Press release

Closed Cell Metal Foam Market is projected to reach the value of USD 85 Million by 2030

According to the report published by Virtue Market Research in global Closed Cell Metal Foam Market was valued at approximately USD 57 million in 2025 and is projected to reach USD 85.71 million by 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 6.0%.Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/closed-cell-metal-foam-market/request-sample

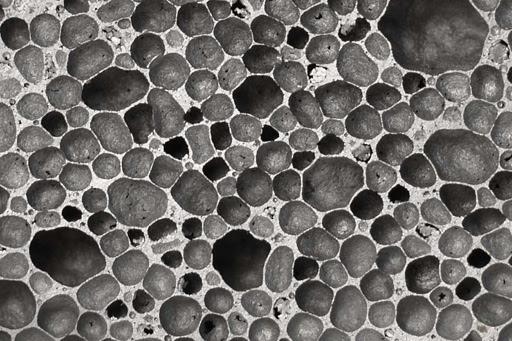

Closed cell metal foams represent advanced cellular materials with isolated pores that create unique combinations of strength, lightness, and energy absorption characteristics. These specialized metallic structures contain gas-filled cavities completely enclosed within solid metal walls, preventing fluid flow between individual cells. Manufacturing processes involve injecting foaming agents or gases into molten metals to create stable bubble structures that solidify into lightweight yet strong materials.

The exceptional properties of closed cell metal foam include high strength-to-weight ratios, superior impact absorption capabilities, excellent vibration damping, thermal management performance, and outstanding fire resistance characteristics. Engineering applications utilize these materials where conventional solid metals prove too heavy or lack adequate energy absorption properties. Quality control systems ensure consistent cell structure and mechanical properties throughout production batches.

Modern manufacturing techniques enable precise control over cell size, distribution, and density to optimize performance for specific applications. Research laboratories continuously develop improved processing methods that reduce production costs while enhancing material properties. These technological advances expand application possibilities across automotive, aerospace, construction, and industrial sectors requiring advanced lightweight materials.

Rising global demand for lightweight materials drives long-term growth in the closed cell metal foam market as industries seek alternatives to conventional heavy materials. Transportation sectors worldwide face increasing pressure to reduce vehicle weight for improved fuel efficiency and lower emissions. Aerospace manufacturers invest heavily in advanced materials that maintain structural integrity while significantly reducing aircraft weight for enhanced performance and operational economics.

Stringent environmental regulations accelerate adoption of lightweight construction materials that reduce energy consumption throughout building lifecycles. Automotive companies develop electric vehicles requiring weight reduction to maximize battery range and performance. These long-term trends create sustained demand for closed cell metal foams that provide exceptional strength-to-weight ratios compared to traditional solid metal components.

The COVID-19 pandemic initially disrupted closed cell metal foam supply chains when specialized manufacturing facilities reduced operations during widespread lockdowns in 2020.

Raw material shortages affected production schedules as international transportation networks experienced significant delays. Several research and development projects postponed advancement activities when laboratories faced access restrictions and social distancing requirements.

However, pandemic-related changes in transportation patterns increased focus on personal vehicle ownership and aviation cargo transport. Delivery services expanded rapidly as online shopping became more prevalent, creating demand for lightweight vehicle components. Healthcare equipment manufacturers required advanced materials for medical device applications that metal foams could provide through specialized properties.

Economic recovery programs emphasized manufacturing reshoring and supply chain resilience that favored domestic metal foam production capabilities. Government infrastructure investments allocated funding for advanced materials research and development. The pandemic highlighted the strategic importance of domestic manufacturing capacity for critical materials including specialized metal foams.

Remote work trends reduced commercial aviation demand temporarily but increased interest in personal transportation solutions. Electric vehicle adoption accelerated during the recovery period, creating new opportunities for lightweight materials. The pandemic ultimately reinforced the importance of material innovation in addressing evolving transportation and industrial requirements.

Automotive lightweighting regulations drive short-term adoption of closed cell metal foams as vehicle manufacturers seek compliance with fuel efficiency standards. Corporate Average Fuel Economy requirements push automakers toward materials that reduce vehicle weight without compromising safety performance. Electric vehicle development intensifies demand for lightweight components that maximize battery range while maintaining structural integrity and crashworthiness characteristics.

Safety regulations increasingly require energy absorption capabilities that closed cell metal foams provide more effectively than conventional materials. Impact protection standards for automotive and aerospace applications favor materials with controlled deformation characteristics. Insurance and liability considerations encourage adoption of advanced materials that enhance occupant protection during collision events.

Renewable energy infrastructure creates significant opportunities for closed cell metal foam applications in wind turbine and solar panel mounting systems. These installations require materials that withstand extreme weather conditions while minimizing structural weight and maintenance requirements. The growing clean energy sector represents substantial new market opportunities for specialized metal foam formulations.

