Press release

Cyanoacrylate Adhesives Manufacturing Plant Project Report 2025: | Raw Material Requirements and Costs

Cyanoacrylate adhesives, commonly known as "super glue" or "instant adhesives," are fast-curing single-component adhesives that polymerize rapidly in the presence of weak bases such as water or hydroxide ions. These versatile adhesives bond quickly to a wide variety of substrates including plastics, metals, rubber, ceramics, and human tissue, making them essential in industries ranging from automotive and electronics to medical devices and consumer goods. Their exceptional bonding strength, ease of application, and rapid curing properties have established cyanoacrylates as indispensable adhesives in modern manufacturing and repair applications.Setting up a cyanoacrylate adhesives manufacturing plant requires specialized chemical processing equipment including synthesis reactors, distillation columns, stabilization systems, filling machines, packaging lines, and comprehensive quality control laboratories. Key considerations include location with proper ventilation systems, compliance with chemical safety standards, temperature-controlled storage facilities, and efficient distribution networks to maintain product stability and performance.

IMARC Group's report, titled "Cyanoacrylate Adhesives Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a cyanoacrylate adhesives manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/cyanoacrylate-adhesives-manufacturing-plant-project-report/requestsample

Cyanoacrylate Adhesives Industry Outlook 2025:

The cyanoacrylate adhesives industry outlook for 2025 shows robust growth driven by expanding applications in automotive lightweighting, electronics miniaturization, and medical device manufacturing. Rising demand for instant bonding solutions in assembly line operations and growing adoption in emerging markets are fueling market expansion.

Technological advancements in formulation chemistry are producing specialized grades with enhanced temperature resistance, flexibility, and cure speed control. The shift toward sustainable packaging and eco-friendly formulations is creating new market opportunities. Despite challenges such as raw material price volatility and competition from structural adhesives, the cyanoacrylate adhesives industry is expected to maintain strong momentum, supported by continuous innovation and diversifying application segments in 2025.

Key Insights for Cyanoacrylate Adhesives Manufacturing Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

• Stabilization Processes

Project Details, Requirements and Costs Involved

• Land, Location and Site Development

• Plant Layout and Safety Infrastructure

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis

Project Economics

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Request for Customized Report: https://www.imarcgroup.com/request?type=report&id=8852&flag=E

Key Cost Components of Setting Up a Cyanoacrylate Adhesives Manufacturing Plant

• Land & Specialized Infrastructure - Chemical processing facilities with proper ventilation, temperature control, and safety systems for handling reactive chemicals

• Raw Material Procurement - High-purity cyanoacetic acid, formaldehyde, stabilizers, thickeners, and specialized packaging materials with controlled storage conditions

• Machinery & Equipment - Synthesis reactors with precise temperature control, distillation systems, filtration units, filling machines, and automated packaging lines

• Labor & Technical Workforce - Chemical engineers, process operators, quality control technicians, and safety specialists trained in adhesive manufacturing

• Energy & Utilities -- Process heating and cooling systems, compressed air, inert gas supply, and emergency safety systems

• Quality Control & Testing - Analytical laboratories for viscosity testing, bond strength analysis, shelf life studies, and performance validation

• Packaging & Storage Systems - Moisture-proof containers, precision dispensing bottles, and climate-controlled storage facilities

• Safety & Environmental Compliance -- Ventilation systems, waste treatment facilities, fire suppression systems, and regulatory compliance monitoring

Economic Trends Influencing Cyanoacrylate Adhesives Manufacturing Plant Setup Costs 2025

• Growing Industrial Automation -- Increased demand for instant bonding solutions in automated assembly processes

• Electronics Sector Expansion -- Rising applications in smartphone, wearables, and IoT device manufacturing

• Medical Applications Growth -- Expanding use in medical device assembly and surgical applications

• Raw Material Price Fluctuations -- Volatility in petrochemical feedstock costs affecting production economics

• Sustainability Initiatives -- Investment in eco-friendly formulations and recyclable packaging solutions

• Emerging Market Penetration -- Growing demand in developing economies driving capacity expansion

Challenges and Considerations for Investors in Cyanoacrylate Adhesives Manufacturing Plant Projects

• Raw Material Volatility -- Price fluctuations in key chemical feedstocks affecting production costs

• Technical Expertise Requirements -- Need for specialized knowledge in adhesive chemistry and process control

