Press release

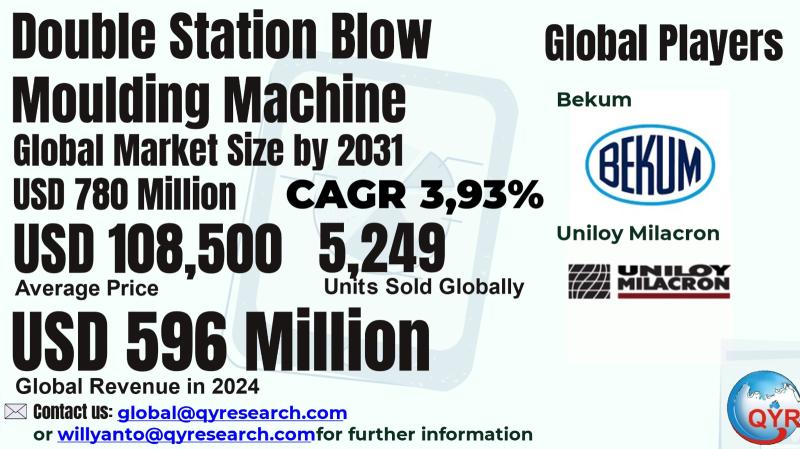

Double Station Blow Moulding Machines Market to Reach USD 780 Million by 2031 Top 15 Company Globally

Double-station blow moulding machines are a widely used class of extrusion blow-moulders that alternate between two independent tool stations to deliver continuous, high-uptime production for hollow plastic products such as jerrycans, drums, barrels, small to mid-size bottles, fuel tanks and industrial containers. The double-station architecture (also called dual-head or shuttle blow-moulding in some vendor lines) allows one mould to be loaded/unloaded and the other to be blown, improving cycle utilisation without requiring a multi-cavity rotary platform. Machines in this family span low-cost, single-extruder two-station units for commodity HDPE/PP containers up to sophisticated co-extrusion and multi-layer versions for specialty packaging; key technical differentiation is in extrusion head design, accumulation vs continuous extrusion, servo control and energy architecture (hydraulic, hybrid, fully-electric). Buyers choose double-station systems where a balance of throughput, flexibility (multiple shapes/sizes) and capital intensity is required typical end markets include chemicals, agrochemicals, lubricants, foodservice, household chemicals and industrial packaging.The global double-station blow moulding machine market at about USD 596 million in 2024 with a CAGR of approximately 3.93% to 2031, which results in a projected double-station market size of about USD 780 million in 2031. The ASP range around USD 108,500, Applying the 2024 market value of USD 596 million to those ASPs implies a 2024 global shipment range of 5,249 units.

Latest Trends and Technological Developments

The double-station segment is being reshaped by three concurrent technology vectors: electrification/all-electric drives (for lower energy use and cleaner operation), higher-efficiency accumulation/extrusion heads and multi-layer/co-ex capability to enable barrier bottles, and tighter Industry-4.0 controls for remote diagnostics and faster job changeovers. Notable dated milestones include vendor demonstrations and product rollouts at major tradeshows: at NPE 2024 multiple vendors highlighted next-gen double-head and dual-station designs Plastiblow demoed a new all-electric double-station PB15ED machine at NPE 2024 (demonstration announced FebMay 2024). Uniloy continued to expand its electric shuttle family and announced the UCS10.E double-station electric shuttle (promoted at events in 2022 and discussed in Uniloy communications through 2024 to 2025), while Uniloys May 2024 acquisition of FGH Systems shuttle-mold and service business signalled consolidation in shuttle/double-station mold services and aftermarket support. Machinery builders also made announcements about high-cavitation, energy-efficient designs and increased service investments in 2024 to 2025 (Uniloy press and trade coverage, NPE 2024 coverage). Additionally, smaller Chinese builders continue to push low-cost, high-automation double-station lines (product listings and SNEC/NPE product pages in 2024 to 2025), expanding accessible capacity in vegetative packaging and mid-format containers. These dated events highlight a market moving toward electrification, automation and broader geographic supply.

