Press release

Purification Mechanisms of Foam Ceramic Filters

I. Sieving-Filter [https://www.beihaicomposite.com/filter/] Cake-Deep Bed Filtration Mechanism1. Sieving (Screening): This mechanism follows the principle of traditional fiberglass mesh filtration, acting like a sieve to block inclusion particles and their agglomerates larger than the filter's surface pores from passing through.

2. Filter Cake Filtration: Many inclusions larger than the filter's pores are captured at the filter's inlet end through sieving. As the number of captured inclusions increases, a "filter cake" composed of large impurities forms on the filter's inlet surface. This "filter cake" refines the liquid, causing even inclusions smaller than the filter's pore size to be partially captured on the "filter cake."

Sieving and filter cake filtration are two stages of the same mechanism, and their duration depends on the amount of inclusions in the liquid and the size of the filter's pores.

3. Deep Bed Filtration: Inside the foam ceramic [https://www.beihaicomposite.com/customized-ceramic-foam-aluminum-foam-ceramic-alumina-high-temperature-resistant-filtration-product/] filter, the melt flows along a tortuous path. In small areas, there are even instances of cross-flow reversal. This primarily serves to increase the probability of inclusion particles contacting the filter greatly. Smaller diameter inclusions, as they flow with the melt, can be trapped in a corner after colliding, thus being captured.

II. Floating Separation Mechanism

When a foam ceramic filter [https://www.beihaicomposite.com/ceramic-foam-filter/]is correctly designed and placed in the gating system, the resistance to metal flow increases, causing the liquid metal to fill the gating system and thereby fully utilize the slag-retaining function of the gating system. Simultaneously, the liquid flow injected from the sprue is throttled by the filter, causing the metal liquid to temporarily dwell in the sprue. This allows less dense slag to float and separate, achieving the advantages of a bottom-pouring gating system. As the metal liquid continues to be poured through the Foam ceramic filter, on one hand, less dense slag floats up, and on the other hand, turbulence is effectively reduced or eliminated.

III. Adsorption Mechanism

When the filter is placed in the runner or ingate of the mold cavity, as the first stream of liquid reaches the filter's inlet surface during pouring, an adsorption phenomenon occurs between the liquid flow and the foam network. This adsorption is primarily a non-selective, multi-molecular layer physical adsorption, where inclusions are adsorbed layer by layer onto the filter's network until blockage occurs.

IV. Rectification Mechanism

Studies on the sources of inclusions in castings reveal that secondary oxidation inclusions account for 83% of total inclusions, inclusions caused by mold material erosion account for 13%, and only 4% are due to incomplete slag removal before pouring. This indicates that most inclusions within castings are formed during the pouring process, and using filters to purify the metal achieves significant purification effects. During the pouring process, in most cases, the metal liquid fills the mold cavity in a turbulent state, especially during the initial stages when it enters the cavity from a certain height. Due to the tortuous and winding flow paths within the foam ceramic filter, it has a strong ability to rectify the liquid metal from turbulent to laminar flow. As a result of the filter's rectifying action, the highly turbulent metal liquid transforms into a laminar state after passing through the filter. When it flows past the filter, it requires a longer transition zone to revert to its original turbulent state. Within this transition zone, the liquid flow does not have enough time to develop into turbulence or significant turbulence, thereby preventing secondary oxidation of the metal and erosion of the mold, and thus acting as a "slag barrier" to prevent the formation of secondary oxide inclusions.

Image: https://ecdn6.globalso.com/upload/p/566/image_other/2025-07/purification-mechanisms-of-foam-ceramic-filters.jpg [https://www.beihaicomposite.com/ceramic-foam-filter/]

Media Contact

Company Name: Beihai Composite Materials Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=purification-mechanisms-of-foam-ceramic-filters]

Country: China

Website: https://www.beihaipower.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Purification Mechanisms of Foam Ceramic Filters here

News-ID: 4174300 • Views: …

More Releases from ABNewswire

Connected Ship Market to Reach USD 7.35 Billion by 2031, Driven by IMO e-Navigat …

Mordor Intelligence has published a new report on the educational robot market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Connected Ship Market Overview

According to Mordor Intelligence, the connected ship market size is estimated at USD 4.24 billion in 2026, growing from USD 3.80 billion in 2025, and is projected to reach USD 7.35 billion by 2031, expanding at a CAGR of 11.63% during the forecast period. This…

Specialty Chemicals Industry is estimated at $1.26 Trillion in 2026, Forecast to …

Mordor Intelligence has published a new report on the Specialty Chemicals Market, offering a comprehensive analysis of trends, growth drivers, and future projections.

The global [https://www.mordorintelligence.com/industry-reports/specialty-chemicals-market?utm_source=abnewswire] is expected to reach USD 1.54 trillion by 2031, up from USD 1.26 trillion in 2026, growing at a CAGR of 4.09% during the forecast period. Market growth is being driven by large-scale infrastructure projects in Asia-Pacific and GCC countries, rising demand for high-purity chemicals…

Foliar Fertilizer Market Size to Reach USD 30.32 Billion by 2031 - Mordor Intell …

Mordor Intelligence has released a comprehensive report on the foliar fertilizer market, outlining market size expansion, growth catalysts, precision agriculture adoption, and regional opportunities shaping the global industry.

