Press release

Multi Channel Spray Drying Systems Market to Reach CAGR 10,8% by 2031 Top 10 Company Globally

Multi-channel spray drying systems are engineered spray-drying platforms that contain multiple, parallel drying chambers, atomizer assemblies or modular spray zones designed to increase throughput, enable multi-product continuous operation and improve process control for sensitive powders; they are used where high uptime, product segregation, flexible production scheduling and rapid changeover matter (infant formula, dairy, pharmaceuticals, specialty chemicals, food ingredients and fine chemicals). These systems range from pilot-scale multi-nozzle laboratory units to large industrial multi-stage towers and modular multi-string production rigs, and they combine core subsystems atomizers (two-fluid nozzles, pressure nozzles, rotary atomizers), heated air handling and recovery, cyclone or baghouse collection, and automated cleaning/segregation modules with digital control systems for repeatable particle-engineering, moisture control and scaleup. Because multi-channel designs reduce per-kg capital intensity for high-mix manufacturers and increase effective line utilization for large batches and continuous programs, they are increasingly specified by dairy, infant-nutrition, pharmaceutical and plant-protein producers that need consistent powder properties and regulatory traceability.The multi-channel spray drying systems market value of approximately USD 481 million in 2024 with a CAGR of about 10.8% to 2031, projected to rach USD 985 million in 2031. Applying a transparent ASP sensitivity to the reconciled 2024 subsegment value of USD 481 million yields the implied blended ASP of USD 126,500 per unit the market implies total of 3,800 units sold in 2024.

Latest Trends and Technological Developments

Technology momentum in multi-channel spray drying is concentrated in automation/ATE integration, process intensification for higher throughput per footprint, containment and hygienic design for pharmaceuticals and infant nutrition, energy recovery improvements, and digital process-analytics for particle engineering. On August 2024, Pulse Drying Systems announced commissioning of its P-25 dryer for abrasive minerals, signalling traction for specialized multi-channel designs in challenging feedstocks and the sectors move to materials-specific dryers. On July 2024, GEA highlighted advanced pharmaceutical spray dryer deliveries and modular plant work that underscore how multi-channel modularity is being deployed for contained API and biopharma drying. More recently, SPX FLOWs Anhydro brand updated its SmartDry automation system (announced August 2025) to increase throughput via smarter control algorithms and tighter integration with upstream feed and atomizer control a clear indicator that automation and digital optimization are being rapidly adopted across multi-channel product lines. These dated vendor and commissioning milestones show that the market is advancing on automation, containment and modularity and that recent product and software updates materially improve effective capacity and reduce per-kg processing cost.

Asia-Pacific is the largest regional market for multi-channel spray drying systems because the region hosts a majority of new infant-formula builds, dairy-powder investments, contract‐manufacturing for pharmaceutical formulations and an expanding specialty-ingredient sector (plant proteins, flavours, nutraceuticals). Country demand is concentrated in China (large domestic dairy and infant-nutrition expansions, plus contract manufacturing), India (rapid growth in dairy, spices and pharma contract manufacturing), and East Asia (Japan, South Korea, Taiwan) where advanced process lines and high-containment pharmaceutical projects drive demand for modular multi-channel installations. Vendors and system integrators report that Asia offers both higher unit volumes and accelerated repeat orders as converters expand line counts; regional market trackers corroborate that APAC is the fastest-growing geographic demand pool for spray-drying equipment and multi-channel configurations. Local service footprints and aftermarket spares are decisive buying criteria for APAC buyers because uptime and local commissioning speed materially affect ROI on multi-channel systems.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5049082

Multi Channel Spray Drying Systems by Type:

Lab Scale Multi Channel Spray Drying Systems

Pilot Scale Multi Channel Spray Drying Systems

Industrial Scale Multi Channel Spray Drying Systems

Others

Multi Channel Spray Drying Systems by Application:

Pharmaceutical Industry

Food and Nutrition Industry

Chemical Industry

New Materials Processing

Others

Global Top 20 Key Companies in the Multi Channel Spray Drying Systems Market

GEA Group

Büchi Labortechnik AG

SPX Flow

Yamato Scientific Co., Ltd.

