Press release

Metal Injection Molding Market to Reach US$ 8.6 Bn by 2032 with 10.5% CAGR Growth

➤ Overview of the MarketThe global metal injection molding (MIM) market is experiencing robust growth as industries demand cost-effective and precise solutions for manufacturing complex metal components. According to Persistence Market Research, the market is projected to expand from US$ 4.3 Bn in 2025 to US$ 8.6 Bn by 2032, reflecting a CAGR of 10.5%. MIM technology combines the versatility of plastic injection molding with the strength of powdered metallurgy, making it ideal for producing small, intricate, and high-performance metal parts at scale. Increasing adoption in industries such as automotive, aerospace, medical devices, and electronics has been pivotal in propelling market expansion.

Market growth is further driven by the rising demand for lightweight yet durable components, particularly in the automotive and aerospace industries where fuel efficiency and precision engineering are paramount. Among product categories, stainless steel-based MIM components dominate due to their excellent mechanical properties and corrosion resistance. Regionally, Asia Pacific leads the global market, supported by a well-established automotive and electronics manufacturing ecosystem, rising investment in advanced manufacturing technologies, and the presence of key MIM producers in China and Japan. The region's cost-effective manufacturing capabilities and strong export base make it the largest hub for MIM adoption.

🔗Dive deeper into the market data: https://www.persistencemarketresearch.com/market-research/metal-injection-molding-market.asp

➤ Key Market Insights

• MIM offers cost efficiency in producing complex-shaped metal parts compared to conventional machining methods.

• Stainless steel remains the dominant material due to its versatility across automotive, healthcare, and industrial applications.

• Asia Pacific accounts for the largest share, driven by high-volume manufacturing and favorable cost structures.

• Miniaturization trends in electronics and medical devices are fueling demand for precision MIM parts.

• Sustainability initiatives are pushing manufacturers to adopt energy-efficient MIM processes and recyclable raw materials.

➤ What are the main advantages of metal injection molding over traditional manufacturing methods?

Metal injection molding offers several advantages over conventional methods like machining or die casting. It enables the production of highly complex and miniaturized parts with tight tolerances at a lower cost when produced in high volumes. MIM also reduces material wastage since the powder-based process utilizes raw materials more efficiently. Additionally, it allows for the use of a wide range of metal powders, offering flexibility in applications across industries. The ability to mass-produce precision parts with excellent mechanical strength and surface finish makes MIM highly suitable for automotive, medical, and consumer electronics sectors.

➤ Market Dynamics

Drivers: The demand for lightweight, durable, and complex parts across automotive, aerospace, and healthcare sectors is the primary growth driver. Rising adoption of minimally invasive medical devices and the growing trend of miniaturization in electronics are also creating significant opportunities for MIM.

Market Restraining Factor: High initial costs associated with tooling and mold setup remain a barrier for smaller-scale manufacturers. Moreover, limitations in component size and density control compared to forging or casting may restrict adoption in certain applications.

Key Market Opportunity: Emerging economies with expanding automotive and healthcare industries present untapped opportunities for MIM. The integration of MIM with 3D printing and nanotechnology also opens pathways for innovation, particularly in high-performance industries.

➤ Market Segmentation

The MIM market is segmented by material and end-use industry. In terms of materials, stainless steel dominates due to its wide application base in automotive, aerospace, and consumer electronics, offering durability, corrosion resistance, and cost efficiency. Low alloy steel and soft magnetic materials also hold significant shares, particularly in the production of mechanical parts and electronic components. Titanium and other specialty alloys are increasingly being used in the medical sector for implants and surgical instruments, reflecting the material's biocompatibility and strength-to-weight ratio.

By end-use industry, the automotive sector leads the market, accounting for the highest demand for MIM components such as gears, turbochargers, and transmission parts. Medical and healthcare applications are gaining momentum due to the need for miniaturized and biocompatible components like dental brackets, surgical tools, and orthopedic implants. Electronics also represent a growing segment, driven by consumer demand for compact, lightweight, and durable devices. Aerospace and defense industries are further adopting MIM for precision parts that require both strength and weight reduction, enhancing overall performance.

➤ Regional Insights

The Asia Pacific region dominates the MIM market, with China, Japan, and South Korea serving as major hubs for automotive and electronics production. Lower manufacturing costs and access to skilled labor have made the region a leader in MIM adoption. North America follows, supported by strong demand from aerospace, medical devices, and defense industries. Europe remains a key market, with Germany and France leading due to advanced automotive and engineering industries. Meanwhile, Latin America and the Middle East & Africa are emerging regions, showing gradual adoption of MIM technologies as industrialization expands.

🔗Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): https://www.persistencemarketresearch.com/samples/35091

➤ Competitive Landscape

The metal injection molding market is moderately consolidated, with companies focusing on research, product innovation, and global expansion strategies.

➤ Company Insights

✦ Indo-MIM

✦ ARC Group Worldwide

✦ OptiMIM

✦ CMG Technologies

✦ Parmaco Metal Injection Molding AG

✦ Hoganas AB

✦ Advanced Materials Technologies Pte Ltd

✦ Sintex A/S

✦ Form Technologies (Dynacast International Inc.)

