Press release

Egg Powder Manufacturing Plant Setup 2025: Detailed Machinery Cost and Business Plan

IntroductionEgg powder is a dehydrated form of fresh eggs made by spray-drying whole eggs, egg yolks, or egg whites. It retains the nutritional value, flavor, and functional properties of fresh eggs while offering longer shelf life, easy storage, and convenient transportation. Widely used in bakeries, confectioneries, instant food mixes, and the hospitality sector, egg powder serves as a versatile ingredient without the need for refrigeration.

Setting up an egg powder manufacturing plant requires investment in advanced spray-drying equipment, pasteurization units, and hygienic processing facilities. Key steps include sourcing quality eggs, ensuring proper cleaning and breaking systems, pasteurization, drying, packaging, and storage. Compliance with food safety regulations, efficient supply chain management, and strong distribution networks are essential. With rising demand in the food industry, egg powder manufacturing presents significant growth opportunities.

IMARC Group's report, titled "Egg Powder Manufacturing Setup Cost 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a egg powder manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Egg Powder Industry Outlook 2025

The outlook for the egg powder industry in 2025 is one of steady expansion and growing relevance across diverse food sectors. Driven by the demand for convenient, shelf-stable ingredients, egg powder remains a preferred choice for bakeries, food processors, and institutional kitchens. Sustainability and supply security are increasingly important, enhancing its appeal amidst shifting consumer expectations. Technological improvements in processing and packaging continue to boost product quality and cost efficiency. As global markets seek reliable, versatile, and long-lasting egg alternatives, the egg powder industry is poised to maintain its strategic importance in the evolving food supply landscape.

Request for a Sample Report: https://www.imarcgroup.com/egg-powder-manufacturing-plant-project-report/requestsample

Key Insights for setting up an Egg Powder Manufacturing Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=8560&method=1911

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components

• Land and Infrastructure: Cost of acquiring or leasing land and constructing buildings for processing, drying, packaging, and storage.

• Machinery and Equipment: Egg breakers, pasteurizers, spray dryers, sieving machines, packaging units, and refrigeration systems.

• Raw Materials: Procurement of fresh eggs, water, and packaging materials (e.g., food-grade containers, pouches, cartons).

• Labor and Skilled Workforce: Wages for technicians, operators, quality control staff, and administrative personnel.

• Utilities and Energy: Electricity, water supply, steam generation, and backup systems for consistent operation.

• Licensing and Regulatory Compliance: Costs for food safety certifications (e.g., FSSAI, ISO), pollution control, and factory licenses.

• Quality Control and R&D: Investment in lab testing equipment, microbial analysis, and product development for export standards.

Economic Trends Influencing Egg Powder Plant Setup Costs 2025

• Surging egg prices due to avian flu: The USDA forecasts egg prices may spike by ~40% in 2025 because of ongoing bird flu outbreaks that have reduced laying flocks, directly increasing raw material costs for egg powder producers.

• Import/export price volatility: While global export prices of whole egg powder in 2024 eased (in the range of $6.50-12.69 per kg), localized procurement costs remain unstable, especially in regions hit by disease-related shortages.

• Rising feed costs for poultry operations: As tensions in grain markets and weather fluctuations push maize and barley costs higher, producers face greater volatility in egg supply pricing, affecting upstream costing for powder plants.

• Energy-intensive drying processes: Spray dryers and pasteurization systems consume significant power, making energy prices a major operational cost component. Future plants often factor in renewable or efficiency investments to manage load.

• Shift to automation and smart production: Automated processing lines-equipped with sensors and digital monitoring-promise better yield and quality but require higher upfront capital, impacting initial capex.

Ask Analyst for Customization:

https://www.imarcgroup.com/request?type=report&id=8560&flag=C

Challenges and Considerations for Investors

• High Initial Capital Investment: Setting up a modern egg powder plant requires substantial funds for machinery like spray dryers, breakers, pasteurizers, and drying systems.

• Raw Material Supply Dependence: Continuous, hygienic, and cost-effective sourcing of eggs is critical; fluctuations in egg prices or supply can affect operations.

