Press release

Corn Flakes Manufacturing Plant Report 2025: Raw Materials Requirement, Project Cost and Profit Margin

Setting up a corn flakes manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Corn Flakes Manufacturing Plant Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a corn flakes manufacturing plant, covering everything from product overview and manufacturing processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/corn-flakes-manufacturing-plant-project-report/requestsample

What is Corn Flakes?

A typical breakfast cereal in the US is the corn flakes, which are milled corn (maize), cooked, flattened, and toasted to form thin crispy flakes. The process of manufacturing includes cleaning and de germinating of corn kernels, cooking with sugar, salt and malt flavoring, rolling the cooked corn into flakes, and toasting them to obtain a golden and crispy result. This is a fortified ready-to-eat cereal that usually contains vitamins and minerals such as iron, B vitamins, and vitamin D, hence it is a healthy breakfast meal. Corn flakes are of light and crunchy texture and have a soft sweet taste that is usually served in milk, fruits, or taken as a snack. They are amongst the most popular breakfast cereals in the world which are attractive to all age groups because of their convenience, taste and health benefits.

What is Driving the Corn Flakes Market?

The rising awareness of health among the people, the need to have convenient meal solutions to busy lifestyles and the rising popularity of ready-to-eat cereals are the drivers behind the corn flakes market. An increase in urbanization and alteration in eating habits especially in the developing world are key growth processes fueling the market. Moreover, the constant product innovation such as organic varieties, gluten-free products, and improved nutritional formulations of added proteins, fibers and micronutrients are also appealing to the health-challenged consumers. There is also increased adoption in the market created by growing demand to use fortified breakfast cereals to deal with nutritional deficiencies, expansion of modern retail channels and aggressive advertising campaigns to families and working professionals. Further, corn is a low-cost and easily accessible raw material, and the rise in disposable incomes as well as the shifting food consumption trends also correlate with market growth aims, which further contribute to the growth of the industry.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=18499&flag=C

Key Steps Required to Set Up a Corn Flakes Manufacturing Plant

1. Market Analysis

The report provides insights into the landscape of the corn flakes industry at the global level. The report also provides a segment-wise and region-wise breakup of the global corn flakes industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of corn flakes, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the corn flakes manufacturing plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for corn flakes manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for corn flakes manufacturing

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Buy now: https://www.imarcgroup.com/checkout?id=18499&method=1911

4. Project Economics

A detailed analysis of the project economics for setting up a corn flakes manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on manufacturing capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Corn Flakes Manufacturing Plant Report 2025: Raw Materials Requirement, Project Cost and Profit Margin here

News-ID: 4186628 • Views: …

More Releases from IMARC Group

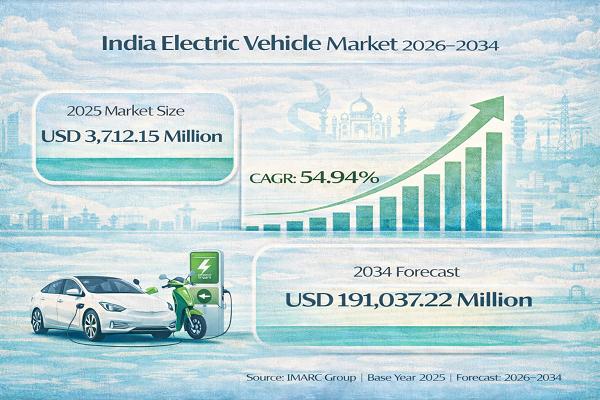

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Corn

US Corn Import Data 2025 | Corn Importers & Buyers in USA

The United States is globally recognized as one of the world's largest producers and exporters of corn. Yet, many businesses are surprised to learn that the US is also an active importer of corn. Understanding US corn import data 2025, the major corn importers & buyers in the USA, and the leading supplier countries helps traders, food processors, and agribusiness professionals make smarter sourcing decisions using reliable US import data…

Corn And Corn Starch Derivatives Market Report Size And Forecast 2024-2033

The Business Research Company recently released a comprehensive report on the Global Corn And Corn Starch Derivatives Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, the cough…

Corn And Corn Starch Derivatives Market Report, Size, Share Report 2024-2033

The new report published by The Business Research Company, titled Corn And Corn Starch Derivatives Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the corn and corn starch derivatives market size has grown strongly in recent years. It will…

Global Corn And Corn Starch Derivatives Market Size, Share, Growth Analysis To 2 …

Year End Offer By The Business Research Company - Get 33% Discount On Opportunities And Strategies Reports And 25% Discount On Global Market Reports

The Business Research Company's Corn And Corn Starch Derivatives Global Market Report 2024 identifies the increased demand for processed food products significantly contributes to the growth of the corn and corn starch derivatives market going forward. Processed foods refer to prepared meals that have already been cleaned,…

Roferro Corn FLakes

We've recently launched the site roferro.com; Roferro Crunchy Cornflakes is a healthy balanced breakfast with lot of nutrition benefits.

Roferro Crunchy Cornflakes is a healthy balanced breakfast with lot of nutrition benefits. Corn Flakes are one of the most popular breakfast giving healthy lifestyle. Roferro crunchy cornflakes can also be your evening snack while you watch a TV show with your family.

Once Chew Died Sebalang

Crispy cornflakes that you have never…

Corn Wet-milling Market Driven by Consumption of Dent Corn for High Fructose Cor …

Corn wet-milling is a process of refining corns to manufacture end products used by millions of people worldwide. The shelled corns are processed by two types dry mills or wet mills. Under corn wet-milling process corns are separated into four components namely starch, fiber, germ, and gluten. The production process of corn wet-milling includes cleaning, steeping, milling & germ separation, fine grinding & screening and separating starch & gluten. The…