Press release

DTF Dallas Champions Eco-Friendly Printing: Cutting Waste and Chemical Use

Sustainability is becoming a core principle in every industry, and printing is no exception. Customers increasingly expect brands to minimize their environmental impact, while governments and communities push for more regulations on waste management and toxic chemicals. Direct-to-film (DTF) printing stands at the forefront of more sustainable printing methods because it reduces waste and minimizes hazardous chemical use. This article delves into how DTF supports eco-friendly practices, how you can implement sustainable processes in your production line and why it matters for your business and the planet.The Environmental Impact of Traditional Printing

Screen printing has long been the standard for decorating apparel, but it comes with environmental drawbacks. Plastisol inks used in many screen printing setups contain polyvinyl chloride (PVC) and phthalates, which can be harmful if improperly disposed of. Excess ink needs to be washed out of screens, generating wastewater that may contain chemicals and microplastics. The emulsion used to create screens must be removed with solvents and water. For small runs or prototypes, the environmental cost per shirt can be disproportionately high.

Digital printing methods like direct-to-garment (DTG) and sublimation are cleaner in some respects, but they still require pretreatment solutions, and sublimation demands polyester-only garments, which are petroleum-based. DTF offers unique environmental benefits because it replaces bulky processes with a streamlined, efficient workflow.

How DTF Reduces WasteNo Screen Creation

Traditional screen printing requires a new screen for each color and design variation. Once a design is printed, screens must be cleaned with water and chemicals before being reused. DTF prints the design digitally on film, eliminating the need for screens entirely. There are no screens to clean or reclaim, and therefore no water used in the process.

Precise Ink Usage

DTF printers use a precise amount of ink on the transfer film. You never mix large batches of ink that might go unused. Even when printing multiple colors, the printer lays down only what's needed for the design. There's no leftover ink to dispose of at the end of a print run.

Efficient Powder Application

The adhesive powder used in DTF sticks only to the printed areas. You shake off the excess and reuse it for the next transfer. Nothing goes to waste, and there's no need to dispose of unused chemicals.

Gang Sheets for Reduced Material Waste

Gang sheets allow you to print multiple designs on one piece of film. This practice reduces film consumption compared to printing each design separately. Less film equals less waste, and efficient layout planning means you're maximizing every inch of material.

Reduced Chemical FootprintWater-Based Inks

Most DTF inks are water-based and free of harmful solvents. They are safer for the environment and easier to handle in the workplace. Because DTF inks are printed onto film, there is no washout process or ink runoff when producing dtf transfers. [https://dtfdallas.com/products/dtf-transfers-by-size]

No Pretreatment Chemicals

Unlike DTG, which often requires pretreating garments with a chemical solution, DTF needs no pretreatment on most fabrics. Eliminating pretreatment chemicals reduces your environmental footprint and saves you time in production.

Minimal Cleaning Agents

Since there are no screens, there's no need for harsh cleaning solvents. Curing ovens or heat presses require little maintenance compared to washout booths and reclaiming stations in screen printing.

Energy EfficiencyLower Heat Requirements

Because DTF curing and pressing take place at relatively moderate temperatures (around 300-340 degrees F), they consume less energy than processes that require higher heat or longer curing times. Screen printing dryers often operate at high temperatures for extended periods, leading to higher electricity usage.

Consolidated Production Runs

Gang sheets [https://dtfdallas.com/products/dtf-gang-sheets] and digital printing allow you to produce transfers in bulk and press them only when needed. This reduces the number of times your printer and curing equipment need to power up and down. Running fewer cycles extends equipment life and decreases energy consumption.

Sustainable Practices with DTF

Beyond the inherent environmental benefits of the DTF process, you can adopt additional practices to make your printing business more sustainable:

*

Recycle PET Film: After peeling off the backing film, collect and recycle it if facilities in your area accept PET. Some recycling programs allow PET film drop-offs or curbside collection.

*

Choose Renewable Energy: If possible, power your equipment with renewable energy sources. Solar panels or green energy plans reduce carbon emissions.

*

Eco-Friendly Garments: Offer garments made from organic cotton, recycled polyester, or other sustainable materials. Pairing eco-friendly apparel with DTF prints creates a fully sustainable product.

*

Educate Customers: Highlight the environmental benefits of DTF on your website and marketing materials. Conscious consumers appreciate learning about eco-friendly options.

*

Reuse and Upcycle: Encourage customers to upcycle old garments by applying new designs or offering a print-on-demand service that transforms unsold clothing into fresh products.

