Press release

Bleaching Powder Manufacturing Plant Setup Report 2025: Raw Material Requirements, Project Cost and Profit Margin

Setting up a bleaching powder production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Bleaching Powder Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a bleaching powder production plant, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/bleaching-powder-manufacturing-plant-project-report/requestsample

What is Bleaching Powder?

Bleaching powder (chemically named calcium hypochlorite [Ca(ClO) 2]) is a disinfectant and a bleaching agent that appears in form of a white or slightly yellow powder. It is manufactured by reaction between dry slaked lime [Ca(OH) 2 ] and chlorine gas at around 40 o C. Available chlorine which averages between 30-35 percent is present in this chemical compound therefore making it to be an efficient oxidizing agent. Bleaching powder has a wide variety of uses which include using it in the water treatment plants in order to disinfect, in textile industries bleaching of cotton and linen, in the paper and pulp industries to whiten and in households as a disinfectant. This is because of its antimicrobial qualities and thus it can be useful in sanitizing swimming pools, treating sewage and in treating bacterial infections amongst other industrial uses.

What is Driving the Bleaching Powder Market?

The factors that are propelling the bleaching powder market are the rising demand of water treatment products and services, improved understandings and awareness of hygiene and sanitation and the expansion in textile and paper sectors. Increasing urbanization and industrialization translates into increased use of water, and wastewater generation necessitating effective disinfection solutions that have a high demand in terms of capacity. The impact of COVID-19 was a major factor in market growth because sanitization was elevated to a high level at healthcare establishment, social, and residential premises. In addition, regulations put in place by the government concerning water quality and environment preservation are fueling the use of the bleaching powder in the city water treatment facilities.

Request for Customization: https://www.imarcgroup.com/request?type=report&id=8555&flag=E

Key Steps Required to Set Up a Bleaching Powder Plant

1. Market Analysis

The report provides insights into the landscape of the bleaching powder industry at the global level. The report also provides a segment-wise and region-wise breakup of the global bleaching powder industry. Additionally, it also provides the price analysis of feedstocks used in the production of bleaching powder, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the bleaching powder production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for bleaching powder production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for bleaching powder production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a bleaching powder production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Buy Report Now: https://www.imarcgroup.com/checkout?id=8555&method=1911

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Bleaching Powder Manufacturing Plant Setup Report 2025: Raw Material Requirements, Project Cost and Profit Margin here

News-ID: 4158349 • Views: …

More Releases from IMARC Group

India Robotics Market Expanding at 15.74% CAGR by 2034, Driven by Make in India …

Summary

The India robotics market size reached USD 1.98 Billion in 2025, according to the latest comprehensive industry analysis by IMARC Group. Fueled by a massive push toward manufacturing modernization, rising labor costs, and robust government support for digital transformation, the market is projected to reach an impressive USD 7.38 Billion by 2034. This highlights a rapid compound annual growth rate (CAGR) of 15.74% during the forecast period (2026-2034).

Request a…

India Robotic Sensors Market Growing at 7.75% CAGR Through 2034, Driven by AI & …

Summary

The India robotic sensors market size reached USD 64.08 Million in 2025, according to the latest comprehensive industry analysis by IMARC Group. Fueled by robust government initiatives, escalating labor costs, and the rapid integration of artificial intelligence in industrial automation, the market is projected to reach USD 125.42 Million by 2034. This highlights a steady compound annual growth rate (CAGR) of 7.75% during the forecast period (2026-2034).

Request a Free Sample…

India Beer Market Size to Reach INR 832.93 Billion by 2034: Industry Trends, Gro …

Summary

The beer market size in india reached INR 477.05 Billion in 2025, according to the latest comprehensive industry analysis by IMARC Group. Driven by rapid urbanization, a burgeoning young demographic, and a massive cultural shift toward premium and craft beverages, the market is projected to reach INR 832.93 Billion by 2034. This represents a steady compound annual growth rate (CAGR) of 6.45% during the forecast period (2026-2034).

