Press release

Thermosetting Carbon Fiber Reinforced Plastic (CFRP) Market is projected to reach the value of USD 28.36 Billion by 2030.

The Thermosetting Carbon Fiber Reinforced Plastic (CFRP) Market was valued at USD 18.9 billion in 2024 and is projected to reach a market size of USD 28.36 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7%.Request Sample @ https://virtuemarketresearch.com/report/thermosetting-carbon-fiber-reinforced-plastic-market/request-sample

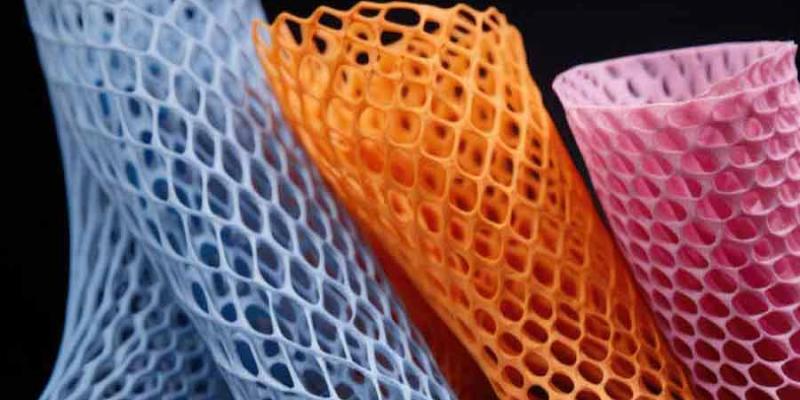

Thermosetting carbon fiber reinforced plastic represents one of the most advanced composite materials available for high-performance applications across multiple industries. These materials combine carbon fiber reinforcement with thermosetting resin matrices that cure into permanent chemical bonds. Once cured, thermosetting CFRP cannot be remolded or reformed, creating exceptionally strong and lightweight structures. Manufacturing processes require precise temperature and pressure control to achieve optimal material properties.

Modern thermosetting CFRP formulations offer superior mechanical properties compared to traditional materials like steel and aluminum. Engineers value the design flexibility that allows optimization of fiber orientation for specific load requirements. These materials resist corrosion, fatigue, and environmental degradation better than metallic alternatives. Quality control throughout manufacturing ensures consistent performance characteristics across large production volumes.

Growing environmental regulations drive long-term adoption of lightweight materials that improve fuel efficiency across transportation industries. Government mandates for reduced emissions push automotive and aerospace manufacturers toward advanced composites. Wind energy expansion requires longer turbine blades that only carbon fiber materials can support effectively. These regulatory trends create sustained market demand for decades ahead.

Infrastructure aging in developed countries creates replacement opportunities for thermosetting CFRP materials in construction applications. Traditional materials like steel and concrete suffer from corrosion and maintenance issues that composites eliminate. Bridge reinforcement and building rehabilitation projects increasingly specify CFRP materials for their durability advantages. Climate resilience requirements also favor materials that withstand extreme weather conditions.

The COVID-19 pandemic initially reduced thermosetting CFRP market demand through disrupted manufacturing operations across key end-use industries. Automotive production declined sharply as showrooms closed and consumer spending shifted away from major purchases. Aerospace orders collapsed as airlines grounded fleets and canceled aircraft deliveries. Construction projects faced delays due to safety protocols and supply chain disruptions.

Recovery patterns emerged differently across various application segments during the pandemic aftermath. Sporting goods demand surged as people sought outdoor recreational activities during lockdowns. Medical equipment manufacturing increased for ventilators and protective equipment that incorporated composite components. Wind energy projects accelerated as governments prioritized green recovery programs in economic stimulus packages.

Enquire Before Buying @ https://virtuemarketresearch.com/report/thermosetting-carbon-fiber-reinforced-plastic-market/enquire

Electric vehicle adoption creates immediate demand for lightweight thermosetting CFRP components that extend battery range through weight reduction. Automotive manufacturers face intense pressure to improve electric vehicle performance while maintaining safety standards. Carbon fiber body panels, structural components, and battery enclosures provide significant weight savings compared to traditional materials. Premium electric vehicle segments accept higher material costs for performance advantages.

Battery weight penalties make every pound of vehicle weight reduction valuable for electric vehicle design optimization. Thermosetting CFRP enables complex geometries that integrate multiple functions into single components. These design efficiencies reduce part counts while improving structural performance, justifying premium material costs through manufacturing savings.

Renewable energy infrastructure expansion presents substantial opportunities for large-scale thermosetting CFRP applications in wind turbine manufacturing. Blade lengths continue increasing to capture more wind energy, requiring materials that maintain stiffness over spans exceeding 100 meters. Traditional materials cannot meet these structural requirements at acceptable weights. Offshore wind projects especially demand corrosion-resistant materials that thermosetting CFRP provides.