Asia Pacific is the single largest regional demand engine for double-station blow moulding machines in 2024, reflecting both high local manufacturing volumes for packaging (chemicals, detergents, lubricants, edible oil) and the presence of both low-cost OEMs and tier-one global machine builders local affiliates. China and India lead on unit volumes, with China supplying many value-priced double-station machines domestically and for export, while Indias expanding consumer-packaged-goods base and growing small/medium packaging converters create sustained demand for mid-range dual-station systems. Japan and Korea continue to be important for premium, high-precision blow-moulders (multi-layer and co-ex heads), and regional exhibitions/technical service hubs (e.g., NPE, Drinktec, interpack-regional events) sustain order pipelines. Local supplier ecosystems in APAC also compress lead times and permit lower-cost retrofit and spare-parts provisioning an advantage for converters pursuing shorter time-to-market for seasonal SKUs or regional private label contracts.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/4949201

Double Station Blow Moulding Machine by Type:

Parallel

Rotary

Double Station Blow Moulding Machine by Application:

Packaging industry

Pharmaceutical Industry

Automotive Parts

Chemical Containers

Others

Global Top 15 Key Companies in the Double Station Blow Moulding Machine Market

Tetra Laval

Krones

KHS

Bekum

Sacmi

SIPA

Aoki Technical Laboratory

Niseel ASB Mavhine

Uniloy Milacron

Mauser

SMF Machinefabrik

Chumpower

BBM Maschinenau

Graham Engineering

Husky Injection Molding

Regional Insights

ASEAN demand for double-station blow moulders is increasing as food and beverage packaging, household chemical producers and industrial container converters scale capacity. Indonesia stands out as a regionally important growth market given its large and dispersed manufacturing base, rising FMCG demand and ongoing investments in backbone packaging infrastructure; local distributors and Chinese exporters have increased machine shipments into Indonesia in 20232025. Thailand and Vietnam show steady adoption among mid-tier converters that serve both domestic and export markets, and Malaysia and the Philippines are important for niche, higher-spec applications and contract packagers. ASEAN owners often prefer a balance of capital cost and local serviceability; therefore lower-cost double-station units from Chinese suppliers and mid-spec machines from global OEMs both have addressable niches. Trade records and supplier announcements over 20232025 document rising inquiries and shipments across ASEAN, reflecting a pipeline driven by e-commerce foodservice packaging and industrial container demand.

Several structural constraints shape the double-station market. First, commodity resin price volatility (HDPE/PP) can compress converters margins and delay capital replacement cycles when customers defer new tooling orders; second, energy-efficiency and emissions regulations are increasing pressure on hydraulic-dominated lines, pushing replacement toward all-electric and hybrid platforms that carry higher upfront ASPs; third, supply-chain constraints for precision heads, molds and servo electronics can lengthen lead times and create order backlogs; fourth, competition from rotary high-cavity and fully-automated multi-station solutions for very large runs can siphon demand away from dual-station platforms where customers prefer higher per-hour output; and finally, ongoing price competition from low-cost machine builders can compress OEM margins and complicate aftermarket parts/service economics. These challenges affect both OEM strategy and converter capital planning.

Winning OEMs and converging converters will pursue three strategies: accelerate electrified double-station lines to reduce operating cost and comply with emissions rules; bundle tooling, digital job recipes and fast-change mold systems to shorten SKU-changeover time and make double-station investments more attractive for multi-SKU converters; and build regional aftermarket and training footprints (especially in APAC/ASEAN) to lock customers into service contracts and spare-parts streams. For converters, the value-case to prefer double-station machines rests on mixed-run flexibility and lower capital outlay versus rotary platforms; converting companies that can move quickly between SKUs and demonstrate reduced per-bottle energy and labor will win more private-label and contract manufacturing work. Investors should model margin expansion from aftermarket parts and service agreements, and they should prioritize OEMs with proven electrification roadmaps and local service networks in APAC and ASEAN.

Product Models

Double-station blow moulding machines are specialized equipment used in the plastic packaging industry to produce hollow containers such as bottles, jars, and industrial parts. With two stations working in parallel, they improve efficiency, reduce cycle time, and support mass production.