Healthcare equipment manufacturing presents expanding markets for biocompatible metal foams in medical implants and surgical instruments. Advanced prosthetics require materials that match human bone density while providing excellent biocompatibility. The aging global population drives demand for medical devices utilizing innovative materials with superior performance characteristics.

Additive manufacturing integration drives trends toward custom closed cell metal foam production for specific application requirements. Three-dimensional printing technologies enable complex internal structures and optimized cell distributions impossible with conventional manufacturing methods. Digital design tools allow engineers to create custom foam architectures for unique performance requirements.

Smart material development incorporates sensing capabilities into closed cell metal foams for structural health monitoring applications. Embedded sensors detect stress, temperature, and damage conditions in real-time. These intelligent materials enable predictive maintenance strategies that prevent catastrophic failures while optimizing component replacement timing.

Market Segmentation:

By Material:

Dominant segment - Aluminum

Aluminum-based closed cell metal foams maintain the largest market share due to their excellent strength-to-weight ratios, corrosion resistance, and cost-effective production capabilities. These lightweight materials provide superior energy absorption characteristics while maintaining structural integrity under demanding operating conditions. Automotive and aerospace industries prefer aluminum foam applications because they significantly reduce component weight while meeting stringent safety and performance requirements for critical structural elements.

Fastest growing segment - Copper

Copper closed cell metal foams experience the fastest growth rate as manufacturers develop applications requiring superior thermal and electrical conductivity properties. These specialized materials enable advanced heat management solutions in electronics cooling and power generation equipment. Growing demand for high-performance thermal interfaces drives rapid adoption of copper foam technologies throughout industrial and commercial cooling applications.

By Application:

Dominant segment - Heat Exchangers

Heat exchanger applications represent the largest segment for closed cell metal foam consumption worldwide, utilizing the high surface area and thermal conductivity properties for enhanced heat transfer performance. Industrial processes require compact, lightweight heat exchangers that provide superior thermal management in limited space environments. The enormous volume of HVAC systems, automotive cooling, and industrial process equipment creates sustained demand for metal foam heat exchanger components.

Fastest growing segment - Anti-Intrusion Bars

Anti-intrusion bar applications show the fastest growth in closed cell metal foam usage as automotive safety regulations require enhanced passenger protection systems. Vehicle manufacturers increasingly specify metal foam barriers that provide controlled energy absorption during side-impact collisions. Growing emphasis on automotive safety and crashworthiness drives rapid adoption of metal foam anti-intrusion systems throughout global automotive manufacturing.

By End-Users:

Dominant segment - Automotive

Automotive industry represents the largest end-user segment for closed cell metal foams, encompassing structural components, safety systems, and thermal management applications. Vehicle lightweighting initiatives create enormous demand for materials that reduce weight while maintaining performance characteristics. The massive scale of global automotive production establishes the automotive sector as the primary market for closed cell metal foam technologies.

Fastest growing segment - Aerospace

Aerospace applications demonstrate the fastest growth in closed cell metal foam consumption as aircraft manufacturers seek advanced materials for weight reduction and performance enhancement. Commercial aviation recovery following pandemic disruptions creates renewed demand for lightweight components that improve fuel efficiency. Space exploration programs require specialized materials with extreme performance characteristics that metal foams can provide through unique cellular structures.

Read More @ https://virtuemarketresearch.com/report/closed-cell-metal-foam-market

Regional Analysis:

Dominant Region - North America

North America leads the global closed cell metal foam market with the largest consumption volume due to advanced automotive and aerospace industries requiring innovative lightweight materials. Established manufacturing capabilities and research infrastructure support continued market leadership. Government defense spending and aerospace programs create consistent demand for specialized metal foam applications throughout the region.

Fastest growing Region - Asia Pacific

Asia Pacific demonstrates the highest growth rate in closed cell metal foam consumption during the forecast period as economic development accelerates automotive production and industrial manufacturing throughout the region. Rising automotive manufacturing in China, India, and Southeast Asian countries drives demand for lightweight materials. Environmental regulations promote adoption of fuel-efficient vehicles that utilize advanced materials for weight reduction.

Latest Industry Developments:

• Manufacturers are increasingly investing in automated production technologies for closed cell metal foams that improve consistency and reduce manufacturing costs, utilizing robotic handling systems and precise process control to achieve uniform cell structures while scaling production capacity to meet growing demand across automotive and aerospace applications.

• Companies across the closed cell metal foam industry are developing hybrid manufacturing processes that combine traditional foaming techniques with additive manufacturing capabilities, enabling custom cell architectures and optimized material distributions for specific performance requirements while reducing lead times and material waste in prototype development.