SaintyCo

Dedert Corporation

European SprayDry Technologies LLP

Sofraden

Tetra Pak

Shinwa Chemical Industries Ltd

Hosokawa Micron Group

Anhydro

Okawara MFG Co., Ltd.

Marion Process Solutions

Sower Group

Pulvis GmbH

Spray Drying Systems Inc

Technoforce Solutions Pvt, Ltd.

Sichuan Xinye Mechanical Equipment Co., Ltd.

Changzhou Yibu Drying Equipment Co., Ltd.

Regional Insights

Within Southeast Asia, ASEAN is an accelerating market for multi-channel spray drying driven by rising processed food demand, infant and toddler nutrition programs, growing dairy processing initiatives (notably in Indonesia), and a rising number of specialty-ingredient plants in Vietnam, Thailand and Malaysia that need flexible production capacities. Indonesias government-backed dairy and nutrition programs, and increasing local formulation and infant-nutrition assembly, have created new demand for local spray-drying capacity and for multi-channel lines that enable multiple SKUs from a single plant footprint; a USDA-Jakarta dairy market assessment (2024) and regional industry notices show expanding dairy capacity and government interest in local powder manufacture. ASEAN buyers typically begin with modular mid-range multi-channel rigs for flexibility and later add further modules as product portfolios mature making rental, retrofit and phased capacity expansion commercially attractive. Regional distributors and integrators that provide local commissioning, spare parts and service contracts gain a competitive edge given the logistical cost of moving large dryer modules internationally.

The multi-channel spray drying segment faces a set of structural and project-level challenges that slow adoption or raise cost. First, long lead times and project complexity for turnkey installations (civil, utilities, GMP containment and integration with upstream concentrate prep) lengthen cash-flow payback and require strong project management capabilities from vendors. Second, high CAPEX and stringent qualification demands for infant-nutrition and pharmaceutical customers raise technical and contractual risk; these buyers demand validated cleaning-in-place (CIP), containment and extensive validation documentation. Third, energy intensity and environmental constraints push buyers to demand heat-recovery and emissions controls that raise initial system cost, requiring suppliers to integrate energy-efficient air handling and multi-cycle recovery systems. Fourth, variable feedstocks (protein, minerals, botanical extracts) accelerate nozzle/atomizer wear and force more frequent maintenance and spare inventory; this dynamic favours suppliers with local spares and service footprints. Finally, technology substitution and lifecycle risk (for example downstream wet agglomeration and fluidized bed agglomeration alternatives) can change the economics for certain powders and create segmentation pressure on multi-channel sales. These constraints appear repeatedly in project post-mortems and vendor case studies.

The strategic winners will be system integrators and OEMs that combine deep process know-how, modular product families and strong regional after-sales coverage. Practical strategies include offering staged, modular contract structures that let buyers spread CAPEX and prove product-market fit; bundling maintenance and spare-parts agreements to monetize lifecycle service; and developing pre-qualified turnkey packages for regulated markets (infant formula, pharma) that shorten time-to-market for buyers. Suppliers should also invest in digital process libraries and model-based control upgrades (the SmartDry example) that demonstrably increase throughput per channel and lower energy per kilogram measurable performance claims that reduce sales friction. For ASEAN and APAC, building local assembly and skid-packaging hubs or partnering with regional contractors reduces freight and import barriers and is an effective near-term moat. Investors should prioritise vendors with signed multi-year service contracts and repeat OEM customers, because the annuity nature of service revenue stabilizes returns against cyclical equipment sales.

Product Models

Multi-channel spray drying systems are advanced drying technologies used to convert liquid feed into uniform powder form through atomization and hot air drying. With multiple nozzles or channels, they increase throughput, efficiency, and scalability across applications such as pharmaceuticals, food & beverage, chemicals, and advanced materials.

