Press release

Friction Tape Market Set for Steady Growth as Innovation and Sustainability Drive Adoption Across Industries

The global friction tape market is poised for steady growth, projected to increase from USD 1.2 billion in 2025 to USD 1.7 billion by 2035. This growth, representing a 41.7% increase over the decade at a compound annual growth rate (CAGR) of 4.1%, reflects the growing demand for durable, non-slip, and mechanically robust insulation and protective wrapping solutions across electrical, automotive, and industrial sectors.Market Dynamics and Drivers

The expansion of the friction tape market is driven by a combination of technological innovation, evolving industrial applications, and a focus on sustainability. Friction tapes, typically made from cloth impregnated with adhesive, provide strong grip, abrasion resistance, and insulation, making them indispensable for mechanical protection and electrical safety. These versatile tapes are widely used for electrical insulation, wire harnessing, sports equipment, and industrial bundling, catering to both repair and original equipment manufacturing needs.

Full Market Report available for delivery. For purchase or customization, please request here: https://www.futuremarketinsights.com/reports/sample/rep-gb-23137

Cloth-backed rubber adhesive tapes have emerged as the preferred choice for many manufacturers due to their flexibility, high tensile strength, and reliable adhesion to irregular surfaces. These properties make them suitable for binding electrical wires, protecting cable splices, and improving grip on tools and sports equipment. Rising environmental regulations are also encouraging the adoption of eco-friendly, solvent-free adhesive formulations that enhance sustainability while maintaining performance standards.

Segmental Insights

The friction tape market is segmented by material, application, adhesion strength, end-use industry, and region. Cotton cloth dominates the market, expected to capture 47.8% share by 2025, due to its superior durability, tensile strength, and adaptability. Manufacturers are increasingly incorporating flame-retardant and weather-resistant enhancements into cotton cloth tapes to meet safety regulations while improving handling comfort.

Electrical insulation applications lead the market, commanding a 39.3% share in 2025. Friction tapes provide reliable protection against shorts, arc faults, and premature wear, making them essential in residential, commercial, and industrial electrical systems. High tack adhesion tapes, accounting for over 51% of the adhesion segment, ensure secure, long-lasting bonds even under challenging conditions, such as vibration, moisture, UV exposure, and temperature fluctuations.

The material diversity also extends to rubber-resin blends and non-woven fabrics, which are used for specialized industrial and automotive applications requiring enhanced abrasion resistance and tensile strength. Application-wise, friction tapes are increasingly used in automotive harnessing, industrial maintenance, sports equipment, and tool wrapping, reflecting their versatility and performance in high-friction environments.

Regional Growth Prospects

Asia-Pacific is emerging as the fastest-growing region, with India leading the market at a CAGR of 5.4% from 2025 to 2035. Growth is supported by infrastructure expansion, electrification projects, automotive production, and government-led initiatives promoting energy efficiency and modernized power distribution. China also demonstrates strong adoption due to rapid industrialization, EV manufacturing, and large-scale manufacturing projects, which are driving demand for high-performance insulation tapes.

In developed economies, the United States is expected to grow at a CAGR of 4.5%, fueled by electrical infrastructure upgrades, industrial maintenance needs, and vehicle electrification programs. Friction tapes are being widely used for high-voltage cable insulation, automotive harnessing, and industrial preventive maintenance. Germany, with its robust automotive and renewable energy sectors, is projected to expand at 4.1% CAGR, supported by premium-grade tapes offering durability, adhesion, and environmental compliance.

The United Kingdom anticipates growth at a CAGR of 3.8%, with demand emerging from construction, marine, and defense sectors, where high-temperature and flame-retardant tapes are increasingly required. Japan's market is expected to grow at 4.2% CAGR, driven by electronics assembly, railways, and industrial machinery, with focus on compact roll designs and biodegradable adhesives. South Korea's friction tape market is projected to expand at 3.7% CAGR, propelled by shipbuilding, semiconductor fabrication, and industrial automation.

Technological Innovations and Emerging Trends

The friction tape market is witnessing a shift toward enhanced formulations that improve weather resistance, dielectric strength, and adhesion performance. Fire-retardant, UV-resistant, and biodegradable variants are gaining traction among manufacturers aiming to meet regulatory standards and sustainability goals. Companies are also exploring smart-label integration and digital-enabled inventory management, creating opportunities for value-added services beyond traditional tape supply.

High-tensile, abrasion-resistant tapes are becoming critical for applications in renewable energy, EV manufacturing, and specialized industrial equipment maintenance. This trend aligns with increased demand for mechanical protection, reliable insulation, and long-term operational safety across sectors.

