Press release

China Leading PCB Board Testing Company Excellence: Morel Shines at NEPCON ASIA 2024

In the relentless tide of the modern electronics manufacturing industry, the quality and reliability of printed circuit boards (PCBs) are paramount. As the very core of all electronic devices, the integrity of a PCB is non-negotiable. This is where PCB board testing technology, a critical process for ensuring product performance and safety, is undergoing unprecedented innovation. Against this backdrop, Morel, as a recognized China leading PCB board testing company (https://www.mo-tek.com/ict-fct-automatic-tester/), demonstrated its outstanding technical prowess and deep industry insight at the NEPCON ASIA 2024 exhibition, once again solidifying its leadership position in the market.A Look Back at NEPCON ASIA 2024: A Showcase of Electronic Manufacturing's Future

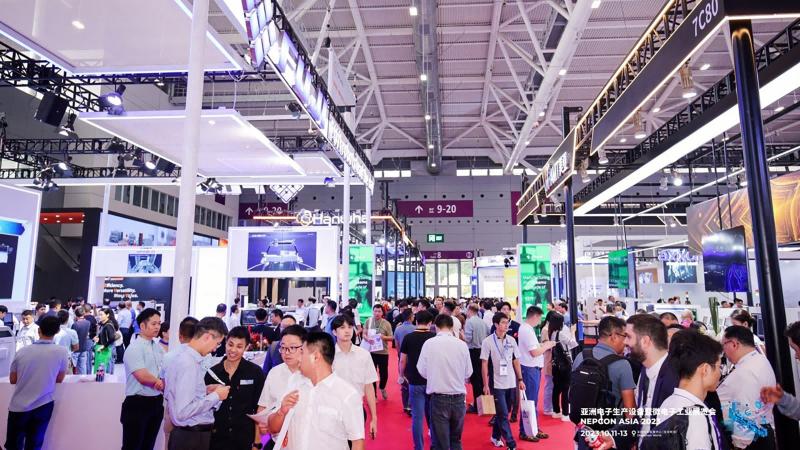

From November 6 to 8, 2024, NEPCON ASIA 2024 took place at the Shenzhen World Exhibition & Convention Center. As the premier event for the electronic manufacturing industry in Asia, the exhibition brought together over 600 leading global companies. They showcased a comprehensive range of cutting-edge technologies, including circuit board assembly, semiconductor packaging, automation, and smart factory solutions, painting a clear picture of the industry's future trajectory.

The Comprehensive Electronic Manufacturing Ecosystem

One of the exhibition's key highlights was the "Electronic Manufacturing Ecosystem" section, which provided a comprehensive overview of solutions in surface mount technology (SMT), testing, automation, and electronic materials. Exhibitors presented their latest products and innovations, from high-speed pick-and-place machines to high-precision testing equipment and from intelligent logistics systems to comprehensive production line management software. Each innovation was designed to boost manufacturing efficiency, optimize production processes, and reduce costs. It was not just a platform for product display but also an excellent opportunity to discuss industry trends and facilitate technical exchange.

The Future of Power Semiconductors and Automotive Electronics

NEPCON ASIA 2024 featured a dedicated "Power Semiconductor Packaging and Testing" zone, where over 60 brands displayed production lines for IGBT and SiC module packaging and testing. The rapid growth of new energy vehicles and industrial automation has led to a surging demand for efficient and reliable power semiconductors. This special zone offered valuable insights to professionals, helping them understand the latest packaging technologies and testing standards to meet market challenges.

Additionally, the "NEPCON ∞ SPACE" section focused on the automotive electronics sector. Through immersive experiences, technical salons, and live vehicle teardowns, this area vividly showcased the future of automotive electronics. Innovations in this field, from Advanced Driver-Assistance Systems (ADAS) to in-vehicle infotainment, are redefining the driving experience and vehicle functionality. The exhibition undoubtedly provided a strong impetus for the deep integration of automotive electronics and traditional electronic manufacturing.

A Feast of Insight and Collaboration

Over the three-day event, more than 40 high-level forums and activities were held. Topics included electronic manufacturing, smart factories and automation, semiconductor packaging and testing, new energy, and ESG. These forums not only featured top industry experts but also provided a platform for attendees to exchange ideas and forge partnerships. International activities like business matching meetings and factory tours were also organized, significantly promoting global cooperation in the electronic manufacturing sector.

