSR Applications Lead the Way

Among the various coating technologies, biopolymer-based coatings are expected to capture 41% of the market in 2025. These coatings offer superior environmental profiles and biodegradability while maintaining high grease and moisture resistance, making them ideal for commercial food packaging. Mineral-based coatings, accounting for 28% of the market, remain essential for applications requiring enhanced barrier performance, while waterborne polymer dispersions serve specialized high-performance applications.

In terms of application, quick-service restaurant wraps and clamshells are projected to dominate with a 39% market share in 2025. The high-volume nature of QSR packaging, combined with regulatory compliance requirements and performance reliability, positions these applications as the backbone of PFAS-free coating adoption. Beyond QSRs, bakery, confectionery, and frozen food packaging segments are increasingly incorporating PFAS-free solutions, signaling broader market penetration.

Distribution Channels and Market Reach

Direct supply to converters is projected to command a leading 53% share of the PFAS-free barrier coatings distribution market by 2025. This channel provides packaging converters with tailored technical support, customized formulations, and integrated solutions that enhance operational efficiency. Foodservice distributors and retail channels also play crucial roles, but direct converter supply remains the primary driver for systematic PFAS-free coating deployment across large-scale food packaging operations.

Technological Innovation and Commercial Viability

The market's growth is underpinned by significant technological advancements. Manufacturers are developing sophisticated biopolymer and hybrid formulations that optimize grease resistance, moisture barrier properties, and manufacturing processability. These innovations not only enhance functional performance but also reduce costs and improve sustainability by incorporating renewable raw materials. Advanced automated application and quality control systems ensure consistent coating performance, allowing for seamless scaling from pilot projects to commercial production.

The development of integrated regulatory compliance frameworks further supports global adoption. Companies are harmonizing PFAS-free certifications with food contact safety standards, facilitating streamlined approvals across multiple jurisdictions. By combining advanced barrier performance with comprehensive compliance documentation, manufacturers are enabling food packaging producers to adopt PFAS-free solutions confidently and efficiently.

Get the Report Brochure Now:

https://www.futuremarketinsights.com/reports/brochure/rep-gb-24982

Global Market Dynamics

The United States is projected to lead the market with a 15.2% CAGR through 2035, driven by state-level PFAS bans in California and New York, as well as federal chemical safety initiatives. Germany and France are experiencing significant growth at 14.1% and 13.5% CAGR, respectively, as EU directives and national regulations encourage PFAS-free adoption. Emerging markets such as India are witnessing rapid expansion at 13.1% CAGR, propelled by the growth of QSRs and evolving regulatory frameworks. Other key markets, including the UK, China, and Japan, are scaling production and implementing PFAS-free solutions in retail and specialized foodservice applications, further broadening market penetration.

Competitive Landscape and Market Leadership

The PFAS-free barrier coatings market is characterized by intense competition among established packaging giants, specialized coating technology providers, and integrated food packaging solution companies. Key players are leveraging their expertise to develop comprehensive PFAS-free coating platforms that combine advanced biopolymer formulations with scalable manufacturing capabilities.

Mondi Plc is positioned to lead the market with a projected 14% share in 2025, thanks to its integrated approach that combines cutting-edge coating technology, large-scale manufacturing, and technical consultation services. Other prominent players include Stora Enso, Huhtamaki Oyj, WestRock Company, Georgia-Pacific, UPM-Kymmene, Nippon Paper Industries, Sealed Air, Smurfit Kappa, and Footprint LLC. These companies are actively investing in R&D, regulatory compliance, and sustainable manufacturing practices to strengthen their market positions and meet growing global demand.

Looking Ahead

Between 2025 and 2030, the PFAS-free barrier coatings market is expected to expand from USD 1.8 billion to USD 3.5 billion, driven by regulatory compliance mandates and widespread adoption in foodservice applications. The subsequent phase, from 2030 to 2035, will see the market grow from USD 3.5 billion to USD 6.4 billion, fueled by penetration into specialty and frozen food packaging, development of hybrid coating technologies, and continued innovation in integrated barrier solutions.

As global demand for environmentally safe and high-performance food packaging intensifies, PFAS-free barrier coatings are emerging as a cornerstone of sustainable packaging strategies. Both established and emerging manufacturers are seizing the opportunity to innovate, scale, and lead the market, transforming the way food is safely packaged while addressing critical environmental and consumer health concerns.

Explore Similar Insights

Barrier Material Market

https://www.futuremarketinsights.com/reports/barrier-material-market

Barrier Tube Packaging Market

https://www.futuremarketinsights.com/reports/barrier-tube-packaging-market

Barrier Shrink Bags Market

https://www.futuremarketinsights.com/reports/barrier-shrink-bags-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release USA PFAS-Free Barrier Coatings for Food Paper Market Set for Explosive Growth, Reaching at 15.2% by 2035 here

News-ID: 4194428 • Views: …

More Releases from Future Market Insights

Japan Caramel Food Colors Industry Outlook to 2036: Strategic Insights for R&D, …

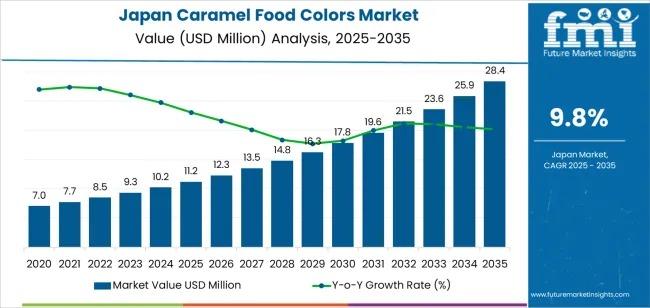

The Japanese caramel food colors market is on a steady growth trajectory, with demand projected to rise from USD 11.2 million in 2025 to USD 28.4 million by 2035, registering a CAGR of 9.8%. The initial phase of the forecast period (2025-2030) anticipates a steady increase in demand, reaching approximately USD 17.8 million by 2030, driven by the expanding use of caramel colors across confectionery, dairy, and baked goods.

