Press release

Carboxymethyl Cellulose (CMC) Production Plant Cost 2025: Setup Detials, Raw Material Requirements and Infrastructure

Carboxymethyl cellulose (CMC), also known as cellulose gum, is a water-soluble polymer derived from cellulose. It is widely used as a thickener, stabilizer, binder, and emulsifier in industries such as food & beverages, pharmaceuticals, cosmetics, detergents, paper, textiles, and oil drilling. A CMC production plant focuses on the chemical modification of natural cellulose using chloroacetic acid under alkaline conditions, followed by purification, drying, and packaging to obtain high-quality grades for diverse applications.IMARC Group's "Carboxymethyl Cellulose (CMC) Production Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for entrepreneurs and investors. It covers capital investment, project financing, operating costs, raw material management, technical setup, manpower requirements, and profit projections, along with process flow and market insights.

Request for a Sample Report: https://www.imarcgroup.com/carboxymethyl-cellulose-manufacturing-plant-project-report/requestsample

Carboxymethyl Cellulose (CMC) Market Outlook 2025:

The global CMC market is expanding due to:

• Rising demand in the food industry for texture enhancement and stabilization

• Increasing applications in pharmaceuticals and personal care formulations

• Extensive use in detergents and cleaning agents as a soil-suspending agent

• Growing demand from the oil & gas sector for drilling mud applications

• Expansion of paper and textile industries utilizing CMC as a binder and sizing agent

Asia-Pacific leads global production owing to abundant raw materials and cost-effective manufacturing, while North America and Europe are strong consumers in food, healthcare, and industrial sectors.

Key Insights for Setting Up a CMC Production Plant:

Detailed Process Flow:

• Cellulose Sourcing and Preparation

• Alkalization with Sodium Hydroxide

• Etherification with Chloroacetic Acid

• Purification and Neutralization

• Drying and Milling

• Packaging and Storage

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout and Infrastructure Design

• Machinery Requirements and Costs (reactors, mixers, filtration units, dryers, milling machines, packaging systems)

• Raw Material Requirements and Costs (cellulose, sodium hydroxide, chloroacetic acid, solvents, packaging materials)

• Utility Requirements and Costs (electricity, steam, water, fuel, HVAC systems)

• Human Resource Requirements and Costs (chemical engineers, operators, quality controllers, technicians)

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

The report includes detailed financial projections:

• Capital Investments (land, buildings, machinery)

• Operating Costs (raw materials, manpower, utilities)

• Revenue Forecasts

• Profit and Loss Analysis

• Taxation and Depreciation

• Financial Metrics (ROI, NPV, Break-even)

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit & Margin

• Net Profit & Margin

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=18496&flag=C

Key Cost Components of a CMC Plant:

• Raw Materials: Cellulose, sodium hydroxide, chloroacetic acid

• Machinery and Equipment: Reactors, filtration units, dryers, milling machines

• Infrastructure Development: Land, utilities, construction

• Labor and Staffing: Skilled chemical engineers and plant operators

• Quality Control: Labs to test viscosity, purity, and compliance with global standards

• Regulatory Approvals: Environmental permits and industry certifications

• Logistics & Supply Chain: Packaging and export infrastructure

Economic Trends Influencing Setup Costs in 2025:

• Price fluctuations in cellulose and chloroacetic acid

• Growing demand for eco-friendly and biodegradable polymers

• Expansion of the oil & gas industry requiring CMC for drilling applications

• Increasing adoption in personal care and food sectors

• Rising energy and utility costs in chemical processing

• Government initiatives supporting sustainable chemical production

Challenges and Considerations for Investors:

• Environmental and safety regulations in chemical production

• Availability of high-quality cellulose feedstock

• High competition from synthetic substitutes and alternative polymers

• Continuous R&D needed for high-purity pharmaceutical-grade CMC

• Waste management and effluent treatment requirements

Buy Now: https://www.imarcgroup.com/checkout?id=18496&method=1911

Conclusion:

Setting up a Carboxymethyl Cellulose (CMC) Production Plant offers profitable opportunities across food, pharmaceuticals, oil drilling, detergents, and paper industries. With rising demand for stabilizers, thickeners, and eco-friendly polymers, the market outlook is highly favorable. However, investors must ensure strict regulatory compliance, cost-effective operations, and innovation in high-grade CMC production to achieve long-term success.

About Us

IMARC Group is a leading market research and consulting firm that provides feasibility studies, market entry strategies, plant setup guidance, regulatory approvals, and investment consulting. Our tailored solutions help businesses minimize risks, reduce costs, and capture global opportunities.