• Industry leaders are expanding research into multifunctional closed cell metal foams that integrate sensing capabilities, self-healing properties, and adaptive characteristics, targeting applications in smart structures and autonomous systems where materials must respond to changing environmental conditions while maintaining structural integrity and performance reliability.

customize the Full Report Based on Your Requirements @ https://virtuemarketresearch.com/report/closed-cell-metal-foam-market/customization

contact Us:

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

About Us:

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Closed Cell Metal Foam Market is projected to reach the value of USD 85 Million by 2030 here

News-ID: 4188640 • Views: …

More Releases from Virtue Market Research

Global Probiotic Soap and Detergent Market is projected to reach the value of US …

According to the report published by Virtue Market Research in Global Probiotic Soap and Detergent Market was valued at USD 6.75 Million in 2024 and is projected to reach a market size of USD 16.1 Million by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.6%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/probiotic-soaps-and-detergent-market/request-sample

The long-term growth of the probiotic…

The Global Polyester Soft Toys Market is expected to reach USD 12.33 billion by …

According to the report published by Virtue Market Research in Global Polyester Soft Toys Market was valued at USD 9.3 billion in 2024 and will grow at a CAGR of 5.8% from 2025 to 2030. The market is expected to reach USD 12.33 billion by 2030.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/polyester-soft-toys-market/request-sample

The polyester soft toys market has evolved into a vibrant and competitive industry shaped by changing consumer habits,…

Global Pet Ball Launcher Market is projected to reach the value of USD 3.93 Bill …

According to the report published by Virtue Market Research in Global Pet Ball Launcher Market was valued at USD 2.8 Billion in 2024 and is projected to reach a market size of USD 3.93 Billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 5.8%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/pet-ball-launcher-market/request-sample

One of the major long-term drivers…

Global Organotin Compounds Market is projected to reach the value of USD 2.97 Bi …

According to the report published by Virtue Market Research in Global Organotin Compounds Market was valued at USD 2.2 Billion and is projected to reach a market size of USD 2.97 Billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 5.1%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/organotin-compounds-market/request-sample

One of the major long-term drivers of the organotin…

More Releases for Closed

Integrated Recirculating Aquaculture System Market Report Covers Closed Type and …

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Integrated Recirculating Aquaculture System (RAS) Market - (By Grade (Closed Type, Semi-Closed Type), By Application (Outdoor System, Indoor System)), Trends, Industry Competition Analysis, Revenue and Forecast To 2034."

According to the latest research by InsightAce Analytic, the Global Integrated Recirculating Aquaculture System (RAS) Market is valued at USD 5.2 Billion in 2024, and it is expected…

Market Outlook for Closed-Cell Aluminum Foam

Closed-cell foam aluminum is a new type of material with excellent phySical properties, widely used in aerospace, automotive manufacturing, building sound insulation, and electronic device heat dissipation. Driven by the transformation and upgrading of manufacturing and environmental protection initiatives, theclosed-cell foam aluminum industry has entered a period of rapid development. The following provides an overview of this industry from the perspectives of market size, technological development, application areas, and future…

Closed Cycle Gifford-Mcmahon Cryocooler Market Size Analysis by Application, Typ …

USA, New Jersey- According to Market Research Intellect, the global Closed Cycle Gifford-Mcmahon Cryocooler market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The market for closed cycle Gifford-McMahon (GM) cryocoolers is anticipated to expand at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025…

BUILDING CONSTRUCTION TECHNOLOGY EXPO 2024 CLOSED SUCCESFULLY

BUILDING CONSTRUCTION TECHNOLOGY EXPO 2024 CLOSED SUCCESFULLY

A hugely successful week in Thailand focused on "building networks" for the construction sector

(Bangkok, October 2024) - Building Construction Technology Expo 2024 (BCT Expo 2024), the Southeast Asian Building and Construction Exhibition and Conference, took place successfully in Bangkok, Thailand from 18th to 20th September 2024.

BCT Expo 2024 organized under the theme "The Construction Meeting Place" saw the participation of 150 exhibiting companies…

Closed End Zipper Market: Growing Application in Clothing and Accessories Fuels …

Global Closed End Zipper Market Overview:

The Closed End Zipper market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Closed End Zipper market has experienced significant growth, driven by factors such as increasing consumer demand, technological advancements, and globalization. This growth…

Hybrid Closed-Loop Insulin Delivery Systems Market

According to a new market research report published by Global Market Estimates, the Global Hybrid Closed-Loop Insulin Delivery Systems Market is projected to grow at a CAGR value of 20.5%.

Browse 151 Market Data Tables and 111 Figures spread through 181 Pages and in-depth TOC on “Global Hybrid Closed-Loop Insulin Delivery Systems Market - Forecast to 2027” https://www.globalmarketestimates.com/market-report/hybrid-closed-loop-insulin-delivery-systems-market-3661

Key Market Insights

• The increasing prevalence of diabetes and growing demand for continuous glucose…