Press release

Steps for manufacturing high-strength carbon fiber tubes

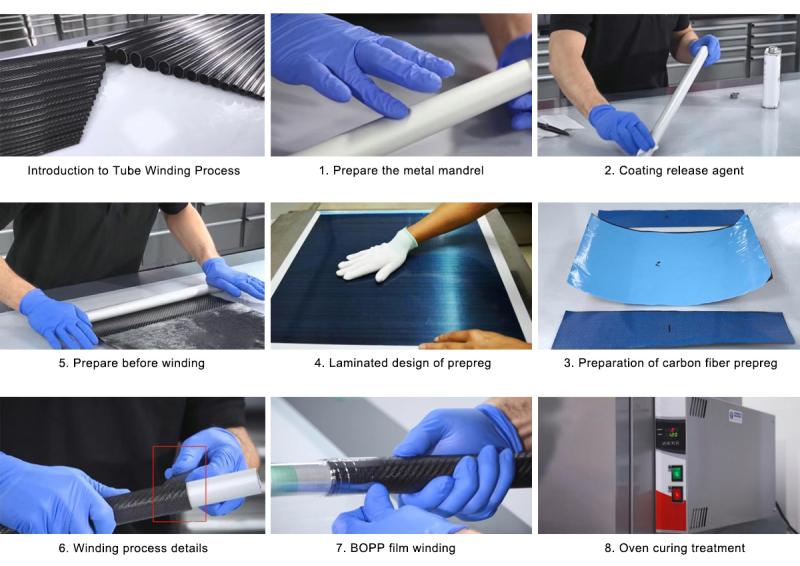

1. Introduction to Tube Winding ProcessThrough this tutorial, you will learn how to use the tube winding process to form tubular structures using carbon fiber prepregs on a tube winding machine, thereby producing high-strength carbon fiber tubes [https://www.fiberglassfiber.com/carbon-fiber/]. This process is commonly used by composite material manufacturers.

If you wish to produce tubes with parallel sides or continuous taper, the tube winding process is the ideal choice. All you need is a metal mandrel of the appropriate size and an oven to create custom carbon fiber tubes tailored to your specific requirements.

For complex-shaped carbon fiber tubes, such as handlebars or more intricate tubular frame structures like suspension forks or bicycle frames, split-mold technology is the preferred method. We will now demonstrate how to use split-mold technology to produce these complex carbon fiber tubes.

2. Processing and Preparation of Metal Mandrels

* The Importance of Metal Mandrels

Before beginning the tube winding process, the first step is to prepare the metal mandrels. The metal mandrels must match the inner diameter of the tubes, and their surface smoothness and appropriate pre-treatment are critical. Additionally, the metal mandrels must undergo proper pre-treatment, such as cleaning and applying a release agent, to simplify the subsequent demolding process.

During the tube winding process, the metal mandrel plays a crucial role as it must support the carbon fiber prepreg [https://www.fiberglassfiber.com/carbon-fiber/] to ensure smooth winding. Therefore, preparing the appropriate size of metal mandrel in advance is essential. Since the carbon fiber will be wound around the outer surface of the mandrel, the outer diameter of the mandrel must match the inner diameter of the carbon fiber tube to be manufactured.

* Applying release agent

Release agents reduce friction and ensure smooth demolding; they must be evenly applied to the mandrel surface. After the metal mandrel is prepared, the next step is to apply the release agent. Commonly used release agents include silicone oil and paraffin, which effectively reduce friction between the carbon fiber and the metal mandrel.

On the prepared metal mandrel, we must ensure it is thoroughly clean and the surface as smooth as possible to facilitate smooth demolding of the product. Subsequently, the release agent should be evenly applied to the surface of the mandrel.

3. Preparation of carbon fiber prepreg

* Types and advantages of prepreg

Only carbon fiber prepregs meet the high requirements for winding accuracy and ease of handling. Although other types of reinforcing materials, such as epoxy-impregnated dry fabrics, could theoretically be used in the winding process, in practice, only carbon fiber prepregs can meet the high requirements for precision and ease of handling in this process.