Business Benefits of Going Green

Adopting eco-friendly printing practices does more than help the planet-it enhances your brand and attracts sustainability-minded customers. Companies and individuals are willing to support brands that prioritize ethical production. Environmental responsibility can become a selling point that differentiates your business from competitors. Additionally, many industries-including apparel-see increasing regulation around chemical use and waste disposal. By adopting clean technologies like DTF, you future-proof your business against potential legislative changes.

Conclusion

Direct-to-film printing represents a significant step forward in sustainable apparel decoration. With its efficient use of materials, reduction of harmful chemicals, lower energy consumption and compatibility with recycled and organic garments, DTF allows print shops and brands to minimize their environmental impact. Implementing gang sheets, recycling PET film and educating customers about your sustainable practices can further reinforce your commitment to the planet. Partner with DTF Dallas [https://dtfdallas.com] for high-quality, eco-friendly transfers and embrace a cleaner, more efficient way to print.

Media Contact

Company Name: DTF Dallas

Contact Person: David

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=dtf-dallas-champions-ecofriendly-printing-cutting-waste-and-chemical-use]

Address:903 N Bowser Rd Suite 250

City: Richardson

State: TX 75081

Country: United States

Website: https://dtfdallas.com

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release DTF Dallas Champions Eco-Friendly Printing: Cutting Waste and Chemical Use here

News-ID: 4185332 • Views: …

More Releases from ABNewswire

Living Forever - AI Selected for Startup Grind Global Conference 2026 - Named Am …

AI-powered platform preserving living people's personalities, voices, and stories earns exhibition and pitch slot at premier Silicon Valley startup event

ATLANTA, GA - February 26, 2026 - Living Forever - AI [https://livingforeverai.com], an Atlanta-based startup building fully interactive video AI digital twins that preserve the personalities, voices, and life stories of living people for future generations, today announced its acceptance into the Startup Grind Global Conference 2026. The company was selected…

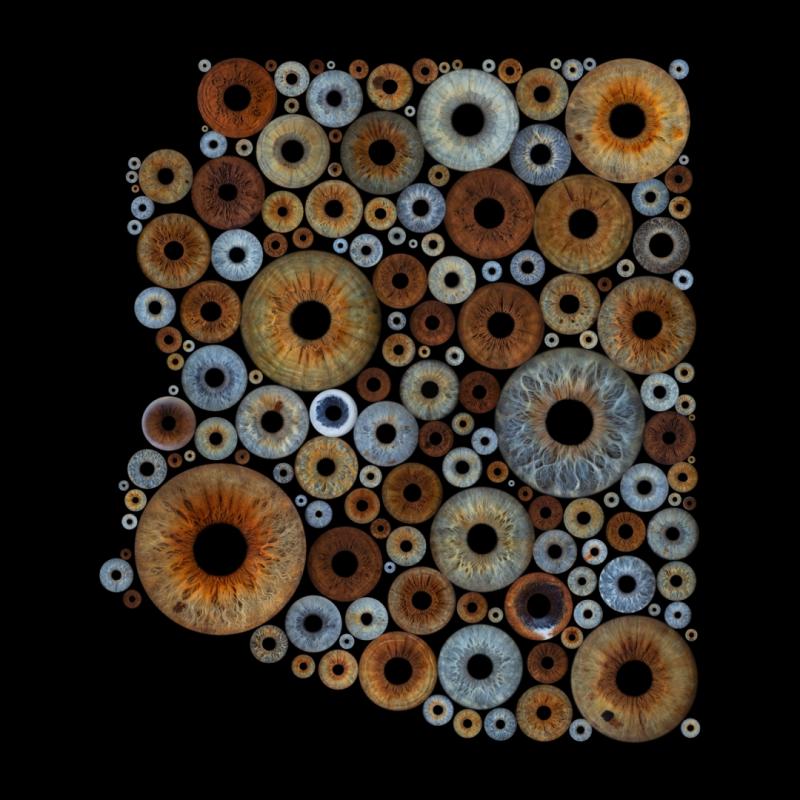

Mesa Studio Blends Iris Photography with the Art of Becoming Through the Iris Wi …

Sol Iris Photography founder Saskia Soliz draws on a background in autism support and personal growth to create a creative experience rooted in self-discovery.

MESA, AZ - February 26, 2026 - Sol Iris Photography, a Mesa-based studio specializing in high-resolution iris photography, is quietly building something beyond photography. Through the Iris Wisdom Project, clients are invited to share a brief piece of wisdom alongside their iris portrait - a thought, truth,…

Power Couple Combines Army Structure and Insurance Expertise to Launch Family-Ow …

Red Rover Roofing, a family-owned roofing company in Williamson County, Tennessee, brings Xactimate-certified insurance claim expertise and CertainTeed Master Shingle Applicator credentials to Middle Tennessee homeowners navigating storm damage roof replacement and insurance disputes across Franklin, Brentwood, Spring Hill, Nashville, and Murfreesboro.

