Press release

What Are Self-Tapping Threaded Inserts? Types, Installation, and Applications

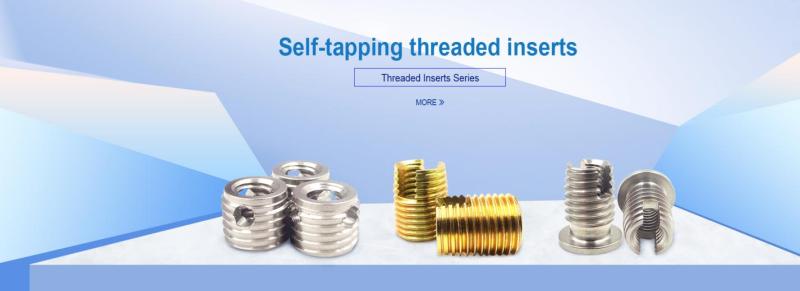

Image: https://ecdn6.globalso.com/upload/p/147/image_other/2025-08/picture-1.jpgWhen people are designing lightweight products, or repairing a worn-out thread, a dependable fastening tool can make a big difference. This is where self tapping threaded inserts can come into play. These inserts eliminate the need for pre-tapping and reduce installation time, as they are engineered to cut their own threads.

They help reinforce assemblies, improve durability, and allow for repeated disassembly without degrading the holding strength, by forming secure internal threads in softer or brittle materials. They are used in literally everything, from industrial equipment, to automobiles, electronic housing and anything in between

In this article, we will talk about what self tapping inserts are, what are some of their common types and applications, and share some installation tips with them.

What are self-tapping threaded inserts?

Image: https://ecdn6.globalso.com/upload/p/147/image_other/2025-08/picture-2.jpg

Selftapping threaded inserts are just like any normal metal bushing, only that they are engineered to have both internal and external threads. These are specially engineered to cut their own mating threads as they're driven into predrilled holes. People don't need to tap the hole in advance, making installation much quicker and cleaner.

They are traditionally made using metals like brass, stainless steel, carbon steel, and zinc-plated steel, based on their intended use. The material chosen depends on the required corrosion resistance, strength and wearability.

As they are turned in, they offer a durable, vibration-resistant threaded joint that holds up even during repeated assembly and disassembly. As the inserts are 'self-tapping', so they form their own thread, making the installation process much simpler. All people need is just drill the right size hole, align the insert, and drive it in with a suitable tool.

The most popular types of self-tapping threaded inserts

Self-tapping threaded inserts [https://www.ppmcn.com/threaded-inserts/4/] come in a few common styles, based on the material and application:

L3020 Series Slotted self tapping thread insert

L3020/L3022 series inserts are the most widely used one among all of the threaded self-tapping inserts. Its two slots function as the cutting edge and slightly renders an inward screw locking performance.

L3070 Series Self tapping thread insert with hole pattern

L3070/L3072/L3080/L3082 series are used in difficult-cutting materials three cutting holes perform the self-tapping action.

Self tapping thread insert for wood

Internal and external tooth design, adding three grooves and guide sections for easy cutting.

Common applications

Image: https://ecdn6.globalso.com/upload/p/147/image_other/2025-08/picture-3.jpg

Self tapping threaded inserts [https://www.ppmcn.com/self-tapping-threaded-insert/] are nearly everywhere. From transportation to electronics, they are a must when people need strong, durable threads in materials that are too soft or thin to hold screws cleanly.

Automotive

These inserts are widely used in the automotive sector, making up around 35% of insert usage. They reinforce threads in lightweight materials like aluminum or plastic, while withstanding vibration and stress.

Electronics and appliances

Threaded inserts [https://www.ppmcn.com/threaded-inserts/] are ideal for plastics used in enclosure housings, control panels, or circuit board mounts. These inserts ensure secure, reusable threads without cracking delicate parts.

Furniture and woodwork

Common in flatpack furniture, threaded inserts are a reliable option where traditional screws might otherwise wade through weak surfaces. Woodworkers also use them when repeated disassembly is needed, like in knockdown desks, modular cabinets, and fixtures.

Industrial machinery

Mostly used in general manufacturing, these inserts help repair stripped threads or add durable fastener points in sheet metal, aluminum, composites, and technical foams. They're especially common in assemblies where components may need to be serviced or replaced later on.

Wherever people need to build things from scratch or restore strong, reusable threads, threaded inserts are a go-to solution. Although, they come with a slightly higher upfront cost, but they are worth every penny.

Installation tips

Selftapping threaded inserts are not tricky to install. Just follow these simple, factbased tips to get it right every time:

Measure hole size and depth carefully

Use the manufacturer's recommended hole diameter, typically slightly smaller than the insert's outer threads, to allow proper engagement. For blind holes, drill to about 1.2 times the insert length so it seats fully without bottoming out.

Ensure cleanliness and alignment

Clean out any dust, chips, or debris before insertion. A clean hole helps the insert cut correctly and engage fully. Keep the insert perfectly perpendicular to the surface to avoid misalignment or stripping.

Use proper tools and lubrication

If possible, use a dedicated installation driver (or a bolt plus jam nut method) to keep things straight. A light coat of PTFE lubricant or wax on the insert can reduce friction, improve alignment, and sometimes speed up installation by ~20%.

Insert steadily and monitor torque

Apply even pressure as people turn the insert into the hole. Stop just short of flush, then verify it's level, and finish seating it gently. Avoid overtightening (especially with brass inserts) as it can damage threads or split the material.

Check final seating and test fit

Once seated, the insert should be flush or just slightly below the surface. In wood or plastic, a light tap with a mallet can help. After installation, insert a bolt to test for smooth threading and secure engagement.

