Press release

Zinc Sulphite Production Cost Report 2025: Plant Setup Economics and Financial Outlook

Setting up a zinc sulphite production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Zinc Sulphite Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a zinc sulphite production plant cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/zinc-sulphite-manufacturing-plant-project-report/requestsample

What is Zinc Sulphite?

Zinc sulphite is an inorganic compound mainly comprised of zinc, sulfur, and oxygen, and is chemically represented as ZnSO3. Being commonly used because of its luminescent and optical properties, it is just a white crystalline powder soluble within acids yet insoluble within water. The compound is valued for specialized applications as phosphors, pigments, and certain luminescent materials. Its capacity for reflecting light or for absorbing light plays a key role for those applications. Additionally, zinc sulphite is applied within electronics, coatings, and specialty chemicals are produced because it is important in industries that require chemical stability and specific material performance.

What is Driving the Zinc Sulphite Market?

The zinc sulphite industry is influenced by multiple trends and by drivers, which do include the rising demand for specialty chemicals used in electronics, in coatings, and in optical materials. Market growth is driven via the increasing use of luminescent as well as phosphorescent materials in LEDs, display panels, and security printing because zinc sulphite offers desirable light-reflective properties. Also, industries center on sustainable efficient choices for pigments plus additives, so this increases the research plus development of improved zinc sulphite formulations. Electronics and automotive sector expansion supports industry growth along with demand for corrosion-resistant coatings. Stringent regulations promote safer plus environmentally friendly chemical compounds. Because of this, industries are adopting zinc sulphite above harmful alternatives, which makes it a key component in modern material innovation along with advanced manufacturing.

Buy now: https://www.imarcgroup.com/checkout?id=11811&method=1911

Key Steps Required to Set Up a Zinc Sulphite Plant

1. Market Analysis

The report provides insights into the landscape of the zinc sulphite industry at the global level. The report also provides a segment-wise and region-wise breakup of the global zinc sulphite industry. Additionally, it also provides the price analysis of feedstocks used in the production of zinc sulphite, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the zinc sulphite production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for zinc sulphite production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for zinc sulphite production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=11811&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a zinc sulphite production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Zinc Sulphite Production Cost Report 2025: Plant Setup Economics and Financial Outlook here

News-ID: 4189895 • Views: …

More Releases from IMARC Group

Biosimilar Market Size, Share, Industry Trends and Forecast 2026-2034

IMARC Group, a leading market research company, has recently released a report titled "Biosimilar Market Size, Share, Trends and Forecast by Molecule, Indication, Manufacturing Type, and Region, 2026-2034." The study provides a detailed analysis of the industry, including the global biosimilar market size, trends, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Biosimilar Market Key Highlights:

• The Biosimilar Market is…

Cost of Setting Up a PET Bottle Manufacturing Plant & DPR 2026

The global PET bottle industry is experiencing sustained growth propelled by rising packaged beverage consumption, pharmaceutical packaging expansion, increasing demand for ready-to-drink products, and the lightweight, recyclable advantages of PET packaging. As urbanization accelerates, consumer lifestyles shift toward convenience packaging, and regulatory frameworks increasingly mandate recyclable materials, establishing a PET bottle manufacturing plant positions investors in one of the most stable and essential segments of the consumer packaging value chain.

IMARC…

India Insurance Market Forecast 2026: Industry Size, Expansion & Future Scope 20 …