Foliar Fertilizer Market Size and Forecast Outlook

According to a research report by Mordor Intelligence, the global foliar fertilizer market size [https://www.mordorintelligence.com/industry-reports/foliar-fertilizer-market?utm_source=abnewswire] is projected to grow from USD 22.63 billion in 2026 to USD 30.32 billion by 2031, registering a CAGR of 6.03% during…

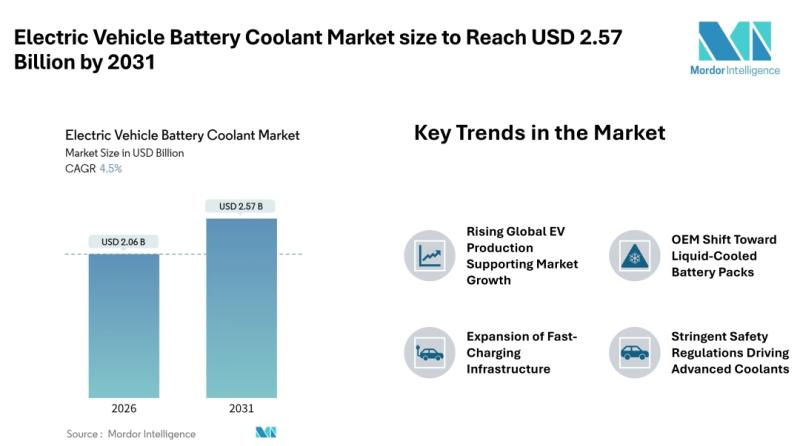

Electric Vehicle Battery Coolant Market size to Reach USD 2.57 Billion by 2031, …

Mordor Intelligence has published a new report on the electric vehicle battery coolant market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Market Overview

According to Mordor Intelligence, the electric vehicle battery coolant market size [https://www.mordorintelligence.com/industry-reports/electric-vehicle-battery-coolant-market?utm_source=abnewswire] was valued at USD 2.06 billion in 2026 and is projected to reach USD 2.57 billion by 2031, registering a CAGR of 4.50% during the forecast period. The electric vehicle battery coolant market…

More Releases for Mechanism

The Noise Attenuation Mechanism of Aluminum Foam

The noise attenuation effect of aluminum Foam [https://www.beihaicomposite.com/foam/] is determined by its unique structural features. Aluminum foam has a high porosity and a high interconnected pore rate, which allows sound waves to enter and be absorbed easily, meeting the structural requirements of typicalsound-absorbing materials [https://www.beihaicomposite.com/]. Additionally, the foam's metallic properties, such as high thermal conductivity and high vibration frequency, also contribute to sound wave absorption. The mechanism of its sound…

NoSQL: A Database Mechanism to Manage Unstructured Data

NoSQL is a database mechanism that enables users to store, access, and analyze huge volume of unstructured data. It allows enterprises to achieve high scalability, simple designs, and precise control over unstructured data. Some of its features include, ease in usage in conventional load-balanced clusters, scalable memory, no fixed schemas, and schema migration without downtime. The growing awareness of advantages over relational database would increase its demand, especially in, social…

Global Artificial Lift Market - By Lift Technology, Mechanism, Application, Regi …

A comprehensive research report created through extensive primary research (inputs from industry experts, companies, stakeholders) and secondary research, the report aims to present the analysis of Global Artificial Lift Market. The report analyses the artificial lift market by Lift Type (Beam/Rod Type, Plunger, Gas Lift, Electric Submersible Pump, Hydraulic Pump, Progressive Cavity Pump, Others), By Mechanism (Pump assisted, Gas assisted), By Application (Onshore, Offshore), By Region (North America, Latin America,…

Microcapsules To Revolutionize and Transform Drug Delivery Mechanism

“Global Microcapsules Drug Delivery Market Opportunity Outlook 2022” report highlights:

* Characterization and Engineering Technology of Microcapsules

* Applicability of Microcapsules in Drug Delivery

* Global Market Perspectives of Microcapsules

* Global Microcapsule Market Dynamics

* Future Indication of Microcapsules

For Report Sample Contact: neeraj@kuickresearch.com or +91-11-47067990

Download Report:

https://www.kuickresearch.com/report-global-microcapsules-drug-delivery-market-opportunity-outlook-2022.php

Report Table of Contents

1. Indispensable Advent of Microcapsules

1.1 Trajectory of Microencapsulation

1.2 Why and wherefores for Microencapsulation

2. Characterization of Microcapsules

…

Gas Pooling Mechanism Market - Global Industry Analysis 2024

The global market for gas pooling mechanism has witnessed huge traction in the past few years as governments and companies look at ways of producing affordable gas to fulfill the ever-increasing energy demand across the globe. The rapid economic development of several regional markets, the exponential rise in the global population, and the rapid industrialization observed in developed regions are some of the major factors contributing to the added pressure…

United States Control Valve Mechanism Market Report 2021

This report studies sales (consumption) of Control Valve Mechanism in USA market, focuses on the top players, with sales, price, revenue and market share for each player, covering

Request Sample Report:

http://www.reportbazzar.com/request-sample/?pid=668829&ptitle=United+States+Control+Valve+Mechanism+Market+Report+2021&req=Sample

AISIN SEIKI

Bosch

Continental

DENSO

FTE Automotive

ATE

Cardone

Dorman

Federal-Mogul

Split by product types, with sales, revenue, price, market share and growth rate of each type, can be divided into

Type I

Type II

Type III

Split by applications, this report focuses on sales, market share and growth rate of Control Valve Mechanism…