✦ Smith Metal Products

➤ Key Industry Developments

Recent industry developments reflect increasing investment in advanced materials and global expansion strategies. Indo-MIM announced the establishment of new production facilities in North America to meet growing demand for precision parts in medical and aerospace applications. Meanwhile, ARC Group Worldwide has expanded its R&D capabilities to explore high-performance alloys for defense and industrial applications.

Additionally, collaborations between MIM companies and automotive OEMs are becoming common to co-develop components that improve fuel efficiency and reduce weight. Several manufacturers are also integrating additive manufacturing technologies with MIM to enhance design flexibility and reduce production times, especially for prototypes and low-volume orders.

➤ Innovation and Future Trends

The future of the MIM market lies in combining advanced materials with digital technologies. Innovations such as the use of titanium alloys for lightweight medical and aerospace applications, and magnetic alloys for electronics, are expected to shape the next phase of market growth. Integration of nanotechnology in powder metallurgy is anticipated to improve material properties, offering better strength, corrosion resistance, and wear performance.

Sustainability is another emerging trend, with manufacturers adopting energy-efficient sintering processes and recyclable feedstocks. Moreover, the hybridization of MIM with 3D printing technologies is paving the way for rapid prototyping and customized manufacturing. As industries push for precision, durability, and efficiency, MIM is expected to evolve into a cornerstone technology for advanced manufacturing in the coming decade.

➤Explore the Latest Trending Research Reports:

• Lead Acid Battery Market - https://www.persistencemarketresearch.com/market-research/lead-acid-battery-market.asp

• Produced Water Treatment Systems Market - https://www.persistencemarketresearch.com/market-research/produced-water-treatment-systems-market.asp

• Us Combined Heat And Power Systems Market - https://www.persistencemarketresearch.com/market-research/us-combined-heat-and-Power-systems-market.asp

➤Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

➤About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding Market to Reach US$ 8.6 Bn by 2032 with 10.5% CAGR Growth here

News-ID: 4157952 • Views: …

More Releases from Persistence Market Research

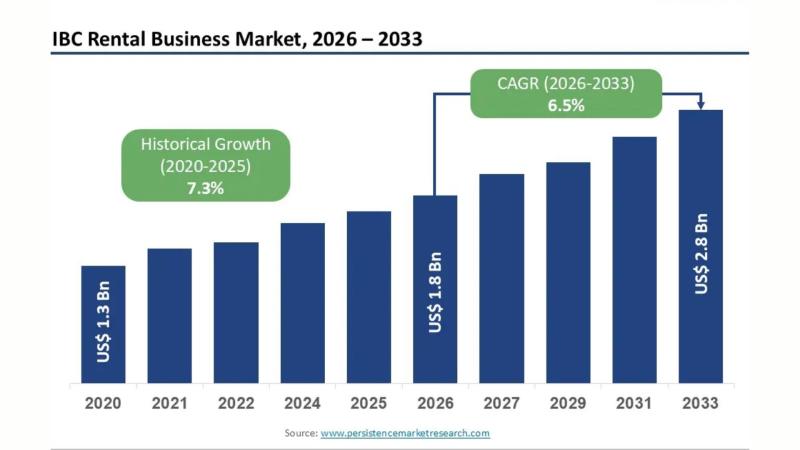

IBC Rental Business Market Projected to Grow to US$2.8 Bn by 2033 Driven by Cost …

Introduction: Rising Demand for Flexible Bulk Packaging Solutions

The global industrial packaging landscape is undergoing a significant shift as companies seek cost-effective, reusable, and sustainable solutions for bulk liquid and material transportation. Intermediate Bulk Containers (IBCs) have emerged as an indispensable packaging format across industries such as chemicals, pharmaceuticals, food & beverages, and agriculture. However, instead of purchasing IBCs outright, many businesses are now opting for rental services to reduce capital…

Shipping Supply Market Expected to Touch US$99.6 Bn by 2033 Driven by E-Commerce …

Introduction: The Backbone of Global Trade and Commerce

The shipping supply market plays a vital role in enabling global trade, industrial operations, and modern retail distribution. From corrugated boxes and pallets to protective packaging and labeling materials, shipping supplies ensure safe transportation of goods across domestic and international supply chains. As globalization intensifies and consumer expectations for fast, damage-free delivery grow, demand for efficient, durable, and sustainable shipping materials has accelerated…

Barrier Coatings for Packaging Market to Hit US$20.6 Bn by 2033 Driven by Rising …

Introduction: The Growing Need for Advanced Packaging Protection

Barrier coatings for packaging have become an essential component in modern packaging solutions, offering protection against moisture, oxygen, light, grease, and contaminants. As global supply chains expand and consumer expectations for longer shelf life increase, manufacturers are turning toward high-performance barrier coatings to preserve product integrity. These coatings enhance the functional performance of packaging materials while supporting lightweight and flexible packaging formats. Their…

Bean Bag Chairs Industry Shows Consistent Expansion Amid Furniture Innovation - …

Introduction

The global Bean Bag Chairs Market has experienced consistent growth over the past decade, driven by changing consumer lifestyles, increasing preference for flexible and informal seating, and the rising popularity of contemporary interior décor. Bean bag chairs are widely used across residential, commercial, and hospitality spaces due to their comfort, portability, lightweight design, and aesthetic appeal. Made using durable fabrics and filled with materials such as expanded polystyrene beads, these…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…