Competitive Landscape

The friction tape market is moderately fragmented, featuring global adhesive leaders, regional specialists, and innovative niche players. Established global players like 3M Company continue to lead the market through premium-grade cotton cloth tapes, abrasion-resistant backings, and reliable electrical insulation performance. Their product strategies increasingly focus on solvent-free adhesives, compliance with international safety standards, and heat-resistant formulations.

Mid-sized companies, including Euro Tapes Pvt. Ltd., Medi Spare, AVR Industries Private Limited, and Champion Tape, are expanding adoption through industrial-grade tapes tailored for mechanical grip, bundling, and wire protection in automotive and heavy equipment sectors. These companies focus on durability under high-friction conditions, adhesion to irregular surfaces, and applicability across indoor and outdoor environments.

Get the Report Brochure Now:

https://www.futuremarketinsights.com/reports/brochure/rep-gb-23137

Regional specialists such as Goyal Electric Works target niche markets with application-specific solutions that balance cost-effectiveness, reliability, and compliance. By catering to localized infrastructure projects, SMEs, and industrial repair services, these players are carving a competitive edge in a growing market.

Key Developments

Several manufacturers are leveraging innovation to reinforce their market presence. For example, 3M Company showcased "Shimmering Victory," a unique installation celebrating excellence in innovation and sports, highlighting their brand's versatility beyond industrial applications. Meanwhile, mid-sized players continue to enhance product offerings with flame-retardant, eco-friendly adhesives, and tailored roll conversions to address the evolving needs of electrical and industrial maintenance markets.

Looking Ahead

As global infrastructure, renewable energy initiatives, EV production, and industrial automation continue to expand, the friction tape market is poised for steady growth through 2035. Both established players and emerging manufacturers are leveraging technological innovation, material enhancements, and sustainability-driven solutions to capture opportunities in this evolving market. With rising adoption in high-friction, high-stress, and safety-critical applications, friction tapes are set to remain an essential component in electrical, automotive, and industrial sectors worldwide.

Explore Similar Insights

Frictionless Remote Monitoring Devices Market https://www.futuremarketinsights.com/reports/frictionless-remote-monitoring-devices-market

Friction Modifiers Market https://www.futuremarketinsights.com/reports/friction-modifiers-market

Friction Modifier Additives Market https://www.futuremarketinsights.com/reports/friction-modifier-additives-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Friction Tape Market Set for Steady Growth as Innovation and Sustainability Drive Adoption Across Industries here