The market's…

Comprehensive Analysis of the Japan Butter Flavor Market: Technology Evolution, …

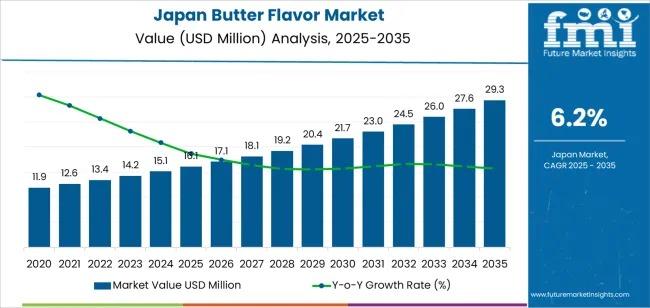

The demand for butter flavor in Japan is projected to rise from USD 16.1 million in 2025 to USD 29.4 million by 2035, reflecting a steady compound annual growth rate (CAGR) of 6.2%. This growth is underpinned by increasing adoption across bakery products, confectionery items, and dairy-based preparations, as manufacturers seek to enhance taste experiences and deliver authentic dairy character in a wide range of food offerings.

The Japanese bakery and…

Japan Casein Peptone Market Deep-Dive 2026-2036: Strategic Forecasts, Market Ent …

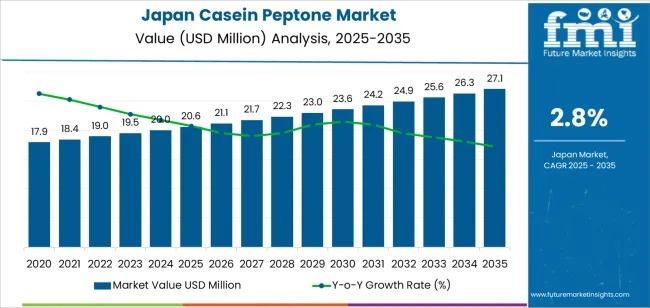

The demand for casein peptone in Japan is projected to grow steadily, reaching USD 27.1 million by 2035, up from USD 20.6 million in 2025, reflecting a compound annual growth rate (CAGR) of 2.8%. During the early forecast period (2025-2030), demand is expected to rise from USD 20.6 million to approximately USD 23.6 million, supported by its widespread applications in biotechnology, pharmaceuticals, and food industries. Casein peptone continues to play…

Global Boride Powder Market Size, Share & Forecast: High-Growth Segments, Value …

The global boride powder market is valued at USD 19.7 billion in 2025 and is projected to reach USD 32.2 billion by 2035, advancing at a steady 5.0% CAGR over the forecast period. This upward trajectory reflects increasing adoption of boride-based compounds in aerospace technology, high-temperature processing environments, and advanced coating applications, where exceptional thermal stability, corrosion resistance, and mechanical strength are essential for operational performance and product reliability.

Key Market…

More Releases for PFAS

PFAS Remediation Market Is Going to Boom |• AquaBlok • Arcadis

Worldwide Market Reports has released a new in-depth research study on the "PFAS Remediation Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities, technological advancements, innovation trends,…

PFAS-Free Synthetic Turf Solutions | Eco-Friendly Artificial Grass and Non-PFAS …

This article delves into the key challenges and difficulties faced by the synthetic turf industry in achieving a "PFAS-free" transition, with a focus on innovative non-PFAS additive solutions designed to offer a sustainable path that balances high performance, safety, and environmental responsibility.

Challenges in Traditional Synthetic Turf Manufacturing | PFAS Risks Performance vs. Safety Dilemma

Traditional synthetic turf often relies on fluorinated polymers to achieve:

- Exceptional UV and weather durability

- Stain and…

Global PFAS-free Membranes Market Outlook Report 2025

Global Info Research's report is a detailed and comprehensive analysis for global PFAS-free Membranes market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the PFAS-free Membranes market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of…

PFAS-free Polymer Membranes Market Demand Analysis Report 2025

Global Info Research announces the release of the report "Global PFAS-free Polymer Membranes Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report provides a detailed overview of the PFAS-free Polymer Membranes market scenario, including a thorough analysis of the PFAS-free Polymer Membranes market size, sales quantity, average price, revenue, gross margin and market share.The PFAS-free Polymer Membranes report provides an in-depth analysis of the competitive landscape,…

PFAS-free Polymer Processing Aids (PFAS-Free PPA Additives), a solution to the p …

In the plastic processing industry, die build-up is a common problem that can lead to surface defects in products, affecting product quality and production efficiency.

Die build-up refers to the accumulation of material at the outlet of the mold during plastic processing, forming deposits that are difficult to remove. This phenomenon usually occurs in injection molding, extrusion and other processes, especially in the processing of high viscosity and high melting point…

PFAS: What they are & how to avoid them

These "Forever Chemicals" have existed for what seems like forever, but they've just recently begun making headlines. Here's what you need to know about these troubling compounds.

In the world we live in today, the alphabet soup of acronyms for both good and bad substances can make your brain feel like mush. But there's one that you've probably seen popping up more and more. And it's one worth remembering.

PFAS, or "Forever…