Contact Us

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Carboxymethyl Cellulose (CMC) Production Plant Cost 2025: Setup Detials, Raw Material Requirements and Infrastructure here

News-ID: 4168238 • Views: …

More Releases from IMARC Group

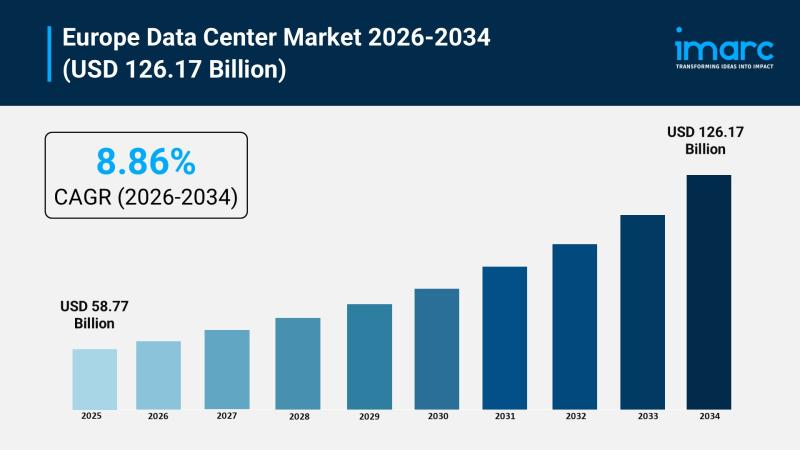

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

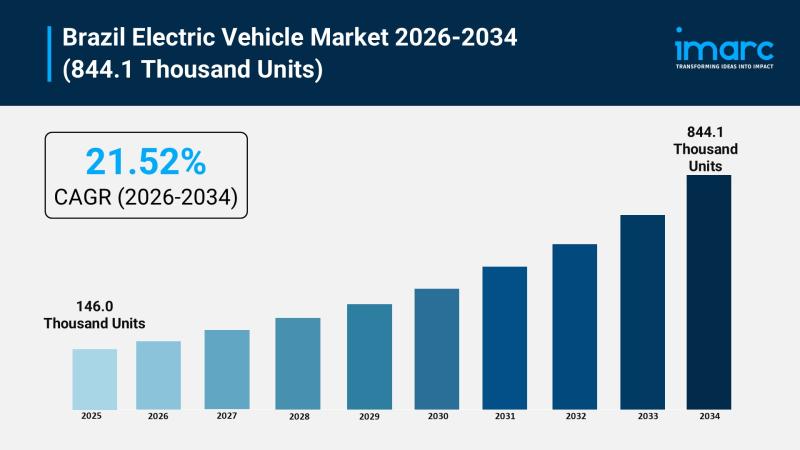

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for CMC

Carboxymethyl cellulose (CMC) Prices, Trend, Chart & Analysis 2025

United States Carboxymethyl cellulose (CMC) Prices Movement Q4 2025:

In Q4 2025, Carboxymethyl Cellulose prices in the USA averaged USD 3,619 per ton. The market was supported by stable demand from food processing, pharmaceuticals, and oilfield applications. Balanced domestic production and steady raw material costs helped maintain firm pricing conditions throughout the quarter.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/carboxymethyl-cellulose-pricing-report/requestsample

China Carboxymethyl cellulose (CMC) Prices Movement Q4 2025:

China recorded Carboxymethyl Cellulose prices at USD…

Key Influencer in the Carboxymethylcellulose (CMC) Market 2025: Pharmaceutical P …

How Are the key drivers contributing to the expansion of the carboxymethylcellulose (cmc) market?

The carboxymethylcellulose (CMC) market is projected to experience a surge driven by an uptick in pharmaceutical production. This production involves the creation of pharmaceutical goods, which can range from medication and vaccines to other kinds of medical therapies. Carboxymethylcellulose plays a crucial role in enhancing viscosity and providing stability to emulsions in various pharmaceutical forms such as…

How to Setup a Carboxymethyl Cellulose (CMC) Manufacturing Plant

Setting up a carboxymethyl cellulose manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Carboxymethyl Cellulose Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a carboxymethyl cellulose…

CMC Central Offers Signals for Enhanced Transactions

CMC Central [https://cmc-central.pro/] announces the availability of signals aimed at improving transaction outcomes. This new offering provides users with insights to navigate the financial market with greater confidence. The signals are designed to be user-friendly, ensuring that individuals can use the platform with ease.

A CMC Central review highlights the simplicity and effectiveness of these signals. Users have reported that the signals provide clear and concise information, which helps in making…

Carboxymethylcellulose (CMC) Market Expands Worldwide During Forecast 2023-2030

During the forecast period (2023-2030), the worldwide carboxymethyl cellulose (CMC) market is anticipated to grow at a CAGR of more than 5%. Monochloroacetic acid, caustic soda, and plant-derived cellulose are used to create the derivative carboxymethyl cellulose. Additionally known as cellulose gum. A considerable increase in the worldwide market is anticipated due to increased demand from the food and pharmaceutical industries. Demand for CMC is rising as a result of…

Carboxymethylcellulose (CMC) Global Market Insights,Forecast to 2025

Press Release – 11 Feb 2019

Research and Development News --

. .

Latest Update "Global Carboxymethylcellulose (CMC) Market Insights,Forecast to 2025" with Industries Survey | Global Current Growth and Future.

' '

Carboxymethylcellulose is made from cellulose, commercially made from wood & chemically modified. CMC cellulose supports in extending the solubility of proteins to a certain pH level. Cellulose gum boosts the aesthetics of the finished product by imparting smooth texture and modifies…