Press release

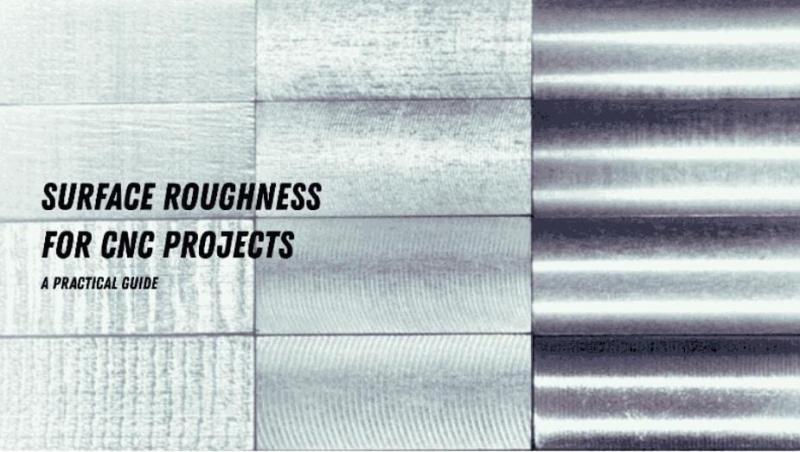

Proleantech Unveils Practical Guide to Surface Roughness in CNC Machining, Helping Businesses Optimize Quality and Costs

Shenzhen, Guangdong, China - Proleantech, a trusted name in precision manufacturing solutions, today announced the release of its comprehensive Practical Guide to Surface Roughness for CNC Projects. This initiative aims to educate engineers, product designers, and manufacturers on how surface finish impacts both performance and cost-effectiveness in CNC machining, empowering businesses to make informed decisions for their production needs.CNC Machining Surface Roughness In custom machining [https://proleantech.com/cnc-machining/], surface roughness affects how a part looks, feels, and performs. A standard finish, called "as machined," has a roughness of about Ra 3.2 m. It feels smooth to the touch but shows fine lines from the cutting tool. This finish works well for most parts.

Sometimes, you'll need a uniform surface, especially for parts that slide and move. A smoother finish helps reduce friction and wear. This makes the part last longer. To obtain this, you can:

*

Use a slower, more precise machining step

*

Add a post-process like polishing and grinding

Smoother finishes take more time and cost more. So it's important to find the right balance between surface quality and cost.

In other cases, a rougher surface is better. For example, a bicycle seat post needs more grip so it doesn't slip. You can't get this texture just by machining. You'll need a secondary process like:

*

Bead blasting

*

Tumbling

The final surface depends on both the machining and any finishing steps. If you're unsure which finish your part needs, keep reading this guide to choose the best option.

Units of Measurement for Surface Roughness

Surface roughness [https://proleantech.com/surface-roughness-everything-you-need-to-know/] is often measured using Ra. It refers to the mean average roughness. It shows the average height between the peaks and valleys on a surface.

*

A low Ra means a smooth surface.

*

A high Ra means a rough surface.

For example, a laptop touchpad has a low Ra because it's smooth. If the Ra value is higher, it would feel rough and be uncomfortable to use. Choosing the right Ra is important before machining starts, especially for parts that need a specific finish.

What Are Ra Units?

Ra means roughness average. It's a standard unit used to measure surface roughness in CNC machining.

Ra is usually calculated in micrometres (m) and micro-inches (in). These units show how much the surface varies from a perfectly flat line.

1 micrometre (m) = 39.37 micro-inches (in)

Ra defines the average height of tiny peaks and valleys across a surface. The smaller the Ra number, the smoother the surface.

*

Low Ra = smoother, more polished finish

*

High Ra = rougher, more textured finish

This value helps you choose the right surface finish for a part's function. For example, smoother parts are better for sliding or sealing. On the other hand, rougher ones may be used for grip and bonding.

How Is Ra Calculated?

Ra is calculated by taking the average of all vertical changes along a measured surface length.

In simple terms: Ra = the average distance from the surface to the centre line

Instead of just measuring the largest bump and dip, Ra looks at the overall roughness across the surface, giving a balanced view of smooth and uneven parts.

Standard Surface Finish in Machining

The most common surface finish for machined parts is Ra 3.2 m. This is known as a general-purpose and standard finish. It's ideal for parts that handle vibration, load, and stress, and is also the most cost-effective.

At this level, tool marks will still be visible. However, it allows fast machining speeds, reducing time and cost.

You can add a finishing pass for parts that require a smoother surface. This will lower the Ra value and add machining time and cost.

Some manufacturers, like Proleantech, offer as-machined finishes at Ra 3.2 m and Ra 1.6 m, depending on your requirements.

Types of Machining Finishes

*

As-Machined Finish: The natural finish after CNC machining. Visible tool marks and slightly rough texture. Suitable for parts where surface appearance is not essential.

*

Smooth Finish: Achieved with grinding and honing, removing tool marks for a cleaner look. Ideal for sliding or sealing parts.

*

Textured Finish: Adds rough patterns via bead blasting or knurling, used for grip or specific aesthetics.

*

Mirror Finish: High-gloss reflective surface achieved through fine polishing, mainly for decorative or high-end parts.

*

Anodised Finish: For aluminium, creates a hard protective coating and allows for colour customization.

Common Surface Finish Symbols

*

= : Standard surface finish symbol (ISO 1302)

*

: Tool marks perpendicular to the surface

*

X : Tool marks in a criss-cross pattern

*

M : Marks from polishing and lapping, random direction

*

C : Concentric circular tool marks

*

R : Tool marks parallel to the surface

How to Measure Surface Roughness?