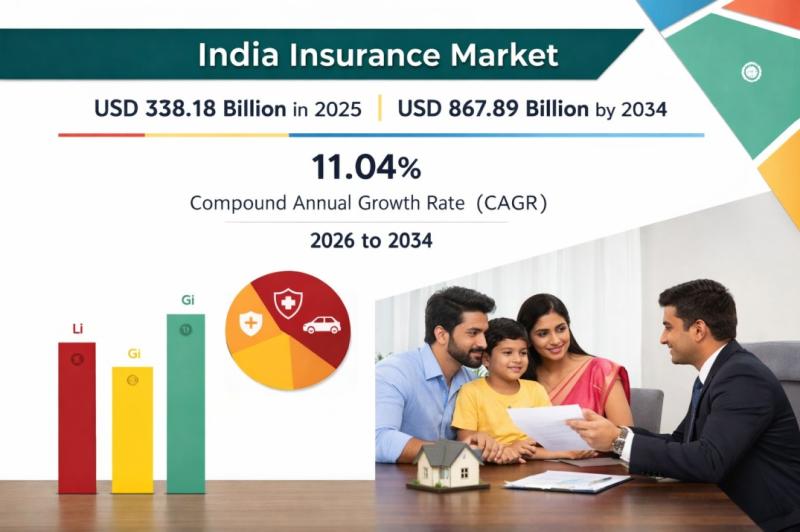

India Insurance Market Overview 2026-2034

According to IMARC Group's report titled India Insurance Market Size, Share, Trends and Forecast by Type of Product, Distribution Channel, End User, and Region, 2026-2034 the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

The India insurance market size was valued at USD 338.18 Billion in 2025 and is projected to reach USD 867.89 Billion by 2034, growing at…

Global Diammonium Phosphate (DAP) Prices January 2026: Asia Gains, Europe Steady …

What is Diammonium Phosphate (DAP)?

Diammonium Phosphate (DAP) is a widely used phosphorus-based fertilizer crucial for global agriculture. Monitoring Diammonium Phosphate (DAP) prices helps manufacturers, distributors, and buyers make informed procurement decisions and manage costs amid fluctuating demand and supply conditions.

Global Price Overview

The global Diammonium Phosphate (DAP) market shows moderate stability with regional supply differences affecting prices. The Diammonium Phosphate (DAP) price trend has remained mixed, while the price index and…

More Releases for Zinc

Zinc Compounds Market Is Going to Boom |• American Zinc Recycling Corp • Zin …

Worldwide Market Reports has added a new research study on "Zinc Compounds Market" is projected to experience substantial growth in the coming years. This report provides a comprehensive analysis of the market landscape using an integrated approach that includes research methodology, market size evaluation, data compilation, and insights gathered from multiple credible sources.

The study covers critical market elements such as market dynamics, drivers, restraints, challenges, threats, growth opportunities, development trends,…

Zinc Chemicals Market 2023 : Industry Trends, Top Players And Outlook 2032 | U.S …

The Business Research Company's global market reports are now updated with the latest market sizing information for the year 2023 and forecasted to 2032

As per the zinc chemicals market report by The Business Research Company, the rapid growth of the automotive industry is expected to drive the zinc chemicals market. The automotive sector includes businesses involved in the manufacture, distribution, retail, and upkeep of automobiles. Zinc is the most…

Paint Grade Zinc Dust market: Players tapping Emerging Markets | EverZinc, US Zi …

"The global Paint Grade Zinc Dust Market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Paint Grade Zinc Dust Market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and…

Paint Grade Zinc Dust market: Players tapping Emerging Markets | EverZinc, US Zi …

"The global Paint Grade Zinc Dust Market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Paint Grade Zinc Dust Market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and…

Inorganic Zinc Chemicals Market Participants TOHO ZINC CO., LTD. Zinc Nacional S …

Inorganic Zinc Chemicals Market: Overview

Zinc is an essential mineral for one’s mental and physical well-being through helping in simple cellular function, and therefore, in the proper functioning of the reproductive organs. Zinc also aids to deter common skin irritations and strengthen the immune system. Zinc cannot be easily absorbed by the body without being attached to other substances, due to which supplemental zinc in the form of inorganic and non-chelated…

Global Inorganic Zinc Chemicals Market 2018 : US Zinc, Zochem, Umicore, Zinc Nac …

This report studies Inorganic Zinc Chemicals in Global market, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, revenue, consumption, import and export in these regions, from 2013 to 2018, and forecast to 2025.

This report focuses on top manufacturers in global market, with production, price, revenue and market share for each manufacturer, covering

- US Zinc

- Zochem

- Umicore

- Zinc Nacional

- ISKY

- Xinxin Chemical

- Bohigh

. .

– Get Sample…