What are the Key…

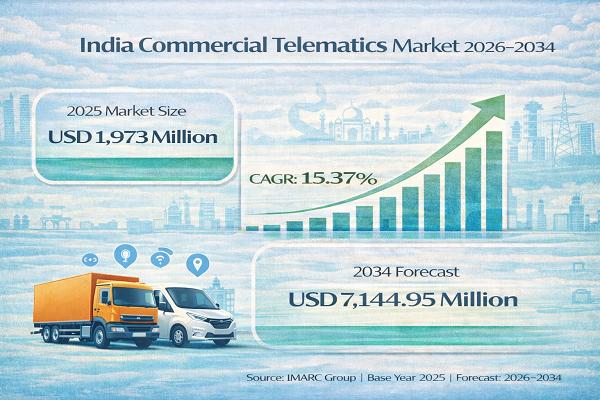

India Commercial Telematics Market Expected to Reach USD 7,144.95 Million by 203 …

India Commercial Telematics Market : Report Introduction

According to IMARC Group's report titled "India Commercial Telematics Market Size, Share, Trends and Forecast by Type, System Type, Provider Type, End Use Industry, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email): https://www.imarcgroup.com/india-commercial-telematics-market/requestsample

Commercial Telematics Market in India : Overview (2026-2034)

The India commercial telematics market…

More Releases for Bleaching

The Bleaching Agent Market: Brightening the Future

The Bleaching Agent Market is poised for a luminous future, with a projected growth at a substantial CAGR of 5.7% during the forecast period. By 2029, the global Bleaching Agent Market is expected to shine at a value of US$ 1093.56 million.

Know More About The Report: https://www.maximizemarketresearch.com/market-report/global-bleaching-agent-market/25043/

Casting Light on Market Drivers and Challenges

The market is set to flourish, primarily driven by the increasing use of bleaching agents across various sectors.…

Bleaching Agent Market Analysis and Forecast

Bleaching Agent Market is expected to grow at a CAGR of 5.7% during the forecast period. Global Bleaching Agent Market is expected to reach US$ 1093.56 Mn by 2029.

Bleaching Agent Market Report Scope and Research Methodology

This comprehensive report offers valuable insights, historical data, and industry-validated market information, using a rigorous research methodology. It aims to identify and analyze market segments and project market size. Furthermore, the report provides a competitive…

Bleaching Agent Market: Regulatory Landscape and Compliance

Bleaching Agent Market is expected to grow at a CAGR of 5.7% during the forecast period. Global Bleaching Agent Market is expected to reach US$ 1093.56 Mn by 2029.

Bleaching Agent Market Report Scope and Research Methodology

This comprehensive report offers valuable insights, historical data, and industry-validated market information, using a rigorous research methodology. It aims to identify and analyze market segments and project market size. Furthermore, the report provides a competitive…

Bleaching Agent Market: Regulatory Landscape and Compliance

Bleaching Agent Market is expected to grow at a CAGR of 5.7% during the forecast period. Global Bleaching Agent Market is expected to reach US$ 1093.56 Mn by 2029.

Bleaching Agent Market Report Scope and Research Methodology

This comprehensive report offers valuable insights, historical data, and industry-validated market information, using a rigorous research methodology. It aims to identify and analyze market segments and project market size. Furthermore, the report provides a competitive…

Strategic Insight into the Bleaching Agent Market

BLEACHING AGENTS ARE BEING USED ON A LARGE SCALE FOR VARIOUS PURPOSES INCLUDING CLEANING, WASHING, WASTEWATER TREATMENT, HEALTHCARE, PERSONAL CARE PRODUCTS, ETC. BLEACHING AGENTS ARE BEING UTILIZED LARGELY FOR HOUSEHOLD APPLICATIONS. HENCE, MANUFACTURERS OF BLEACHING AGENTS ARE FOCUSING ON INNOVATION IN CHEMICAL BLEACHING TO PRODUCE A BETTER PRODUCT, EMITTING LESS CONTAMINANTS INTO AIR, WATER, AND SOIL. BLEACHING AGENTS ARE ALSO USED IN OXIDATIVE HAIR DYING AND TEETH BRIGHTENING PRODUCTS.

Request to…

Bleaching Clay Market Forecast & Research Report, 2026

Bleaching clay refers to a category of clay which has relatively high adsorption power for decolorizing and refining oils and fats. The primary source material for bleaching clay is montmorillonite which can also be referred as hydrated aluminum silicates, which imparts indispensable adsorption characteristics to bleaching clays. Since the early 19th century, natural bleaching clays have been used for the refining of edible oils and fats, however, the activation process…