Press release

Global Dry Electrode Technology Market 2025 Tesla and LG Lead Growth Toward USD 575 Million by 2031 at 46.5% CAGR

According to the recent report from QYResearch, dry electrode technology is entering a decisive stage of industrial validation. After years of laboratory and pilot-scale development, the past two years have brought concrete progress in pilot lines, customer shipments, and OEM acceptance testing. With a projected market growth from US$41 million in 2024 to US$575 million by 2031 at a CAGR of 46.5% (2025-2031), the industry is now positioned to make solvent-free manufacturing a mainstream solution in batteries and capacitors.Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) https://www.qyresearch.com/sample/4859351

Leading Companies

Tesla

LiCAP Technologies

GMCC Electronic Technology

Plannano Technology

Sakuu

LG

AM Batteries

Tsingyan Electronic

Panasonic

PowerCo

Applications

Capacitors

Lithium Batteries

Other

Classification

Adhesive Fibrillation Method

Spraying Method

Latest Data

• Market Title: Global Dry Electrode Technology Market Outlook, In-Depth Analysis & Forecast to 2031

• Forecasted Market Size 2031: US$575 million

• CAGR (2025-2031): 46.5%

• Years Covered: 2025-2031

• Regions Covered: North America, Europe, Asia Pacific, South America, Middle East & Africa

• Segmentation by Type: Adhesive Fibrillation Method; Spraying Method

• Segmentation by Application: Capacitors; Lithium Batteries; Other

• Coverage: Revenue and volume forecast, company share, competitive landscape, growth factors and trends, value chain overview, strategic recommendations

2025 Company Achievements

AM Batteries - In late 2024, the company shipped its first rolls of dry-coated electrodes from an engineering pilot line and opened a Customer Success Center in Massachusetts. Recognized for energy and CO2 reductions of up to 40 percent, AM Batteries has positioned its Powder-to-ElectrodeTM technology as a direct path for gigafactories.

LG Energy Solution - Established a pilot dry-electrode line at its Ochang facility by the end of 2024, targeting stepwise commercialization in 2028. This program marks one of the most structured industrial roadmaps for solvent-free electrode production.

Tesla - Tested 4680 cells with dry-coated cathodes for use in Cybertruck battery packs during 2024. Although challenges remain in throughput and scr-ap rates, Tesla is committed to scaling dry-coating processes across its in-house production.

PowerCo (Volkswagen Group) - In 2025, PowerCo completed factory acceptance testing of a dry-coating system developed with Koenig & Bauer. Early trials demonstrated up to 30 percent energy savings and 15 percent floor-space reduction compared to conventional lines.

LiCAP Technologies - In 2025, LiCAP produced more than 500 meters of dry-coated cathode film using its Activated Dry Electrode® process. The company also entered a strategic partnership with Dürr and Cellforce to establish a pilot plant in Germany, planned for operation in 2026.

Panasonic Energy - Opened a new facility in Osaka in 2024 to validate dry-coating technologies at production scale. The site is focused on shortening the development-to-industrialization cycle for next-generation batteries.

Equipment Providers - China's LEAD announced a high-speed dry-coating process capable of reducing energy consumption by more than 35 percent and costs by more than 20 percent. Fraunhofer IWS continued advancing its DRYtraec approach, emphasizing solvent-free manufacturing as an upcoming industry standard.

Product Snapshots

Tesla - 4680 Cell with Dry-Coated Cathode

• Pre-industrial variant of Tesla's cylindrical 4680 cell.

• Uses dry coating on the cathode in addition to earlier dry anode work.

• Vehicle-level testing carried out in 2024 for Cybertruck packs.

• Potential to reduce cost and CO2 footprint by eliminating solvents and drying ovens.

LG Energy Solution - Ochang Pilot Line

• Pilot dry-electrode process for both anode and cathode materials.

• Transition from lab to pilot completed in late 2024.

• Mass-production readiness targeted for 2028.

• Designed for rollout across multiple global production sites.

AM Batteries - Powder-to-ElectrodeTM Dry Deposition

• Solvent-free spray deposition of powders directly onto current collectors.

• Eliminates long drying ovens and solvent recovery steps.

• First customer rolls delivered in 2024 from a pilot line.

• Demonstrated potential energy and CO2 savings up to 40 percent.

LiCAP Technologies - Activated Dry Electrode® (ADE)

• Solvent-free pressing method to create dense, conductive films.

• In 2025, produced over 500 meters of continuous cathode film.

• Collaborative pilot plant with Dürr and Cellforce to begin operation in 2026.

• Targets lower costs and environmental impact compared to slurry methods.

PowerCo (Volkswagen Group) - Dry Coating System

• Roller-based dry coating co-developed with Koenig & Bauer.

• Factory acceptance test completed in 2025.

• Demonstrated around 30 percent energy savings and 15 percent footprint reduction.