• Stringent Hygiene and Regulatory Standards: Egg products are highly sensitive to contamination, requiring strict compliance with food safety laws (FSSAI, HACCP, ISO).

• Cold Chain and Storage: While egg powder has a longer shelf life than liquid eggs, climate-controlled storage is still essential to maintain quality.

• Export-Oriented Market Volatility: A significant share of egg powder demand comes from exports, making the business vulnerable to international trade regulations and currency fluctuations.

• Technology and Skilled Labor Needs: Advanced processing requires trained staff and consistent quality control to maintain efficiency and product standardization.

Conclusion:

Setting up an egg powder manufacturing plant presents a valuable opportunity in the growing processed food industry. With increasing demand for shelf-stable, protein-rich ingredients across food service, bakery, and export markets, egg powder offers both versatility and profitability. Though the plant setup requires investment in drying equipment, hygiene standards, and regulatory compliance, the long shelf life and transport ease of the product make it commercially viable. By ensuring consistent quality, sourcing fresh raw materials, and exploring diverse market channels, investors can establish a sustainable and scalable operation in this promising segment.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Egg Powder Manufacturing Plant Setup 2025: Detailed Machinery Cost and Business Plan here

News-ID: 4149703 • Views: …

More Releases from IMARC Group

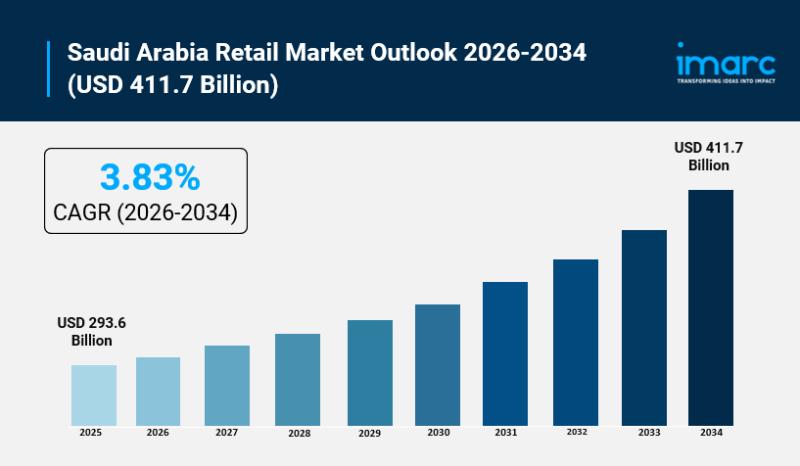

Saudi Arabia Retail Market Size to Surge to USD 411.7 Billion by 2034 | CAGR of …

Saudi Arabia Retail Market Overview

Market Size in 2025: USD 293.6 Billion

Market Size in 2034: USD 411.7 Billion

Market Growth Rate 2026-2034: 3.83%

According to IMARC Group's latest research publication, "Saudi Arabia Retail Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia retail market size was valued at USD 293.6 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 411.7 Billion by 2034, exhibiting a…

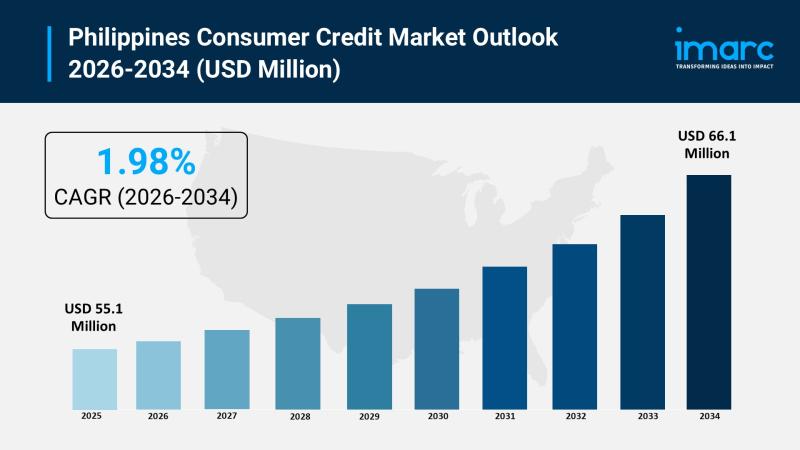

Philippines Consumer Credit Market 2026 | Worth USD 66.1 Million by 2034

Philippines Consumer Credit Market Overview:

The Philippines consumer credit market size reached USD 55.1 Million in 2025. The market is projected to reach USD 66.1 Million by 2034, exhibiting a growth rate (CAGR) of 1.98% during 2026-2034. The market is expanding steadily as rising financial inclusion, mobile-first lending platforms, and Buy Now Pay Later adoption bring formal credit to previously underserved Filipinos. Fintech innovation, neobank growth, and supportive BSP regulatory frameworks…

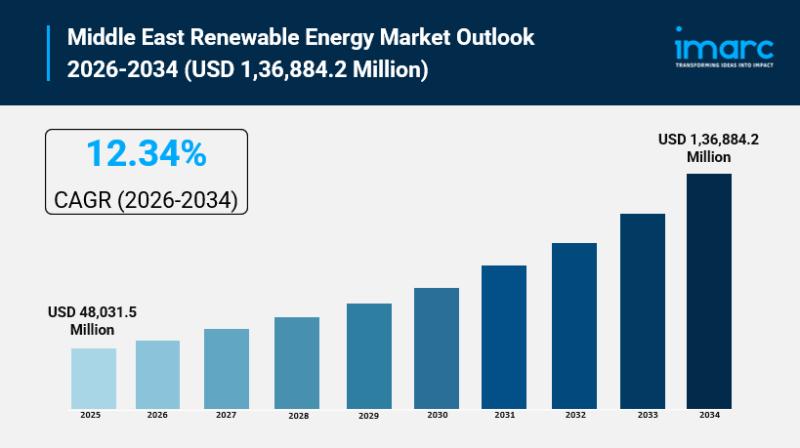

Middle East Renewable Energy Market Size to Hit USD 1,36,884.2 Million by 2034 | …

Middle East Renewable Energy Market Overview

Market Size in 2025: USD 48,031.5 Million

Market Size in 2034: USD 1,36,884.2 Million

Market Growth Rate 2026-2034: 12.34%

According to IMARC Group's latest research publication, "Middle East Renewable Energy Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", the Middle East renewable energy market size was valued at USD 48,031.5 Million in 2025. Looking forward, IMARC Group estimates the market to reach USD 1,36,884.2 Million by…

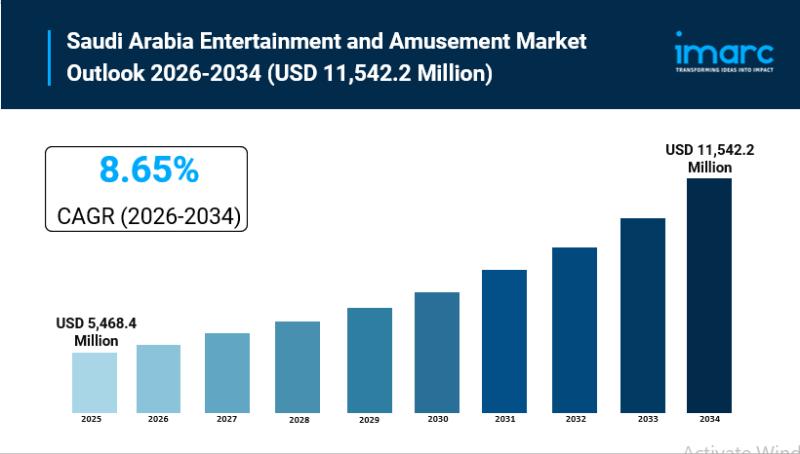

Saudi Arabia Entertainment and Amusement Market Size to Reach USD 11,542.2 Milli …

Saudi Arabia Entertainment and Amusement Market Overview

Market Size in 2025: USD 5,468.4 Million

Market Size in 2034: USD 11,542.2 Million

Market Growth Rate 2026-2034: 8.65%

According to IMARC Group's latest research publication, "Saudi Arabia Entertainment and Amusement Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", the Saudi Arabia entertainment and amusement market size reached USD 5,468.4 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 11,542.2 Million…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…