Parallel Double Station Blow Moulding machines which feature two molds running side-by-side for simultaneous production. Notable products include:

Kautex KCC Series Double Station Kautex Maschinenbau: High-precision German-made machine for packaging bottles and containers.

Bekum H Series Parallel Double Station Bekum Maschinenfabriken: Reliable parallel system designed for automotive and consumer packaging.

Techne DBM Parallel Double Station Techne Graham Packaging Systems: Known for energy efficiency and high-volume bottle production.

Parker Plastic Machinery PBS Series Parker Taiwan: Parallel system designed for chemical bottles and household packaging.

Chia Ming CM-SB Series Chia Ming Machinery: Dual-station machine ideal for cosmetic and pharmaceutical containers.

Rotary Double Station Blow Moulding machines which rotate molds between stations to maximize continuous output. Examples include:

Kautex Rotary Double Station Series Kautex Maschinenbau: High-speed rotary system for mass production of beverage bottles.

Bekum R Series Rotary Blow Moulding Machine Bekum Maschinenfabriken: German rotary technology optimized for multilayer containers.

Uniloy ISBM Rotary Double Station Uniloy Milacron: Rotary injection stretch-blow moulding system for PET packaging.

Techne Rotary Double Station Machine Techne Graham Packaging Systems: Continuous rotary design for fast, large-scale container production.

SMF Rotary Double Station SMF Poland: PET rotary blow moulding line known for high automation.

Double-station blow moulding machines form a substantial and durable subsegment of the broader blow-moulder market, combining flexible throughput with competitive capital intensity for mid-range container production. With a reconciled 2024 market baseline of approximately USD 596 million and a modeled CAGR of 3.93% to 2031 (producing roughly USD 780 million by 2031 under the central scenario), the subsegment will grow as converters chase regional private-label work, packaging upgrades and co-ex/multi-layer functionality. Asia Pacific led by China and India will remain the volume heartland, while ASEAN offers above-trend unit growth as converters and packagers localize production for domestic and regional markets. Electrification, faster changeover systems and stronger aftermarket service networks will be the major vectors that separate winners from laggards.

Investor Analysis

For investors, the what is exposure to equipment sales and recurring aftermarket revenue in a capital-goods niche that supports essential packaging industries. The how is through stakes in OEMs that can electrify product lines, scale spare-parts and service contracts (which drive higher margin annuities), or through investments in regional distributors/converters that can capture conversion economics by localizing production for ASEAN customers. The why is timing and defensibility: packaging demand is resilient, regional reshoring and e-commerce continue to increase small/medium container production demand, and OEMs that demonstrate lower life-cycle operating cost and local service will secure multi-year supplier relationships. Due diligence should focus on warranty and spare-parts margins, demonstrated energy savings on electrified platforms, and the depth of regional service networks in APAC/ASEAN.

Request for Pre-Order Enquiry On This Report

http://qyresearch.com/customize/4949201

5 Reasons to Buy This Report

It reconciles specialized double-station market reporting with broader blow-molding machine studies to deliver a defensible 2024 baseline and a transparent CAGR to 2031.

It converts revenue into ASP and unit-shipment scenarios using documented vendor price bands so planners can stress-test production and dealer networks.

It catalogues dated product and trade-show signals that materially affect competitive positioning.

It provides actionable regional intelligence for APAC and ASEAN (including Indonesia) to inform go-to-market, local assembly and service hub decisions.

It profiles the technology vectors electrification, co-ex heads, Industry-4.0 controls and the top vendors that are best positioned to capture both machine and higher-margin aftermarket revenues.

5 Key Questions Answered

What is the most defensible estimate of the global double-station blow-moulding machine market size in 2024 and what CAGR should be used to model to 2031?

What realistic ASP bands exist for double-station machines today and what do those imply for units shipped globally in 2024 under alternative price scenarios?

Which dated product launches, acquisitions and trade-show demonstrations in 20232025 signal vendor strategy and near-term demand?

How do Asia and ASEAN market dynamics including Indonesias converter growth and import patterns shape regional procurement and service needs for double-station platforms?