• Planned integration into gigafactories in Europe and North America.

Downstream Customers

Volkswagen Group

Porsche AG

Tesla, Inc.

Cellforce Group GmbH

Siemens AG

ABB Ltd.

Škoda Transportation a.s.

Medcom Sp. z o.o.

Koenig & Bauer AG

Hitachi Energy Ltd.

CAF S.A.

Alstom SA

General Motors Co.

BMW Group

Hyundai Motor Company

Market Trends

Lab-to-Pilot Transition

2024 and 2025 marked the transition from laboratory-scale demonstrations to tangible pilot operations. AM Batteries began shipping customer-ready electrode rolls, while LiCAP produced long continuous cathode films. LG Energy Solution established its first pilot line, underscoring that the industry is entering a validation phase with direct customer engagement.

Equipment Industrialization

Equipment development is advancing rapidly. PowerCo's acceptance testing of its dry-coating system demonstrates readiness for factory deployment. LEAD's high-speed lines highlight that solvent-free coating can meet industrial throughput standards while reducing energy costs.

Energy, Footprint, and Compliance Gains

One of the strongest drivers is the reduction of manufacturing energy and space requirements. Reported savings range from 30 to 40 percent in energy and up to 15 percent in factory footprint. Eliminating solvents like NMP also reduces compliance costs and accelerates permitting for new facilities.

Enabling High-Loading Electrodes

Dry electrode methods are enabling thicker, high-loading electrodes, improving energy density per cell. By removing long drying steps, manufacturers can shorten cycle times while producing higher-performance electrodes. This supports roadmaps for fast charging and higher-capacity packs.

OEM Engagement and Partnerships

Automakers and battery cell developers are increasingly involved. Tesla is testing dry-coated cathodes in vehicles, PowerCo validated its first systems, and Porsche's Cellforce is co-building a pilot facility with LiCAP and Dürr. These moves show OEMs no longer view dry coating as distant research but as an industrial option.

Capacitors Lead in Deployed Systems

While lithium-ion batteries dominate headlines, dry-electrode supercapacitors are already deployed at scale. Siemens, Medcom, and Škoda use solvent-free electrodes in rail and industrial braking energy recovery systems. These applications provide proof of durability and cycle life, strengthening the case for lithium-ion adoption.

Request for Pre-Order Enquiry On This Report https://www.qyresearch.com/customize/4859351

Geographic Distribution

Germany is central, with PowerCo, Cellforce, and Siemens active in dry electrode development. The United States hosts AM Batteries' pilot and customer center. Japan's Panasonic advances process validation, while Korea's LGES has set a timeline to mass production. China's LEAD pushes ahead in equipment, creating a globally diversified landscape.

Risks and Challenges

Scaling to industrial production is not without issues. Tesla's efforts show the challenge of balancing throughput and yield with dry cathodes. Binder fibrillation, powder flow, and calendaring uniformity remain critical. Manufacturers are therefore expanding cautiously through pilot lines before committing to full gigafactory adoption.

Chapter Outline:

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Details

Tel: +1 626 2952 442 ; +41 765899438(Tel & Whatsapp); +86-1082945717

Email: john@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About us:

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Dry Electrode Technology Market 2025 Tesla and LG Lead Growth Toward USD 575 Million by 2031 at 46.5% CAGR here

News-ID: 4152675 • Views: …

More Releases from QYResearch Europe

Global Aerospace Grade Smart Assembly Lines Market 2024 USD 4251 Million to 2031 …

According to recent report from QYResearch, the global market for aerospace-grade smart assembly lines stood at US$4,251 million in 2024 and is projected to reach US$8,712 million by 2031 at a 10.2% CAGR (2025-2031). In 2024, approximately 670 lines were produced globally at an average selling price (ASP) of about US$6.343 million per line. These highly automated systems integrate AI, industrial robotics, advanced sensing, and digital control to deliver repeatable,…

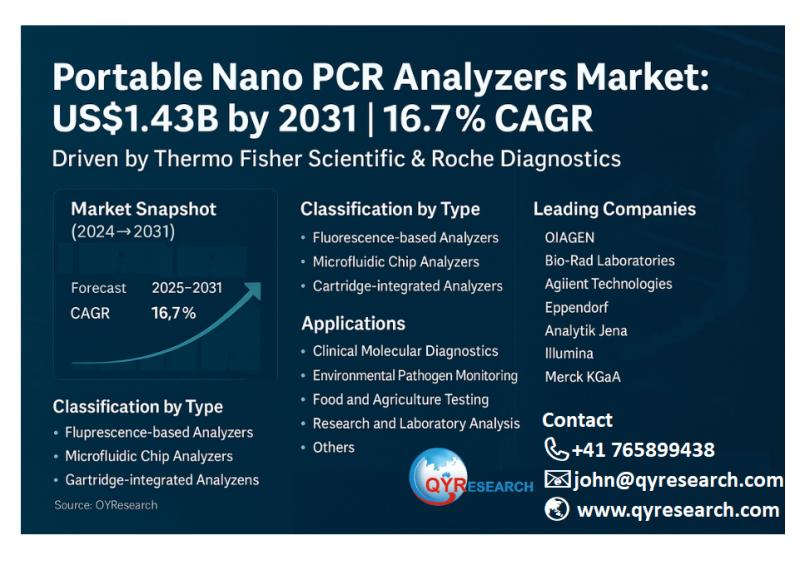

Portable Nano PCR Analyzers Market Growth to US$1.43 Billion by 2031 with 16.7% …

