Press release

Propane Production Cost Report 2025: Plant Setup Economics and Financial Outlook

Propane is a three-carbon alkane hydrocarbon (C3H8) that exists as a colourless, odorless gas under normal conditions but is easily liquefied under moderate pressure for storage and transport. It is a major component of liquefied petroleum gas (LPG) and is obtained primarily as a by-product of natural gas processing and crude oil refining. Propane is widely used as a clean-burning fuel for heating, cooking, and vehicles, as well as in industrial applications such as metal cutting, petrochemical feedstock, and refrigeration. Its portability and efficiency make it a key energy source worldwide.Setting up a propane production plant involves securing access to natural gas or crude oil refineries, installing gas separation and purification units, and integrating liquefaction and storage facilities. The plant must include safety systems, pressurized tanks, and distribution infrastructure while adhering to environmental and safety regulations. Energy efficiency and scalability are critical for economic feasibility.

IMARC Group's report, titled "Propane Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a propane production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/propane-manufacturing-plant-project-report/requestsample

Propane Industry Outlook 2025

The Propane industry outlook for 2025 appears promising, driven by rising demand across residential, commercial, industrial, and transportation sectors. As a clean-burning and efficient fuel, propane is increasingly being adopted for heating, cooking, and power generation, particularly in regions lacking natural gas pipelines. Industrial usage in metal processing, petrochemical feedstock, and refrigeration is also supporting steady growth. Additionally, the global shift toward cleaner fuels is boosting propane's role as an alternative to coal and heavy oil, aligning with sustainability goals. Growth in the automotive sector, with propane-powered vehicles and forklifts, adds further momentum. Expanding applications in agriculture, such as crop drying and greenhouse heating, also contribute to market demand. However, price fluctuations tied to crude oil and natural gas markets, along with regulatory considerations for carbon emissions, remain key challenges. Technological advancements in storage, distribution, and energy efficiency are expected to enhance propane's competitiveness, positioning the industry for sustained growth through 2025.

Buy now: https://www.imarcgroup.com/checkout?id=7658&method=1911

Key Insights for setting up a Propane Production Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components

• Raw Material Costs

• Natural Gas or Crude Oil Feedstock: Propane is primarily obtained during natural gas processing and crude oil refining. Feedstock cost is a major expense, often influenced by global oil and gas prices.

• Separation and Extraction

• Cryogenic Distillation or Absorption Units: Capital and operational costs for facilities that separate propane from other hydrocarbons like methane and butane.

• Energy consumption in separation is also a significant operational cost.

• Compression and Storage

• Costs for compressors, pressurized storage tanks, and liquefaction processes needed to store propane safely as a liquid under pressure.

• Utilities and Energy

• Electricity, steam, and cooling water for processing operations.

• Energy costs are high, especially during the compression and distillation stages.

• Labor and Maintenance

• Skilled labor costs for plant operation, maintenance, and safety.

• Routine and preventive maintenance expenses for equipment and instrumentation.

• Environmental and Safety Compliance

• Costs related to emission controls, flare systems, leak detection, and compliance with regulations (e.g., OSHA, EPA, local fire codes).

• Packaging and Transportation

• Storage cylinders, tanker trucks, and bottling units.

• Logistics for delivering propane to industrial, residential, or commercial users.

• Capital Investment and Depreciation

• Initial plant setup costs including land, infrastructure, and machinery.

• Depreciation of fixed assets over the project lifecycle.

Economic Trends Influencing Propane Plant Setup Costs 2025

• Volatility in Crude Oil and Natural Gas Prices

• Propane is a byproduct of crude oil refining and natural gas processing. Fluctuating global oil and gas prices directly affect raw material costs and feedstock supply security.

• Rising Capital Expenditure (CapEx)

• Inflation in construction materials (steel, cement), equipment, and engineering services is increasing the upfront investment required for setting up new propane plants.

• Energy Cost Inflation

• Higher electricity and fuel costs, driven by global energy market instability, are pushing up operating expenses, particularly in energy-intensive separation and compression stages.

• Stricter Environmental Regulations

• Growing regulatory pressure for low-emission processes and safer handling of flammable gases is increasing compliance costs, including investments in advanced emission controls and safety systems.