Lab Scale Systems for research and formulation development. Notable products include:

LabPlant SD-06 Spray Dryer LabPlant UK: Compact benchtop unit for laboratory-scale powder processing.

GEA Niro Mobile Minor® Lab Spray Dryer GEA Group: Small-scale system suitable for testing multiple formulations.

Yamato Pulvis Spray Dryer GB210 Yamato Scientific: Japanese-made compact lab dryer for pharmaceuticals and chemicals.

Labultima Mini Spray Dryer Labultima India: Small-scale unit tailored for pharmaceutical R&D labs.

SpraySolutions MiniSpray Dryer SpraySolutions: Research-scale system for fine powder development.

Pilot Scale Systems for process optimization and small-batch production. Examples include:

GEA Pilot Spray Dryer PSD-1 GEA Group: Scalable pilot system for process development and small batches.

Yamato Pulvis Pilot Spray Dryer GB220 Yamato Scientific: Mid-sized dryer for pilot pharmaceutical and chemical production.

SPX Anhydro Pilot Spray Dryer SPX FLOW: Pilot drying solution for dairy, food, and chemical industries.

Labultima Pilot Spray Dryer Labultima India: Designed for scale-up studies in pharma and biotech.

Pilotech YC-018 Pilot Spray Dryer Pilotech Shanghai: Mid-range spray dryer for trial batches in research institutes.

Industrial-Scale Systems for large-scale commercial powder production. Notable products include:

GEA Niro Industrial Spray Dryer GEA Group: Large-scale dryer for dairy, pharma, and chemical powders.

SPX Anhydro Industrial Spray Dryer SPX FLOW: High-capacity dryer used in global food production facilities.

Dedert Industrial Spray Dryer Dedert Corporation: Designed for high-volume chemical and food industries.

OKF Industrial Spray Dryer I-500 OKF Corporation: Multi-channel dryer for high throughput in food and chemical plants.

Tetra Pak Spray Dryer Pro Tetra Pak: Industrial-grade system widely used in dairy powder processing.

Multi-channel spray drying systems are a premium subsegment of spray-drying equipment that address the needs of high-mix, regulated and throughput-sensitive powder manufacturers; using specialist subsegment data, the market for multi-channel systems is estimated at about USD 481 million in 2024 and given current industrial, infant-nutrition and pharmaceutical investment patterns we model a 10,8% CAGR to 2031, implying substantial value creation from modular turnkey projects, automation upgrades and retrofit projects in APAC and ASEAN. Unit volumes in 2024 are sensitive to product mix: the implied shipment range is roughly at 3,800 units; Asia-Pacific and a growing ASEAN corridor will be central to unit growth and aftermarket service demand as regional processors upgrade local powder production capability.

Investor Analysis

What investors should care about is that the multi-channel subsegment sits at the intersection of large, durable end markets (infant nutrition, dairy powders, pharmaceuticals, specialty ingredients) and a capital-goods business model that can generate high-margin recurring service and spare parts revenue. How value is captured: equity stakes or debt in leading integrators with established APAC service footprints, minority investments in automation/software providers that raise throughput (and thus increase effective gross margin per installed unit), or financing structures that enable buyers to procure turnkey installations via project financing or equipment-as-a-service convert CAPEX into annuity streams. Why act now: project pipelines for infant formula, speciality proteins and contract pharma manufacturing in APAC and ASEAN are large and near-term, and vendors that can offer validated, energy-efficient, contained multi-channel packages with local commissioning and spare parts will rapidly accumulate high-quality service annuities; diligence should focus on order backlog composition (number of turnkey vs skid orders), service-revenue percentage, installed-base location (APAC concentration is positive), and any IP or automation edge that demonstrably increases throughput or reduces energy intensity.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5049082

5 Reasons to Buy This Report

It isolates the multi-channel spray drying systems subsegment from the broader spray-dryer market and reconciles a defensible 2024 baseline with a transparent growth model to 2031.

It converts value to practical unit-shipped scenarios using clear ASP bands, enabling capex, manufacturing and project-finance planning. citeturn0search3

It documents dated vendor and commissioning events that change throughput and automation economics.