According to the latest QYResearch Report, the global market for Portable Nano PCR Analyzers was valued at US$484 million in 2024 and is expected to reach US$1,427 million by 2031, growing at a CAGR of 16.7% during the forecast period of 2025-2031. Global production in 2024 reached around 96,800 units, with an average price of about US$5,000 per unit. These portable devices utilize nanotechnology-enhanced PCR processes for rapid on-site genetic…

Global Multiphase Flow Conveying Equipment Market to Reach USD 10.88 Billion by …

The global market for Multiphase Flow Conveying Equipment is transitioning from a specialized engineering niche to a core enabler of industrial efficiency across upstream energy, chemicals, mining, and wastewater sectors. According to QYResearch 2025 edition of Multiphase Flow Conveying Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031, the market was valued at US$7,380 million in 2024 and is projected to reach US$10,879 million by 2031,…

Global Smart Eye-Tracking Medical Devices Market Size Reaches US$3.0 Billion by …

The global Smart Eye-Tracking Medical Devices market has entered a stage of accelerated clinical adoption and product diversification. According to QYResearch 2025 Global Smart Eye-Tracking Medical Devices Market Research Report, the market was valued at US$973 million in 2024 and is projected to reach US$3,009 million by 2031, growing at a CAGR of 17.5% from 2025 to 2031. Global output in 2024 reached approximately 64,900 units, with an average price…

More Releases for Tesla

What Is The Voltage Of a Tesla Charger? Can One Use Any Charger With a Tesla?

What is the voltage of a Tesla charger [https://www.midaevse.com/nacs-350a-max-tesla-plug-tesla-connector-with-tesla-cable-product/]?

The voltage of a Tesla charger can vary depending on the specific model and type of charger. However, most Tesla chargers operate at a voltage of 240 volts for home charging, and up to 480 volts for superchargers at Tesla's charging stations. It's important to note that the voltage and charging capabilities can differ based on the region and the specific…

CCC Solar Now Tesla Certified to Install Tesla Charging Stations and Solar Roofs …

CCC Solar, a premier solar company in Northern Illinois, is proud to announce its new Tesla certification, enabling CCC Solar to install Tesla charging stations and Tesla solar roofs for residential and commercial properties. This certification expands CCC Solar's commitment to sustainable energy, allowing them to bring state-of-the-art Tesla products to customers across Rockford, Roscoe, Loves Park, Machesney Park, and surrounding areas.

As a Tesla-certified installer, CCC Solar now provides local…

Tesla Accessories Shop Launches Innovative Hubcaps and Wheel Covers for Tesla Ow …

Fort Collins,Colorado - September 30, 2024 - Tesla Accessories Shop is excited to announce the launch of its new line of hubcaps and wheel covers specifically designed for Tesla vehicles. As electric vehicle ownership continues to rise, our latest offerings provide Tesla owners with stylish, durable, and eco-friendly options to enhance their vehicle's aesthetic and performance.

The new collection features a range of designs that not only elevate the look of…

Protect Tesla with Premium Sunshades and Mudguards: The Essential Accessories fo …

In today's fast-paced automotive industry, Tesla owners are constantly seeking ways to protect and enhance the longevity of their vehicles. For Tesla Model S owners, two accessories have proven indispensable in maintaining both comfort and vehicle condition: sunshades and mudguards. As the demand for Tesla parts continues to grow, companies like Thetapai (https://Thetapai.com/ [https://thetapai.com/]) are at the forefront of offering high-quality aftermarket solutions to meet these needs.

One of the primary…

Charging Gun Coolant Market Trends, Geographical Outlook, Business Opportunities …

LOS ANGELES, United States: The global Charging Gun Coolant market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Charging Gun Coolant market. For instance, the market dynamics section digs deep into the drivers, restraints,…

Nanocoating Market Booming Worldwide | Buhler AG,Tesla NanoCoatings, Inc, PPG In …

For a powerful business growth, companies must take up Nanocoating Market

research report service which has become quite vital in this rapidly altering marketplace. This Nanocoating Market research report is formed with a nice combination of industry insight, smart solutions, practical solutions and newest technology to give better user experience. The Nanocoating Market report focuses on many aspects related to industry and market. To name a few…