• Quality Consistency Challenges -- Maintaining uniform product performance across different production batches

• Storage and Handling Complexity -- Managing product stability and preventing premature polymerization

• Regulatory Compliance -- Meeting chemical safety standards and environmental regulations across different markets

• Competition from Established Players -- Market dominated by large chemical companies with established distribution networks

• Application-Specific Formulations -- Need for customized products requiring R&D investment and technical support

Conclusion:

The cyanoacrylate adhesives industry in 2025 presents significant growth opportunities driven by expanding industrial applications and technological innovations. Establishing a cyanoacrylate adhesives manufacturing plant offers strong potential for investors with technical expertise and adequate capital resources, but requires careful attention to process control, quality assurance, and market positioning.

Success in this industry demands investment in advanced manufacturing technology, comprehensive quality control systems, and strong customer technical support capabilities. The growing demand across automotive, electronics, medical, and consumer sectors provides multiple market entry points for new manufacturers.

Investors who can develop specialized formulations, maintain consistent quality standards, and build effective distribution partnerships will be well-positioned to capitalize on the expanding cyanoacrylate adhesives market. The industry's continued evolution toward high-performance and environmentally sustainable solutions creates opportunities for innovative manufacturers to establish competitive advantages in this dynamic market segment.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cyanoacrylate Adhesives Manufacturing Plant Project Report 2025: | Raw Material Requirements and Costs here

News-ID: 4158227 • Views: …

More Releases from IMARC Group

Mexico Digital Fitness Coaching Market Size, Growth, Key Players, Opportunity an …

IMARC Group has recently released a new research study titled "Mexico Digital Fitness Coaching Market Size, Share, Trends and Forecast by Streaming, Session, Revenue Model, Device, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Digital Fitness Coaching Market Overview

The Mexico digital fitness coaching market size reached USD 181.82 Million in 2024. Looking…

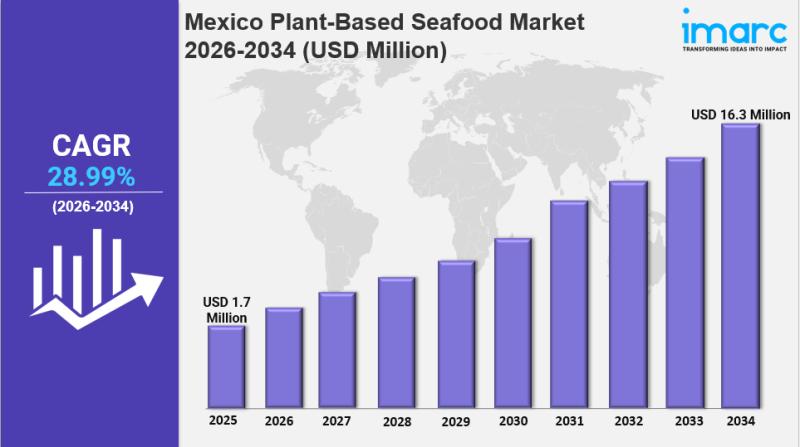

Mexico Plant-Based Seafood Market Size, Share, Latest Insights and Forecast To 2 …

IMARC Group has recently released a new research study titled "Mexico Plant-Based Seafood Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico plant-based seafood market size was valued at USD 1.7 Million in 2025 and is projected to reach USD…

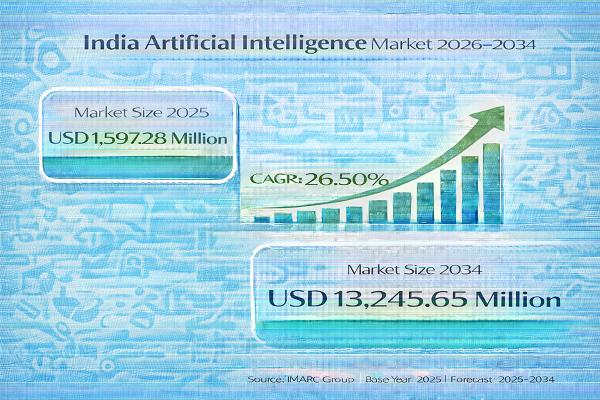

India Artificial Intelligence Market Projected to Reach 13,245.65 Million by 203 …