It provides APAC and ASEAN drills that tie local dairy, infant-nutrition and pharma demand to on-the-ground service and spare-parts needs critical for regional go-to-market plans.

It profiles the competitive supplier set and strategic levers so investors can prioritize targets with recurring revenue and differentiated tech.

5 Key Questions Answered

What is a defensible 2024 market size for multi-channel spray drying systems and what CAGR should financial models use to 2031?

What realistic ASP ranges apply by system class and what unit volumes did 2024 revenue imply?

Which dated vendor and commissioning events (20242025) materially shift throughput and automation economics for multi-channel installations?

How will Asia and ASEAN drive regional demand, and what local service and spare strategies shorten lead times and improve margins?

Which supplier capabilities most reliably translate into durable margins and why?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Multi Channel Spray Drying Systems Market to Reach CAGR 10,8% by 2031 Top 10 Company Globally here

News-ID: 4185389 • Views: …

More Releases from QY Research

High Margins, High Growth: Inside the Global Luxury Beauty Opportunity

Luxury beauty encompasses premium skincare, cosmetics, fragrance, haircare, dermo-cosmetics, and prestige personal care products positioned with superior ingredients, branding, exclusivity, and high ASPs.

Core value drivers include brand heritage, innovation in active ingredients, dermatological efficacy, sustainability claims, and experiential retail.

Consumers increasingly view luxury beauty as self-care + wellness investment, not discretionary spending alone.

Distribution mix: specialty beauty retail, department stores, travel retail, e-commerce, brand boutiques, medical aesthetic clinics.

Global Market Snapshot

Market size (2025):…

Security Seals Market 20252032: Smart Tech, Recurring Revenue, and Investor Upsi …

Single use security seals are tamper-evident mechanical or plastic locking devices designed for one-time application to secure containers, trucks, meters, ballot boxes, airline carts, cash bags, and logistics assets

Core function: theft deterrence, chain-of-custody control, compliance with customs, transport, and regulated industries

Widely used in logistics, utilities, aviation catering, banking, postal, healthcare, and e-commerce fulfillment

Market characterized by high volume, low ASP consumables with recurring replacement demand

Global Overview

Global market size (2025): USD 352…

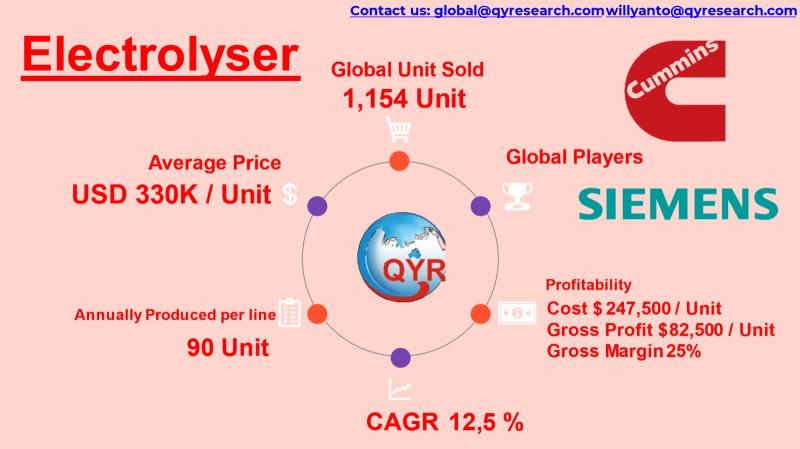

Hydrogen Infrastructure Surge: Why Electrolysers Are the Next Energy Investment …

Electrolyser systems are core equipment for producing green hydrogen through water electrolysis, converting electricity (increasingly renewable) into hydrogen and oxygen.

The industry underpins decarbonization across refining, fertilizers, steelmaking, mobility, and grid storage, making electrolysers a critical enabling technology for the global energy transition.

Technology categories include alkaline (AEL), proton exchange membrane (PEM), and solid oxide (SOEC), each optimized for different cost, efficiency, and operating profiles.