*

Contact Profilometer: Uses a diamond tip to measure height changes. Accurate but slower.

*

Non-Contact Profilometer: Uses light and lasers for a 3D surface map. Fast and non-invasive.

*

Portable Surface Roughness Tester: Handheld device for quick readings.

*

Surface Roughness Comparator: Physical samples for visual/tactile comparison. Less precise.

How to Pick the Right Surface Roughness Consider usage, durability needs, and budget.

*

Ra 3.2 m: Cost-effective for most parts.

*

Ra 1.6 m: Smoother, fewer tool marks.

*

Ra 0.8-0.4 m: Precision parts, higher cost, better accuracy.

Use smoother finishes only when necessary; otherwise, standard finishes save time and money.

Key Takeaways Surface roughness affects both performance and feel. The right finish depends on the part's function and cost constraints. Understanding Ra measurements and finish symbols ensures accurate communication with manufacturers, avoiding unnecessary costs.

Media Contact

Company Name: Proleantech

Contact Person: Mr.David

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=proleantech-unveils-practical-guide-to-surface-roughness-in-cnc-machining-helping-businesses-optimize-quality-and-costs]

City: Shenzhen

State: Guangdong

Country: China

Website: https://proleantech.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Proleantech Unveils Practical Guide to Surface Roughness in CNC Machining, Helping Businesses Optimize Quality and Costs here

News-ID: 4148680 • Views: …

More Releases from ABNewswire

Best Deals on MercyMe 2026 Tour Tickets: Get Affordable Seats at CapitalCityTick …

MercyMe's Wonder + Awe Tour 2026 kicks off March 12 in Greensboro, NC, featuring hits like "I Can Only Imagine" and new tracks from their upcoming album. With special guests Big Daddy Weave, Tim Timmons, and Sam Wesley, the 24+ city spring run spans the U.S., from East Coast arenas to West Coast venues, wrapping April 25 in Spokane, WA.

MercyMe's Wonder + Awe Tour 2026 [https://www.capitalcitytickets.com/MercyMe-Tickets] is bringing an uplifting…

Upcoming Book Offers Readers a Rare Perspective, Taking Them on a Mother's Journ …

Sarah Standifird's upcoming book, Citizen's Prey, will be released on March 28 and offers a rare, unflinching look at what happens when families are forced to navigate the justice system after preventable tragedy.

With years of experience in the legal industry, Sarah Standifird once worked alongside attorneys nationwide. Now, she writes from the other side of the courtroom-as a grieving mother navigating the system as a client-offering a rare and unflinching…

Peak Grounding Sets New Industry Standard with Filtration Technology That Elimin …

"We asked ourselves why the wellness industry was accepting a 43% side effect rate as normal when other health categories would find that statistic completely unacceptable. Our filters represent a fundamental reimagining of what grounding products should deliver: pure benefits without compromise, allowing users to earth confidently and comfortably."

The grounding and earthing movement has captured the attention of wellness enthusiasts worldwide, driven by compelling research suggesting that direct connection with…

Top Fintech Software Development Companies In France

France has become a booming center for financial technology innovation in the last several years. The country has attracted both local and worldwide technology experts who offer top-notch fintech software development services. This is because it has a strong digital infrastructure, more money is being put into fintech firms, and the government is doing things to help. If you want to develop safe, scalable, and compliant fintech solutions, you need…

More Releases for Surface

How Pressure Washing Varies From Surface to Surface With Cardwell Cleaning

Greensboro, NC - Pressure washing is a highly versatile process that can be used to clean many different surfaces. However, not all surfaces can be washed the same way, and techniques need to be adjusted to match the job. This is the only way to ensure quality results. Cardwell Cleaning, [https://www.cardwellcleaning.com] a local pressure washing business, understands the exact needs of every material and exterior surface and takes the correct…

Key Trend Reshaping the Surface Computing Market in 2025: Advancing Surface Comp …

What industry-specific factors are fueling the growth of the surface computing market?

The surge in smartphone usage is projected to spur the expansion of the surface computing market in future. Smartphones are handheld devices that meld the functions of a mobile phone with advanced computing capabilities, including internet access, touchscreens, and a multitude of apps. The escalating popularity of smartphones is due to a variety of factors, such as advanced features…

Surface Analysis Market Report 2024 - Surface Analysis Market Growth And Trends

"The Business Research Company recently released a comprehensive report on the Global Surface Analysis Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The surface analysis market size…

World Leading Companies involved in The Growing Surface Protection Antifoulin …

A new Report by Worldwide Market Reports, titled "Surface Protection Antifouling Service Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Surface Protection Antifouling Service market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts, as well as insightful analysis.…

Surface Protection Service Market Set for More Growth | Surface Shields, Surface …

New Jersey, United States,- The "Global Surface Protection Service Industry, 2021 Market Research Report" provides a detailed overview of the further development of the market for Surface Protection Service. The "Market Research Intellect" is now publishing a new market analysis with the help of various analytical methods, the study examines the decisive key trends for the growth of the global market, and in a narrower sense also of the Chinese…

Surface Protection Tape Market Growth, Trends and Forecast –3M, Tesa Tape, Sur …

The Surface Protection Tape Market report provides the overall structure and business outlook of the global and regional industries. The study also involves the important Achievements of the market, Research & Development, new product launch, product responses, and regional growth of the leading competitors operating in the market on a global and local scale. This study provides information about the growth and revenue during the historic and forecasted period of…