India Artificial Intelligence Market : Report Introduction

According to IMARC Group's report titled "India Artificial Intelligence Market Size, Share, Trends and Forecast by Type, Offering, Technology, System, End-Use Industry, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-artificial-intelligence-market/requestsample

India Artificial Intelligence Market Overview

The India artificial intelligence market size was valued at…

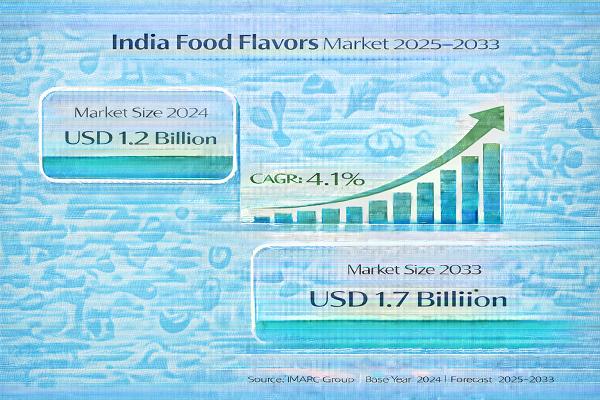

India Food Flavors Market Expected to Reach USD 1.7 Billion by 2033, Driven by 4 …

India Food Flavors Market Report Introduction

According to IMARC Group's report titled "India Food Flavors Market Size, Share, Trends and Forecast by Type, Form, End User, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Note : We are in the process of updating our reports to cover the 2026-2034 forecast period. For the most recent data, insights, and industry updates,…

More Releases for Cyanoacrylate

Cyanoacrylate Adhesives Market Revolutionizing Bonding Solutions Across Industri …

"Cyanoacrylate adhesives are revolutionizing bonding applications-discover their increasing use in automotive, electronics, and healthcare industries."

On March 5, 2025, Exactitude Consultancy., Ltd. Newly released a research report titled "Cyanoacrylate Adhesives Market". The cyanoacrylate adhesives market is growing due to their quick-drying and strong bonding properties, which make them essential in industries such as automotive, electronics, medical devices, and packaging. These adhesives are widely used for bonding a variety of materials, including…

Global Cyanoacrylate Polymers Market Research Report 2023-2029

Global Cyanoacrylate Polymers Market: Driven factors and Restrictions factors

The research report encompasses a comprehensive analysis of the factors that affect the growth of the market. It includes an evaluation of trends, restraints, and drivers that influence the market positively or negatively. The report also outlines the potential impact of different segments and applications on the market in the future. The information presented is based on historical milestones and current trends,…

Iron Supplement Market Product Type (2-Octyl Cyanoacrylate Adhesive, N-Butyl Cya …

Iron is one of the most important nutritional requirements of the human body as it plays an important role in managing many vital biological processes. Growing health concerns among consumers and widening applications of iron supplements are among the major growth drivers for iron supplements demand.

Download Sample PDF at https://www.theinsightpartners.com/sample/TIPRE00021200/?utm_source=OpenPR&utm_medium=10379

Key Players Analysis:

• Nature Made

• Nature's Bounty

• Solgar

• Rainbow Light

• NOW Foods

• Amway

• Garden of Life

• Spring Valley

• GNC

• Fergon

The report covers key developments in the Iron Supplement Market as…

Global Skin Adhesives Market By Type (2-Octyl Cyanoacrylate Adhesive, N-2-Butyl- …

The Global Skin Adhesives Market 2020 report implement in-depth research of the industry with a focus on the current market trends future prospects. The Global Skin Adhesives Market report aims to provide an overview of Skin Adhesives Market players with detailed market segmentation by product, application and geographical region. It also provides market share and size, revenue forecast, growth opportunity. The most recent trending report Worldwide Skin Adhesives Market Economy…

Cyanoacrylate Instant Adhesives Market Size by 2025

"Up Market Research, has recently developed a report on the ‘Cyanoacrylate Instant Adhesives market’ which presents substantial inputs about the market size, market share, regional trends, and profit projection of this business sphere. The report also enlightens users regarding the foremost challenges and existing growth tactics implemented by the leading organizations that constitute the dynamic competitive gamut of this industry.

The Global Cyanoacrylate Instant Adhesives market 2019 research provides a basic…

Epoxy-Cyanoacrylate Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Epoxy-Cyanoacrylate Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Epoxy-Cyanoacrylate players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Epoxy-Cyanoacrylate with respect to individual growth trends, future prospects,…