Global Market Overview

Global market size (2025): USD 381…

Top 30 Indonesian Dairy Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Indofood Sukses Makmur Tbk (INDF)

PT Indofood CBP Sukses Makmur Tbk (ICBP)

PT Ultrajaya Milk Industry & Trading Company Tbk (ULTJ)

PT Cisarua Mountain Dairy Tbk (CMRY)

PT Diamond Food Indonesia Tbk (DMND)

PT Mulya Boga Raya Tbk

PT Campina Ice Cream Industry Tbk

PT Kurniamitra Duta Sentosa Tbk

PT Greenfields Indonesia

PT Indolakto (subsidiary/brand under Indofood)

PT Ultra Jaya Frozen Foods (group affiliate)

PT Heilala Dairy Indonesia (export arm/processing)

PT Diamond Milk Products (non-listed…

More Releases for Spray

HaloGlow Hair Spray Review: Does This Spray Really Deliver Thicker Hair?

HaloGlow Hair Spray is a topical formula designed to combat thinning hair and promote fuller growth using natural ingredients applied directly to the scalp. Users spray it daily to nourish follicles, reduce shedding, and encourage new hair, making it suitable for men and women noticing early signs of hair loss from stress, hormones, or age.

Get salon worthy shine instantly with HaloGlow Hair Spray >> https://rebrand.ly/tryhalogrow

What Is HaloGlow Hair Spray?

HaloGlow Hair…

Key Trend Reshaping the Spray Drying Equipment Market in 2025: Innovative Mini S …

How Are the key drivers contributing to the expansion of the spray drying equipment market?

The spray drying equipment market is likely to witness growth, fueled by the rising consumption of both processed and ready-to-eat (RTE) foods over the forecast period. Spray drying systems are increasingly being utilized by manufacturers of packaged foods. For example, a report released in April 2024 by the National Association of Convenience Stores (NACS), a US-based…

Congela Biocosmetics Introduces XO Spray, A Revolutionary Oxygen Infusion Spray

Delivering JuveXO exosomes and skincare serums directly into the skin.

Image: https://www.getnews.info/uploads/a3d78ff50568f394aa57426170ea73fb.jpg

Renowned for its precision skincare exosomes, Congela Biocosmetics [https://juvexo.com/pages/xo-spray] is excited to announce the launch of the XO Spray [https://juvexo.com/pages/xo-spray], a revolutionary delivery system for JuveXO exosomes and other topical serums. The leading innovator in skincare technology is further expanding its footprint by offering this skincare game-changer that enhances product application and promotes skin rejuvenation.

Brian Pla, Chief Commercial Officer at…

Spray Pump Market 2019 | Global Forecast 2025 | Top Key Players - PMT Spray Pump …

Up Market Research added a new “Spray Pump Market research report for the period of 2019 – 2025. Report focuses on the major drivers and restraints providing analysis of the market share, segmentation, revenue forecasts and geographic regions of the market.

Get Exclusive Free Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/73974

The report highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Spray Pump…

Spray Guns Market

https://www.qandqmarketresearch.com/reports/7468045/spray-guns-market-40

Global Spray Guns market size will increase to Million US$ by 2025, from Million US$ in 2018, at a CAGR of during the forecast period. In this study, 2018 has been considered as the base year and 2019 to 2025 as the forecast period to estimate the market size for Spray Guns.

This report researches the worldwide Spray Guns market size value, capacity, production and consumption in key regions like United…

Thermal Spray Market 2023 Competitive Landscape :- Flame Spray Coating Company , …

Thermal Spray Industry report offers a comprehensive insight into the development policies and plans in addition to manufacturing processes and cost structures. On the basis of product, this report displays the Cost Structure, Sales Revenue, Sales Volume, Gross Margin, market share and growth rate.

Synopsis of Thermal spray Market:-

Thermal spraying is an industrial process of coating that involves the formation of substrates in the semi-molten and molten state. Thermal spraying provides…