• Supply Chain Disruptions

• Global supply chain challenges, including delays in machinery imports and spare parts, are impacting timelines and increasing logistics and procurement costs.

• Technological Advancements

• Newer, more energy-efficient technologies may offer long-term savings but require higher initial investment, shifting the cost-benefit dynamics for plant developers.

• Government Incentives and Policies

• In some regions, subsidies for cleaner fuels or LPG usage (which includes propane) can reduce effective costs, while taxes or carbon pricing can increase them in others.

• Labor Market Conditions

• Skilled labor shortages and rising wages, especially in oil and gas engineering sectors, are increasing construction and operational staffing costs.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=7658&flag=C

Challenges and Considerations for Investors

• Feedstock Availability and Price Volatility

• Propane supply is tied to natural gas processing and crude oil refining. Any disruption in upstream availability or global price volatility can impact margins and supply stability.

• High Capital and Infrastructure Requirements

• Setting up a propane production plant involves significant investment in cryogenic distillation units, pressurized storage, and safety systems. Long payback periods may deter short-term investors.

• Regulatory and Environmental Compliance

• Increasing pressure from environmental regulations on emissions, flaring, and storage safety adds to operational complexity and costs. Non-compliance can result in heavy penalties or shutdowns.

• Market Demand Fluctuations

• Demand is influenced by seasonal heating needs, petrochemical sector activity, and LPG competition. Overcapacity or sudden demand drops can lower profitability.

• Transportation and Distribution Bottlenecks

• Propane requires specialized logistics infrastructure like pressurized tanks and pipelines. Inadequate distribution networks can limit market access, especially in developing regions.

• Technological Barriers

• Older technologies may be less efficient or environmentally compliant. Investing in modern systems adds to capital costs but is necessary for long-term viability.

• Safety and Risk Management

• Propane is highly flammable, requiring stringent safety protocols, risk mitigation strategies, and insurance - all of which impact operating expenses.

• Policy and Taxation Uncertainty

• Shifting government policies regarding fossil fuels, subsidies, or carbon taxes can affect profitability projections and investor confidence.

Conclusion

The propane industry in 2025 presents strong growth potential, fuelled by global energy demands, increased adoption in residential and industrial sectors, and advances in cleaner fuel technologies. However, setting up a propane production plant involves substantial capital investment, regulatory compliance, and logistical planning. Investors must navigate challenges such as feedstock volatility, infrastructure costs, and evolving environmental standards. A well-informed, strategic approach backed by detailed feasibility and cost analysis-such as provided in IMARC's comprehensive report-can help stakeholders mitigate risks and capitalize on emerging opportunities in this dynamic market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Propane Production Cost Report 2025: Plant Setup Economics and Financial Outlook here

News-ID: 4151767 • Views: …

More Releases from IMARC Group

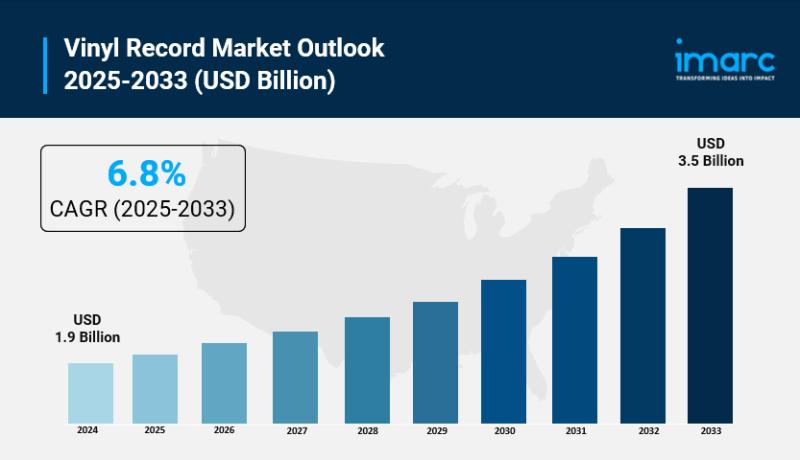

Vinyl Record Market Size to Reach USD 3.5 Billion by 2033 | With a 6.8% CAGR

Market Overview:

According to IMARC Group's latest research publication, "Vinyl Record Market Report by Product (LP/EP Vinyl Records, Single Vinyl Records), Feature (Colored, Gatefold, Picture), Gender (Men, Women), Age Group (13-17, 18-25, 26-35, 36-50, Above 50), Application (Private, Commercial), Distribution Channel (Supermarkets and Hypermarkets, Independent Retailers, Online Stores, and Others), and Region 2025-2033", The global vinyl record market size reached USD 1.9 Billion in 2024. Looking forward, IMARC Group expects the…

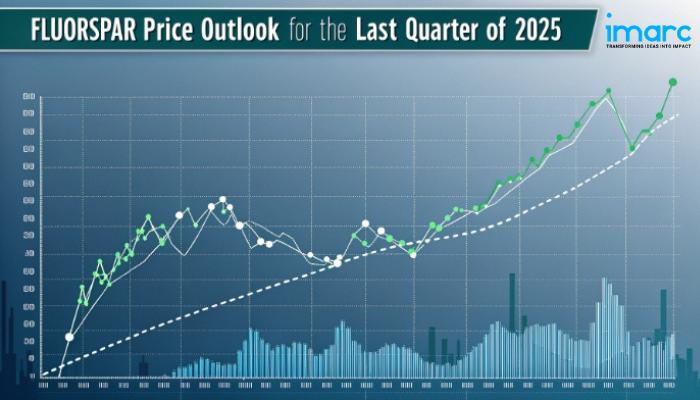

North America Fluorspar Prices Rise in Q4 2025: USA at USD 484/MT, Canada Peaks …

North America Fluorspar Prices Movement Q4 2025:

Fluorspar Prices in USA:

In Q4 2025, fluorspar prices in the USA averaged USD 484 per metric ton. Stable demand from aluminum production and chemical manufacturing supported price levels. Domestic mining operations maintained consistent output, while transportation and energy costs influenced overall supply. Moderate industrial activity and inventory management helped prevent significant price fluctuations across the regional market.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/fluorspar-pricing-report/requestsample

Note: The analysis…

Brazil Hybrid Electric Vehicle Market: Growth Dynamics, Consumer Shifts, and Com …

The Brazil hybrid electric vehicle market size was 348.75 Thousand Units in 2025 and is forecasted to reach 2,551.74 Thousand Units by 2034, reflecting a CAGR of 24.75% during 2026-2034. This robust expansion is fueled by increasing environmental awareness, rising fuel costs, and government policies aimed at emission reduction. Advances in battery technology and flex-fuel hybrid variants leveraging Brazil's ethanol resources also contribute to market growth.

Sample Request Link: https://www.imarcgroup.com/brazil-hybrid-electric-vehicle-market/requestsample

Study Assumption…

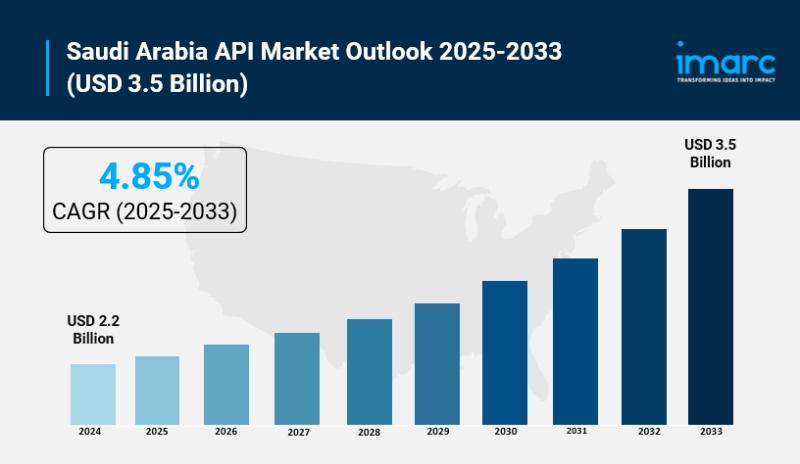

Saudi Arabia API Market Size to Expand USD 3.5 Billion by 2033 at a CAGR of 4.85 …

Saudi Arabia API Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.5 Billion

Market Growth Rate 2025-2033: 4.85%

According to IMARC Group's latest research publication, "Saudi Arabia API Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Saudi Arabia API market size reached USD 2.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.5 Billion by 2033, exhibiting a growth rate…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…