By keeping a precise hole size, perfect alignment and controlling the pressure, they'll get clean, strong, and reliable installs every time.

Can threaded inserts be reused?

While in most cases, self tapping threaded inserts are good for one-time use only, in some cases, people can also reuse them. Some types, like metal helical inserts, can be removed and installed again.

Before considering the reuse, assess the inserts and surrounding material thoroughly and if people notice any wear, then do not reuse.

Conclusion

Self-tapping threaded inserts are engineered to provide a blend of strength, efficiency, and versatility. This is what makes them a smart choice across various industries.

If people are looking for reliable and self tapping threaded inserts [https://www.ppmcn.com/self-tapping-threaded-insert/], then must check out the amazing collection from In-Sail. We have mastered the high quality fastening systems, automation tools, electronic components and other machining tools since 1982.

Media Contact

Company Name: In-saiL

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-are-selftapping-threaded-inserts-types-installation-and-applications]

Country: China

Website: https://www.ppmcn.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What Are Self-Tapping Threaded Inserts? Types, Installation, and Applications here

News-ID: 4165788 • Views: …

More Releases from ABNewswire

Peak Grounding Sets New Industry Standard with Filtration Technology That Elimin …

"We asked ourselves why the wellness industry was accepting a 43% side effect rate as normal when other health categories would find that statistic completely unacceptable. Our filters represent a fundamental reimagining of what grounding products should deliver: pure benefits without compromise, allowing users to earth confidently and comfortably."

The grounding and earthing movement has captured the attention of wellness enthusiasts worldwide, driven by compelling research suggesting that direct connection with…

Top Fintech Software Development Companies In France

France has become a booming center for financial technology innovation in the last several years. The country has attracted both local and worldwide technology experts who offer top-notch fintech software development services. This is because it has a strong digital infrastructure, more money is being put into fintech firms, and the government is doing things to help. If you want to develop safe, scalable, and compliant fintech solutions, you need…

The Operator Vault Announces How To Setup OpenClaw a Workshop For Non Techies

The Operator Vault, founded by Kevin Jeppesen, announced a new recorded OpenClaw workshop priced at $19 and expanded access to its Operator Vault community for creators and operators building automation systems.

NEW YORK, N.Y. - Feb. 20, 2026 - The Operator Vault, a training platform and community founded by Kevin Jeppesen, today announced the release of a new recorded workshop focused on OpenClaw, a tool used to build practical automation workflows…

Interior Painting Contractor in Philadelphia, PA, Observes Spring Surge as Homeo …

Philadelphia, PA - As temperatures warm and daylight extends, Beauty Walls and Floor is experiencing the annual spring surge that owner Sviat Oleksyuk has come to anticipate each year. The seasonal shift brings a wave of homeowners eager to refresh their living spaces, transforming interiors that may have been neglected during the darker winter months.

"Summer is the best, as well as spring time, when people get inspired with new ideas…

More Releases for Threaded

Threaded Inserts: The Small Parts That Make Big Connections

All durable plastic products, such as car dashboards and phone cases, have one tiny component that keeps all the other parts together: the threaded insert. These metallic inserts make soft plastic into hard and reusable joints. There are different types of threaded inserts and the most useful ones are the self-tapping threaded insert, threaded sleeve insert and the tailless thread insert.

All of them produce plastic components as strong as metal…

Threaded Rods & Bars, Hex Bolts, Hex Nuts Fasteners Strut

Kanika Exports are manufactures & exporters of various types of products like- Threaded Rods/ Bars, Coil Rods/ Tie Rods , Threaded Studs, Hex Nuts, Hex Bolts, Plain Washers, Spring Washers, Spring Channel Nut,Strut Channel ,Channel Accessories ,Channel Brackets, Channel Fitting Accessories, Mild Steel Threaded Rods , Zinc Plated Threaded Rods, Steel Threaded Rods, Medium Carbon Steel Threaded Rods, Double Ended Threaded Rods, Fully…

Threaded Fasteners Market: Competitive Dynamics & Global Outlook 2025

LP INFORMATION recently released a research report on the Threaded Fasteners analysis, which studies the Electrical Cord Reels's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “Threaded Fasteners 2020-2025” Research Report categorizes the global Threaded Fasteners by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share, growth rate, opportunities…

New report: Global Threaded Nozzle Market forecast 2019 – 2025

The global Threaded Nozzle market is comprehensively and accurately detailed in the report, taking into consideration various factors such as competition, regional growth, segmentation, and market size by value and volume. This is an excellent research study specially compiled to provide latest insights into critical aspects of the global Threaded Nozzle market. The report includes different market forecasts related to market size, production, revenue, consumption, CAGR, gross margin, price, and…

Threaded Thermowells Market Size, Share, Development by 2023

New report published by Global Info Research which offers insights on the global Threaded Thermowells market.

Threaded thermowells are utilized when pressure, high velocity and corrosive process media exist. This serves to isolate and protect the sensing instrument and permits removal of a sensing instrument without shutting down the process.

Click to view the full report TOC, figure and tables:

https://www.globalinforesearch.com/global-threaded-thermowells-market_p91831.html

Global Threaded Thermowells Market: Forecast by Type / Application / Region

The worldwide market…

Automotive Fasteners Market Basis Of Characteristics Removable, Semi-permanent, …

Fasteners are the mechanical components that holds, joins or affixes two or more parts together, automotive industry is the largest market for the fastener. Automotive fasteners are made up of various materials such as Iron, Aluminum, Brass, Nickel, Stainless steel, Plastic, they are further classified with their distinct characteristics. Automotive fasteners are generally used for the clamping parts of vehicle together to avoid their separation or wobbling, transmitting loads as…