In this tutorial, we use a specific prepreg layering method to enhance the performance of the tubing.

* Prepreg Layup Design

A layer of woven prepreg is laid on the inner side of the tube, followed by several layers of unidirectional prepreg, and finally another layer of woven prepreg is applied on the outer side of the tube. This layup design fully leverages the fiber orientation advantages of woven prepreg at the 0 degrees and 90 degrees axes, significantly enhancing the tube's performance. The majority of unidirectional prepregs laid on the 0 degrees axis confer excellent longitudinal stiffness to the pipe.

4. Pipe winding process flow

* Pre-winding preparation

After completing the prepreg layup design, the process proceeds to the pipe winding process. Prepreg processing involves removing the PE film and release paper, and reserving appropriate overlap areas. This step is critical for ensuring the smooth progression of subsequent winding processes.

* Details of the winding process

During the winding process, it is essential to ensure smooth winding of the prepregs, with the metal core shaft placed steadily and force applied uniformly. The metal core shaft should be placed steadily at the edge of the first layer of prepregs, ensuring even force application.

During winding, additional prepregs can be wound at the ends to facilitate product removal during demolding.

* BOPP Film Wrapping

In addition to prepreg, BOPP film can also be used for wrapping. BOPP film increases consolidation pressure, protects, and seals the prepreg. When applying BOPP wrapping film, it is crucial to ensure sufficient overlap between the tapes.

5. Oven Curing Process

* Curing Temperature and Time

After tightly wrapping the prepreg carbon fiber reinforced material, it is sent to the oven for curing. Temperature control is critical during curing in the oven, as different prepregs have different curing conditions. This step is crucial for ensuring material stability and enhancing performance.

Through the high-temperature environment in the oven, the carbon fiber [https://www.fiberglassfiber.com/carbon-fiber/] and resin matrix react fully, forming a robust composite material.

6. Removal and Processing

After removing the BOPP wrapping film, the cured product can be removed. The BOPP film can be removed after curing. If necessary, the appearance can be improved through sanding and painting. For further aesthetic enhancement, additional finishing processes such as sanding and painting can be performed.

Image: https://www.fiberglassfiber.com/uploads/Steps-for-manufacturing-high-strength-carbon-fiber-tubes.jpg [https://www.fiberglassfiber.com/carbon-fiber/]

Media Contact

Company Name: China Beihai Fiberglass Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=steps-for-manufacturing-highstrength-carbon-fiber-tubes]

Country: China

Website: https://www.fiberglassfiber.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Steps for manufacturing high-strength carbon fiber tubes here

News-ID: 4174284 • Views: …

More Releases from ABNewswire

Key Factors to Consider When Choosing a Demolition Company in Singapore

Looking for a trusted demolition company in Singapore? Discover the key factors to consider, including experience, safety standards, licensing, and pricing, to ensure a smooth and compliant project. Read now and choose the right partner with confidence!

Demolition work is a critical part of construction and renovation projects in Singapore. Whether you are clearing a small residential property or a large commercial site, choosing the right demolition company in Singapore [https://demosquad.sg/services/commercial-hacking-and-demolition/]…

Choosing a Reliable Custom Mobile App Company in Singapore

Looking for a reliable custom mobile app company in Singapore? Discover key factors to consider, expertise, portfolio, pricing, and support, to ensure your app's success. Read now and choose the right partner today!

In today's digital landscape, mobile applications are no longer optional for businesses, they are essential. From improving customer engagement to streamlining internal operations, mobile apps play a pivotal role in business growth. However, the success of an app…

Life-Changing Injury: The need of a Greenville Spinal Cord Injury lawyer.