SPRING HILL, TN - February 26, 2026 - When retired U.S. Army Captain Courtney Hostetler came home from deployment in Kuwait, she and her husband Alex knew they wanted…

Primary Biliary Cholangitis Market: Rapid Increment Driven by Innovation by 2034 …

The Key Primary Biliary Cholangitis Companies in the market include - CymaBay Therapeutics, Inc., Zydus Therapeutics Inc., Gannex Pharma Co., Ltd., Nanjing Chia-tai Tianqing Pharma, Intercept Pharmaceuticals, Enanta Pharmaceuticals, COUR Pharmaceutical, Novartis, Merck, Mirum Pharmaceuticals, Inc., Genfit, CymaBay Therapeutics, Inc., Calliditas Therapeutics, HighTide Biopharma Pty Ltd, Albireo, Curome Biosciences, Biotie Therapies Corp., and others.

DelveInsight's "Primary Biliary Cholangitis Market Insights, Epidemiology, and Market Forecast-2034 report offers an in-depth understanding of the…

More Releases for DTF

SAILLAGE Showcases its DTF Products at Global Exhibitions

SAILLAGE: A Global Participant in DTF Industry Exhibitions

As a forward-looking enterprise dedicated to the innovation and promotion of Direct-to-Film (DTF) printing technology, SAILLAGE has been actively participating in major global exhibitions since 2025, bringing its high-quality DTF products(https://www.saillage.com/dtf-film-series/) and professional solutions to industry peers and partners around the world. Through continuous participation in international and domestic industry events, SAILLAGE has not only demonstrated its strong R&D strength and product competitiveness…

Can You Recommend Top Reliable DTF Film Manufacturers

Introduction: Why the Right DTF Film Manufacturer Matters

When global textile printing, customization, and garment enterprises seek high-quality DTF (Direct to Film) film(https://www.saillage.com/dtf-film-series/), price is no longer the sole deciding factor. Modern buyers prioritize ink adhesion, transfer durability, material compatibility, and consistent batch-to-batch performance. Amid China's booming DTF film market, Shanghai Saillage International Trade Co., Ltd. has stood out as a trustworthy partner for global clients pursuing stable, high-performance DTF film…

DTF printerusa Unveils Comprehensive Guide: DTF Printing vs. Traditional Printin …

The printing industry has witnessed numerous technological advances, but few have been as transformative as Direct-to-Film (DTF) printing. To understand the true value proposition of DTF printer [https://dtfprinterusa.com/collections/dtf-printers-and-dryers] technology, it's essential to compare it comprehensively with traditional printing methods across various performance metrics, cost factors, and practical considerations.

Screen printing has long been the gold standard for high-volume apparel decoration, offering excellent durability and cost-effectiveness for large runs. However, DTF printing…

DTF CENTER Expands Market Reach with Premium DTF Transfers and Gang Sheets

Los Angeles, CA - DTF CENTER, a leading U.S. provider of Direct-to-Film (DTF) transfers and gang sheets, today announced its expanding role in the fast-growing custom apparel printing industry. With demand for personalized, durable, and cost-effective printing solutions on the rise, DTF CENTER is empowering businesses and entrepreneurs nationwide to scale their operations with professional-grade printing technology.

Driving Innovation in Apparel Printing

The apparel printing industry has undergone a rapid transformation, fueled…

DTF printing: exploring the application of DTF powder shaking thermal transfer f …

Direct-to-film (DTF) printing has become a revolutionary technology in the field of textile printing, with bright colors, delicate patterns and versatility that are difficult to match with traditional methods. One of the key components of DTF printing is the DTF powder shake thermal transfer film, which plays a vital role in the transfer process. This article will explore the application of DTF powder shake thermal transfer film and its main…

Why DTF Printing is Revolutionizing the Industry: Best DTF Printers, Inks, and F …

Whether you're looking to upgrade your printing process or start a new custom apparel business, Direct-to-film offers a future-proof solution.

Garment printing has developed into an industry with the evolution of new technologies, especially Direct-to-Film or (DTF). DTF printing is a versatile, durable, and cost-effective solution for custom apparel and textile designing. DTG Pro assures high-quality results with enhanced color vibrancy and long-lasting durability on all fabrics, including cotton, polyester, and…