Press release

Ethyl Vinyl Ether Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview

Setting up a ethyl vinyl ether production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Ethyl Vinyl Ether Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a ethyl vinyl ether production plant cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/ethyl-vinyl-ether-manufacturing-plant-project-report/requestsample

What is Ethyl Vinyl Ether?

Ethyl Vinyl Ether (EVE) production cost refers to the total expenditure incurred in the manufacturing process of this important organic compound, widely used as a monomer and intermediate in the production of specialty polymers, coatings, adhesives, and pharmaceuticals. The production of ethyl vinyl ether typically involves the reaction of acetylene with ethanol in the presence of a catalyst, or through other synthetic routes, depending on technological adoption and raw material availability. The overall cost structure is influenced by several key factors, including the price of feedstock materials such as ethanol and acetylene, energy consumption during production, labor expenses, utility requirements, and equipment maintenance. Additionally, factors like plant capacity, process efficiency, and regional variations in raw material availability significantly impact production economics. Compliance with environmental and safety regulations also adds to operating costs, particularly in regions with stricter emission standards. Transportation, packaging, and distribution further contribute to the total cost of delivering ethyl vinyl ether to end-use markets. Understanding production cost is critical for stakeholders, as it helps manufacturers optimize processes, evaluate profitability, and assess competitiveness within the global market, where margins are closely tied to raw material fluctuations and energy price volatility.

What is Driving the Ethyl Vinyl Ether Market?

The market dynamics influencing ethyl vinyl ether production cost are primarily driven by raw material availability, global energy trends, and the rising demand from end-use industries. Ethanol and acetylene, the main feedstocks for producing ethyl vinyl ether, are subject to fluctuations in global commodity markets, directly impacting overall production economics. Rising energy costs, especially electricity and natural gas prices, further add to operational expenditures since the production process is energy-intensive. On the demand side, increasing consumption of ethyl vinyl ether in pharmaceuticals, adhesives, coatings, and specialty chemicals drives consistent market growth, prompting manufacturers to optimize production efficiency to maintain cost competitiveness. Technological advancements in catalytic processes and process integration are also shaping cost trends by improving yields and reducing waste. Regional differences in labor, infrastructure, and compliance costs create variations in production expenses across Asia-Pacific, North America, and Europe. Additionally, stricter environmental and safety regulations, especially in developed economies, raise compliance costs, influencing overall production economics. Global supply chain dynamics, including logistics disruptions and transportation costs, also play a critical role. As demand continues to rise in diverse applications, manufacturers face pressure to balance operational efficiency with sustainable practices, making cost management a central driver of market performance.

Buy Now: https://www.imarcgroup.com/checkout?id=10849&method=1911

Key Steps Required to Set Up a Ethyl Vinyl Ether Plant

1. Market Analysis

The report provides insights into the landscape of the ethyl vinyl ether industry at the global level. The report also provides a segment-wise and region-wise breakup of the global ethyl vinyl ether industry. Additionally, it also provides the price analysis of feedstocks used in the production of ethyl vinyl ether, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the ethyl vinyl ether production plant project is elaborated in the report.

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for ethyl vinyl ether production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for ethyl vinyl ether production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=10849&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a ethyl vinyl ether production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ethyl Vinyl Ether Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview here

News-ID: 4184169 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

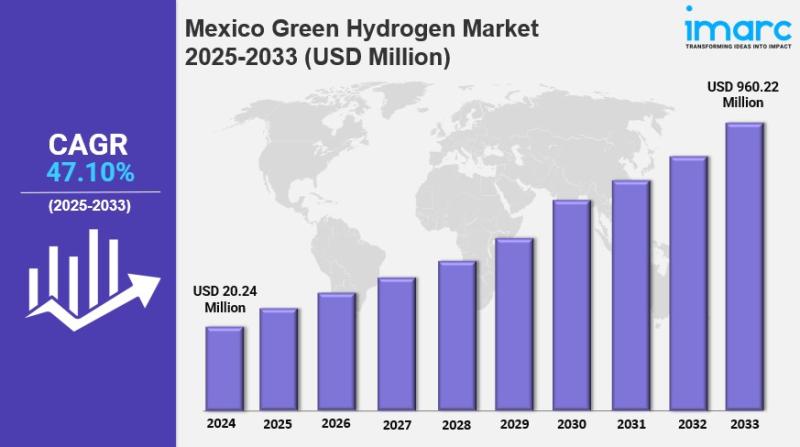

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Ethyl

Prominent Ethyl Lactate Market Trend for 2025: Growing Facility Expansion In The …

How Are the key drivers contributing to the expansion of the ethyl lactate market?

Advancements in the food and drink sector are projected to stimulate the progression of the ethyl lactate market in the coming future. This field is a pillar of the economy, managing the manufacture, dispersal, and consumption of food and beverages. Ethyl lactate, a naturally derived organic compound, is used in this industry for enhancing flavors and acting…

Ethyl Acrylate Market Size and Forecast

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- The global Ethyl Acrylate Market is expected to record a CAGR of XX.X% from 2024 to 2031 In 2024, the market size is projected to reach a valuation of USD XX.X Billion. By 2031 the valuation is anticipated to reach USD XX.X Billion.

The ethyl acrylate market is expanding, driven by its diverse applications in industries such as paints and coatings, adhesives, textiles, and plastics. As a key…

Ethyl Acetoacetate Market Size and Forecast

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- The global Ethyl Acetoacetate Market is expected to record a CAGR of XX.X% from 2024 to 2031 In 2024, the market size is projected to reach a valuation of USD XX.X Billion. By 2031 the valuation is anticipated to reach USD XX.X Billion.

The ethyl acetoacetate market is witnessing steady growth due to its widespread use in various industries, including pharmaceuticals, agrochemicals, and manufacturing. Ethyl acetoacetate is a…

Ethyl Caproate (Ethyl Hexanoate) Market Revenue, Insights, Overview, Outlook, An …

Ethyl Caproate (Ethyl Hexanoate) (CAS#123-66-0)is a colorless liquid with strong fruity and wine aromas, with apple, pineapple, banana-like aromas.

The global Ethyl Caproate (Ethyl Hexanoate) market was valued at US$ million in 2022 and is anticipated to reach US$ million by 2029, witnessing a CAGR of % during the forecast period 2023-2029. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-35A9504/Global_Ethyl_Caproate_Ethyl_Hexanoate_Market_Research_Report_2022

North American market…

Global Ethyl Acetate Market Size & Trends

According to a new market research report published by Global Market Estimates, the global ethyl acetate market is expected to grow at a CAGR of 6.8% from 2024 to 2029.

The global ethyl acetate market growth is driven mainly by increasing applications across different sectors such as painting, pharmacy and packaging.

Unlock the Executive Summary of the report at only USD 249. Book a call now: https://tidycal.com/yashsushiljain/unlock-strategic-insights-press-release

Key Market Insights

• As per the…

Ethyl Acetate Price, Historical Charts, Forecasts & News

Product Name - Ethyl Acetate

HS Code - 29153100

Molecular Weight - 88.11g/mol

Chemical Formula - CH3COOC2H5

Synonyms - 141-78-6, Ethyl Ethanoate, Acetic Acid Ethyl Ester, Acetoxyethane, Acetic Ester

Currency US$ (Data can also be provided in local currency)

Supplier Database Availability - Yes

Customization Scope - Our services can be customized as per the requirements of the customer

Post-Sale Analyst Support - 360-degree analyst support after service delivery

Region/Countries for which Data is available

Asia Pacific: China, India, Indonesia, Pakistan,…