Hydrogen storage applications represent emerging opportunities as the hydrogen economy develops for clean energy transportation and industrial processes. High-pressure hydrogen tanks require materials that combine strength, lightweight properties, and hydrogen barrier characteristics. Thermosetting CFRP meets these demanding requirements better than alternative materials, positioning the technology for rapid growth in hydrogen applications.

Automation integration transforms thermosetting CFRP manufacturing through advanced placement systems and quality monitoring technologies. Automated fiber placement reduces labor costs while improving consistency compared to manual layup processes. Real-time monitoring systems detect defects during manufacturing rather than after completion, reducing waste and improving efficiency. These technological advances make thermosetting CFRP more cost-competitive with traditional materials.

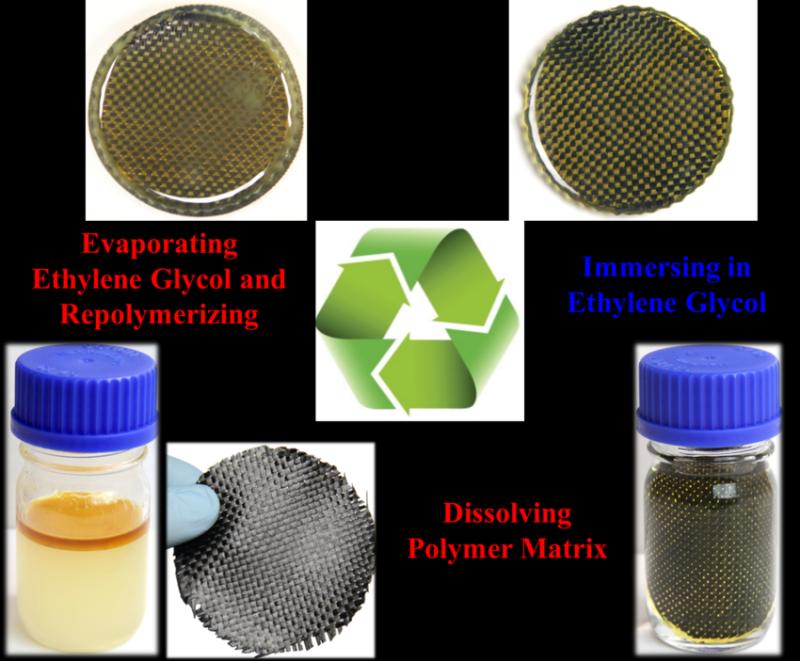

Recycling technology development addresses end-of-life concerns that previously limited thermosetting CFRP adoption in some applications. Chemical recycling processes recover carbon fibers from cured composites for reuse in new applications. Mechanical recycling creates chopped fiber reinforcement suitable for secondary applications. These innovations support circular economy initiatives while reducing raw material costs.

Market Segmentation:

By Resin Type:

Dominant segment - Epoxy

Epoxy resin systems dominate the thermosetting CFRP market with approximately 65% market share due to their excellent mechanical properties and processing characteristics. These resins provide superior adhesion to carbon fibers while offering wide processing windows that accommodate various manufacturing techniques. Aerospace applications particularly value epoxy systems for their proven reliability and extensive qualification databases that reduce certification risks.

Fastest growing segment - Polyester

Polyester resin systems demonstrate the fastest growth rate among thermosetting CFRP applications due to their cost advantages and simplified processing requirements. Automotive and wind energy applications increasingly adopt polyester-based composites where cost considerations outweigh the premium performance characteristics of epoxy systems. Improved polyester formulations narrow performance gaps while maintaining significant cost advantages for high-volume applications.

Buy Now @ https://virtuemarketresearch.com/checkout/thermosetting-carbon-fiber-reinforced-plastic-market

By End-Use Industry:

Dominant segment - Aerospace & Defense

Aerospace and defense applications represent the largest end-use industry segment with over 40% market share, driven by demanding performance requirements that justify premium material costs. Military aircraft, commercial aviation, and space applications require materials that perform reliably under extreme conditions. Long qualification cycles and established supply relationships create barriers to entry that protect market positions for established suppliers.

Fastest growing segment - Automotive

The automotive industry shows the fastest growth rate in thermosetting CFRP adoption as electric vehicle production accelerates and lightweight materials become essential for performance optimization. Carbon fiber components migrate from exotic supercars to mainstream electric vehicles as manufacturing costs decrease through automation and scale. Crash safety requirements drive adoption of energy-absorbing composite structures that outperform traditional materials.

By Manufacturing Process:

Dominant segment - Prepreg Layup

Prepreg layup processes dominate thermosetting CFRP manufacturing with approximately 45% market share due to superior quality control and material properties achieved through this technique. Aerospace applications particularly favor prepreg materials for their consistent fiber volume fractions and void content. Autoclave curing provides optimal consolidation and mechanical properties that meet demanding performance specifications.

Fastest growing segment - Resin Transfer Molding (RTM)

Resin Transfer Molding demonstrates the fastest growth rate among manufacturing processes as automotive applications demand high-volume production capabilities. RTM enables complex geometries with excellent surface finishes while maintaining cost-effectiveness for medium to high production volumes. Automated RTM systems reduce cycle times and labor requirements compared to traditional prepreg layup processes.