News-ID: 4179752 • Views: …

More Releases from Future Market Insights

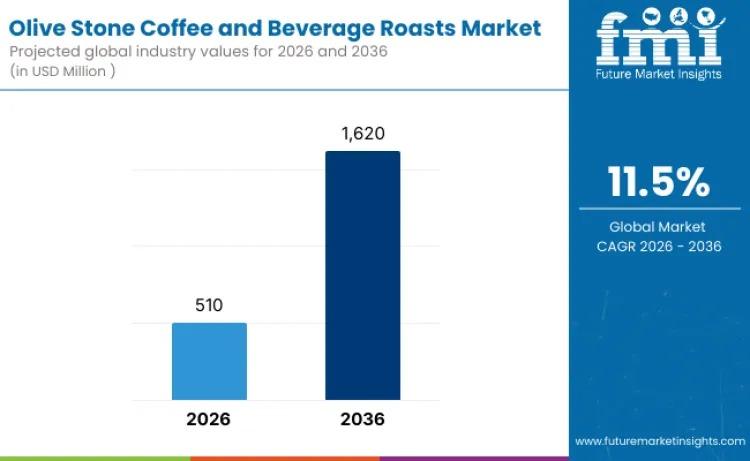

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

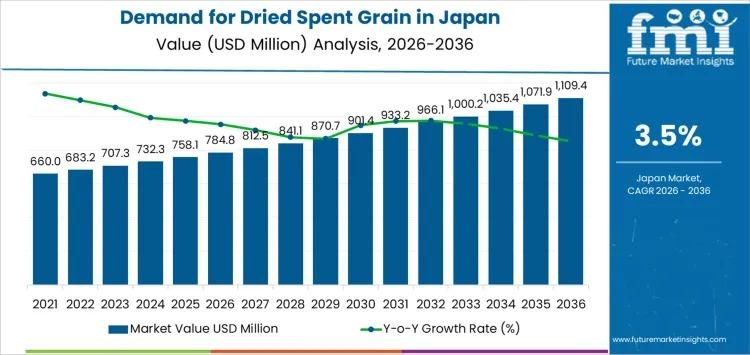

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

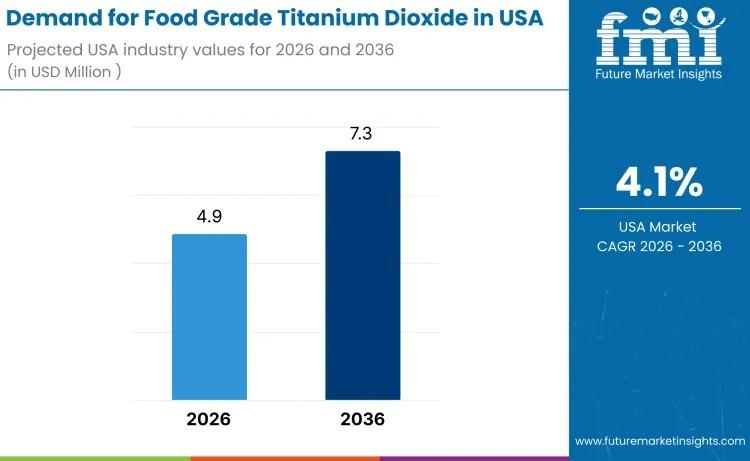

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

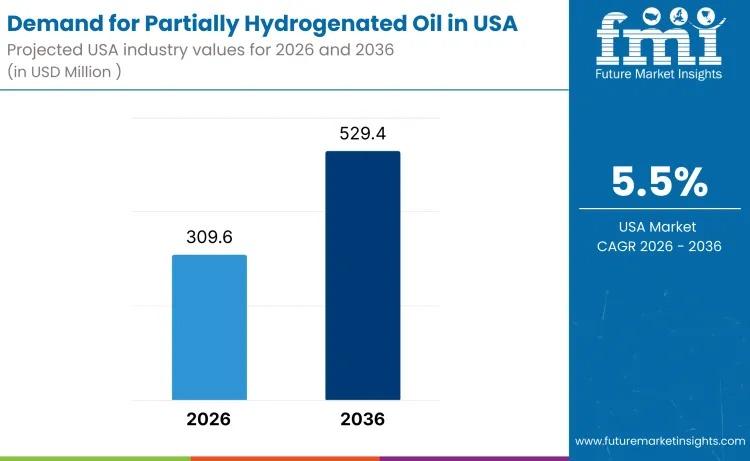

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Friction

Friction Products and Materials Market Is Booming Worldwide | Tenneco, Carlisle …

The latest research study released by AMA on the Friction Products and Materials Market offers over 181 pages of analysis on business strategies employed by key and emerging industry players. It provides insights into current market developments, landscape, technologies, drivers, opportunities, market outlook, and status. The market study is segmented by key regions driving market growth. The Friction Products and Materials study combines qualitative and quantitative market data, primarily collected…

Friction Materials Market Analysis By Top Keyplayers - ABS FRICTION CORP., Akebo …

The "Friction Materials Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Friction Materials Market, 2024-2031

Verified Market Research's most recent report, "Friction Materials Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth…

Friction Modifiers Market, By Type (Organic Friction Modifiers and Inorganic Fri …

Data Bridge Market Research analyses that the friction modifiers market will witness a CAGR of 9.7% for the forecast period of 2022-2029. Friction modifiers market report analyses the growth, due to accelerating application of friction modifiers in advertising and promotions of various brands.

Friction modifiers, also known as boundary lubrication additives, are oil-soluble chemicals used in lubricants as transmission and internal combustion engine additives. These lubricants are used in machine components…

Friction Product Market 2027 Worldwide Analysis on Revenue, Segmentation and Key …

MARKET INTRODUCTION

Friction products are used to produce friction in order to reduce the velocity or stop the movement of a particular object. Friction is the resistance which opposes the movement of object. Friction products cover wide range of pads, linings, blocks, rolls, sheets, clutches etc. Commonly used materials in friction based products are paper (cotton or cellulose fiber and phenolic resin mixture), elastomerics, graphitics, sintered metal ceramics, advanced fibers and…

Global Friction Products and Materials Market 2018 Top Players are: ABS Friction …

Friction material is used in every-day mundane applications such as automotive brakes and clutches to commercial and industrial applications.

According to this study, over the next five years the Friction Products and Materials market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019. In particular, this report presents the global market share (sales and…

GMP Friction Products Develops Friction Materials for Wind Energy Turbine Market …

Brakes Stop and Hold Wind Turbine Blades for Emergency, High Winds or Maintenance

AKRON, OHIO (January 19, 2012) – GMP Friction Products, working with wind turbine manufacturers and the suppliers to the OEM market, has developed high-speed friction brake materials designed to reduce rotational speed below maximum value or bring the blades of a wind energy turbine to a standstill. Following more than 1,000 braking sequence tests, they have developed friction…