Among the numerous exhibitors, Morel's booth attracted considerable attention. This was a testament not only to their technical strength but also to their unique market positioning and deep understanding of customer needs. Morel's presence served as a vital bridge connecting the exhibition's grand narrative with the specific practices of a leading enterprise.

The Morel Advantage: Redefining PCB Testing (https://www.mo-tek.com/) for a Smarter World

In an era where electronic manufacturing relentlessly pursues higher precision, faster speeds, and smaller sizes, traditional PCB testing methods can no longer keep up. This is the challenge Morel has taken on. With over 15 years of experience in the Surface Mount Technology (SMT) industry, the company has not only identified these challenges but has also transformed them into a catalyst for innovation. Their journey reflects a profound understanding of customer needs, evolving from a provider of accessories into a comprehensive one-stop solution provider.

Core Strengths and Technical Innovation

Morel's core strength lies in its holistic and sophisticated solutions. They go beyond providing a single piece of testing equipment, integrating hardware, software, services, and industry expertise into a seamless whole. Morel's equipment is renowned for its high precision, efficiency, and reliability, capable of meeting diverse testing needs from research and development to small-batch and large-scale production.

For a deeper dive into their solutions and capabilities, you can explore their website at https://www.mo-tek.com/.

Morel's main products are widely applied in several critical fields, each demanding a unique approach to quality assurance:

Consumer Electronics: Smart devices like smartphones, tablets, and smart wearables demand extremely high standards for PCB size, integration, and reliability. Morel's testing equipment ensures that these products can achieve stable, complex functionality within minimal space, meeting the rigorous demands of the market.

Automotive Electronics: The trend towards vehicle electrification and intelligence has led to a significant increase in the number and complexity of PCBs in cars. Morel offers robust testing solutions for automotive manufacturers and suppliers, ensuring the safety and stability of in-vehicle electronic systems in harsh, real-world environments.

Industrial Control & Automation: Industrial equipment requires exceptionally durable and reliable PCBs. Morel's solutions are engineered to withstand severe conditions like high vibration, extreme temperatures, and electromagnetic interference, guaranteeing continuous and efficient industrial production.

Communication Equipment: The advent of the 5G era has placed higher demands on PCBs in communication devices. Morel's testing technology helps clients tackle challenges like high-frequency signal integrity and multi-layer board testing, ensuring the quality and reliability of critical communication infrastructure.

Customer Cases and Industry Impact

Morel's success stories are built on its long-term partnerships with clients who are not just purchasers but collaborators in innovation. By deeply understanding their production processes and pain points, Morel provides tailored solutions that help customers optimize production efficiency, enhance product quality, and ultimately gain a competitive edge.

For instance, in a collaboration with a leading global consumer electronics giant, Morel provided a customized high-speed PCB testing solution that successfully reduced testing time by 30% while significantly improving test coverage. This not only saved the client substantial costs but also helped them bring new products to market faster. In the automotive electronics sector, Morel partnered with a renowned Tier 1 supplier to co-develop an automated testing platform for battery management systems (BMS) in new energy vehicles, guaranteeing the ultimate safety and performance of the vehicles.

The Future is Intelligent: Morel's Vision

Looking ahead, the PCB testing industry is evolving towards greater intelligence, automation, and data integration. The fusion of artificial intelligence and big data will make testing processes more efficient and smarter. Morel, as an industry pioneer, is already taking decisive steps in this direction.

Morel's vision is to become the "intelligent brain" of global electronic manufacturing. By providing increasingly forward-looking and competitive testing solutions, the company aims to empower its customers. This includes not only upgrading hardware but also intelligentizing software platforms, integrating cloud services, and building a global technical support network. Morel firmly believes that only by growing alongside its customers can it truly achieve its value and maintain its leading position in the ever-changing global electronic manufacturing landscape.

Morel's outstanding performance at NEPCON ASIA 2024 is not only a testament to its past achievements but also a clear signal of its future potential. It showed the world the immense progress that Chinese enterprises have made in the PCB testing field and set a new benchmark for the entire industry.

+86-755-21635007

Email: sales@morequip.com

MOREL, With over 15 years of experience in the Surface Mount Technology (SMT) industry

Morel has evolved from a provider of accessories into a comprehensive one-stop solution provider. This journey reflects not only our growth but also our deep commitment to understanding and meeting the diverse needs of our customers

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release China Leading PCB Board Testing Company Excellence: Morel Shines at NEPCON ASIA 2024 here

News-ID: 4168955 • Views: …

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…