By Precursor Material:

Dominant segment - PAN-based

PAN-based carbon fibers capture the largest market share with over 90% of thermosetting CFRP applications due to their excellent mechanical properties and established supply chains. Polyacrylonitrile precursor materials provide the optimal balance of strength, stiffness, and cost for most composite applications. Manufacturing infrastructure and technical expertise concentrate around PAN-based fiber production, supporting market dominance.

Fastest growing segment - PAN-based

PAN-based carbon fibers maintain their position as both the largest and fastest-growing precursor material segment due to continuous technological improvements and expanding production capacity. Cost reductions through manufacturing scale and process optimization make PAN-based fibers accessible to broader application ranges. Alternative precursor materials remain niche applications with limited growth potential compared to PAN-based systems.

Regional Analysis

Dominant Region - North America

North America leads the global thermosetting CFRP market with approximately 38% market share, supported by major aerospace manufacturers and advanced automotive development programs. The United States aerospace industry creates substantial demand for high-performance composites while defense spending supports technology development. Established supply chains and skilled workforce availability enable complex manufacturing operations that other regions struggle to replicate.

Fastest growing Region - Asia Pacific

The Asia Pacific region demonstrates the highest growth rate in thermosetting CFRP consumption, driven by expanding automotive production and renewable energy infrastructure development. China's electric vehicle manufacturing surge creates enormous demand for lightweight composite components. Wind energy projects across the region require large-scale composite structures that traditional materials cannot provide effectively.

Latest Industry Developments:

• Leading thermosetting CFRP manufacturers are partnering with automotive OEMs to develop integrated supply chain solutions that combine material production with component manufacturing, enabling cost reductions through vertical integration while ensuring quality control and delivery reliability for high-volume automotive applications.

• Major industry players are investing heavily in next-generation recycling technologies that can recover high-quality carbon fibers from end-of-life thermosetting CFRP components, addressing sustainability concerns while creating secondary raw material sources that reduce dependence on virgin carbon fiber production and lower overall material costs.

• Composite manufacturers are implementing advanced digital manufacturing systems that integrate artificial intelligence and machine learning algorithms for real-time process optimization, quality prediction, and automated defect detection, significantly improving production efficiency and material consistency while reducing waste and manufacturing costs.

Read More @ https://virtuemarketresearch.com/report/thermosetting-carbon-fiber-reinforced-plastic-market

About Us:

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

103 Kumar Plaza,SRPF Road,

Ramtekadi,Pune,

Maharashtra - 411013

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Thermosetting Carbon Fiber Reinforced Plastic (CFRP) Market is projected to reach the value of USD 28.36 Billion by 2030. here

News-ID: 4193493 • Views: …

More Releases from Virtue Market Research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for CFRP

Carbon Fiber Reinforced Plastics Cfrp Market Size and Forecast

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- The global Carbon Fiber Reinforced Plastics Cfrp Market is expected to record a CAGR of XX.X% from 2024 to 2031 In 2024, the market size is projected to reach a valuation of USD XX.X Billion. By 2031 the valuation is anticipated to reach USD XX.X Billion.

The Carbon Fiber Reinforced Plastics (CFRP) market is experiencing rapid growth due to its exceptional properties such as high strength, lightweight, and…

Recycled CFRP Market Growth Status and Outlook 2023-2029 |

The global Recycled CFRP market is researched with great precision and in a comprehensive manner to help you identify hidden opportunities and become informed about unpredictable challenges in the industry. The authors of the report have brought to light crucial growth factors, restraints, and trends of the global Recycled CFRP market. The research study offers complete analysis of critical aspects of the global Recycled CFRP market, including competition, segmentation, geographical…

CFRP Recycle Market Outlook 2021: Big Things are Happening

Latest published market study on Global CFRP Recycle Market provides an overview of the current market dynamics in the CFRP Recycle space, as well as what our survey respondents—all outsourcing decision-makers—predict the market will look like in 2027. The study breaks market by revenue and volume (wherever applicable) and price history to estimates size and trend analysis and identifying gaps and opportunities. Some of the players that are in coverage…

Global CFRP Recycle Market Huge Growth Opportunity between 2020-2025

LP INFORMATION recently released a research report on the CFRP Recycle market analysis, which studies the CFRP Recycle's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global "CFRP Recycle Market 2019-2025" Research Report categorizes the global CFRP Recycle market by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share, growth…

CFRP Recycle Market Report Explored in Latest Research

The research report CFRP Recycle Market has incorporated the analysis of different factors that augment the market's growth. It constitutes trends, restraints, and drivers that transform the market in either a positive or negative manner. This section also provides the scope of different segments and applications that can potentially influence the market in the future. The detailed information is based on current trends and historic milestones. This section also provides…

CFRP Propeller Shaft Market Size, Share, Development by 2024

LP INFORMATION offers a latest published report on CFRP Propeller Shaft Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the CFRP Propeller Shaft market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019.…