Image: https://www.abnewswire.com/upload/2026/02/11bdc9efa74221f15b62c0eea53d9460.jpg

Introduction

One of the worst effects of any accident is a spinal cord injury. One accident in Woodruff Road or a crash of a truck in I-385 or fall will permanently change your capacity to move, work, and live without assistance. The financial, emotional and physical burden is immense. The victims not only have to contend with an immediate medical emergency but also a life of specialized care and rehabilitation.…

Injured on the Job in Augusta The reason why a Workers' Compensation Lawyer is n …

Image: https://www.abnewswire.com/upload/2026/02/fdb5a0803ebb4effcac2ba3a57689a46.jpg

Introduction

An injury at a workplace can make your life another way within a second. It does not matter whether you are in construction, manufacturing, healthcare, or retail in Augusta, one lapse of care or a crash could leave you with crippling injuries, accruing medical care expenses and lost wages. The workers compensation system implemented in Georgia is aimed at offering compensation to injured employees but the employees find it…

More Releases for BOPP

E-commerce Activities Fuels Growth In BOPP Film Market: Strategic Insights Drivi …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

How Large Will the Biaxially Oriented Polypropylene (BOPP) Film Market Size By 2025?

The market size for biaxially oriented polypropylene (BOPP) film has witnessed significant growth in the past years. The market value is projected to increase from $29.56 billion in 2024 to $31.57 billion in 2025, showcasing a…

Shaping the Biaxially Oriented Polypropylene (BOPP) Film Market in 2025: Innovat …

"How Big Is the Biaxially Oriented Polypropylene (BOPP) Film Market Expected to Be, and What Will Its Growth Rate Be?

The market size of Biaxially Oriented Polypropylene (BOPP) film has exhibited significant growth in the preceding years. The market is forecasted to expand from $29.56 billion in 2024 to $31.57 billion in 2025, showcasing a compound annual growth rate (CAGR) of 6.8%. The historical growth pattern can be linked to the…

Global BOPP Films for Packaging Market Size - By Product Type(BOPP Anti-fogs Fil …

BOPP Films for Packaging Market Insights: Trends, Drivers, and Outlook 2024 - 2031

BOPP Films for Packaging Market Scope: Unveiling Today's Trends

BOPP Films for Packaging are biaxially oriented polypropylene films widely used for their excellent clarity, moisture resistance, and flexibility in packaging applications. The market for these films has been experiencing significant growth, driven by increasing demand from sectors such as food and beverages, pharmaceuticals, and consumer goods. As sustainability becomes…

Introducing heat sealable bopp film: Cloud Film Unveils Revolutionary Heat Seala …

Qingdao Cloud Film Packaging Materials Co., Ltd., a leading innovator in the packaging industry, is thrilled to announce the launch of heat sealable bopp film, a breakthrough heat sealable BOPP film set to revolutionize flexible packaging and labeling applications globally. This exciting development represents a significant advancement in packaging technology and underscores Qingdao Cloud Film's commitment to delivering cutting-edge solutions to its customers worldwide.

In a world where packaging integrity and…

BOPP Labels Market : Scope And Opportunities Analysis

We live in the era of digital transformation; the consumer market has gone through a paradigm shift in the last few years. The outbreak of covid-19 pandemic has opened the digital platforms like never before.

Read Report Overview- https://www.transparencymarketresearch.com/bopp-labels-market.html

The number of e-commerce sites and platforms for various goods have increased since the outbreak of covid- 19 crisis, leading to increasing in manufacturing of BOPP labels to suit the product requirements of…

Latest Trends in BOPP Labels Market 2020-2025

This report also researches and evaluates the impact of Covid-19 outbreak on the�BOPP Labels�industry, involving potential opportunity and challenges, drivers and risks. We present the impact assessment of Covid-19 effects on�BOPP Labels�and market growth forecast based on different scenario (optimistic, pessimistic, very optimistic, most likely etc.).

GLOBAL INFO RESEARCH�added a new�research report to its exhaustive repository. The research report, titled [Global and China BOPP Labels Market 2020 by Manufacturers, Type and…