Which five suppliers are most influential in this segment and what product/aftermarket differentiators should investors and buyers prioritize?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Double Station Blow Moulding Machines Market to Reach USD 780 Million by 2031 Top 15 Company Globally here

News-ID: 4172375 • Views: …

More Releases from QY Research

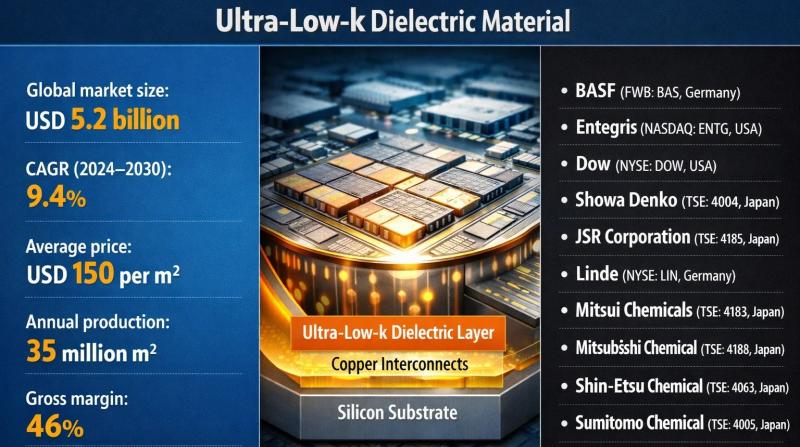

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for Double

Next double victory for ritterwerk

Next double victory for ritterwerk: serano⁸ becomes test winner in ETM TESTMAGAZIN's all-purpose slicer comparison test - icaro⁵ achieves strong third place

Gröbenzell, June 2025 - ritterwerk GmbH can celebrate its next outstanding double success: In the latest comparison test by the renowned ETM TESTMAGAZIN (issue 06/2025), two all-purpose slicers from ritter were honored. The serano⁸ impressed with a test result of 96.1 % and was deservedly crowned the test winner.…

QuickBooks Multicurrency's double whammy

Brandon, MB- March 15, 2022: Enabling the multi-currency feature has a wealth of benefits

Foreign accounts can be reconciled like banks and credit cards in their native currency, without having to consider the exchange rate. Customers can be invoiced in their native currency, purchase orders can be issued to vendors in their native currency, QuickBooks can also easily calculate the gains or losses on foreign exchange as well as…

LotNova Partners With EasyKnock To Eliminate Double Move, Double Mortgage for Ne …

Chicago, IL – Startup homebuilding platform LotNova announced that they have become the first residential single family homebuilder to partner with EasyKnock, offering homebuyers a seamless solution to sell their current home, lease it back during construction, and move when their new home is complete.

EasyKnock is the first technology-enabled residential sale-leaseback company that helps homeowners sell their home without moving. Their MoveAbility program helps homeowners planning on moving in…

The global economy’s double challenge

It is difficult to think about the weather tomorrow when you are navigating a storm right now. The trouble is that that is the situation that various sectors of the global economy find themselves in. They need to be managing a fast-changing environment while simultaneously looking ahead at which strategic investments are going to help ensure that they either stay at the top of the market if they are already…

Global Double Edges Blade (Double Edge Blades) Market 2019 - Gillette, Edgewell, …

This new report by Eon Market Research, titled “Global Double Edges Blade (Double Edge Blades) Market 2019 Research Report, 2015 – 2025” offers a comprehensive analysis of Double Edges Blade (Double Edge Blades) industry at a global as well as regional and country level. Key facts analyzed in this report include the Double Edges Blade (Double Edge Blades) market size by players, regions, product types and end industries, history data…

Glass Double Pushchairs Market 2019 | Shinybb, Kinderwagon, Wellborn, Micralite, …

Market Research Hub (MRH) has actively included a new research study titled “Global Double Pushchairs Market” Research Report 2019 to its wide online repository. The concerned market is discoursed based on a variety of market influential factors such as drivers, opportunities and restraints. This study tends to inform the readers about the current as well as future market scenarios extending up to the period until forecast period limit; 2025. In…